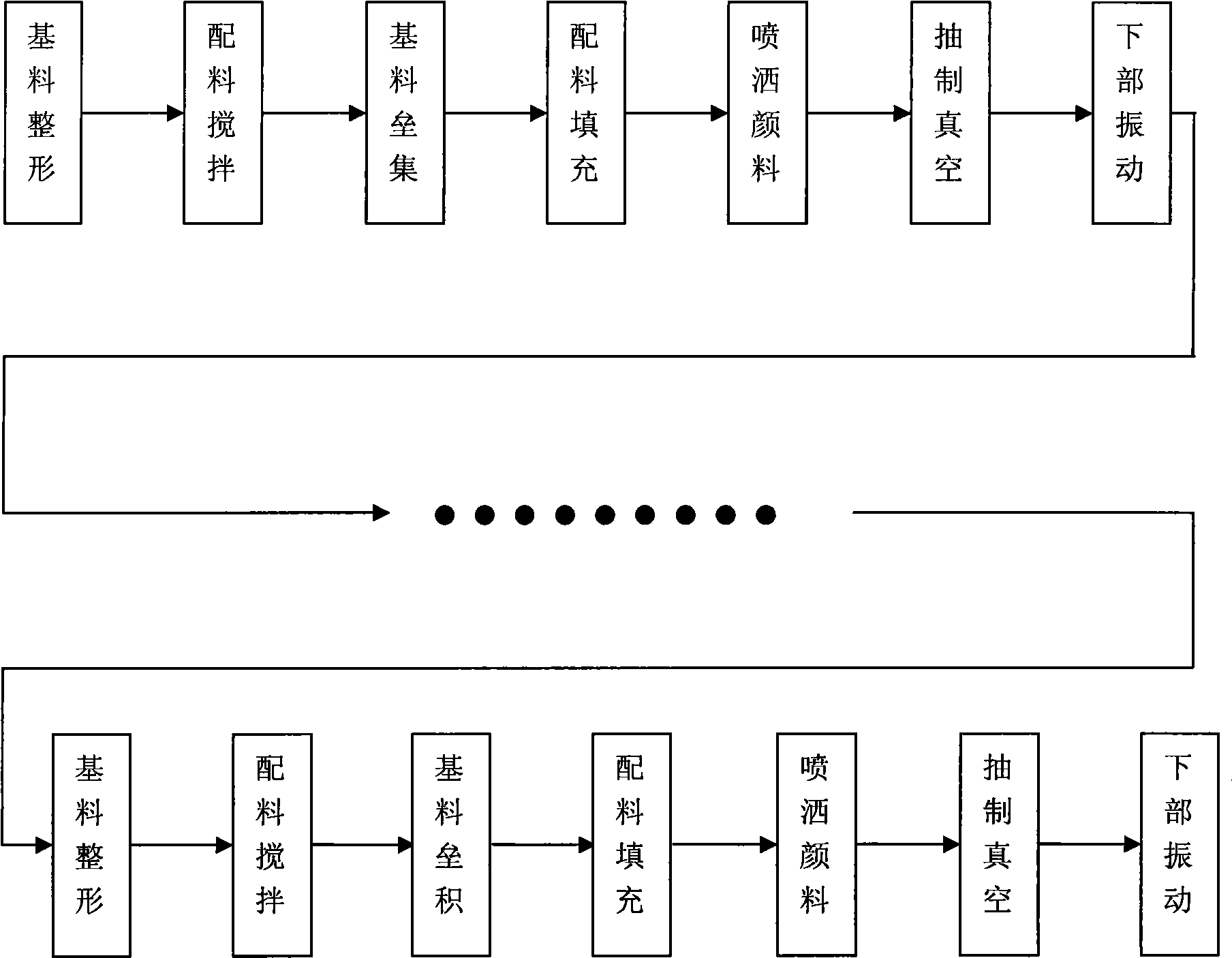

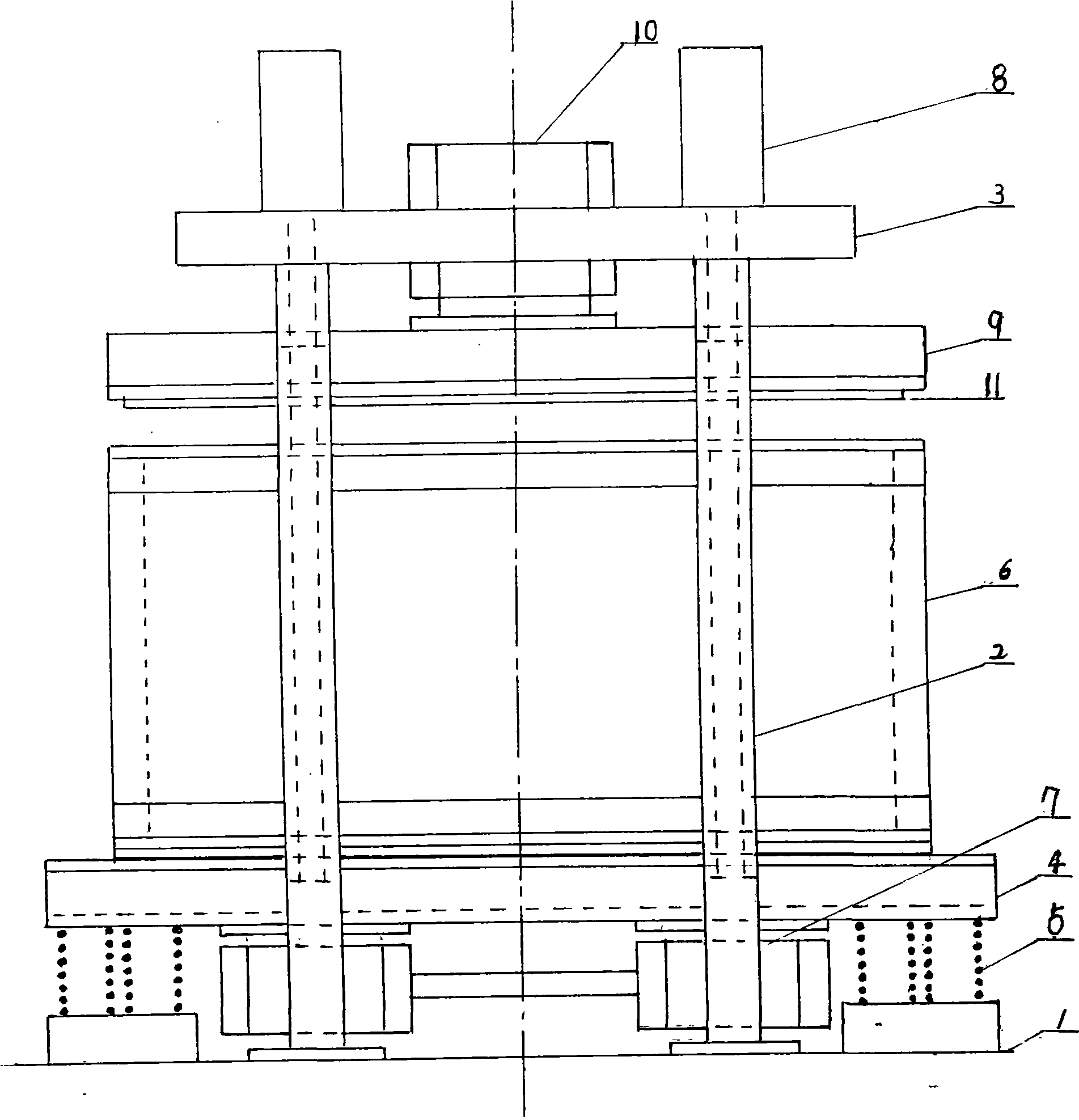

Method for synthesizing stone by layered vibration and moulding vibration device

A technology of synthetic stone and base material, which is applied in the directions of mixing operation control device, ceramic molding machine, clay preparation device, etc. Complex structure and other problems, to achieve the effect of large market value, low equipment depreciation cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The market-popular marble is used as the base material, and 12% unsaturated polyester resin adhesive, snowflake white stone particles and stone powder are used as raw materials; 305cm (length) × 85cm (width) × 150cm (height) In the mold box, 6 layers (6 cycles) of layer-by-layer spray texture and layer-by-layer vibration and vacuuming are carried out to complete the block molding. The formula of the base material and ingredients is:

[0017] 1. Base material colored marble (pebble shape) 4-20cm

[0018] Colored marble 0.5—3cm

[0019] 2. Ingredients white marble 4 mesh

[0020] White marble 20 mesh

[0021] White marble 80 mesh

[0022] Calcium carbonate powder 1000 mesh

[0023] The amount of unsaturated polyester resin adhesive accounts for 12% of the total weight of the ingredients, and the weight-number ratio of the above-mentioned base material to the ingredients is 6:1.

[0024]The specific synthesis steps are as follows: b...

Embodiment 2

[0027] Using expanded perlite and marble stone as the base material, the ingredients are mixed with 18% unsaturated polyester resin, marble stone particles and calcium carbonate stone powder, and 8 layers (8 cycles) of layer-by-layer spraying are carried out in the mold box. Make texture, vibrate layer by layer and vacuumize to complete block molding. The formula of base material and ingredients is:

[0028] 1. Base material: light-colored marble particle size 0.5-2cm

[0029] Expanded perlite particle size 0.5-2cm

[0030] 2. Ingredients white marble 20 mesh

[0031] White marble 40 mesh

[0032] White marble 80 mesh

[0033] Calcium carbonate powder 800 mesh

[0034] The amount of unsaturated polyester resin adhesive accounts for 18% of the total weight of the ingredients, the weight ratio of the above base material and ingredients is 2:1, and the weight ratio of marble particles and expanded perlite in the base material is 6:1-6 ratio composi...

Embodiment 3

[0038] The recipe for the base and ingredients is:

[0039] 1. Base material: black gold sand, particle size 5-15cm

[0040] Golden dream granite particle size 5-15cm

[0041] Jade particle size 0.5-2cm

[0042] Obsidian particle size 0.5-2cm

[0043] 2. Ingredients

[0044] Quartz sand 10 mesh

[0045] Quartz sand 40 mesh

[0046] Quartz sand 80 mesh

[0047] Quartz powder 400 mesh

[0048] The amount of unsaturated polyester resin adhesive accounts for 6% of the total weight of the ingredients, and the ratio of the weight and number of the above-mentioned base materials to the ingredients is 1:1.

[0049] The specific synthesis steps are as follows: base material shaping: granite fragments are processed into approximate squares with hammers and chisels due to their brittleness and homogeneity and easy to shape; ingredients mixing: add the ingredients of the above ingredients into a twin-shaft mixer Stir e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com