Quick-charging negative electrode material production process and device

A negative electrode material and production process technology, which is applied in the field of fast charging negative electrode material production process and device, can solve the problems of increasing the irreversible capacity of the first charge and discharge, reducing the charge and discharge efficiency of the electrode material, and high specific surface area of the negative electrode material, and achieving continuous production of the process method. , The effect of excellent cycle performance and outstanding anti-attenuation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

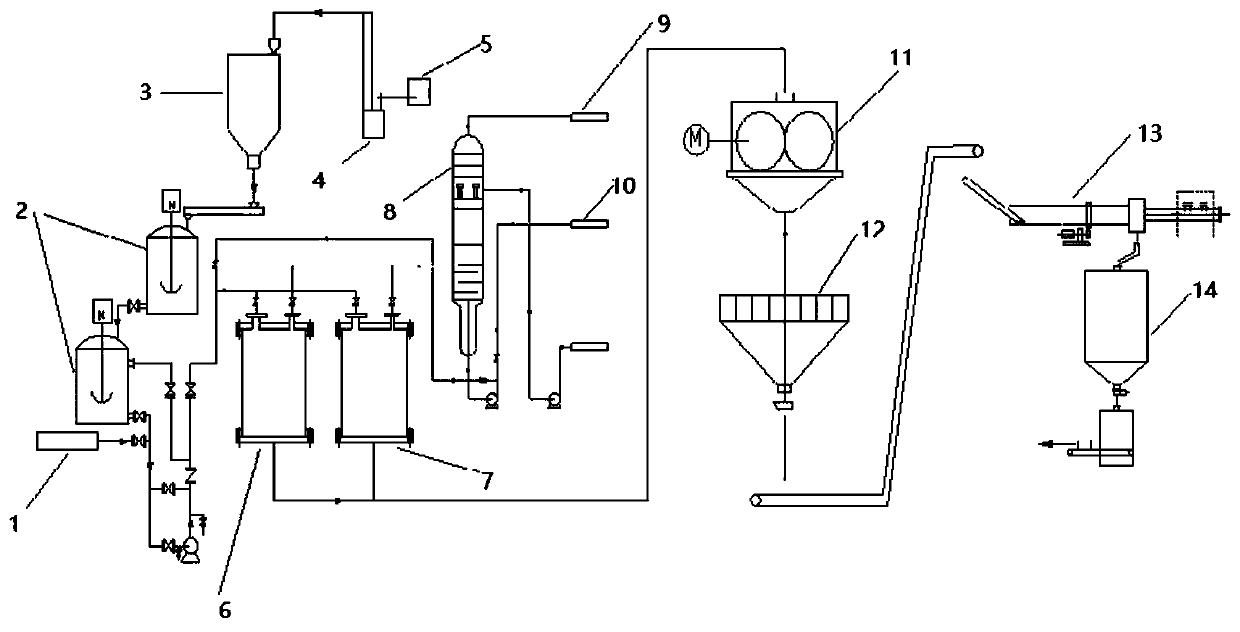

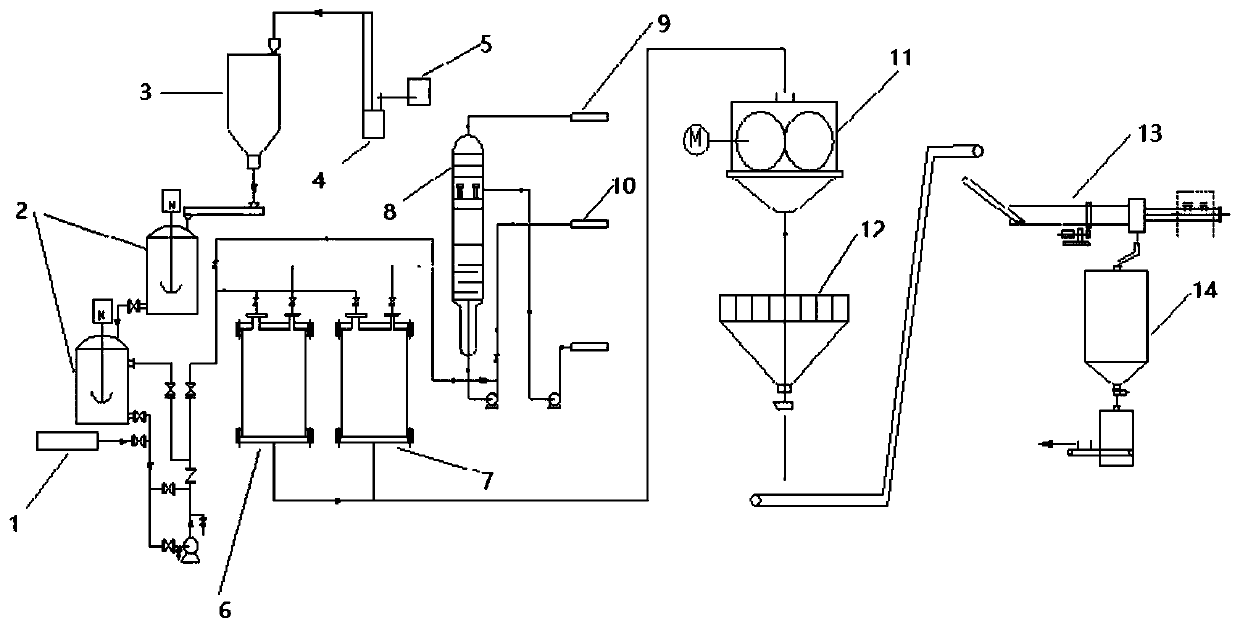

Image

Examples

Embodiment

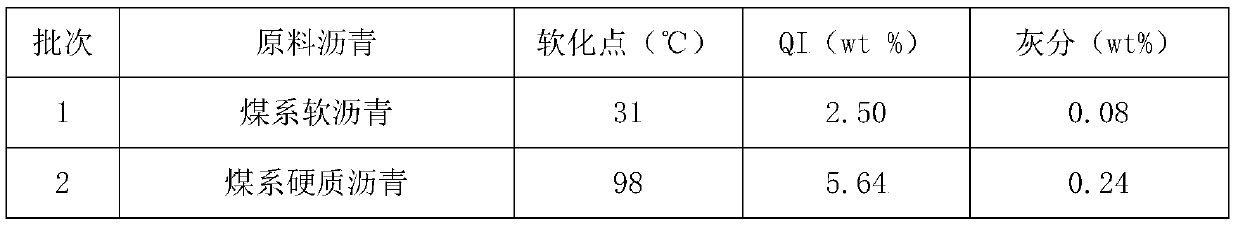

[0050]Adopting a production process of the fast-charging negative electrode material of the present invention, the main indexes of 5 batches are recorded in Table 1;

[0051] Table 1 Raw materials and main indicators of each batch

[0052]

[0053]

[0054] In the embodiment, the process parameters of the pressurized tower are shown in Table 2:

[0055] Table 2 Main parameters of delayed coking process

[0056]

[0057] The negative electrode material index of each batch in the embodiment is shown in Table 3

[0058] Table 3 Main indicators of negative electrode materials

[0059] batch D50(μm) d 002 (nm)

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com