Method for improving optical element additional surface shape caused by force of gravity, and clamping system thereof

An optical element and surface shape technology, applied in the control of the additional surface shape of ultra-thin optical elements, the additional surface shape of large-diameter ultra-thin transmissive optical elements, and the field of clamping systems, which can solve the problem of surface shape changes without optimization and control. , complex control, large additional surface shape and other problems, to achieve the effect of improving additional surface shape, simple theory, and small residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

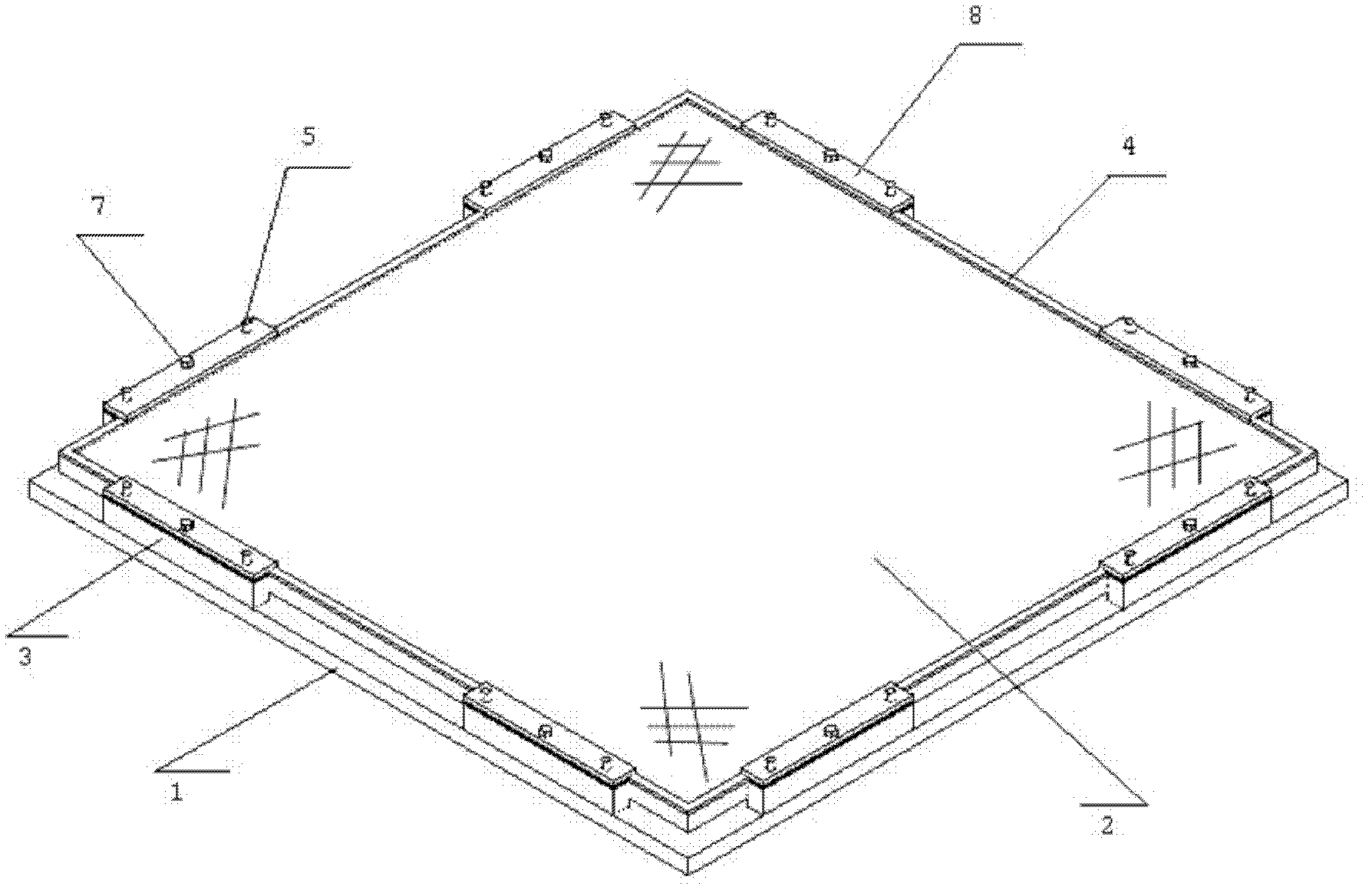

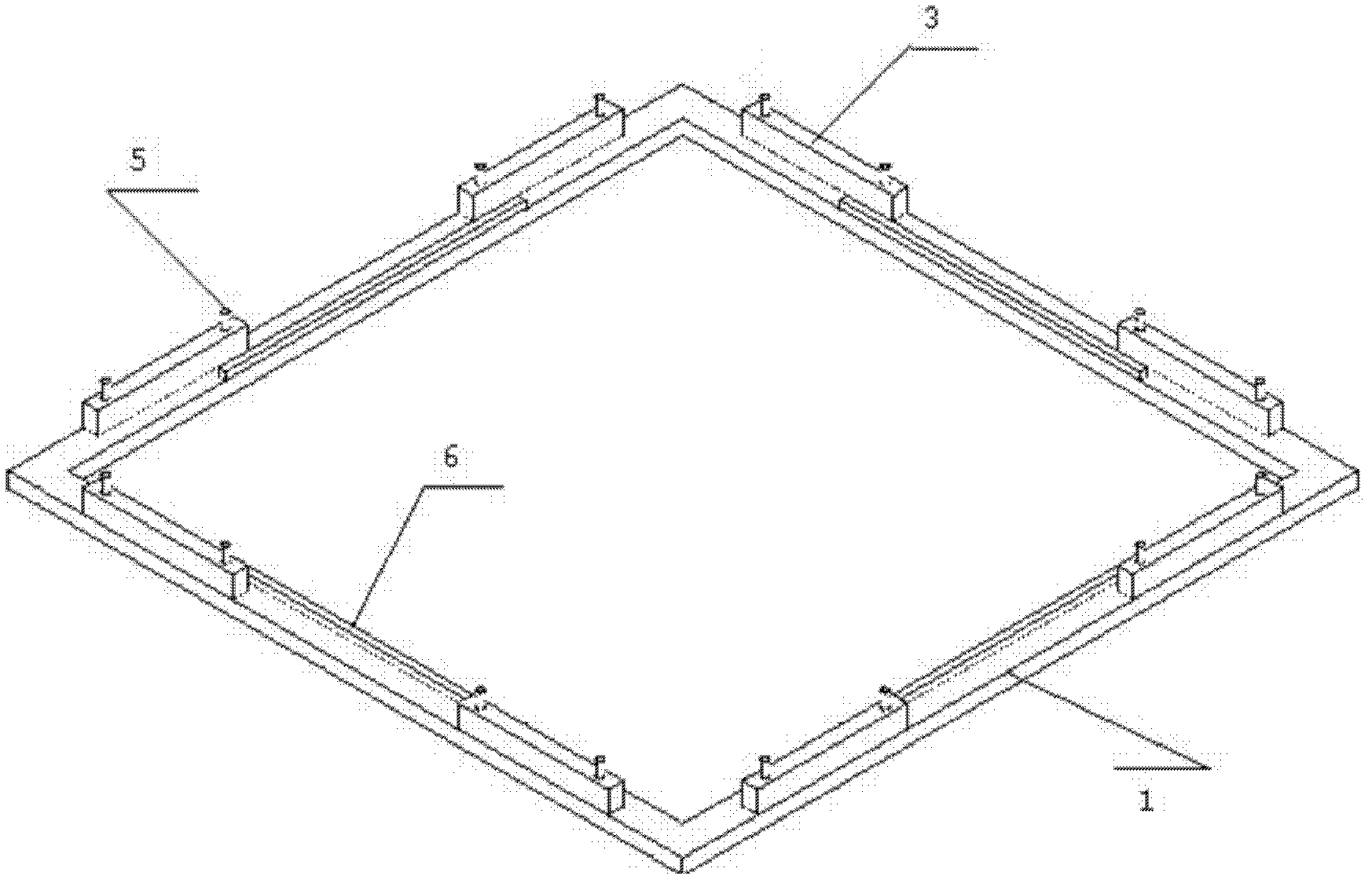

[0059] In this embodiment, as figure 1 and figure 2 The shown structure of the clamping system is used to improve the additional surface shape of the large-aperture ultra-thin KDP crystal 2 caused by gravity, according to figure 1 Install the clamping system as shown in and adjust the components.

[0060] For 330×330mm 2 Diameter, KDP crystal with a thickness of 10mm, its effective aperture is not less than 300mm, each part in the clamping system is made of stainless steel, the 330×330mm 2The additional surface shape in the effective clear aperture of the KDP crystal with a diameter of 10mm and a thickness of 10mm is used as the optimized objective function. Through the calculation and simulation of the finite element analysis software ANSYS, the solution that the change value of the additional surface shape is relatively the smallest when it is placed at different angles to achieve equilibrium is obtained. According to this minimum solution, it is determined that the leng...

Embodiment 2

[0063] In this embodiment, as figure 1 and figure 2 The shown structure of the clamping system is used to improve the additional surface shape of the large-aperture ultra-thin KDP crystal 2 caused by gravity, according to figure 1 Install the clamping system as shown in and adjust the components.

[0064] For 430×430mm 2 For a KDP crystal with a caliber and a thickness of 10mm, its effective aperture is not less than 400mm, and the components in the clamping system are made of stainless steel, and the 430×430mm 2 The additional surface shape in the effective clear aperture of the KDP crystal with a diameter of 10mm is used as the optimized objective function, and the solution that the value of the additional surface shape change is relatively the smallest when it is placed at different angles to achieve equilibrium is obtained through the calculation and simulation of the finite element analysis software ANSYS According to this minimum solution, it is determined that the l...

Embodiment 3

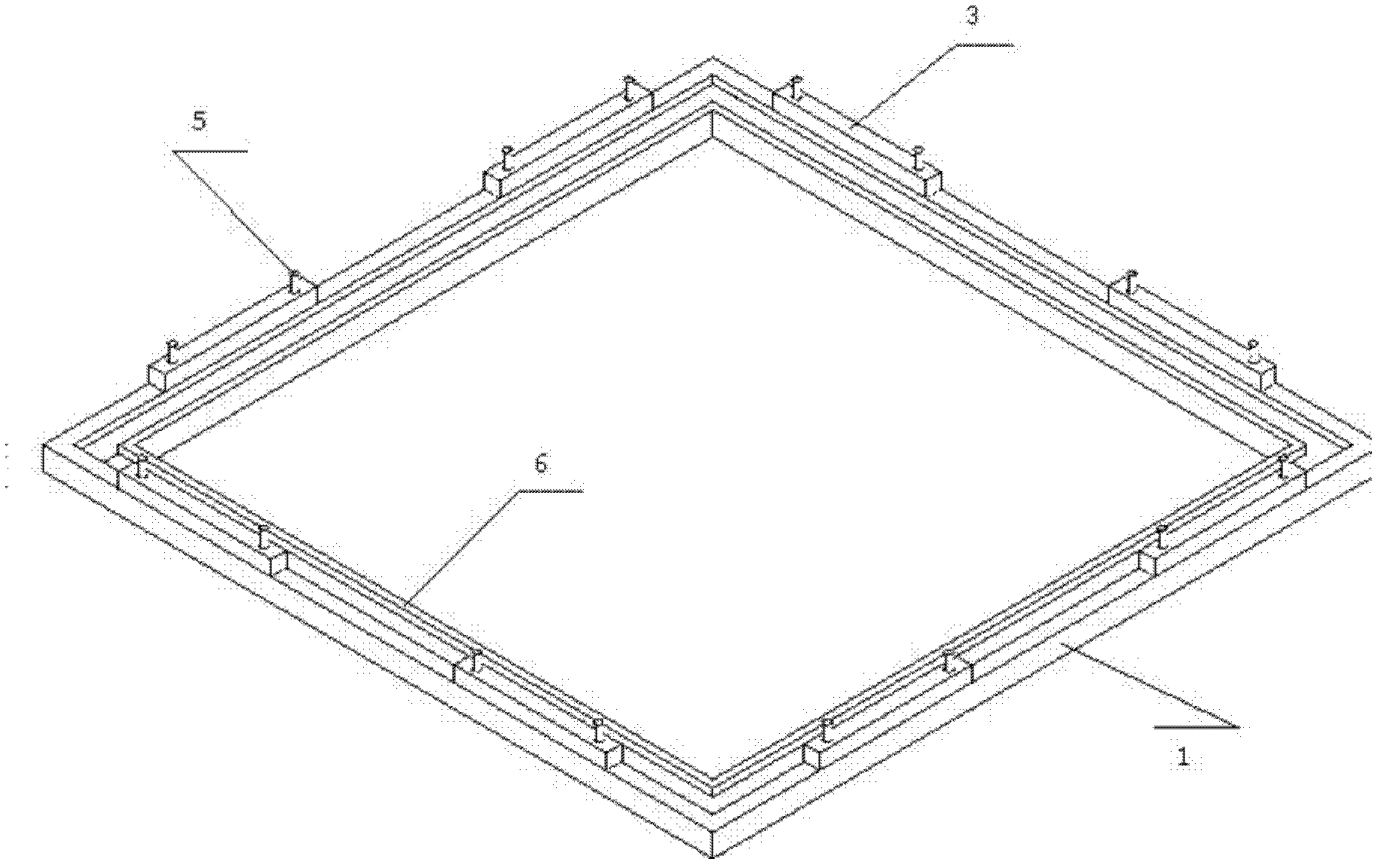

[0067] In this embodiment, as figure 1 and image 3 The shown structure of the clamping system is used to improve the additional surface shape of the large-aperture ultra-thin KDP crystal 2 caused by gravity, according to figure 1 Install the clamping system as shown in and adjust the components.

[0068] For 330×330mm 2 For a KDP crystal with a caliber and a thickness of 10mm, its effective aperture is not less than 300mm. The components of the clamping system are made of stainless steel. The 330×330mm 2 The additional surface shape in the effective clear aperture of the KDP crystal with a diameter of 10mm is used as the optimized objective function, and the solution that the value of the additional surface shape change is relatively the smallest when it is placed at different angles to achieve equilibrium is obtained through the calculation and simulation of the finite element analysis software ANSYS According to this minimum solution, it is determined that the thickness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com