Positive electrode material, preparation method thereof and lithium ion battery

A positive electrode material and positive electrode technology, applied in the direction of positive electrodes, battery electrodes, secondary batteries, etc., can solve the problems of low yield of positive electrode materials, cumbersome synthesis process, and loss of cycle capacity, so as to improve the cycle retention rate and simplify the synthesis process , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

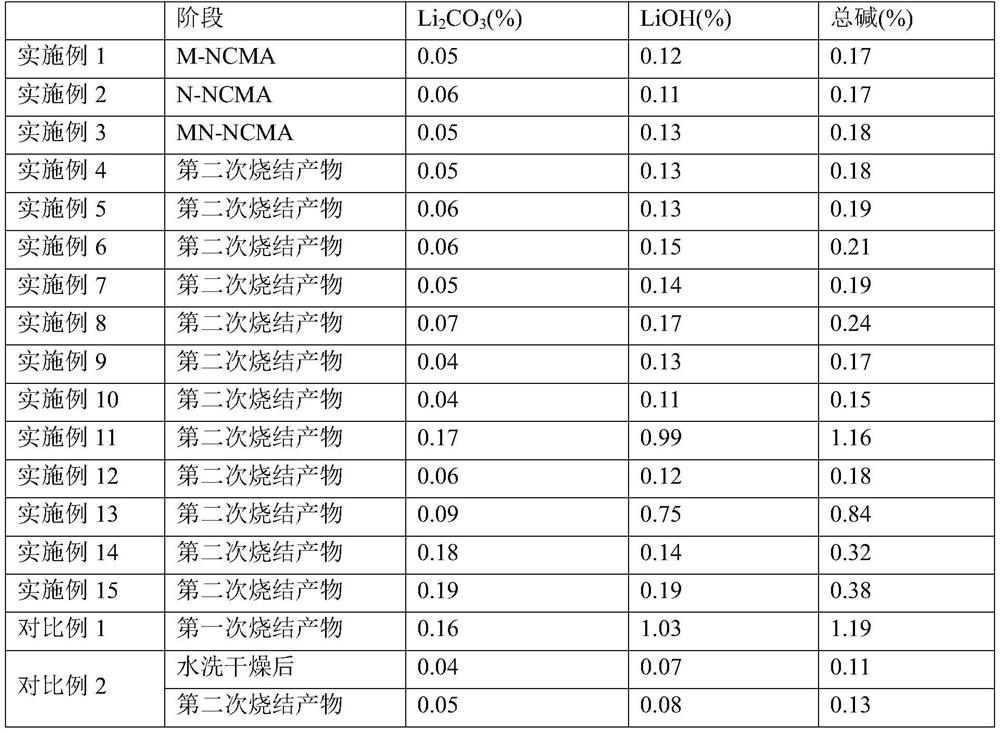

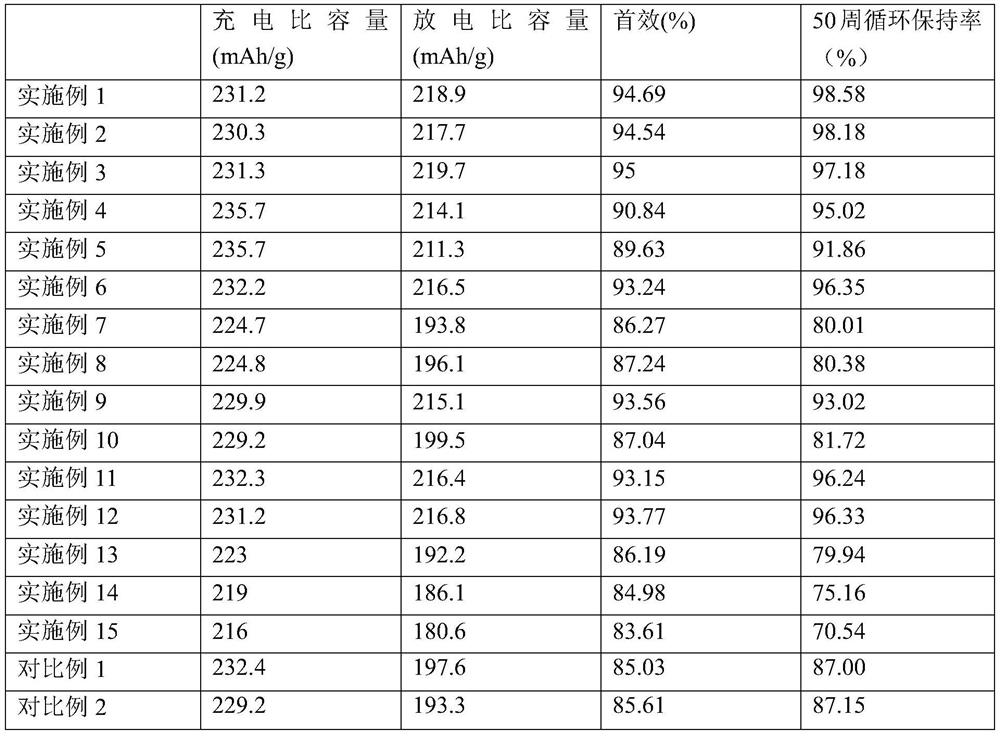

[0020] As described in the background art, the existing preparation methods of positive electrode materials have the problems of cumbersome synthesis process, high energy consumption, non-environmental protection, low yield of positive electrode materials and loss of cycle capacity. In order to solve the above technical problems, the present application provides a method for preparing a positive electrode material, the preparation method comprising: performing a first sintering treatment on the lithium source material and the positive electrode precursor material (precursor material containing nickel, cobalt, manganese and aluminum), to obtain The first sintered product: coating the surface of the first sintered product with a coating agent, and then performing a second sintering treatment to obtain the positive electrode material, wherein the coating agent is a nickel source material and / or a manganese source material.

[0021] During the first sintering process, the lithium s...

Embodiment 1

[0038] (1) The precursor Ni 0.92 co 0.05 mn 0.02 Al 0.01 (OH) 2 Dry mixing with lithium source in a certain proportion, wherein the precursor and the Li element in the lithium source are mixed at a molar ratio of 1:1.05, then sintered at 850°C in an oxygen atmosphere for 10 hours, cooled, crushed and sieved with a 400-mesh sieve Sieve to obtain the first sintered similar single crystal positive electrode material.

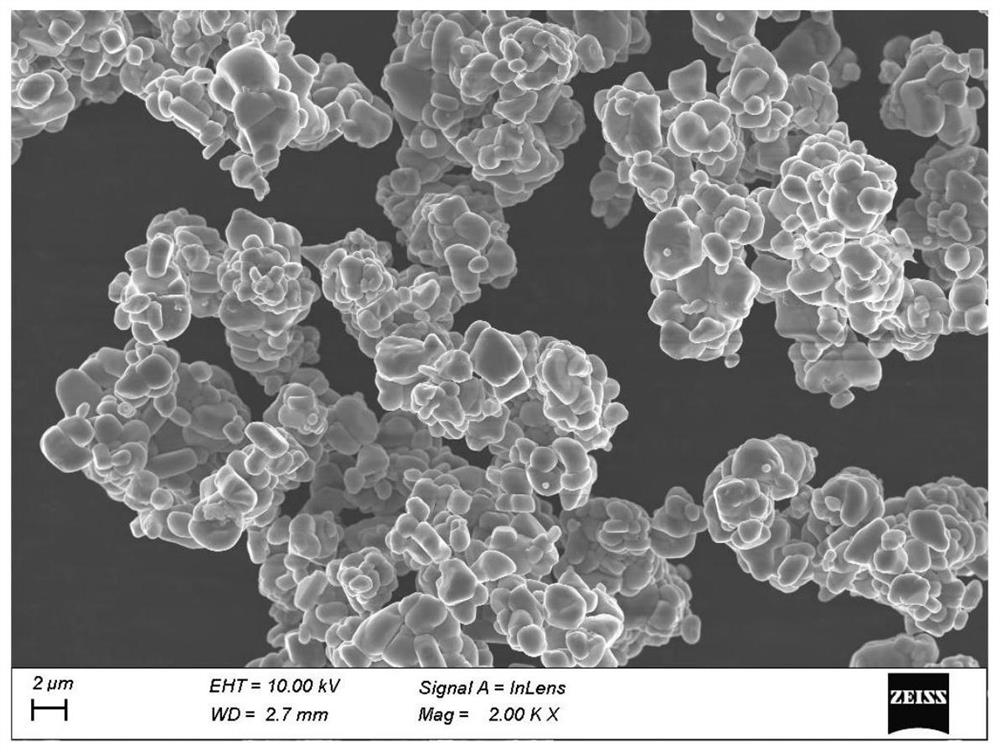

[0039] (2) The first sintered single-crystal cathode material obtained in step (1) and the coating agent Mn(OH) 2 After the Mn element in the mixture is mixed evenly by dry method according to the mass ratio of 1:0.0008, the secondary sintering is carried out at 200°C in an oxygen atmosphere for 6 hours, cooled, crushed and sieved with a 400 mesh sieve to obtain the single crystal positive electrode material M-NCMA, SEM image See figure 1 .

Embodiment 2

[0041] (1) The precursor Ni 0.92 co 0.05 mn 0.02 Al 0.01 (OH) 2 Dry mixing with lithium source in a certain proportion, in which the precursor and the Li element in the lithium source are mixed in a certain molar ratio of 1:1.05, and then sintered at 850°C in an oxygen atmosphere for 10 hours, cooled, crushed and sieved with a 400-mesh sieve Sieve to obtain the first sintered similar single crystal positive electrode material.

[0042] (2) Combine the first-time sintered single-crystal cathode material obtained in step (1) with the coating agent Ni(OH) 2 The Ni element in the mixture was mixed uniformly by dry method according to the mass ratio of 1:0.00085, and the second sintering was carried out at 200°C in an oxygen atmosphere for 6 hours, cooled, crushed and sieved with a 400-mesh sieve to obtain the final single-crystal cathode material N-NCMA.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com