Resin material, preparation method and applications of resin material

A resin material and resin technology, applied in the field of polymer materials, can solve the problems of no anti-static and dust-proof effect, unsuccessful card swiping, and injury to people who touch the body, so as to improve the anti-static and dust-proof effect, and improve the surface of the plastic shell. Excellent clean, antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

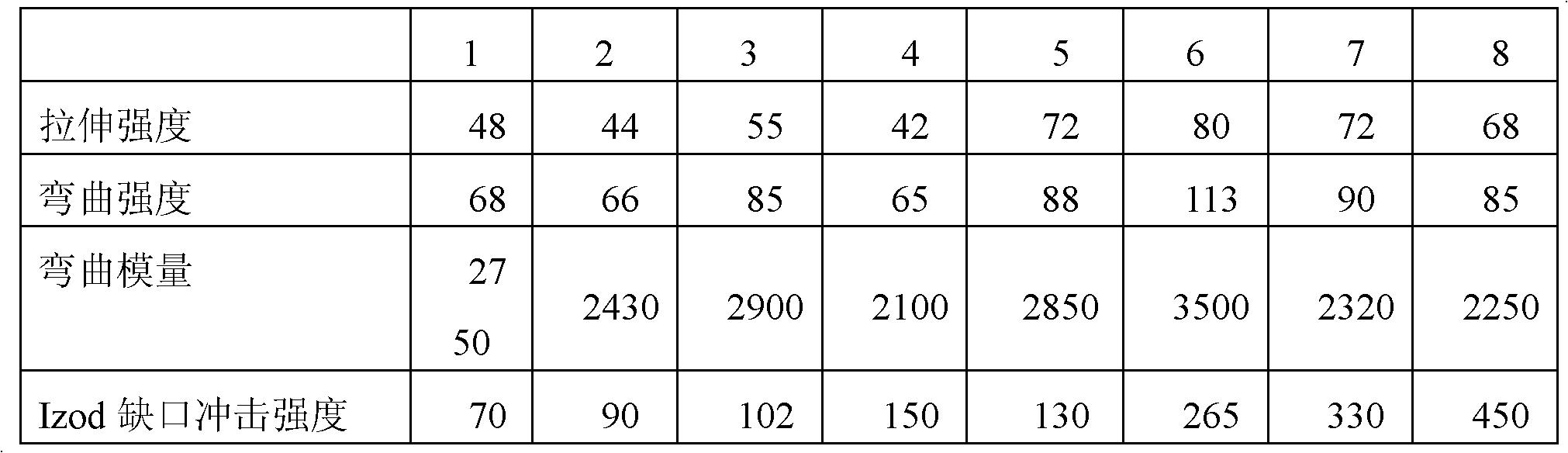

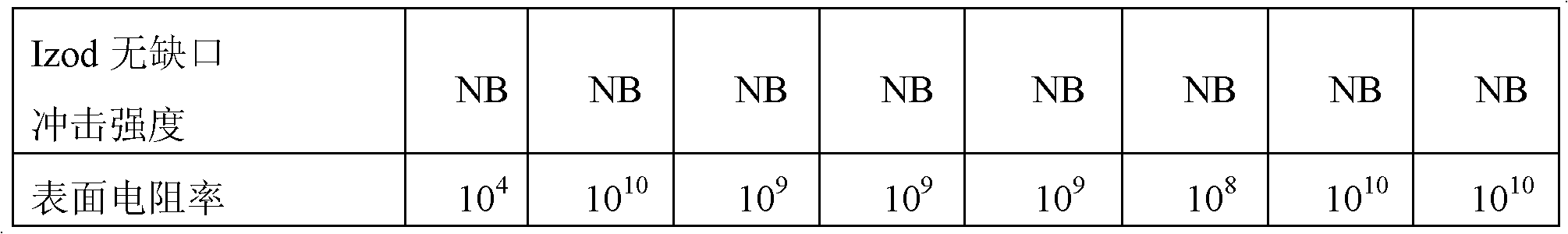

Embodiment 1

[0036] Weigh 70 parts of ABS resin, 5 parts of compatibilizer I, 9 parts of compatibilizer II, 0.5 part of processing aid EBS, 0.2 part of anti-oxidation auxiliary agent 1010 and 0.3 part of 168, put them into a high-speed mixer and fully mix them with The metering and conveying device sends the mixed material into the twin-screw extruder. After the shearing action of the screw, it is fully mixed. In the middle section of the screw of the extruder, 15 parts of conductive powder are added to the screw by a side feeder Material I, wherein the length-to-diameter ratio of the twin-screw extruder is 42:1, the screw speed is 300 rpm, the working temperature range of the twin-screw extrusion is 180-240°C, the molten blend is extruded, drawn Strips, cooled, diced. Packaged into a finished product. The composites prepared in each example were injection-molded into standard specimens for testing according to the standard size, and the physical properties were tested according to the na...

Embodiment 2

[0038] Weigh 82 parts of ABS resin, 5 parts of compatibilizer II, 0.5 parts of processing aid EBS, 0.1 parts of antioxidant additives 1010 and 0.4 parts of 168, put them into a high-speed mixer and mix them thoroughly, and use a metering and conveying device to mix the mixed The material is sent into the twin-screw extruder, through the shearing action of the screw, fully mixed, in the middle section of the screw of the extruder, 12 parts of conductive material I are added to the screw by using a side feeder, wherein the twin-screw extrudes The length-to-diameter ratio of the machine is 40:1, the screw speed is 350 rpm, and the working temperature range of twin-screw extrusion is 180-240°C. The melted blend is extruded, drawn, cooled and pelletized. Packaged into a finished product. The prepared compound was injection molded into a standard sample for testing according to the standard size, and the physical properties were tested according to the national standards of our coun...

Embodiment 3

[0040] Weigh 88 parts of ABS resin, 5 parts of compatibilizer III, 1 part of processing aid EBS, 0.4 parts of antioxidant additives and 1680.6 parts, put them into a high-speed mixer and mix them thoroughly, and use a metering and conveying device to mix the mixed The material is sent into the twin-screw extruder, and after the shearing action of the screw, it is fully mixed. In the middle section of the screw of the extruder, 5 parts of conductive material II are added to the screw by a side feeder, and the twin-screw extruders The length-to-diameter ratio of the machine is 44:1, the screw speed is 300 rpm, and the working temperature range of twin-screw extrusion is 180-240°C. The melted blend is extruded, drawn, cooled and pelletized. Packaged into a finished product. The prepared compound was injection molded into a standard sample for testing according to the standard size, and the physical properties were tested according to the national standards of our country, as show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com