Preparation method and application of photo-thermal interface evaporation material under transient normal stress action

A normal stress, photothermal technology, applied in chemical instruments and methods, general water supply saving, coating, etc., can solve the problems of lack of preparation methods for photothermal interface evaporation materials, and achieve excellent photothermal evaporation rate and efficiency, high light Heat conversion efficiency, efficient and uniform dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

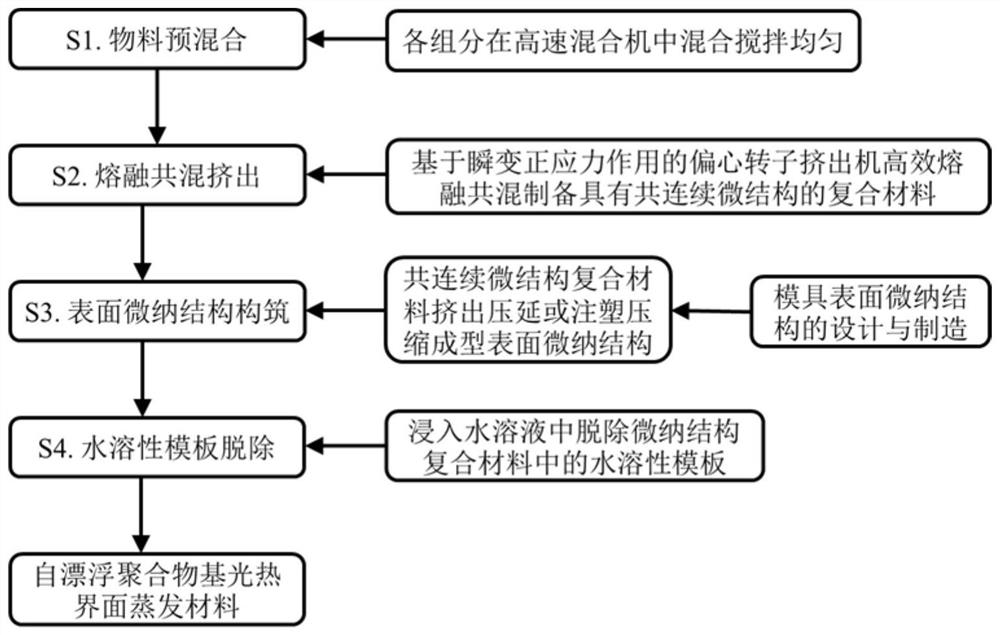

[0043] A method for preparing a photothermal interface evaporation material under the action of transient normal stress, such as figure 1 shown, including the following steps:

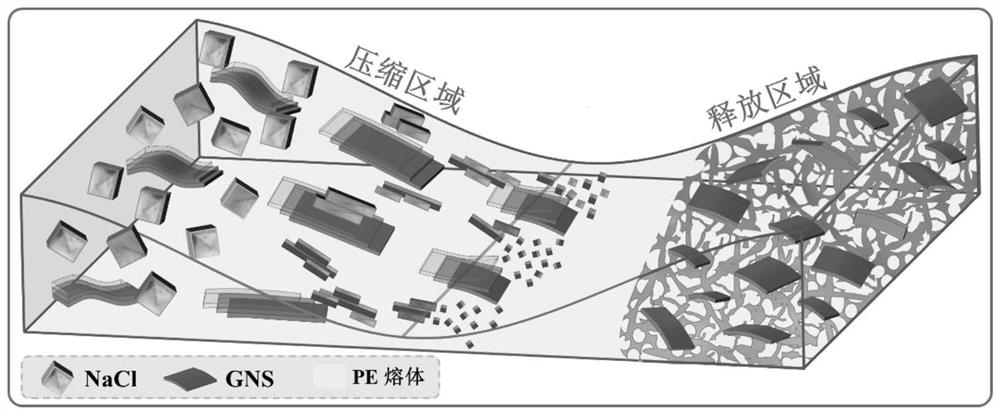

[0044] (1) PE, NaCl and GNs are pre-mixed in a high-speed mixer at a mass ratio of 20:80:2, and then fed into a single-shaft eccentric rotor extruder through a feeder, and the rotor drives multiphase in the inner cavity of the stator The system makes the positive displacement pulsation continuous plastic blending with the velocity gradient vector approaching the flow direction, and the alternating action of volume compression and release deformation forces the continuous dynamic generation and evolution of the micro-interface in the multi-phase system, resulting in the refined high-content NaCl being GNs The filled PE matrix is coated to form a PE / NaCl / GNs composite material with a co-continuous microstructure. The schematic diagram of the preparation principle is shown in figure 2 shown;

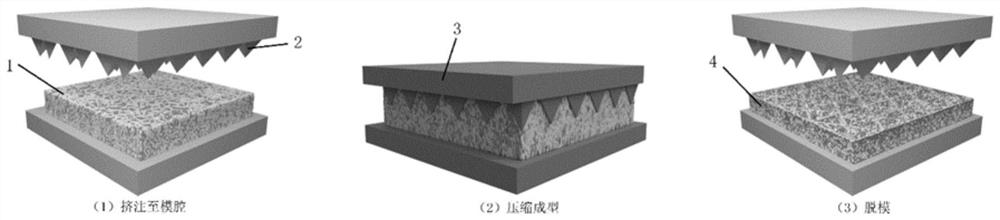

[0045]...

Embodiment 2

[0051] A method for preparing a photothermal interface evaporation material under the action of transient normal stress, comprising the following steps:

[0052] (1) PE, NaCl and CNTs are pre-blended according to the weight ratio of 20:80:1.6, and then fed into the uniaxial eccentric rotor extruder through the feeder. The rotor drives the multiphase system in the inner cavity of the stator to make a speed gradient The positive displacement pulsation continuous plastic blending with the vector approaching the flow direction, the alternating volume compression and release deformation force the continuous dynamic generation and evolution of the micro-interface in the multiphase system, resulting in the refined high-content NaCl particles8 being filled with CNTs The PE matrix 9 is coated to form a PE / NaCl / CNTs composite material with a co-continuous microstructure, and the composite material is continuously extruded through a rod die to form a product ( Image 6 );

[0053] (2) A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com