Centrifugal powder particle mixing device

A mixing device and centrifugal technology, applied in the field of separation and mixing devices, to achieve the effects of high mixing efficiency, small damage and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

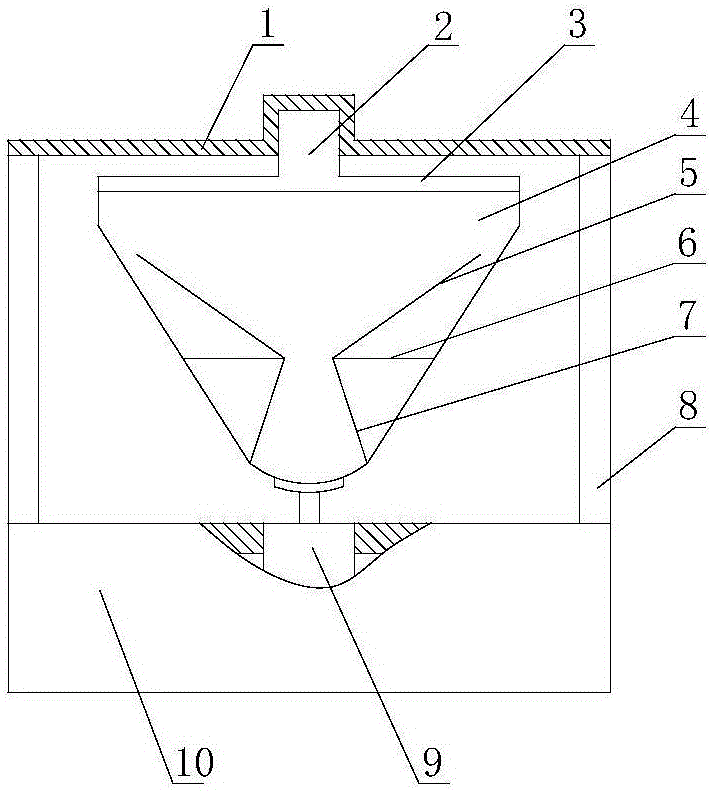

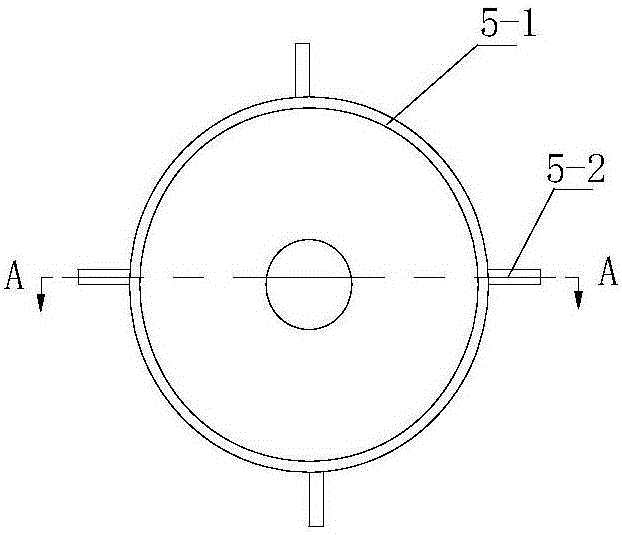

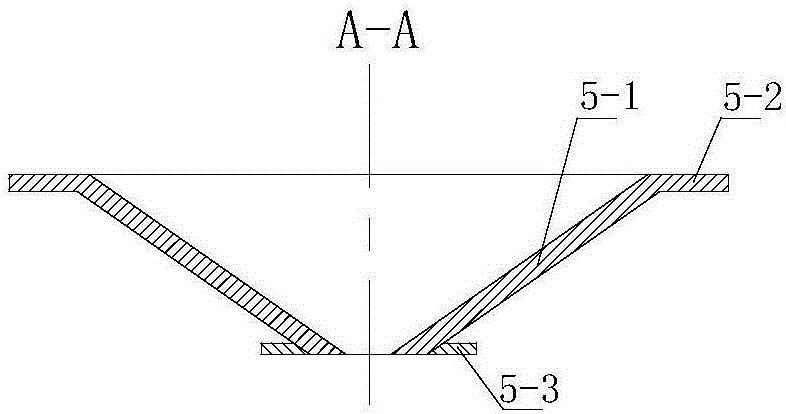

[0022] In this embodiment, the structure of the powder mixing tank 4 is that the inverted conical cylinder is integrated with the outer convex spherical bottom. The ratio of the large diameter to the small diameter of the conical cylinder is 1.5, and the lower screen 7, the upper screen 6, and the retaining cylinder 5 are arranged in the powder mixing tank 4 from bottom to top, and the angle between the busbar of the lower screen 7 and the axis is 45° , the included angle between the busbar of the retaining cylinder 5 and the axis is 35°, the diameter ratio of the diameter of the large end face of the retaining cylinder 5 to the small end face is 1.5, and the mesh diameter of the lower screen 7 and the upper screen 6 is 2mm .

[0023] The other components and the connection relationship of the components are the same as in Embodiment 1.

Embodiment 3

[0025] In this embodiment, the structure of the powder mixing tank 4 is that the inverted conical cylinder is integrated with the outer convex spherical bottom. The ratio of the large diameter to the small diameter of the conical cylinder is 3, and the lower screen 7, the upper screen 6, and the retaining cylinder 5 are arranged in the powder mixing tank 4 from bottom to top, and the angle between the busbar of the lower screen 7 and the axis is 65° , the included angle between the 5 generatrixes of the retaining cylinder and the axis is 55°, the diameter ratio of the diameter of the large end face of the retaining cylinder 5 to the small end face is 3, and the mesh diameter of the lower screen 7 and the upper screen 6 is 5mm . The other components and the connection relationship of the components are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com