A kind of high retention rate nano-composite solder and preparation method thereof

A nano-composite, retention rate technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of easy precipitation, easy agglomeration of nano-enhanced phases, low actual retention rate, etc., to achieve elongation, thermal conductivity and other properties. Improves, stabilizes material structure, and enhances shear/tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

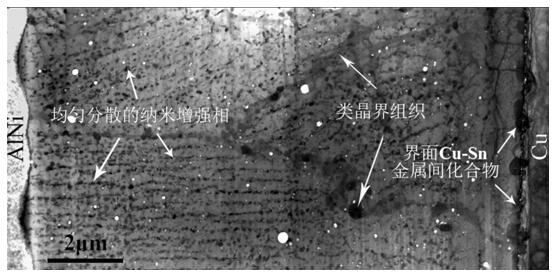

[0049] Embodiment 1 A kind of high retention rate nanometer Cu / Ag particle reinforced composite Sn-Bi solder, its preparation method comprises:

[0050] (1) Select No. 3 Sn52Bi48 powder as the solder matrix, select nano-Ag particles with an average particle size of 50nm as the reinforcing phase, and use a pure Sn plate and drilling process to prepare a cavity with a wall thickness of 2mm;

[0051] (2) Use 4 wt.% formic acid alcohol solution to ultrasonically clean the solder matrix powder, nano-Ag particles and cavity respectively, the molar ratio of formic acid to solder matrix powder or nano-Ag particles is 1:1, and use absolute ethanol Ultrasonic cleaning 3 times to remove impurities on the surface of the solder matrix and cavity, as well as organic dispersants and oxides on the surface of nanoparticles, and dry at 50°C for 30 minutes under vacuum to obtain pure metal powder;

[0052] (3) Use a planetary mixer and a ball mill to mix the dried solder matrix and nanoparticles...

Embodiment 2

[0054] Embodiment 2 A kind of high retention rate nano-IMC reinforced composite solder joint, its preparation method comprises:

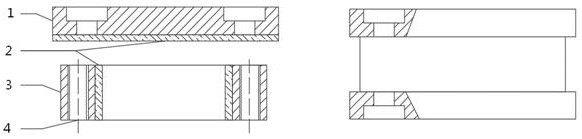

[0055] (1) Select a pure Sn sheet with a thickness of 40 μm as the solder matrix, and deposit Ag with a thickness of 0.25 μm on its surface by electroplating or electroless plating, in which the mass ratio of Ag is about 2%, and at the same time select a sheet with a thickness of 20 μm Al-Ni self-propagating film as a heat source for rapid local heat treatment;

[0056] (2) Sequentially use 2.5 wt.% HCl alcohol solution and absolute ethanol to ultrasonically clean the surface pads, self-propagating films and Sn sheets with Ag plating to be soldered, and dry them under vacuum at 50°C for 30 minutes. Obtain pure welding material.

[0057] (3) Based on the classic "sandwich" structure of pad-Sn sheet-self-spreading film-Sn sheet-pad, place the dried preform and self-spreading film in alignment between the device to be soldered and the pad and hot pre...

Embodiment 3

[0060] Embodiment 3 A kind of high retention rate nano-graphene reinforced bulk composite material, its preparation method comprises:

[0061] (1) Select bulk SAC305 metal ingot as the material matrix, select high-purity graphene sheet as the reinforcing phase, and use stainless steel splicing to prepare the cavity. The wall thickness of the cavity is 3mm, and the surface of the cavity is prefabricated with threaded holes;

[0062](2) SAC305 metal ingots were cut, polished, pickled with 3% HCl alcohol, and cleaned with absolute ethanol in sequence, so that the size of the obtained material matrix was consistent with the cavity, and at the same time, the inner surface of the stainless steel cavity was plated with Sn by chemical method, with a thickness of 1μm, and Ni-plated on the surface of the high-purity graphene sheet to improve the wetting and bonding force between the graphene sheet and the SAC305 substrate. After the above materials were prepared, they were ultrasonicall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com