Liquid preliminary distribution device with gas distribution function

A gas distributor and gas distribution technology, applied in the field of distributors, can solve the problems of large fluctuation of liquid flow in spray holes, decreased mass transfer efficiency of packed towers, low mass transfer efficiency, etc., and achieves easy installation, low requirements, and flexible operation range. The effect of widening and saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

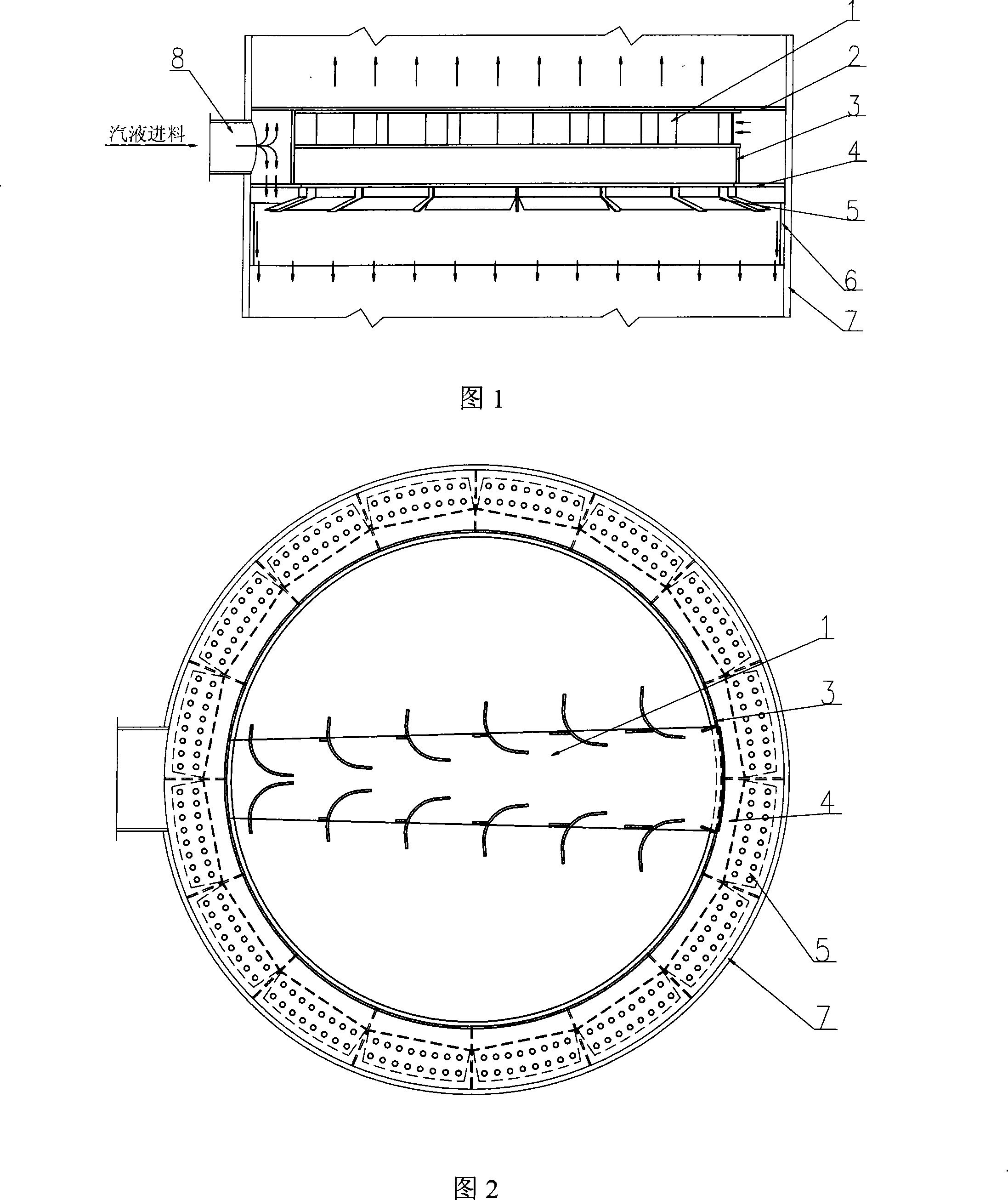

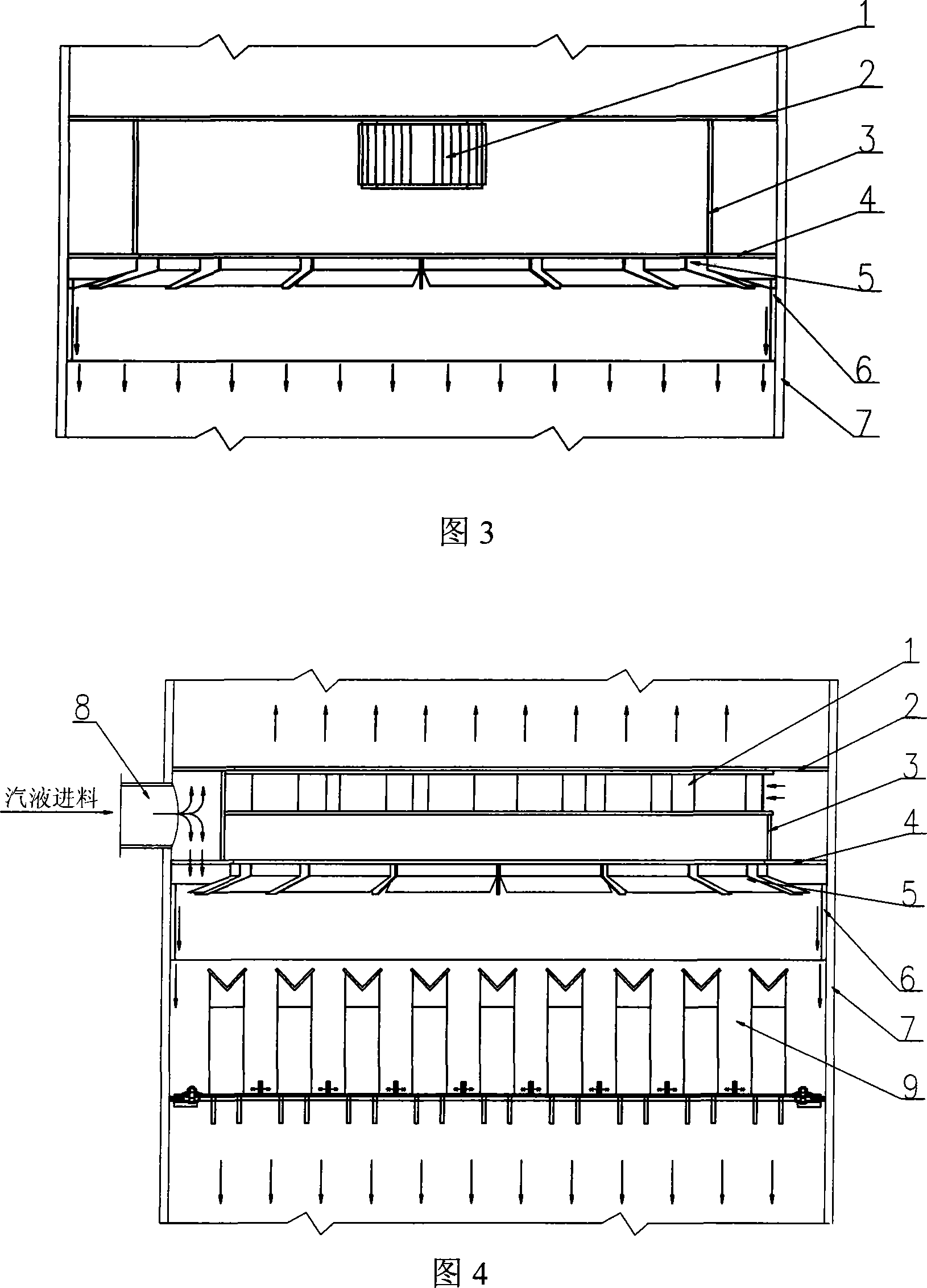

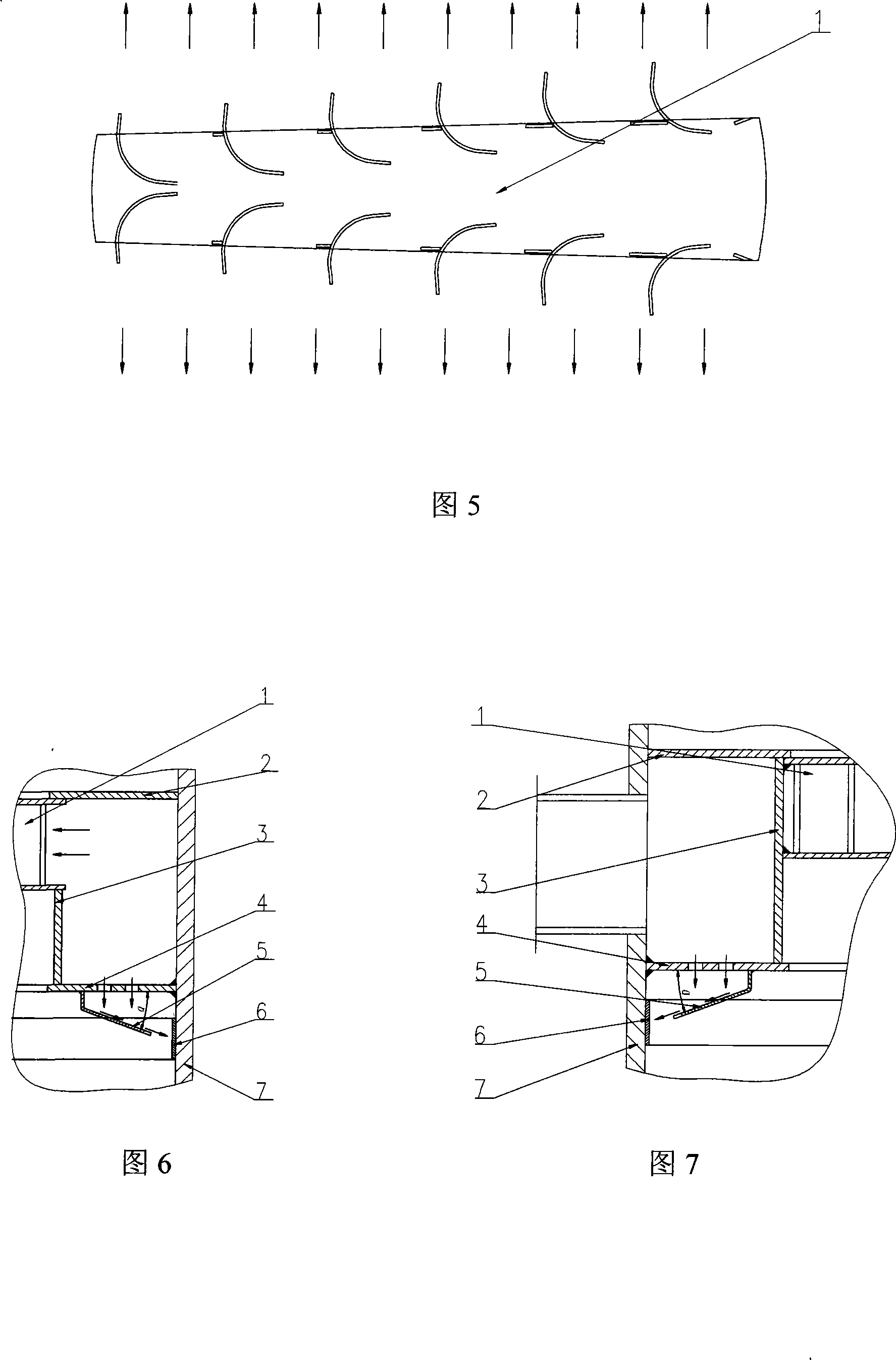

[0034] Below in conjunction with accompanying drawing 1-7, the present invention is described in further detail: referring to accompanying drawing 1, Fig. 2 and Fig. 3 contain a certain amount of gas feed solution and send in the tower from feed pipe 8, at first enter into the liquid collecting The inner cylinder 3, the liquid collecting bottom ring 4, the gas-blocking sealing ring 2, and the tower wall 7 jointly form an annular vapor-liquid separation and storage space, in which the gas is separated or flashed from the solution and stored in the upper part of the space without gas The solution is stored in the lower part of the space; the gas in the upper part enters into the plane-symmetrical two-dimensional guide type double-row blade gas distributor 1 through the square or circular gas outlet arranged on the liquid collection inner cylinder 3 at a certain flow rate, see Attached Figure 5, the gas distributor evenly distributes the gas into the upper packing layer; see Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com