Silicon-based composite material, preparation method and application thereof

A silicon-based composite material and reaction technology, which is applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of no improvement and control, and it is difficult to ensure product consistency, so as to achieve good structural stability and enhance electronic performance. Effects of conductive connectivity, improvement of hardness and bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

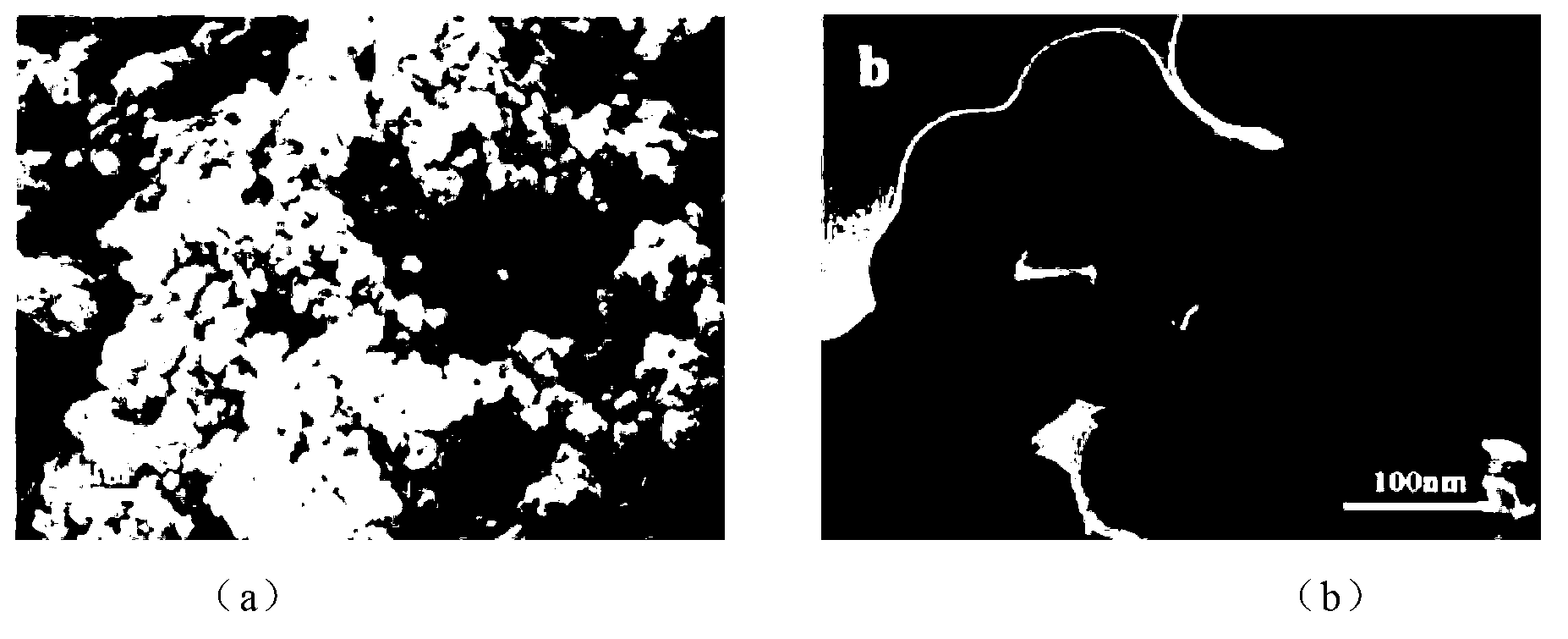

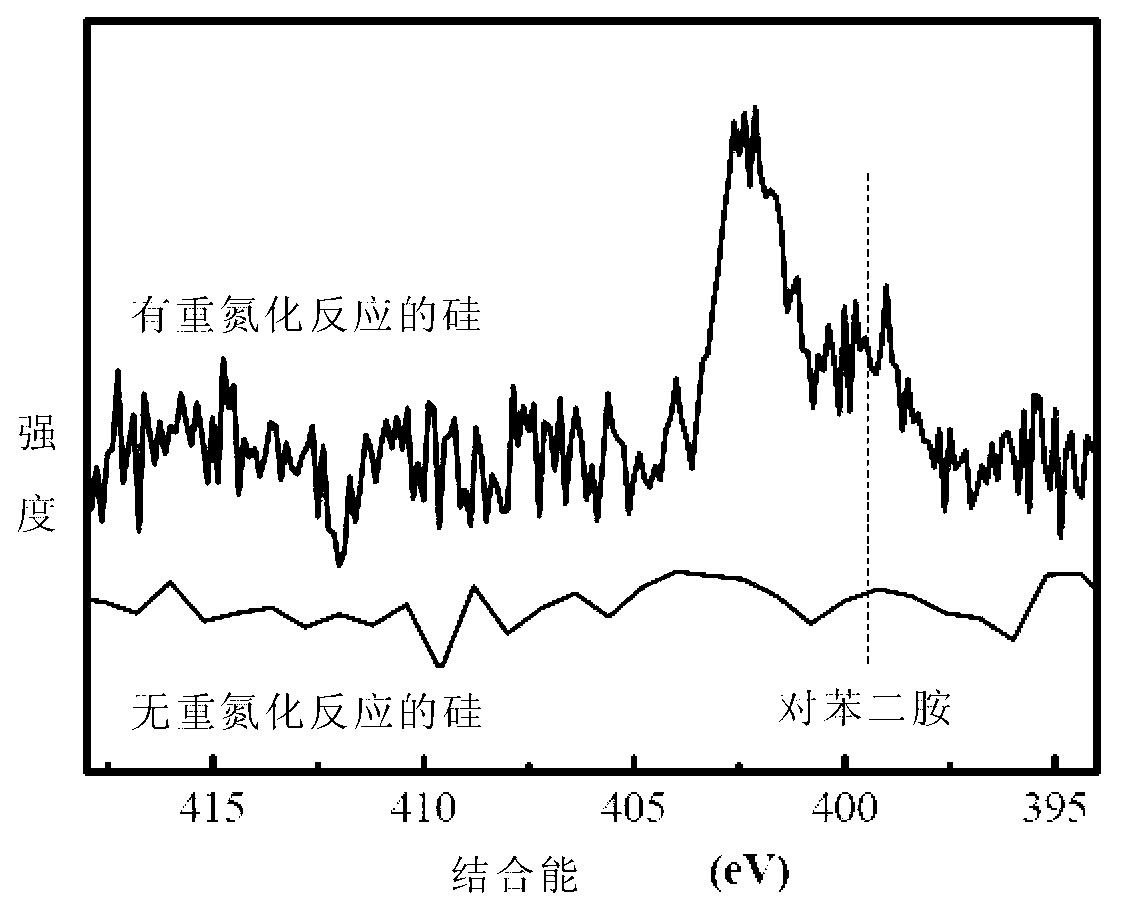

[0027] According to the preparation method of the silicon-based composite material of the second aspect of the present invention, it is used to prepare the silicon-based composite material according to the first aspect of the present invention, comprising the following steps: using p-phenylenediamine (H 2 N-Ar-NH 2 ) under nitrite and acidic conditions, a diazotization reaction occurs to generate a diazonium salt; nano-silicon particles are added to the solution where the diazotization reaction is completed, and a substitution reaction is carried out to obtain a Si-C covalent bond. The nano-silicon precursor that the aniline monomer is connected to the surface of the nano-silicon particles; the nano-silicon precursor is added to the microemulsion formed by mixing the oil phase and the water phase to adjust the pH of the solution, and then the aniline monomer is added; the initiation of the aniline polymerization The polyaniline is added into the microemulsion to undergo anilin...

Embodiment 1

[0038] Prepare the precursor:

[0039] Add 20g of p-phenylenediamine into 500mL of 1mol / L HCl solution, and stir at 150rpm for 10min in a thermostat at 10°C;

[0040] 100mL5.797mol / L sodium nitrite (NaNO 2 ) solution was added dropwise to the above HCl solution at a speed of 10mL / min, and continued to stir at a speed of 150rpm for another 10min;

[0041] Add 3.54g of nano-silicon particles (D50, 40nm) to the above solution, stir at 300rpm for 10min, vacuum filter, and wash with tetrahydrofuran and ethanol, then wash with deionized water until oil-free, and then dry in a vacuum oven 6h, to obtain 3.70g precursor (diazotized nano-silicon particles, that is, the connection between silicon and aniline);

[0042] Prepare composite material:

[0043] Mix 20mL ethanol and 20mL deionized water evenly, mix 90mL cyclohexane and 10mL Tween 80 evenly, then mix the total volume of 40mL ethanol and deionized water (water phase) and 100mL cyclohexane and Tween 80 (oil Phase) was stirred ...

Embodiment 2

[0047] Prepare the precursor:

[0048] Add 10g p-phenylenediamine to 500mL1mol / L H 2 SO 4 In the solution, stir at 150rpm for 10min in a constant temperature bath at 10°C;

[0049] 50mL5.797mol / L sodium nitrite (NaNO 2 ) solution was added dropwise to the above H at a rate of 10mL / min 2 SO 4 solution, and continuously stirred at 150rpm for 10min;

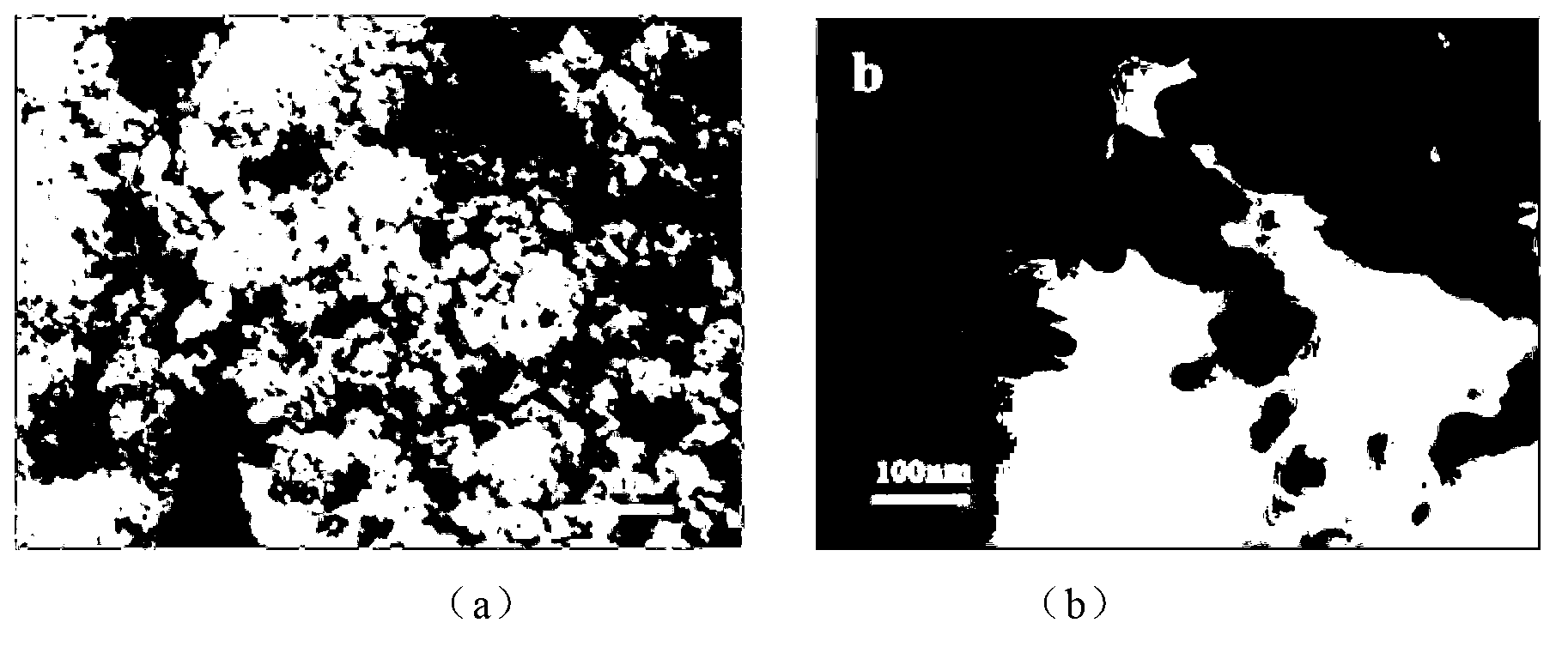

[0050] Add 3.54g of nano-silicon particles (D50, 100nm) to the above solution, stir at 300rpm for 10min, vacuum filter, and wash with tetrahydrofuran and ethanol, then wash with deionized water until oil-free, and then dry in a vacuum box for 6h , to obtain 3.61g precursor.

[0051] Prepare composite material:

[0052] Mix 20mL ethanol and 20mL deionized water evenly, mix 90mL cyclohexane and 10mL Tween 80 evenly, then mix the total volume of 40mL ethanol and deionized water (water phase) and 100mL cyclohexane and Tween 80 (oil Phase) was stirred at a speed of 300rpm for 10min to form a microemulsion;

[0053] Add 2.8g of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com