Polycrystalline silicon electric resistance and manufacturing method thereof

A polysilicon resistor and manufacturing method technology, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of large occupied area and disadvantageous chip cost, and achieve the effect of saving cost and reducing chip occupied area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

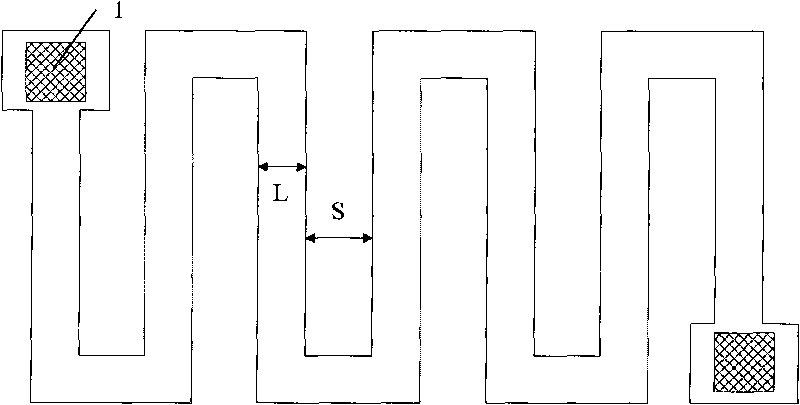

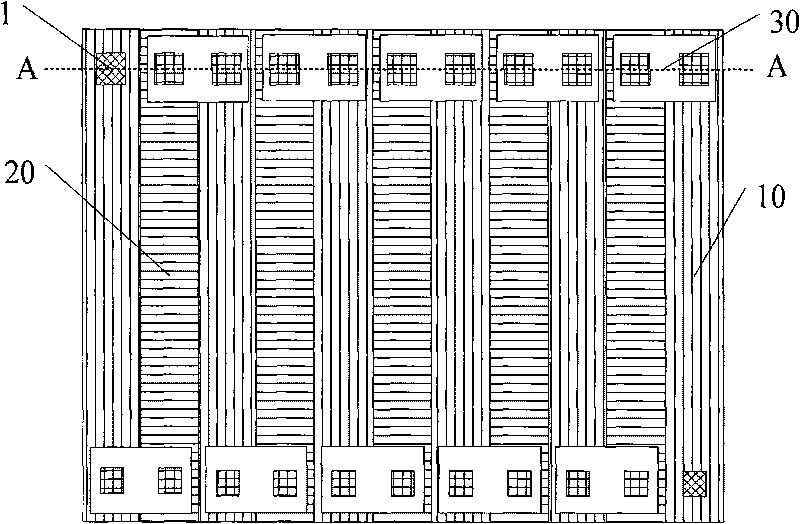

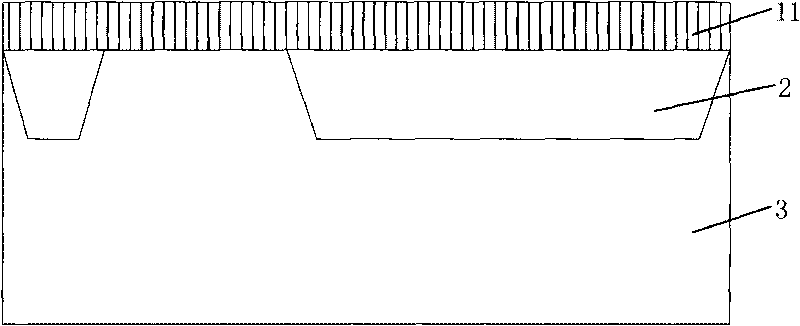

[0028] Such as figure 2 , Figure 9 As shown, the polysilicon resistance of the present invention includes double-layer polysilicon, namely the first layer of polysilicon 10 and the second layer of polysilicon 20, the two layers of polysilicon 10,20 are distributed up and down, and an insulating layer 40 is arranged between the two layers of polysilicon 10,20; The layers of polysilicon 10 and 20 are connected to the first layer metal line 30 through the contact hole 1 . Figure 9 for figure 2 Sectional view of A-A in the middle.

[0029] The insulating layer 40 may be silicon oxide, silicon nitride or a combination thereof. The function of the insulating layer 40 is to isolate the upper and lower layers of polysilicon 10 and 20 .

[0030] The manufacturing process method of polysilicon resistance of the present invention, forms polysilicon resistance by following steps:

[0031] 1. If image 3 As shown, on the P-type substrate 3, the non-doped first layer of polysilico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com