Multi-stage solid particle heat absorber for tower type solar thermal power generation

A technology of tower solar energy and solid particles, which is applied in solar thermal power generation, solar collectors, solar heat storage, etc., can solve problems such as thermal stress damage, wear on the inner wall of metal pipes, and excessive falling speed of particles, and achieve uniform energy Fluid density distribution, avoiding local overheating, and reducing the effect of temperature differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

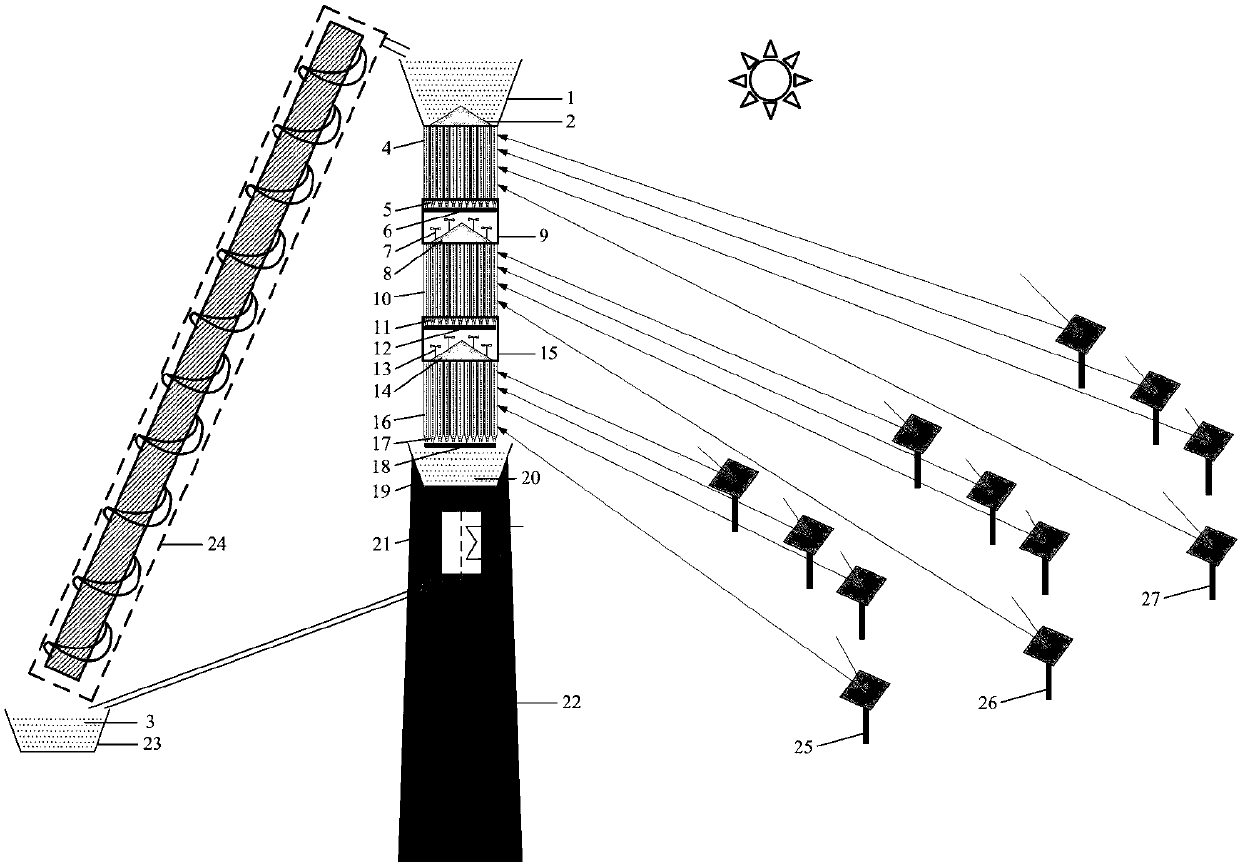

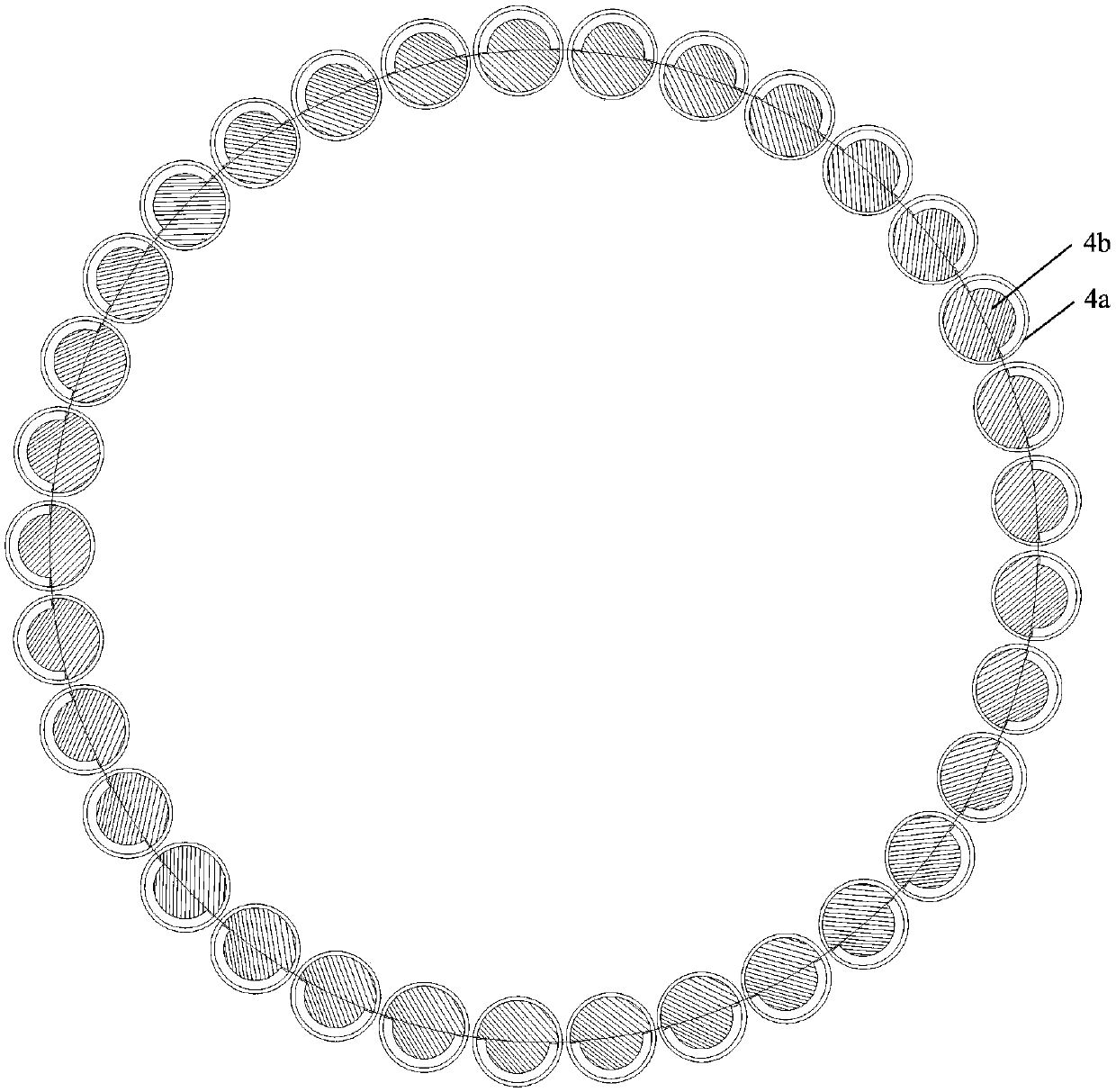

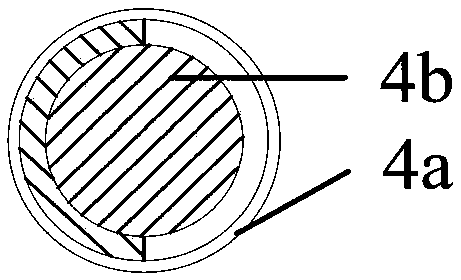

[0058] Such as figure 1 As shown, the solid particle heat absorber of the present invention includes a particle distributor 1, a first conical reforming fluid 2, solid particles 3, a first heat absorption section 4, a second heat absorption section 10, and a third heat absorption section 16. High-temperature solid particle storage tank 19, particle heat exchanger 21, heat absorption tower 22, low-temperature solid particle storage tank 23, screw elevator 24, first-stage particle mixing chamber 9, second-stage particle mixing chamber 15, third-stage particle mixing chamber The first-stage conical funnel 17 and the third-stage flow regulating mechanism 18, the inner ring heliostat field 25, the middle ring heliostat field 26, and the outer ring heliostat field 27. A first conical reforming body 2 is placed in the particle distributor 1 at its bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com