Unintermittent phase change energy storage and heat exchange system

A phase change energy storage and heat exchange system technology, applied in indirect heat exchangers, heat storage equipment, heat exchanger types, etc., can solve the inconsistency between heat time and space, reduce heat exchange efficiency and service life of heat exchangers , time and space energy supply conflicts, etc., to achieve the effect of flexible and reasonable allocation of time and space, low cost of materials and structures, and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

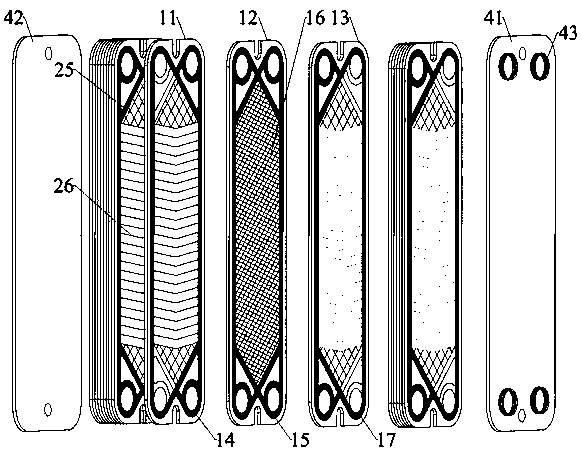

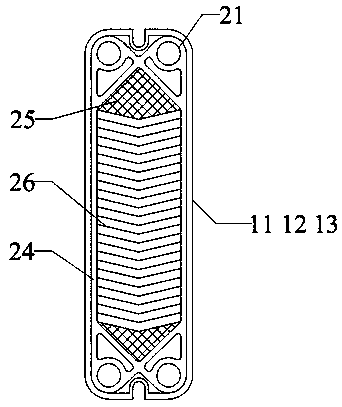

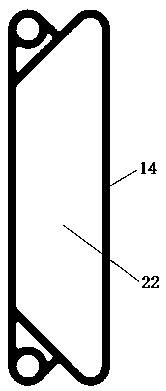

[0017] Example Figure 1 to Figure 4 As shown, the uninterrupted phase change energy storage and heat exchange system of the present invention includes several sequentially stacked phase change energy storage and heat exchange units, and the phase change energy storage and heat exchange units include a first plate heat exchange fin 11, a second Plate heat exchange fins 12, third plate heat exchange fins 13, first semi-enclosed seal ring 14, second semi-enclosed seal ring 17, fully enclosed seal ring 15 and phase change material 16, the first plate heat exchange fin 11 1. The second plate heat exchange fin 12 and the third plate heat exchange fin 13 are respectively arranged in parallel at intervals, and the four corners are respectively provided with through holes 21, and the first semi-closed sealing ring 14 is arranged on the first plate heat exchange fin 11 Between the second plate heat exchange fin 12 and the upper and lower through holes on one side of the first plate hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com