Super-capacitor electrode material and preparation method thereof

A technology for supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc. It can solve the problems of low energy density of supercapacitors, and achieve the effects of easy industrial production, easy removal, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

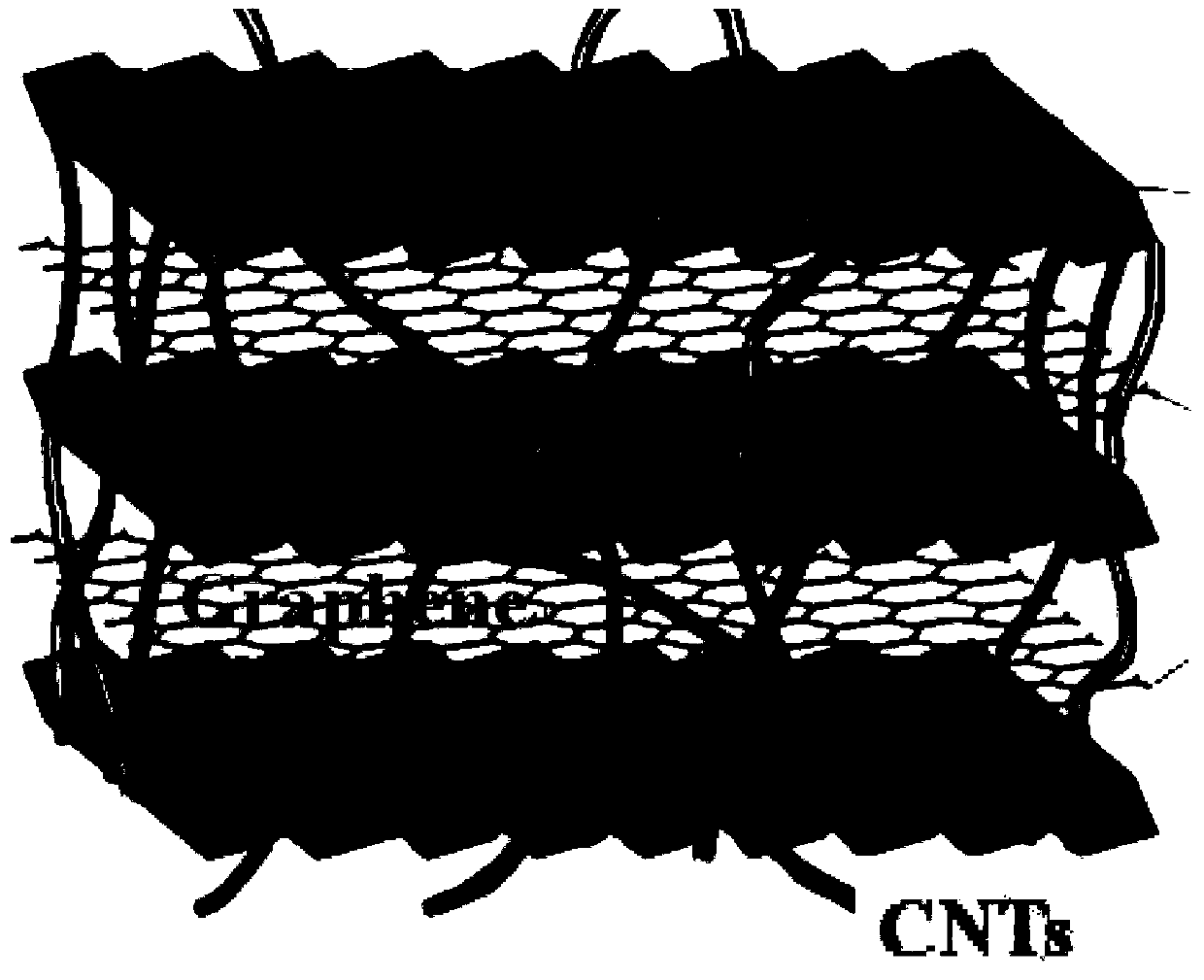

[0042] Embodiment 1: This supercapacitor electrode material is the carbon nanotube / nickel hydroxide / graphene compound that utilizes microwave method to prepare, and its specific preparation method is directly take graphene as carrier, prepares carbon nanotube / nickel hydroxide / graphite ene complex, comprising the following steps,

[0043] Step 1): First, ultrasonically disperse 60mg of graphene in 120ml of ethylene glycol;

[0044] Step 2): Add 0.025mol / L nickel acetate glycol solution to the mixture obtained in step 1) at room temperature, stir for 2 hours, and adjust the pH of the solution with 0.5mol / L sodium hydroxide glycol solution at Between 9 and 10, continue to stir and react for 1h;

[0045] Step 3): Microwave the mixture obtained in step 2) for 3 minutes at a power of 700W, take it out and heat and stir at 60°C for 10 hours. During the continuous stirring process, add a certain amount of carbon nanotube ethylene glycol slurry, and continue stirring for 2 hours;

[...

Embodiment 2

[0047] Embodiment 2: This supercapacitor electrode material is the carbon nanotube / nickel hydroxide / graphene composite that utilizes microwave method to prepare, and its specific preparation method is to prepare carbon nanotube / nickel hydroxide / graphene composite from graphite oxide, Include the following steps,

[0048] Step 1): Take graphite and sodium nitrate, put them in a certain amount of concentrated sulfuric acid in an ice bath with a mass ratio of 2:1, add potassium permanganate 3 times the mass of the graphite under stirring, mix well, and control the temperature When the temperature is lower than 20°C, raise the temperature to 32-38°C and react for 2 hours, slowly add quantitative deionized water dropwise, stir well, and when the temperature of the system drops, add hydrogen peroxide to terminate the reaction, filter, wash, and dry to obtain graphite oxide;

[0049] Step 2): First, ultrasonically disperse 60 mg of graphite oxide obtained in step 1) in 120 ml of ethy...

Embodiment 3

[0052] Embodiment 3: This supercapacitor electrode material is the carbon nanotube / nickel hydroxide / graphene compound that utilizes microwave method to prepare, and its specific preparation method is directly take graphene as carrier, prepares carbon nanotube / nickel hydroxide / graphite ene complex, comprising the following steps,

[0053] Step 1): First, ultrasonically disperse 30mg of graphene in 60ml of ethylene glycol;

[0054] Step 2): Add 0.025mol / L nickel acetate glycol solution to the mixture obtained in step 1) at room temperature, stir for 2 hours, and adjust the pH of the solution with 0.5mol / L sodium hydroxide glycol solution at Between 9 and 10, continue to stir and react for 1h;

[0055] Step 3): Microwave the mixture obtained in step 2) for 3 minutes at a power of 700W, take it out and heat and stir at 60°C for 10 hours. During the continuous stirring process, add a certain amount of carbon nanotube ethylene glycol slurry, and continue stirring for 2 hours;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com