Measuring apparatus and measuring method for gas-solid fluidized bed particle mixing

A measurement device and measurement method technology, applied in the field of fluidized bed and multiphase flow measurement, can solve the problems of large randomness, limitation, difficulty in particle mixing, etc., and achieve the effect of good penetration characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

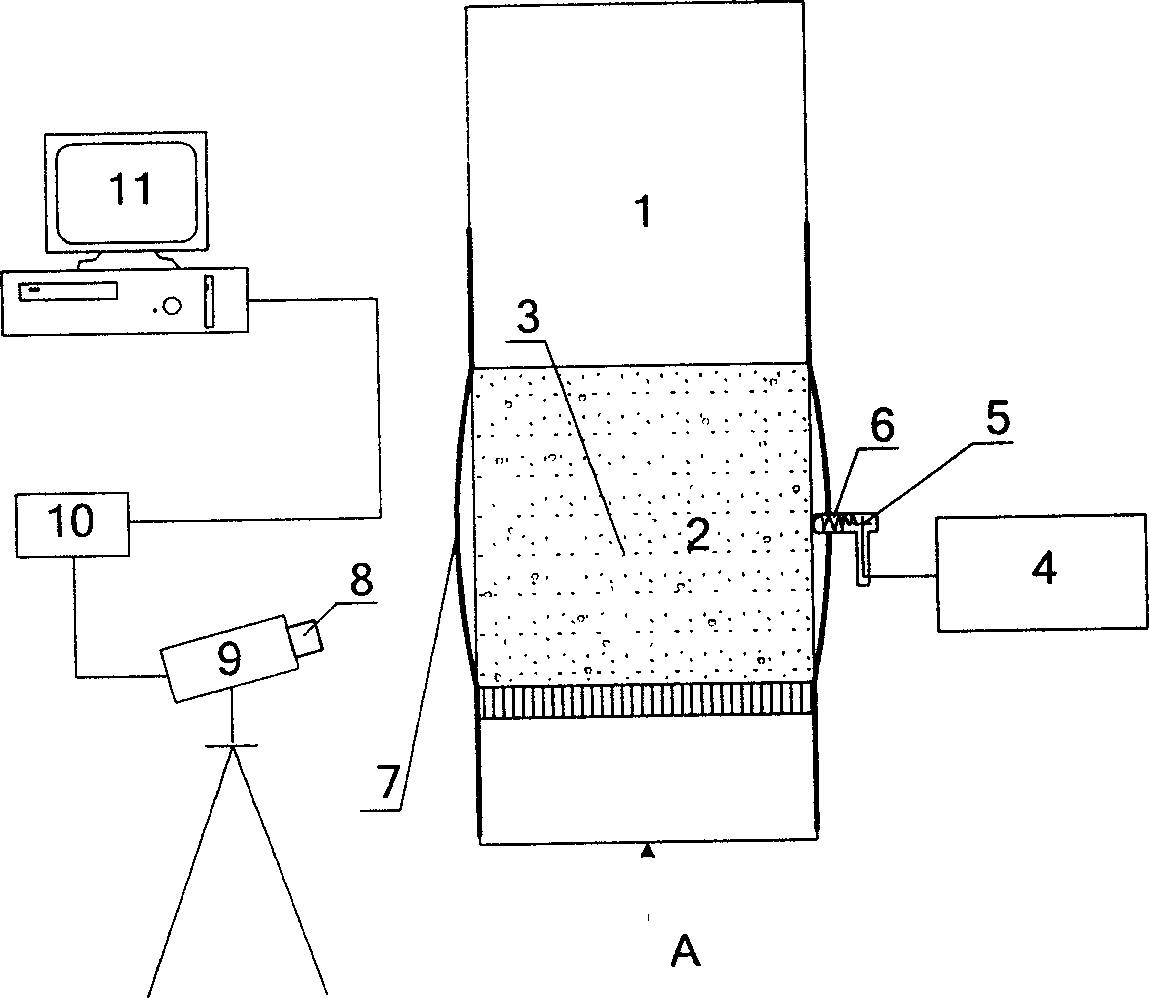

[0022] Refer to the following figure 1 The present invention will be described in detail.

[0023] The object of the present invention is achieved like this: figure 1 As shown, a microwave generating device 4 is installed on one side of the fluidized bed 1, and the generated microwave is emitted by the transmitting antenna 5 and then guided by the waveguide 6 to radiate to the bed; microwave is a kind of ultra-high frequency electromagnetic wave, which oscillates every second Tens of billions of times, when microwave radiation to the polar H 2 Tracer particles for O molecules 3, polar H 2 The arrangement direction of O molecules will change tens of billions of times per second, causing the water molecules to rotate and oscillate at high speed, and collide with the surrounding water molecules, squeeze and rub against each other to generate a lot of heat. The tracer particles 3 can rapidly rise in temperature in a very short period of time. The microwave reflection screens 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com