A method for preparing nano-and micro-scale core-shell ternary cathode materials by low temperature self-propagation method

A cathode material, self-propagating technology, applied in electrical components, battery electrodes, electrochemical generators, etc., can solve the problems of high cost of time instruments, three wastes, increased costs, etc., and achieve the effect of shortening the production cycle and reducing the three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

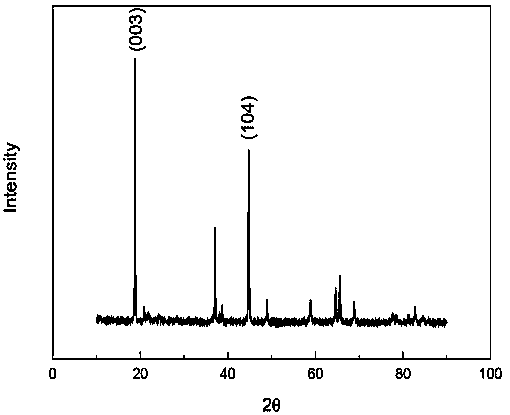

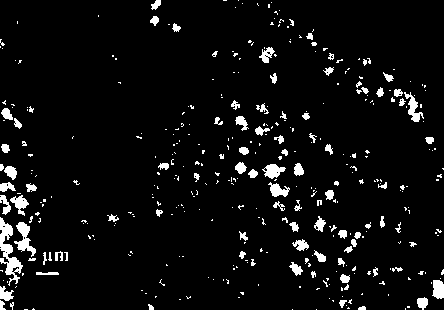

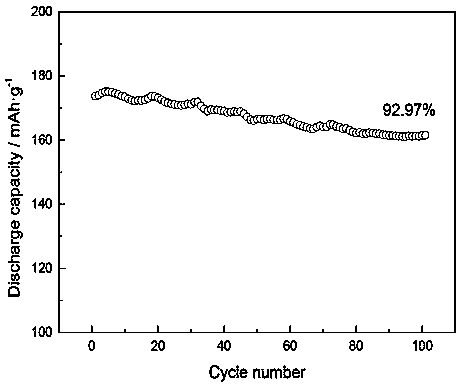

[0029] In this example, 0.9 parts of Li are first prepared 1.2 Ni 0.133 co 0.133 mn 0.534 o 2 Lithium-rich core, then prepare 0.1 part of LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 The low-nickel shell, the general structural formula is Li 1.18 Ni 0.153 co 0.153 mn 0.514 o 2 . Prepare 2mol / L LiNO according to the stoichiometric ratio of 9:1:1:4 3 , Ni(NO 3 ) 2 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O and Mn(NO 3 ) 2 (50% aqueous solution) metal salt mixed solution 45ml, add 0.6mol glycine, stir evenly, add ammonia water dropwise to adjust pH to 9, and obtain solution A. Pour solution A into a crucible, burn it at 600°C, then raise the temperature to 900°C, keep it warm for 4 hours, take it out after cooling in the furnace to obtain powder B, collect and grind B. Configure 0.5mol / L LiNO at a stoichiometric ratio of 3:1:1:1 3、 Ni(NO 3 ) 2 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O and Mn(NO 3 ) 2 (50% aqueous solution) Metal salt mixed solution 20ml, add 0.2mol glycine, stir evenly, add ...

Embodiment 2

[0032] In this example, prepare 0.7 parts of LiNi first 0.8 co 0.1 mn 0.1 o 2 of high nickel core, and then prepare 0.3 parts of LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 The low-nickel shell, the general structural formula is LiNi 0.66 co 0.17 mn 0.17 o 2 .

[0033] Prepare 1mol / L LiNO according to the stoichiometric ratio of 100:80:10:10 3 , Ni(CH 3 COO) 2 4H 2 O, Co(CH 3 COO) 2 4H 2 O and Mn(NO 3 ) 2 (50% aqueous solution) Metal salt mixed solution 35ml, add 0.3mol citric acid, stir evenly, add ammonia water dropwise to adjust pH to 8.5, and obtain solution A. Pour solution A into a crucible, burn it at 500°C, then raise the temperature to 750°C, keep it warm for 2 hours, take it out after cooling in the furnace to obtain powder B, collect and grind B. Configure 0.5mol / L LiNO at a stoichiometric ratio of 3:1:1:1 3、 Ni(CH 3 COO) 2 4H 2 O, Co(CH 3 COO) 2 4H 2 O and Mn(NO 3 ) 2 (50% aqueous solution) Metal salt mixed solution 30ml, add 0.2mol citric acid, stir ev...

Embodiment 3

[0036] In this example, 0.6 parts of LiNi are prepared first 0.7 co 0.15 mn 0.15 o 2 of high nickel core, and then prepare 0.4 parts of LiNi 0.4 co 0.2 mn 0.4 o 2 The low-nickel shell, the general structural formula is LiNi 0.58 co 0.17 mn 0.25 o 2 .

[0037] Prepare 1mol / L LiNO according to the stoichiometric ratio of 100:70:15:15 3、 Ni(CH 3 COO) 2 4H 2 O, Co(CH 3 COO) 2 4H 2 O and Mn(NO 3 ) 2 (50% aqueous solution) metal salt mixed solution 60ml, add 0.5mol urea, stir evenly, add ammonia water dropwise to adjust pH to 8, and obtain solution A. Pour solution A into a crucible, burn it at 500°C, then raise the temperature to 750°C, keep it warm for 2 hours, take it out after cooling in the furnace to obtain powder B, collect and grind B. Configure 1mol / L LiNO at a stoichiometric ratio of 100:40:20:40 3、 Ni(NO 3 ) 2 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O and Mn(NO 3 ) 2(50% aqueous solution) Metal salt mixed solution 40ml, add 0.4mol urea, stir evenly, add am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com