High temperature and high pressure microwave chemical reactor

A chemical reactor, high temperature and high pressure technology, applied in the field of chemical equipment, can solve the problems of low microwave power, loss of microwave energy, poor airtight structure, etc., achieve high utilization rate, reduce leakage rate, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

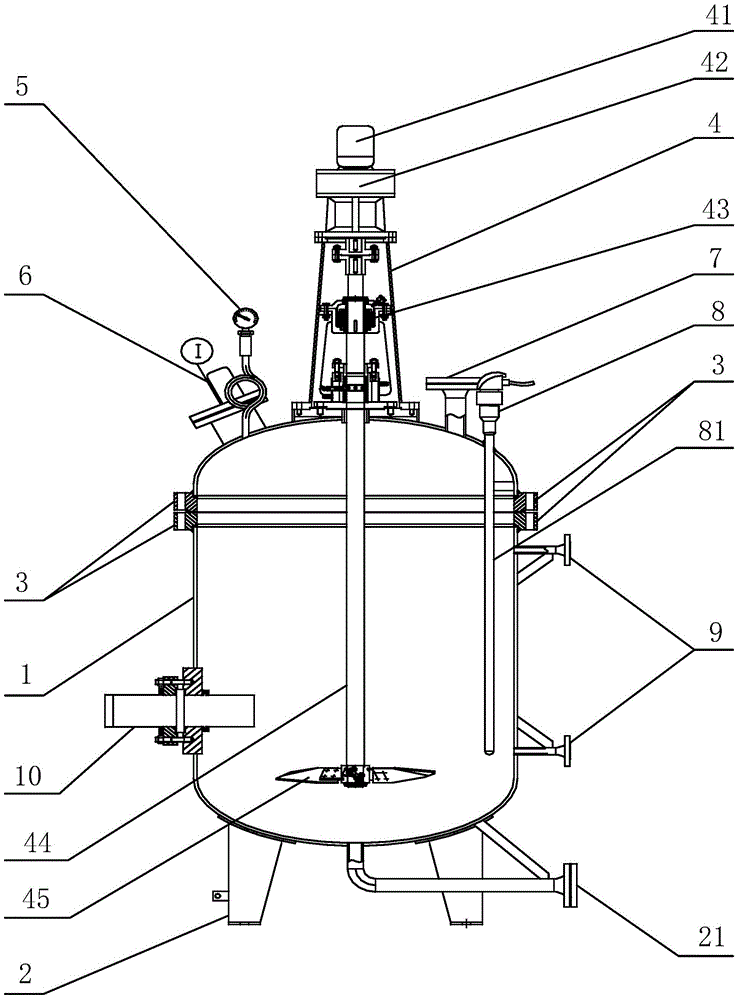

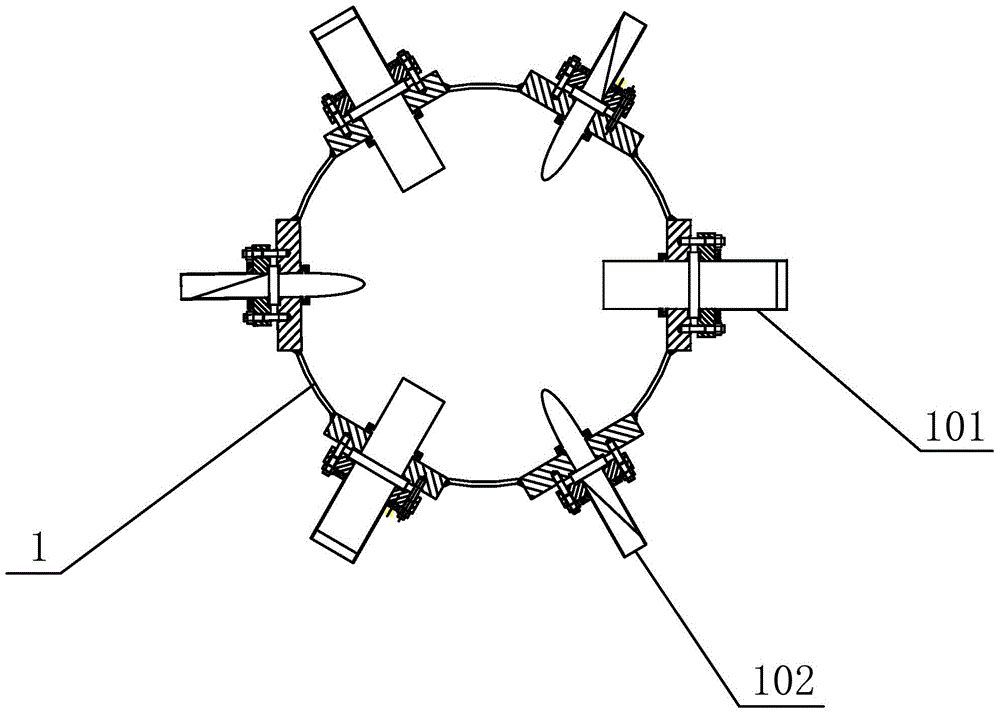

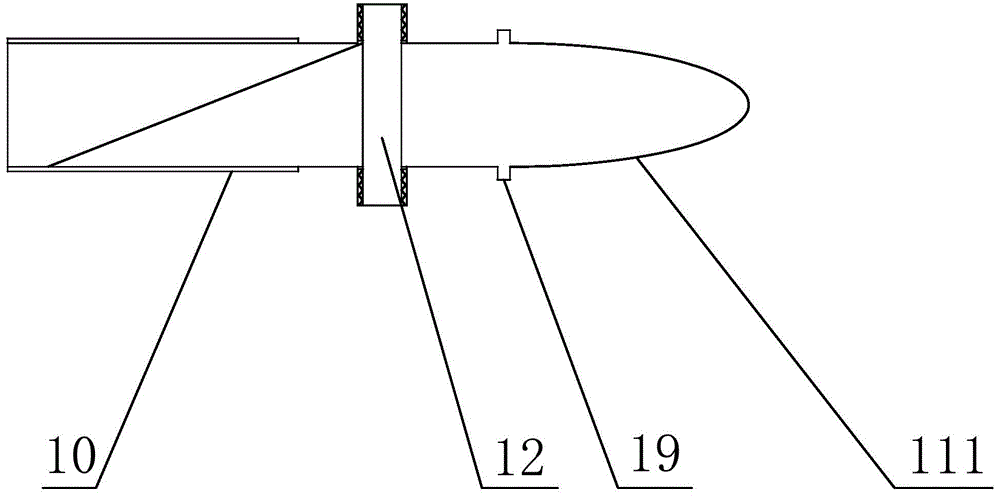

[0034] Such as Figure 1 to Figure 4 As shown, a high-temperature and high-pressure microwave chemical reactor includes a pressure-bearing shell 1 with an internal cavity structure, a stirring system 4 arranged on the top of the pressure-bearing shell 1, and a microwave oven set on the side wall of the pressure-bearing shell 1. feed into the device. The mixing system 4 is mainly composed of a motor 41, a reducer 42, a bearing 43 and an agitator, the motor 41 is connected to the reducer 42, the agitator is connected to the power output shaft of the reducer 42, and the bearing 43 is installed on the agitator. The top and the lower part of the agitator are placed in the inner cavity of the pressure housing 1 . The motor 41 is externally connected to an external power supply, and the external power supply drives the motor 41 to rotate, and the motor 41 drives the reducer 42 to work, so that the stirrer connected to the reducer 42 produces rotation and agitation. The top of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com