Water-based conductive binder for lithium ion battery and preparation method of water-based conductive binder

A conductive adhesive and lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of difficulty in dispersion, affecting lithium ion transmission and diffusion speed, and poor bonding strength of adhesives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

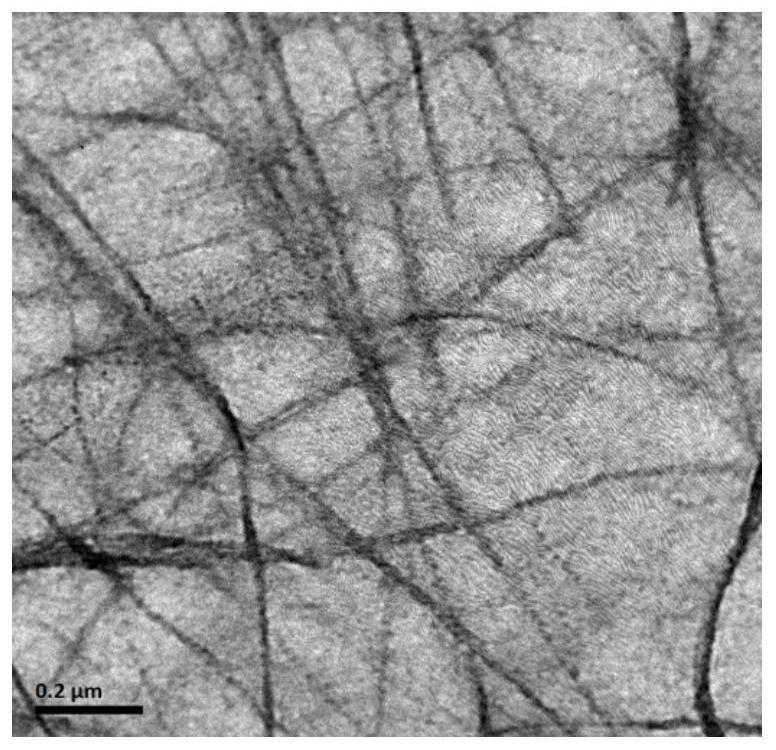

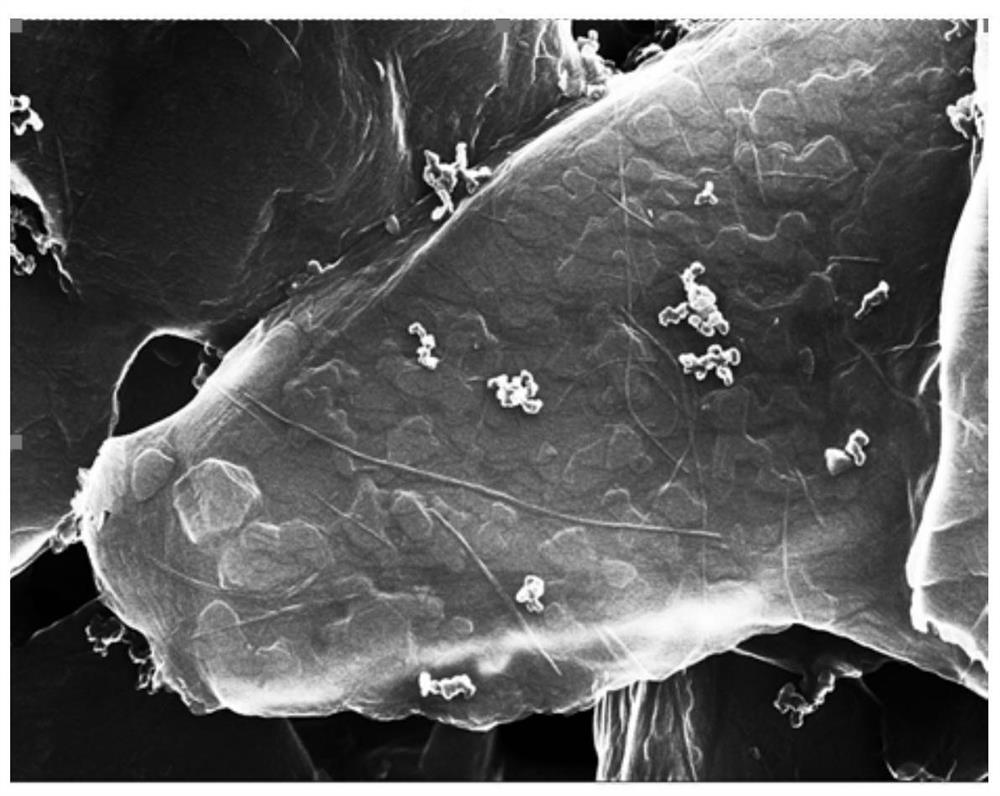

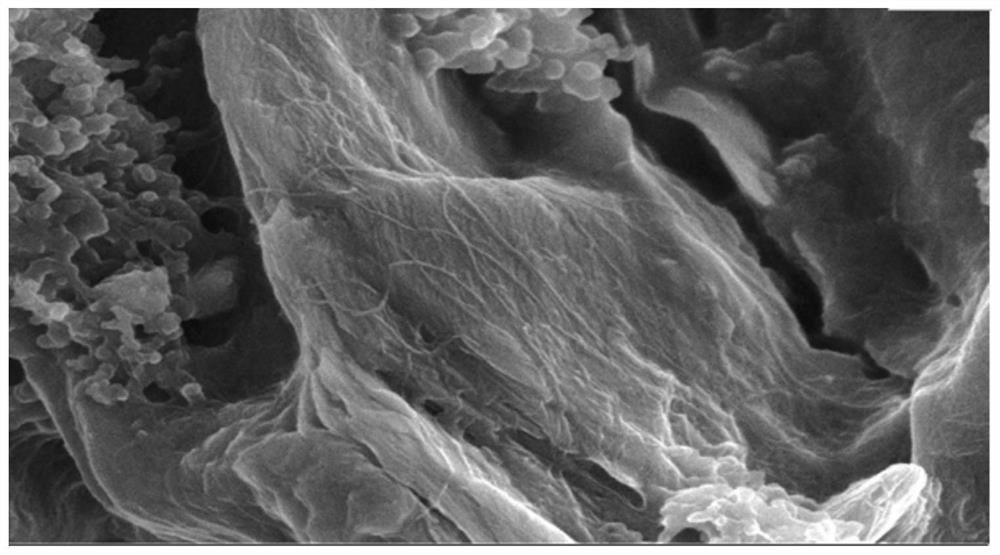

Image

Examples

Embodiment 1

[0027] A water-based conductive binder for lithium-ion batteries, comprising the following components in parts by weight:

[0028] Basic binder: 20 parts of sodium carboxymethylcellulose, 100 parts of functional binder, intrinsic conductive polymer: 5 parts of polyaniline, 2 parts of hydroxyl modified single-wall carbon tubes, 1000 parts of deionized water, Neutralizer: 0.2 parts of ammonia water, curing agent: 0.5 parts of Covestro curing agent 401-70.

[0029] Preparation method: comprising the following steps:

[0030] (1) Preparation of intrinsic conductive mother liquor: Mix 5 parts of intrinsic conductive polymer polyaniline and 20 parts of basic binder sodium carboxymethyl cellulose in parts by mass, and pass through a planetary disperser at room temperature at 12000r / Min speed range for pre-dispersion, add deionized water to adjust the viscosity, and make intrinsic conductive mother liquid;

[0031] (2) Preparation of functional binder: At room temperature, mix mono...

Embodiment 2

[0035] A water-based conductive binder for lithium ion batteries, comprising the following components in parts by weight: basic binder: 30 parts of styrene-butadiene copolymer, functional binder: 100 parts, intrinsically conductive Polymer: 10 parts of polyaniline, 10 parts of amino-modified single-wall carbon tube, 1000 parts of deionized water, neutralizer: 0.1 part of sodium hydroxide, 2 parts of Covestro curing agent 401-70.

[0036] The preparation method comprises the following steps:

[0037] (1) Preparation of intrinsic conductive mother liquor: mix 10 parts of intrinsic conductive polymer polyaniline and 30 parts of basic binder styrene butadiene copolymer in parts by mass, pre-disperse at room temperature, add deionized Water adjusts the viscosity to obtain the intrinsic conductive mother liquid;

[0038](2) Preparation of functional binder: at room temperature, mix monomers containing hydroxyl groups with ionized water according to the set solid content, add emulsi...

Embodiment 3

[0042] A water-based conductive binder for lithium-ion batteries, comprising the following components in parts by weight: basic binder: 20 parts of styrene-butadiene copolymer, 120 parts of functional binder, intrinsically conductive polymer Materials: 10 parts of polythiophene, 20 parts of amino-modified multi-walled carbon tubes, 1000 parts of deionized water, neutralizer: 0.1 part of sodium hydroxide, 2 parts of Covestro curing agent 304.

[0043] (1) Preparation of intrinsic conductive mother liquor: mix 10 parts of intrinsic conductive polymer polythiophene and 20 parts of basic binder styrene butadiene copolymer in parts by mass, pre-disperse at room temperature, add deionized Water adjusts the viscosity to obtain the intrinsic conductive mother liquid;

[0044] (2) Preparation of functional binder: at room temperature, mix monomers containing hydroxyl groups with ionized water according to the set solid content, add emulsifier, stir and emulsify to obtain monomer mixtur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com