Patents

Literature

40 results about "Hot particle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A hot particle is a microscopic piece of radioactive material that can become lodged in living tissue and deliver a concentrated dose of radiation to a small area. A controversial theory proposes that hot particles within the body are vastly more dangerous than external emitters delivering the same dose of radiation in a diffused manner. Other researchers claim that there is little or no difference in risk between internal and external emitters.

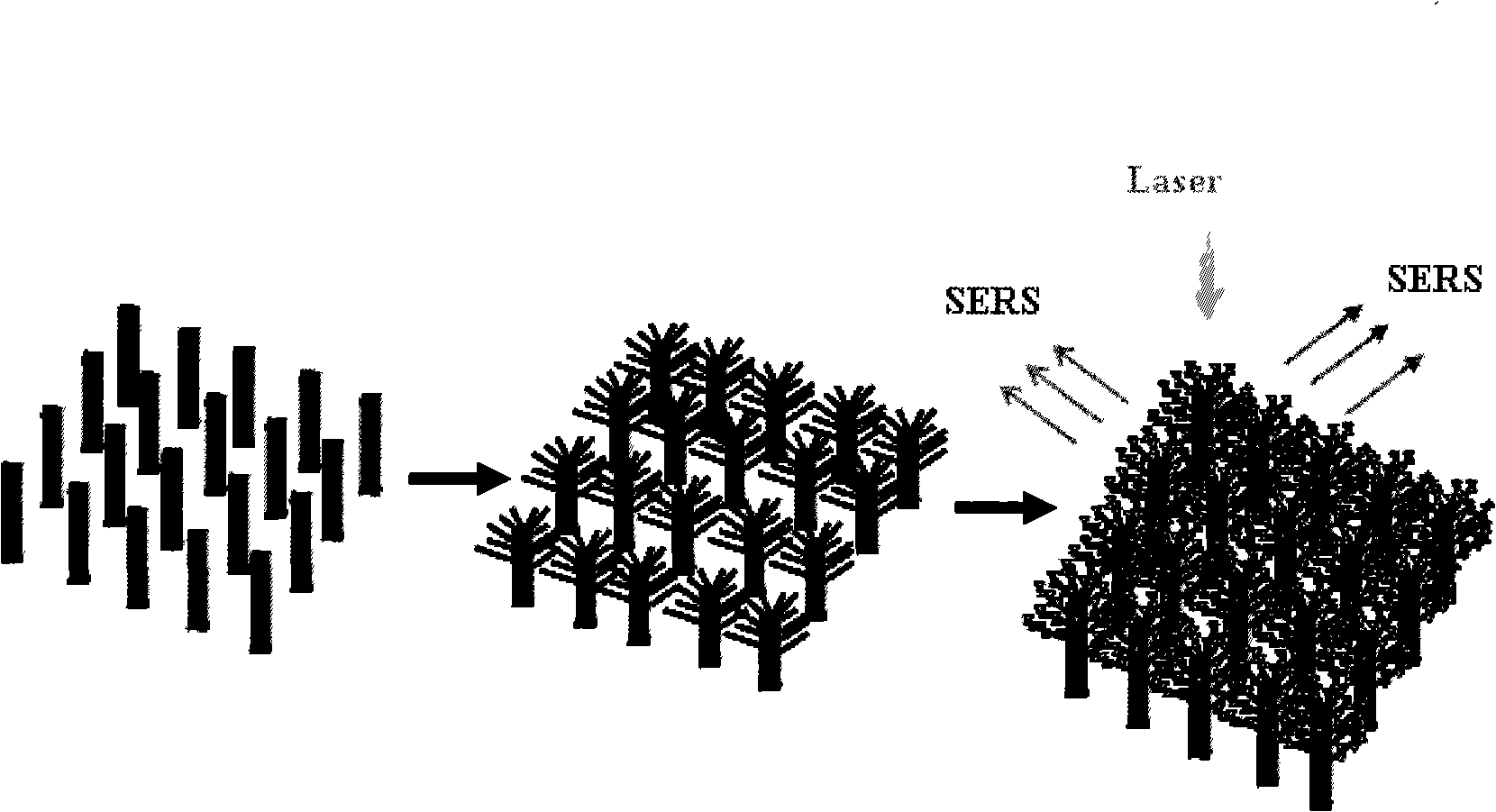

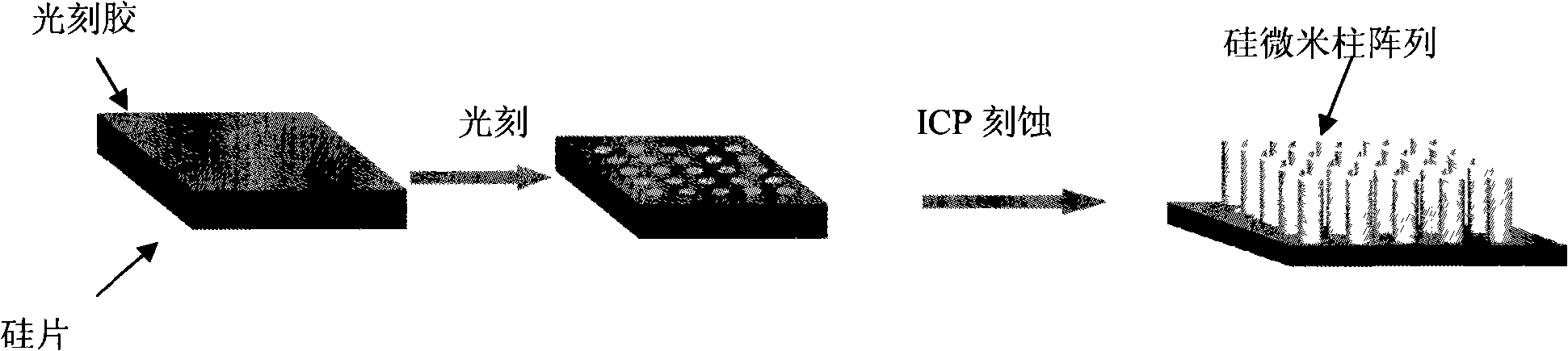

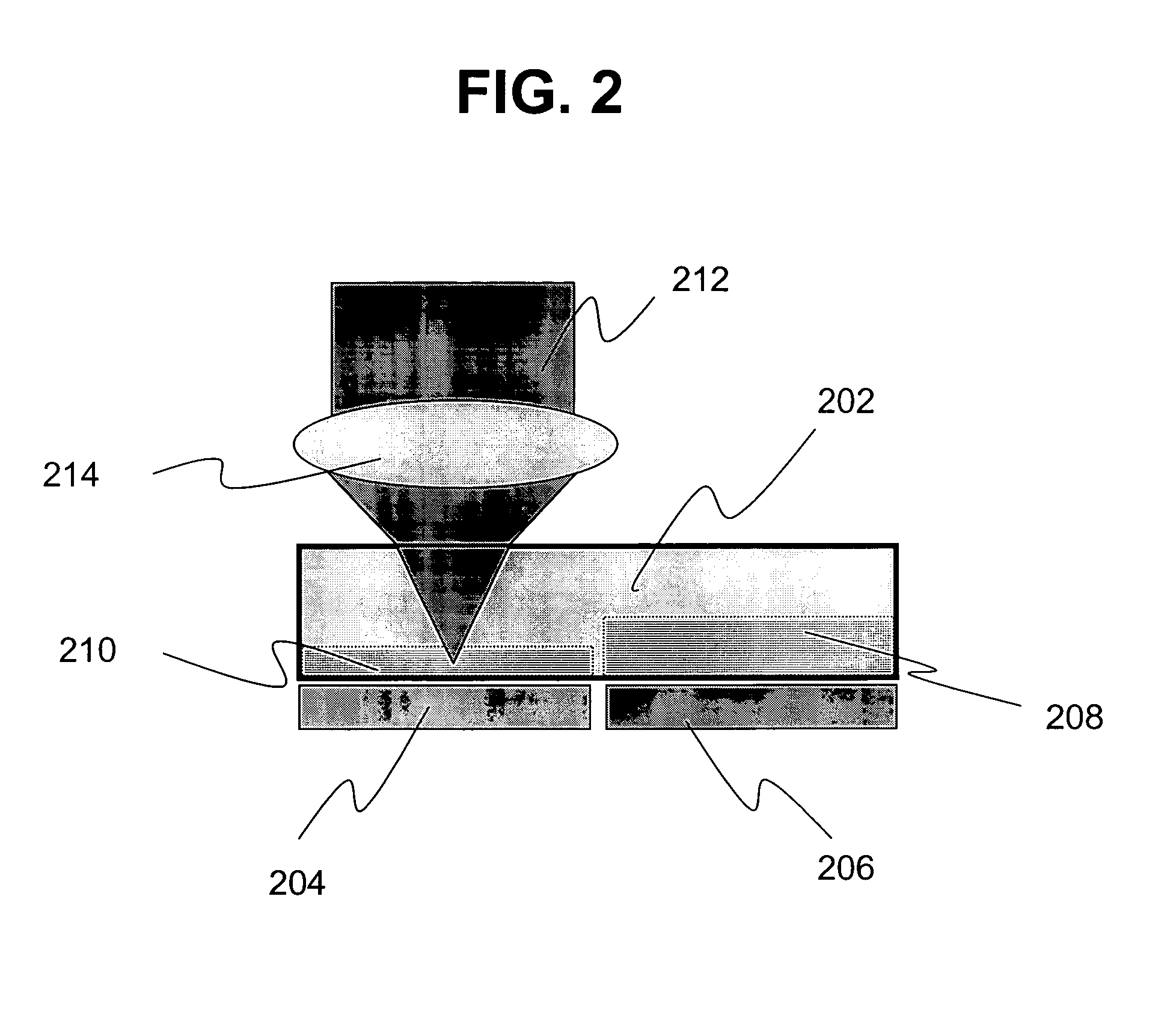

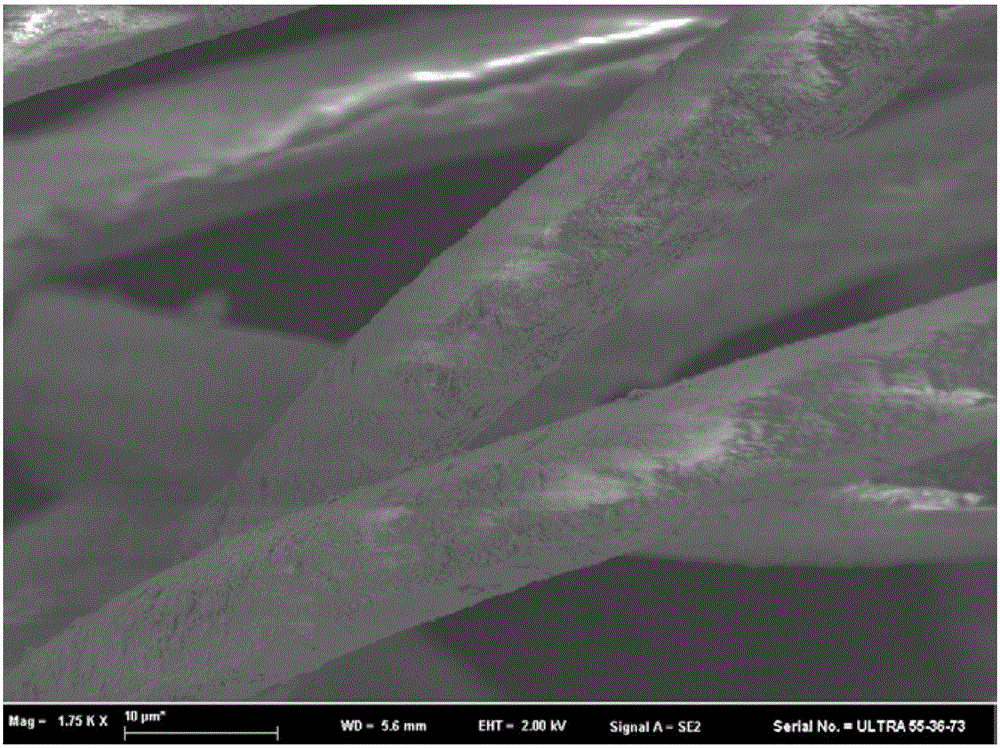

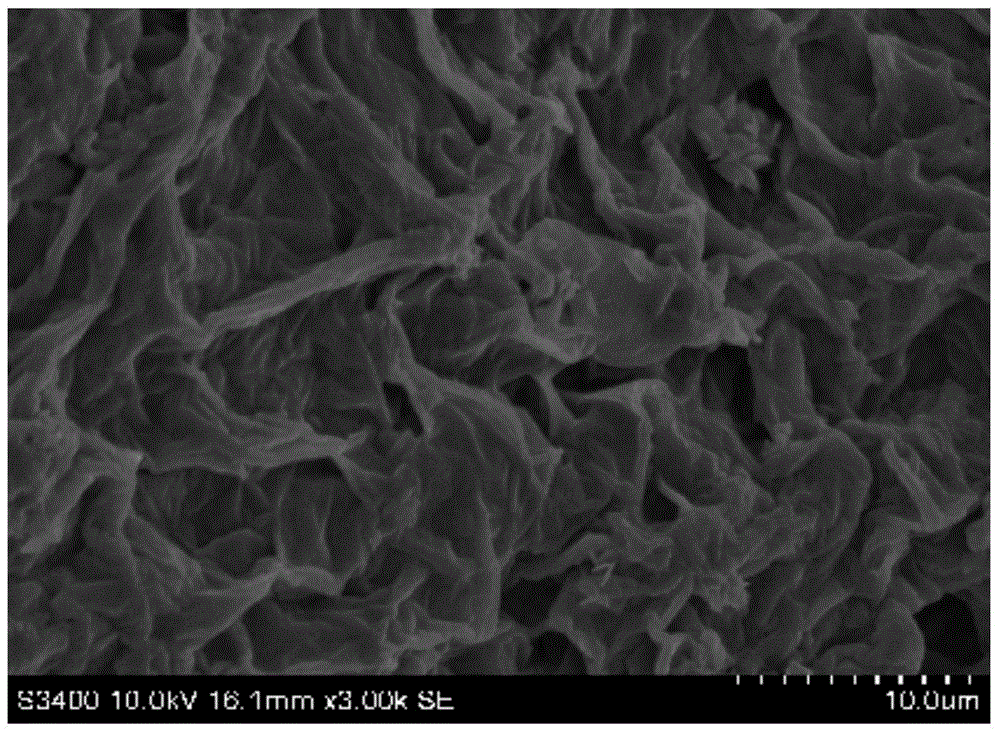

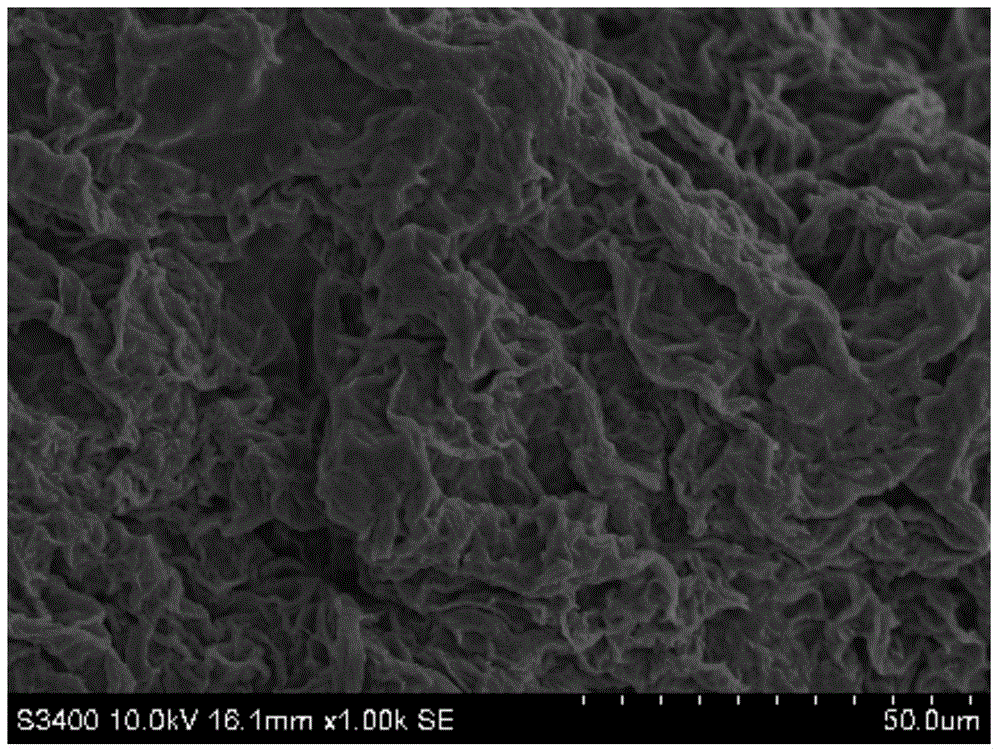

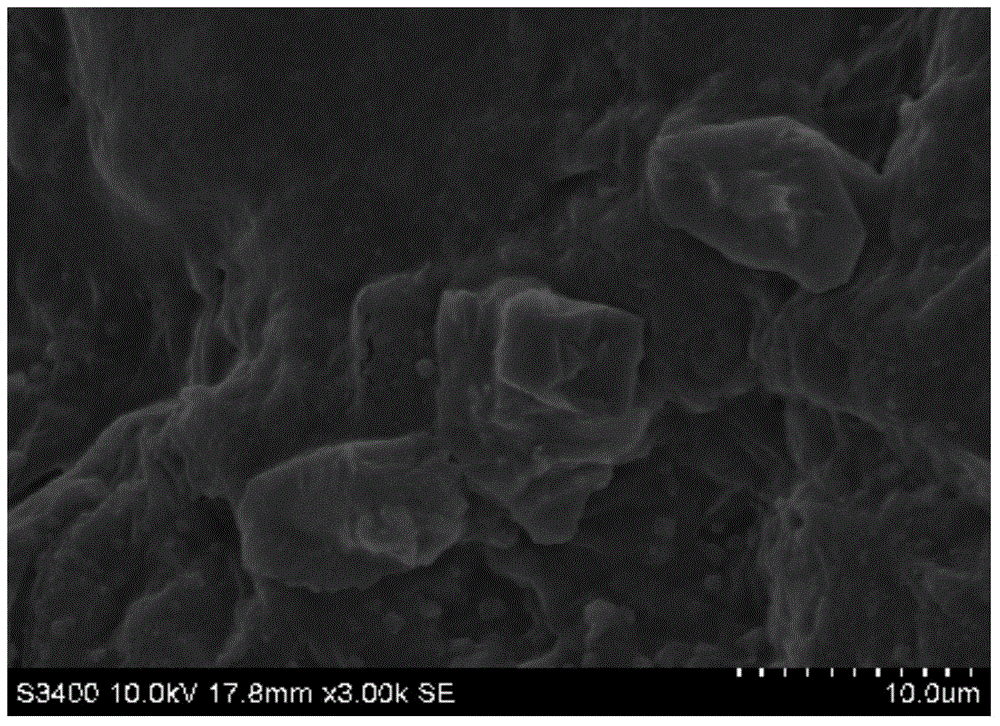

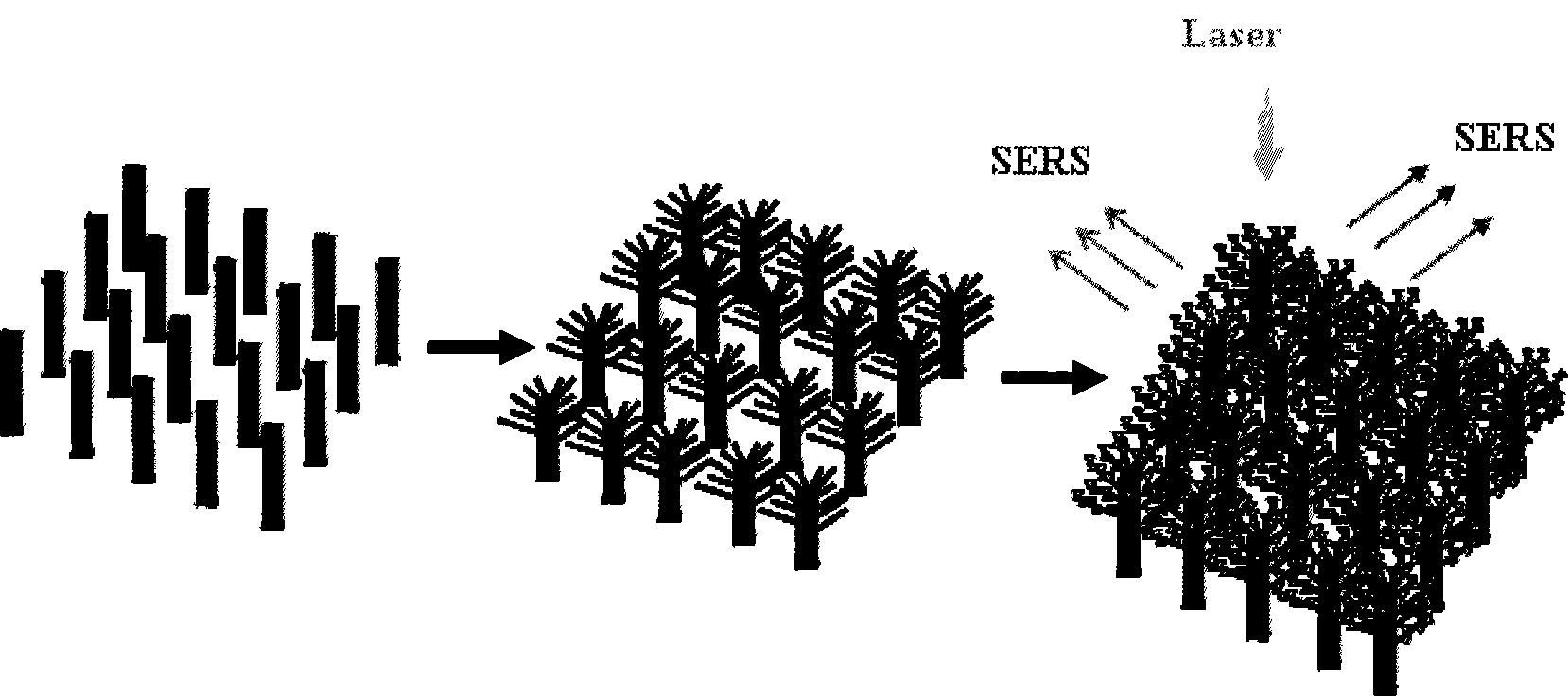

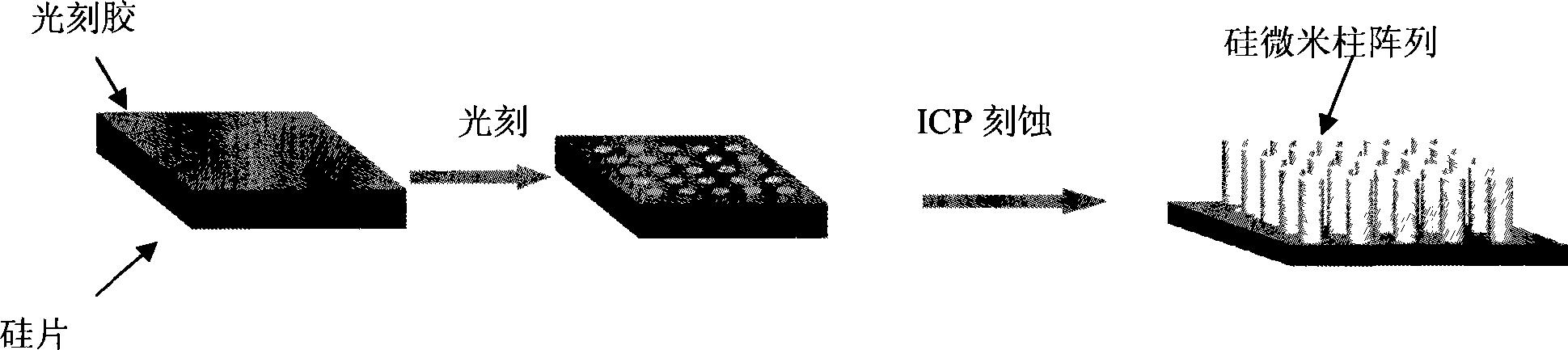

Preparation of surface reinforced Raman active substrate of large area micro-nano dendritical structure array

InactiveCN101281133AHighly sensitive SERS activitySuitable for testingDecorative surface effectsRaman scatteringMicro nanoBasement

The invention discloses a preparation method for increasing raman activity of a basement in a surface of a large area of a micro-nano tree structure array, which firstly prepares a large area of a silicon micron cylinder array; a nanometer assembling technology is used for producing a nanometer stick in the silicon micron cylinder array. then a three-dimensional ordered periodic micro-nano structure array is obtained; and various appearance of metal nano-particles are embedded into the three-dimensional ordered periodic micro-nano structure array by using a way of a hydro-thermal synthesis method. A SERS activity basement of the invention can achieve homogenization from a centimeter grade to a large area. The invention designs SERS activity hot-particles on the three-dimensional ordered micro-nano structure, and assembles increasing effect of antenna, the increasing effect of metal / semiconductor intersection and the increasing effect of a gap into one body, then high sensitivity of the SERS activity is obtained, and the SERS activity hot-particles is firmly embedded into the tree micro-nano structure, then the invention is not only applicable for a SERS test of trace liquid-phase analyte, but also for the SERS test of trace gaseous-phase analyte.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Bag house filters and media

A bag filter having a support structure clothed in a filter bag. The cloth of the filter bag is a composite of at least one substrate layer and at least one nanoweb bonded thereto in a face-to-face relationship. The nanoweb is positioned at the surface of the filter bag first exposed to the hot particle laden gas stream and can have a basis weight of greater than about 2 gsm.

Owner:EI DU PONT DE NEMOURS & CO

Removal of residual acetaldehyde from polyester polymer particles

In one embodiment, there is provided a process comprising introducing polyester polymer particles containing residual acetaldehyde into a vessel at a temperature within a range of 130° C. to 195° C. to form a bed of particles within the vessel, flowing a gas through at least a portion of the particle bed, and withdrawing finished particles from the vessel having a reduced amount of residual acetaldehyde. In this process, it is not necessary to introduce a hot flow of gas at high flow rates otherwise required to heat up cool particles to a temperature sufficient to strip acetaldehyde. Rather, this process provides a benefit in that, if desired, gas introduced into the vessel at low flow rates and low temperatures can nevertheless effectively strip acetaldehyde in a reasonable time because the hot particles quickly heat a the gas to the particle temperature.

Owner:ALPEK POLYESTER SA DE CV

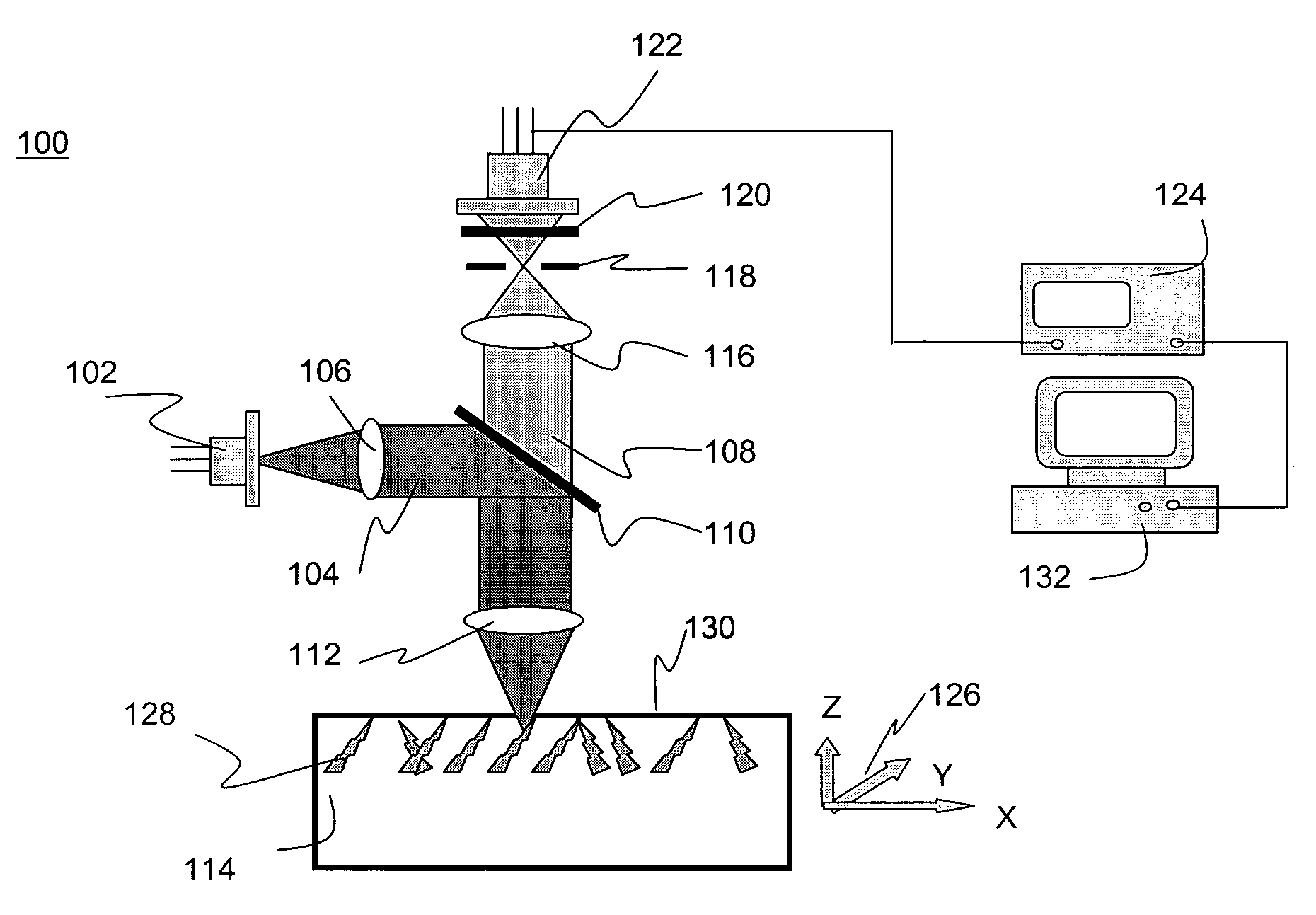

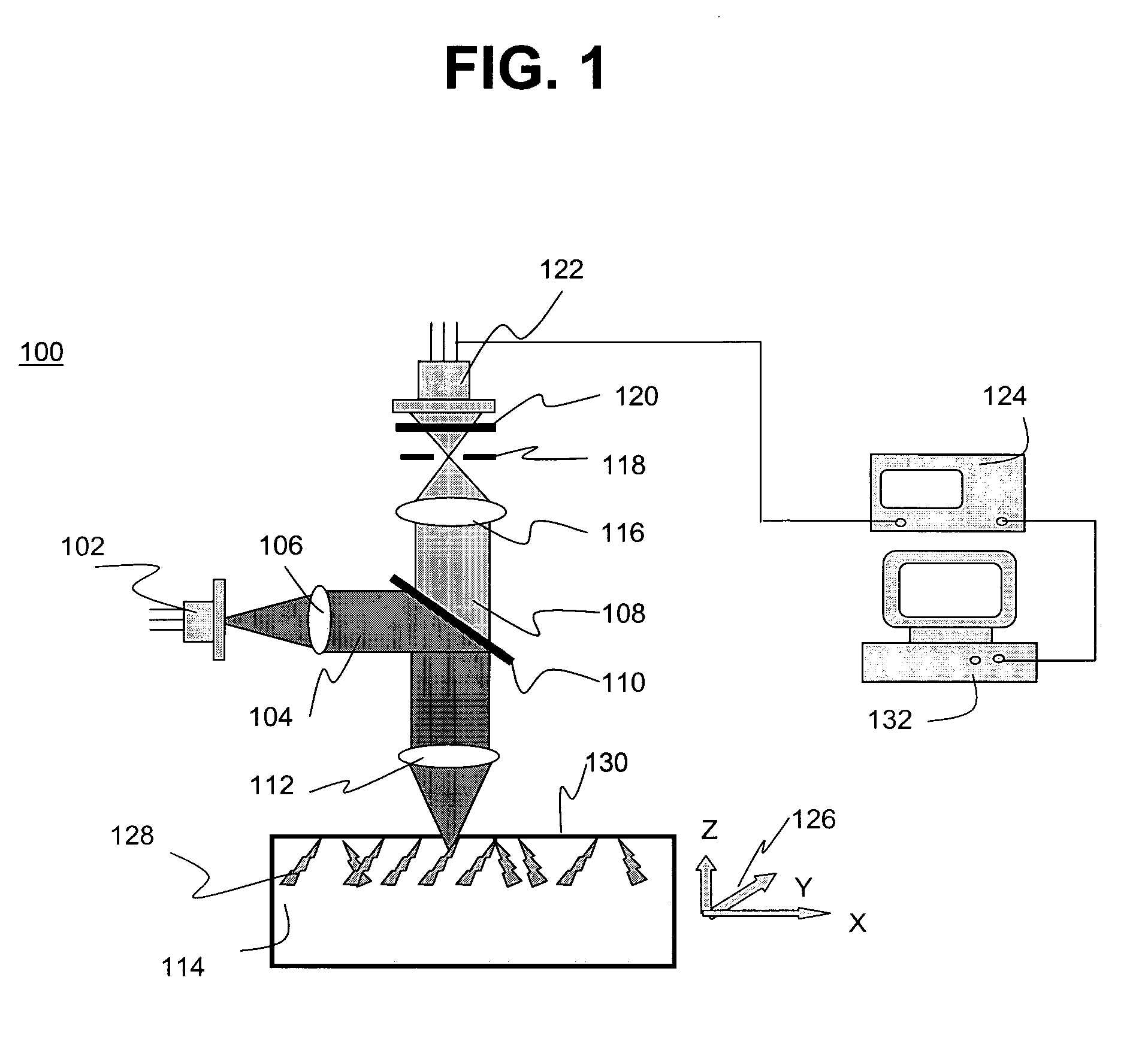

Detection of neutrons and heavy charged particles

The present invention provides a method and system for measuring the spatial distribution of fluorescence from the excited radiochromic luminescent material; and for signal processing of the spatial distribution of fluorescence to thereby detect tracks of one or more heavy charged particles with which the luminescent material has been irradiated. The present invention also provides a method and system for measuring the spatial distribution of fluorescence from an excited radiochromic luminescent material that has been irradiated with a hot particle of a radioactive material. The present invention provides a method for detecting thermal and fast neutrons as well as a method for determining parameters of heavy charge particles. In several embodiments of the present invention, the luminescent material comprises Al2O3 doped with magnesium and carbon.

Owner:LANDAUER INC

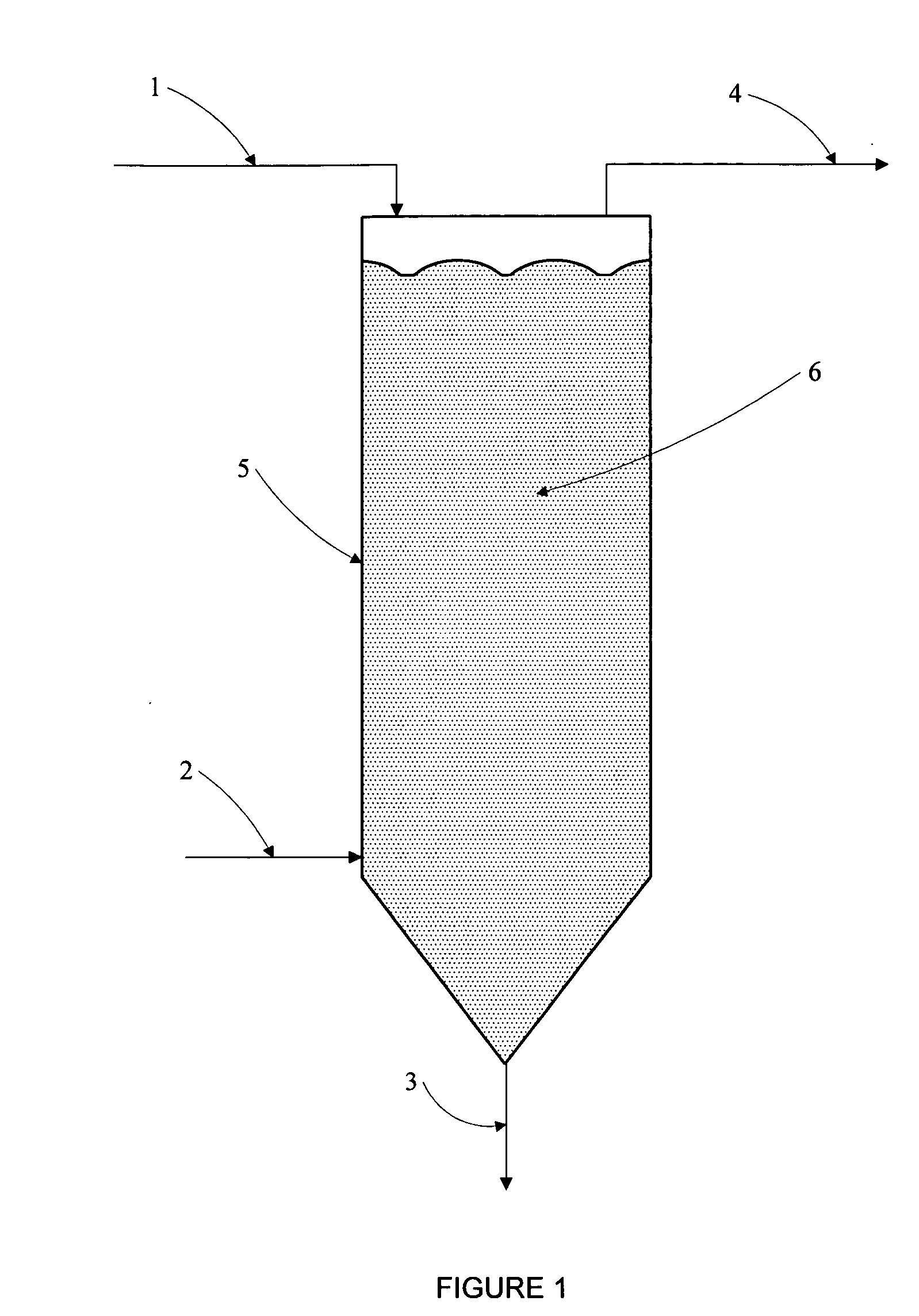

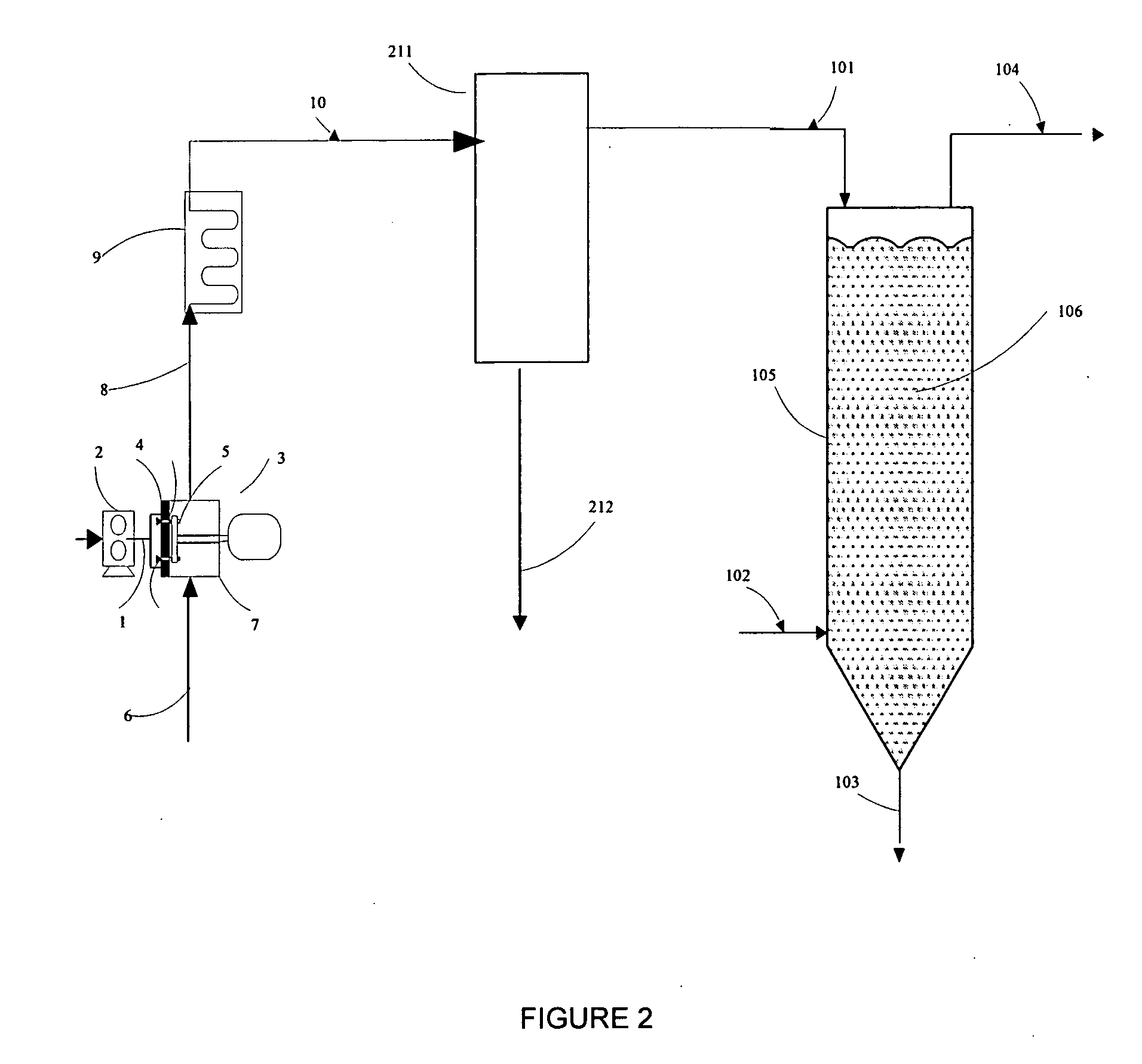

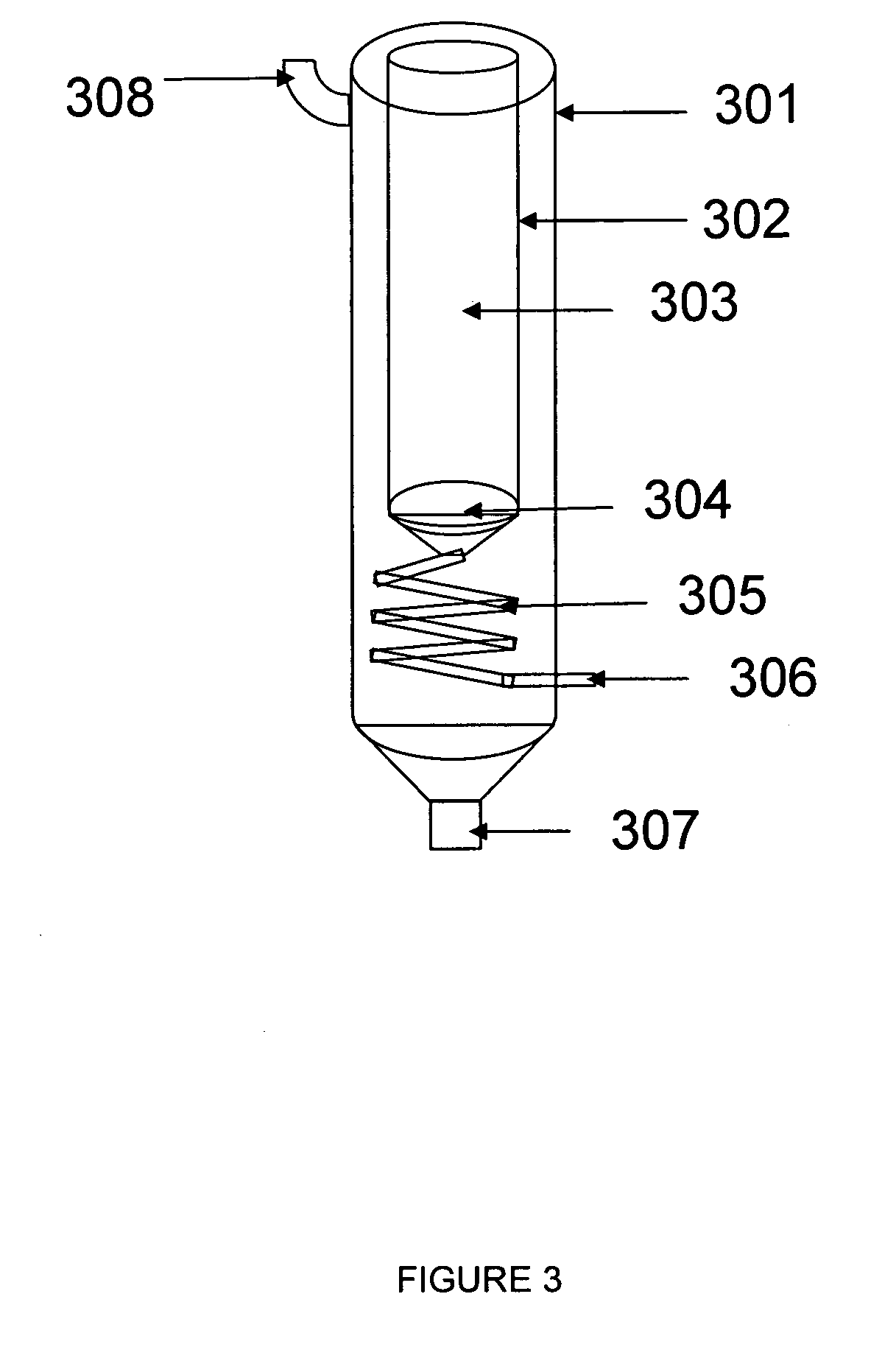

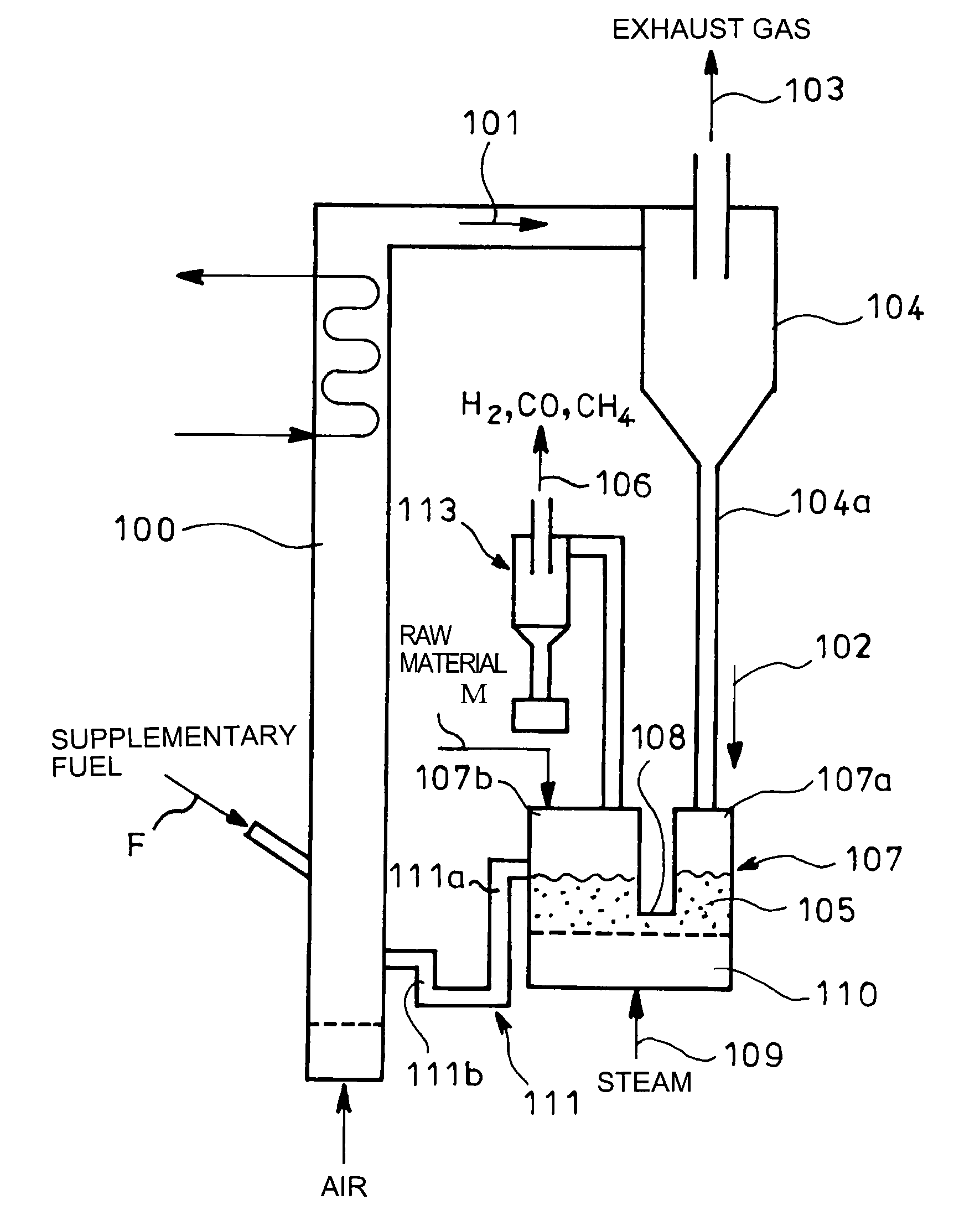

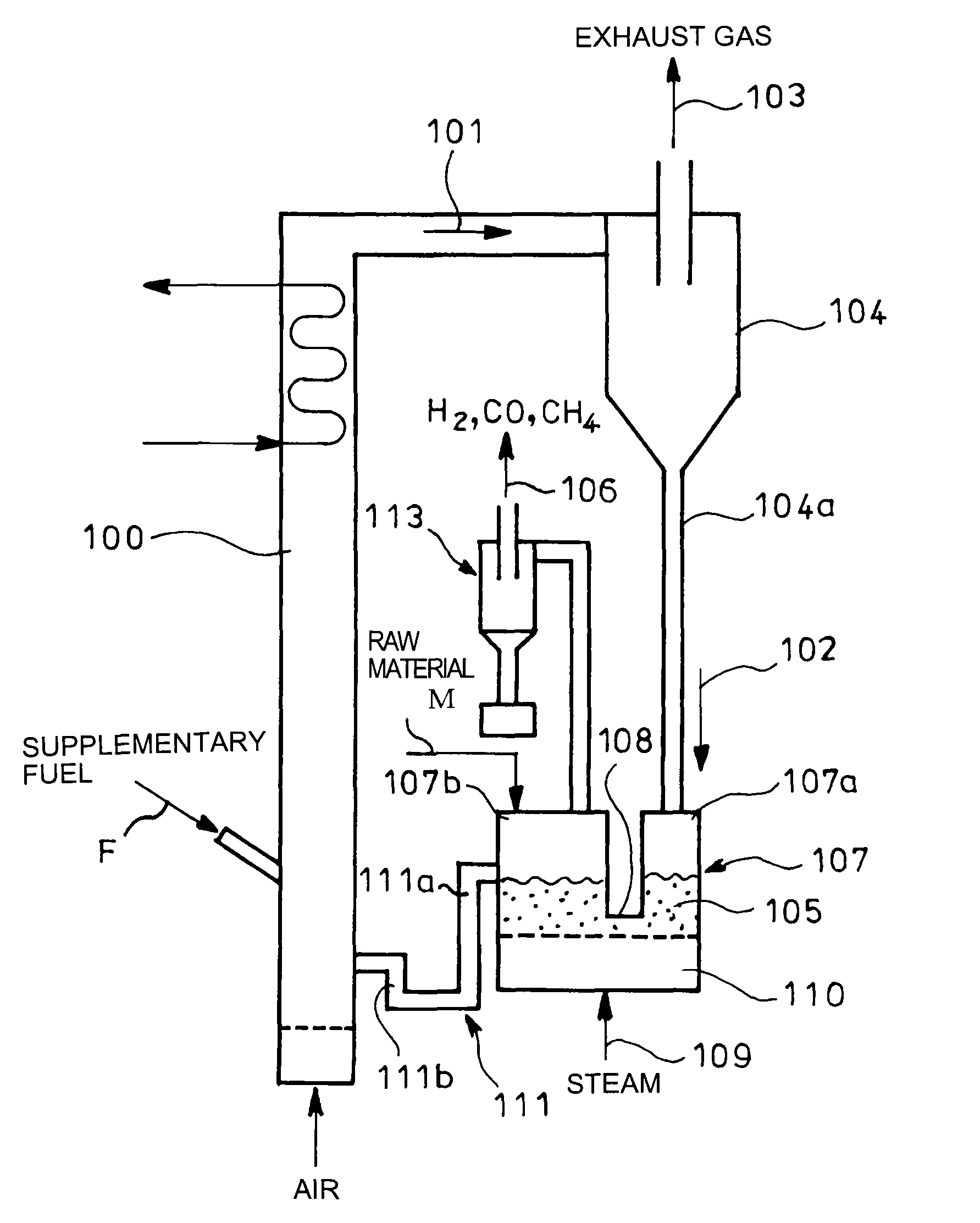

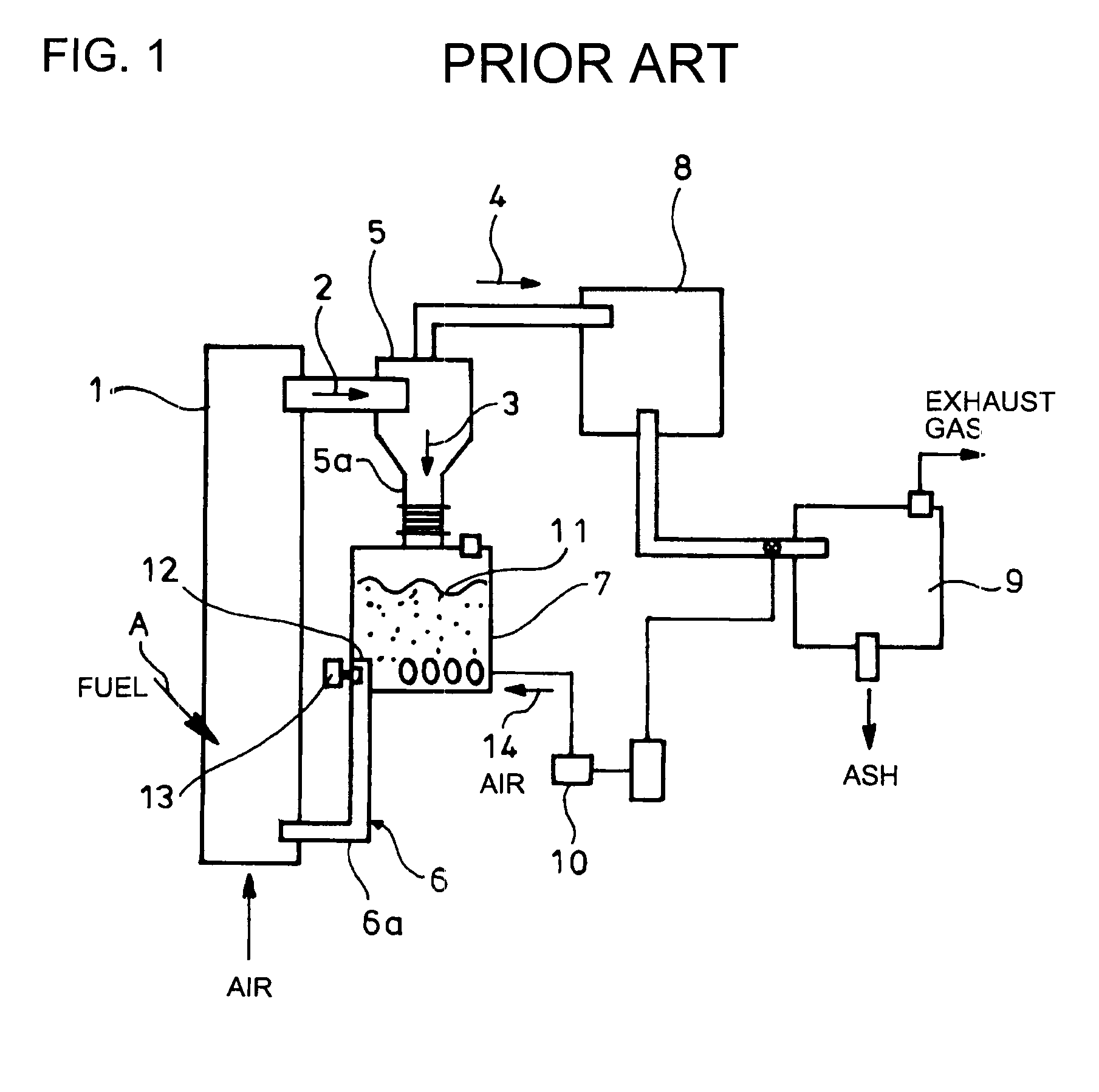

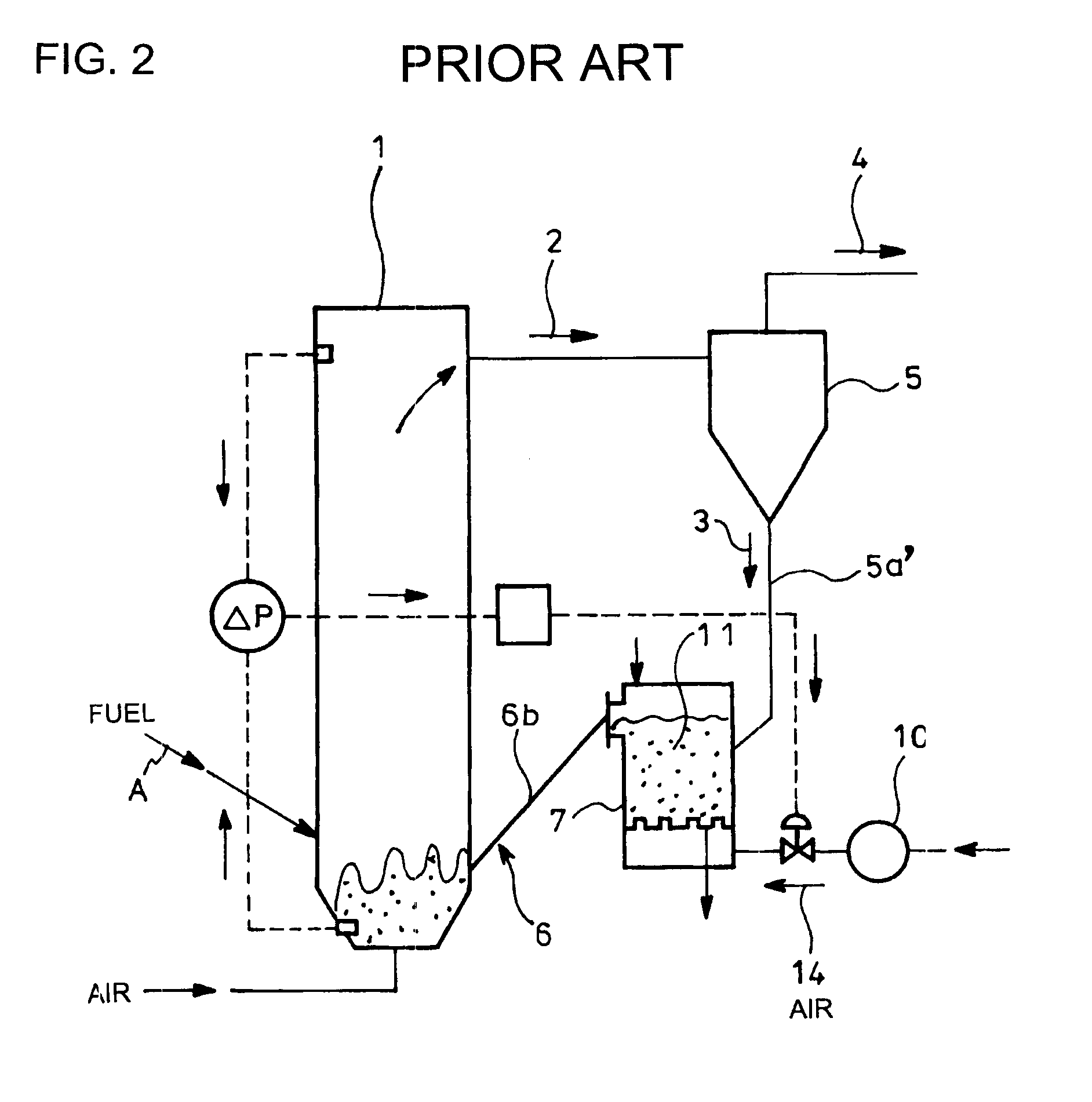

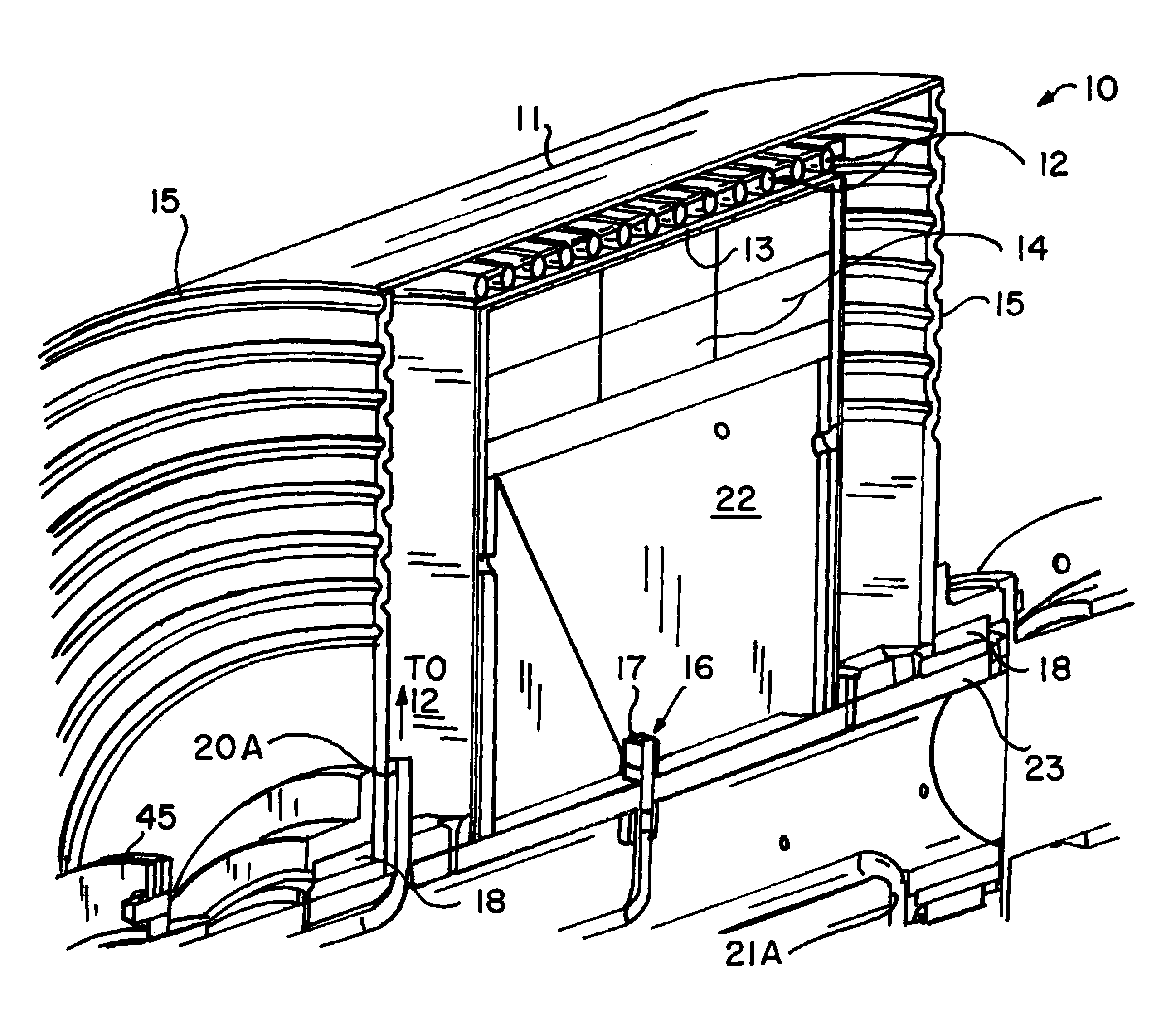

System for controlling circulatory amount of particles in circulating fluidized bed furnace

ActiveUS20100024297A1Improve gasification efficiencyFluidized bed combustionLevel controlFluidized bed gasifierDifferential pressure

The invention has its object to arbitrarily adjust an amount of particles to be circulated without changing a flow rate of a gasification agent to thereby enhance gasification efficiency in a fluidized bed gasification furnace.The fluidized bed gasification furnace 107 comprises first and second chambers 113 and 114 in communication with each other in a fluidized bed 105. The hot particles 102 separated in the separator 104 and raw material M are introduced into the first chamber 113. The particles 102 introduced from the first chamber 113 through interior in the fluidized bed 105 to the second chamber 114 are supplied in an overflow manner to the fluidized bed combustion furnace 100. A first pressure controller 121 is provided to control the resultant gas induction means 116 such that the pressure in the first chamber 113 is kept to preset pressure 120; and a second pressure controller 124 is provided to control the exhaust gas induction means 118 such that difference between pressure in the first and second chambers 113 and 114 is equal to the preset differential pressure 123, so that the fluidized bed 105 in the first chamber 113 is controlled in height to control an amount of particles 102 to be circulated.

Owner:IHI CORP

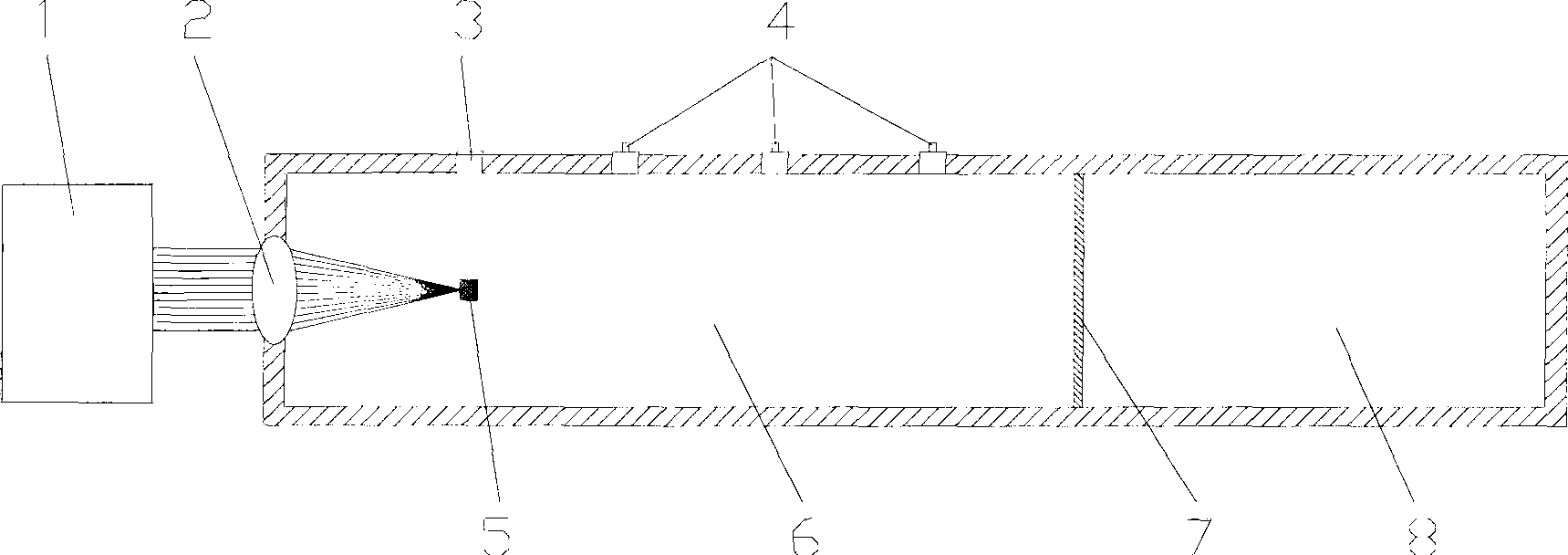

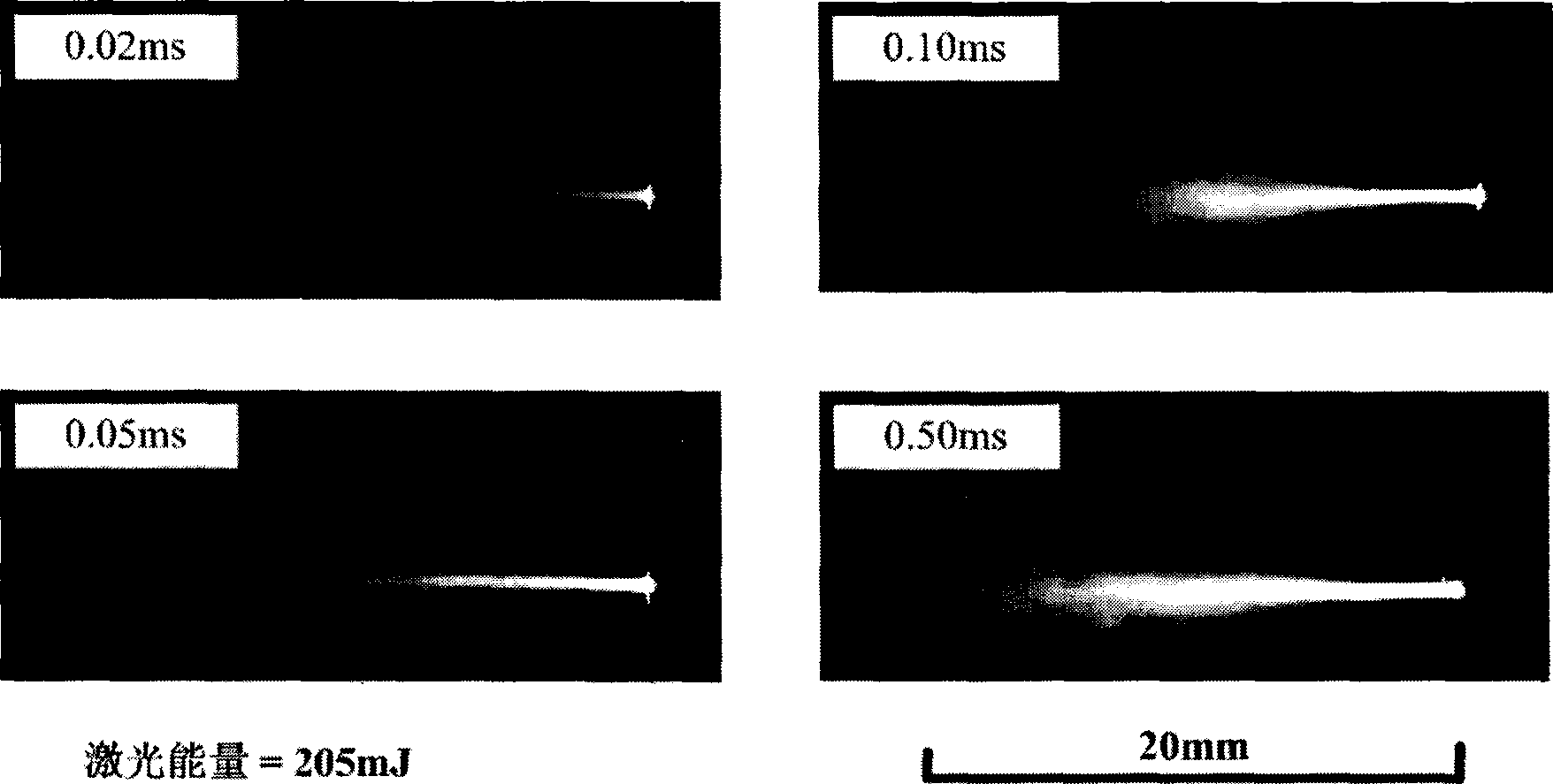

Laser-induced microparticle jetting ignition method

InactiveCN101363391AImprove convenienceImprove continuityEngine ignitionMachines/enginesCombustion chamberHigh power lasers

The invention discloses a laser-induced particle jet ignition method; the method is as follows: laser pulses are led into a combustion chamber of an engine through a focusing lens in a common way; the focal position of the focusing lens in the combustion chamber is provided with an absorbing target; the hot particle jet which is generated after the absorbing target is intensively heated by laser is used for starting the combustion or the detonation of flammable mixture in the combustion chamber. The laser ignition method of the invention avoids the use of high-power laser, and increases the convenience for selecting ignition positions and the probability of high-frequency continuous ignition. In addition, the ignition mode is suitable for the ignition of different types of engines.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

System for controlling circulatory amount of particles in circulating fluidized bed furnace

ActiveUS8292977B2Improve gasification efficiencyFluidized bed combustionLevel controlFluidized bed gasifierDifferential pressure

The invention has its object to arbitrarily adjust an amount of particles to be circulated without changing a flow rate of a gasification agent to thereby enhance gasification efficiency in a fluidized bed gasification furnace.The fluidized bed gasification furnace 107 comprises first and second chambers 113 and 114 in communication with each other in a fluidized bed 105. The hot particles 102 separated in the separator 104 and raw material M are introduced into the first chamber 113. The particles 102 introduced from the first chamber 113 through interior in the fluidized bed 105 to the second chamber 114 are supplied in an overflow manner to the fluidized bed combustion furnace 100. A first pressure controller 121 is provided to control the resultant gas induction means 116 such that the pressure in the first chamber 113 is kept to preset pressure 120; and a second pressure controller 124 is provided to control the exhaust gas induction means 118 such that difference between pressure in the first and second chambers 113 and 114 is equal to the preset differential pressure 123, so that the fluidized bed 105 in the first chamber 113 is controlled in height to control an amount of particles 102 to be circulated.

Owner:IHI CORP

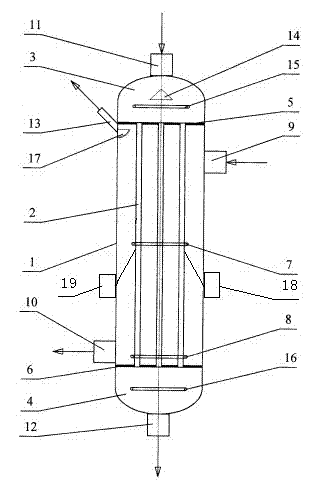

Shell and tube heat exchanger

InactiveCN103808174AReduce cokingLower water vapor partial pressureThermal non-catalytic crackingStationary tubular conduit assembliesPlate heat exchangerShell and tube heat exchanger

The invention provides a shell and tube heat exchanger. The shell and tube heat exchanger mainly comprises a casing, heat exchange tubes, an upper head, a lower head, an upper tube plate, a lower tube plate, a middle-shell-side fluidization air distributor, a lower-shell-side fluidization air distributor, a cold spent catalyst inlet, a hot spent catalyst outlet, a hot regenerant inlet, a cold regenerant outlet and a hot stripped oil gas outlet. Heat transferring media flow in corresponding heat exchange tubes which are externally connected with temperature sensor contacts. According to the shell and tube heat exchanger, particle fluidizers are arranged in the heat exchanger to fluidize cold and hot particles, so that fluidized particles with fluid flow characteristics are obtained and flow in the heat exchanger in the flow direction, heat exchange between cold and hot solid particles is achieved, and the temperatures of the heat transferring media are monitored at any moment.

Owner:WUXI ACC HEAT EXCHANGER

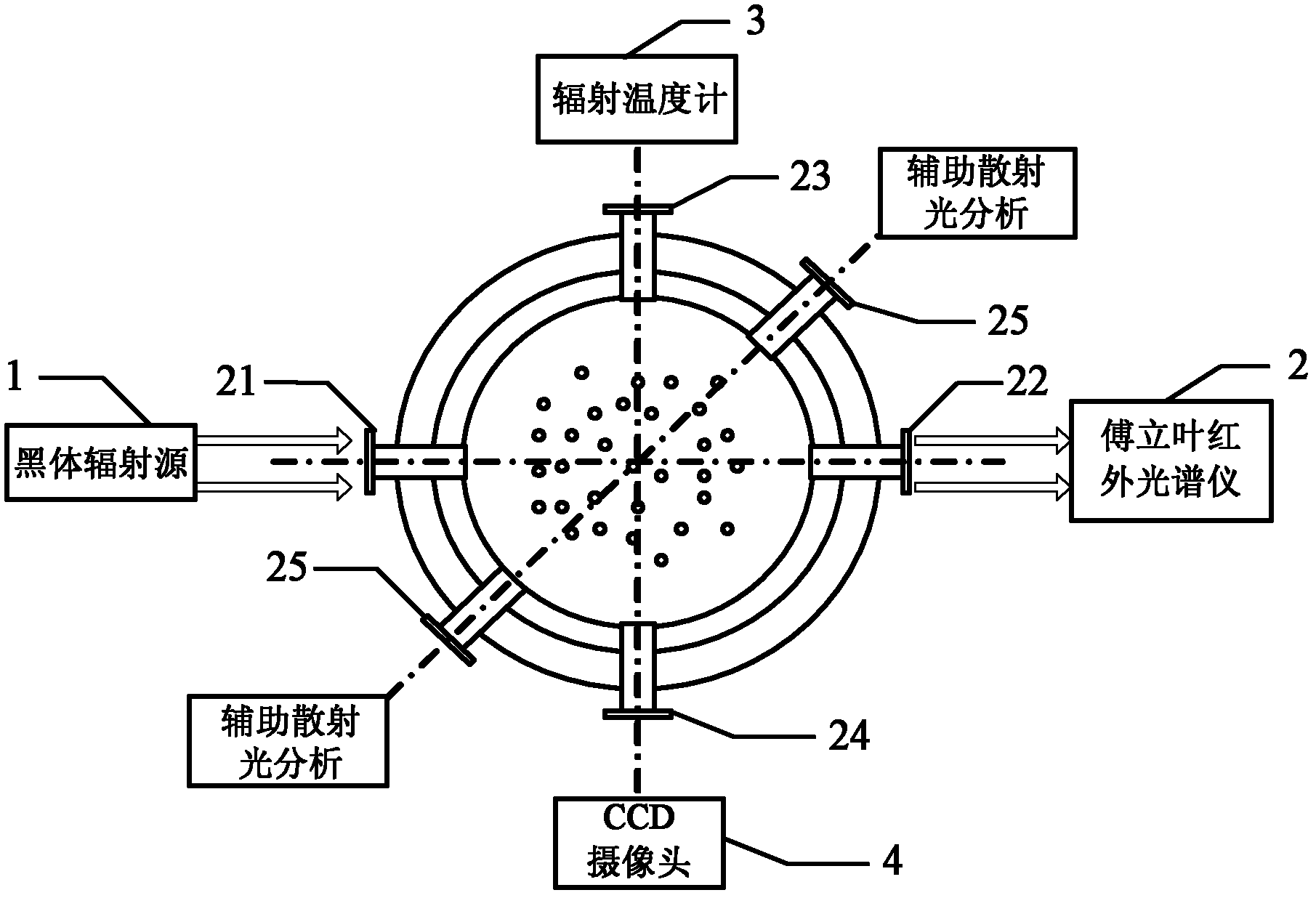

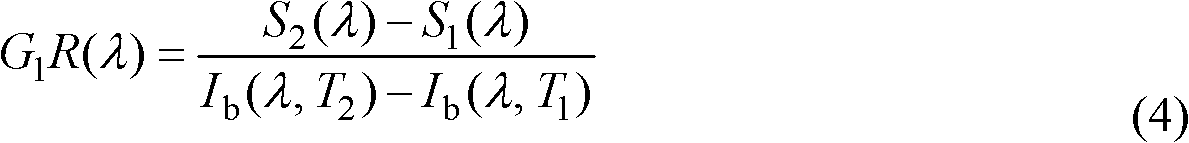

Measuring device and method for infrared spectral radiation characteristics of high-temperature particles

InactiveCN102279049ADetermine applicabilityRealize measurementSpectrum investigationMeasurement deviceNatural state

The invention relates to a measuring device and method for infrared spectral radiation characteristics of high-temperature particles, relating to a measuring device and method for infrared spectral radiation characteristics of dispersed particles, which solves the problem that the prior art cannot measure the natural state particle radiation characteristics in the high-temperature continuous spectrum range. The invention adopts the environmental compensation algorithm, realizes the measurement of the spectral equivalent transmittance of high-temperature particles in the natural state, determines the applicability of the measurement of the radiation characteristics of high-temperature particles in the continuous spectrum range, and provides a basis for further inversion of the complex refractive index of high-temperature particles The research provides reliable experimental data and experimental devices, and the measurement uncertainty of the present invention is less than 2%. The invention can be widely used in the fields of chemical industry, metallurgy, power, construction, medicine, biology, food, aerospace, military affairs, atmospheric science and the like.

Owner:HARBIN INST OF TECH

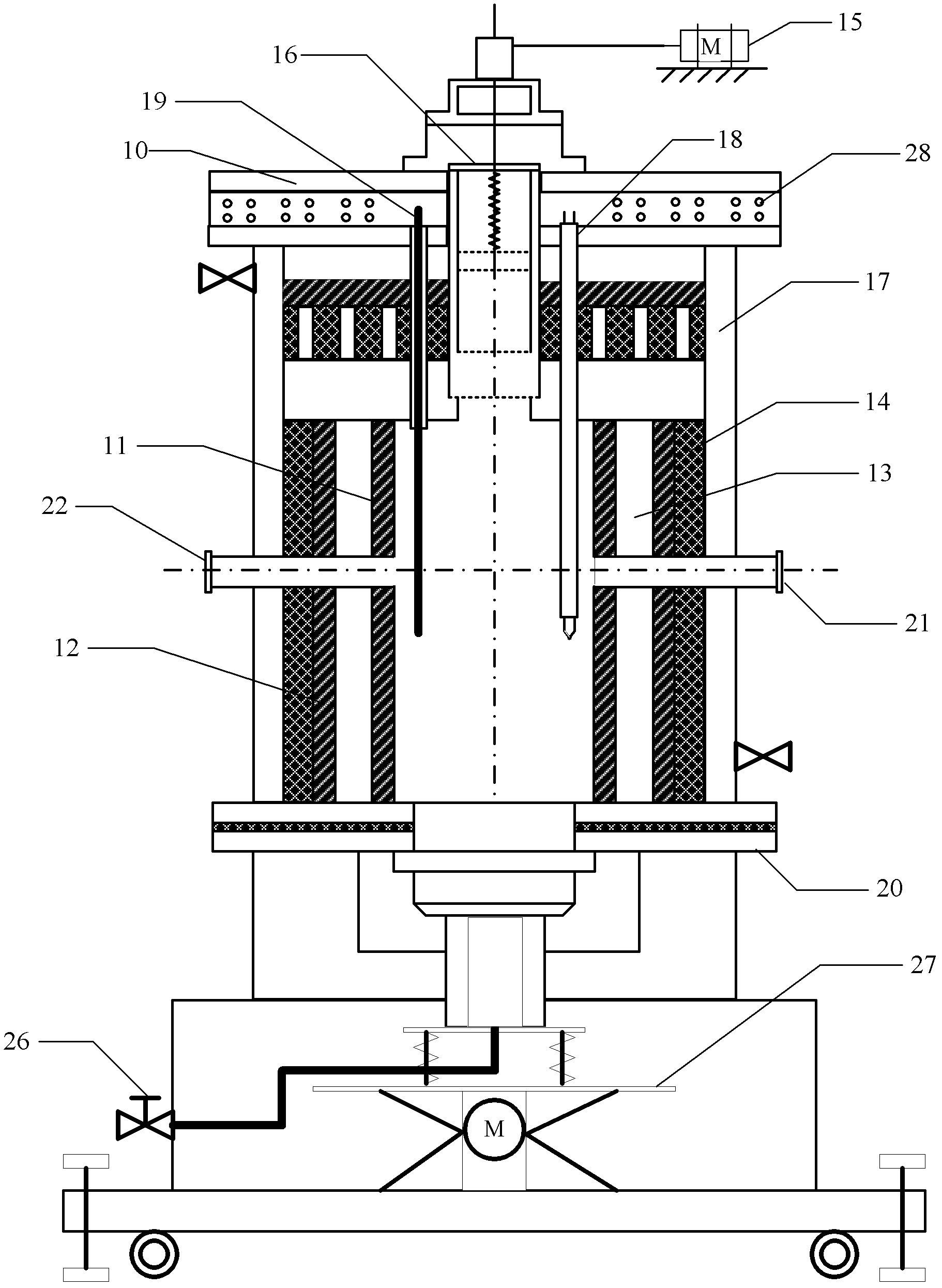

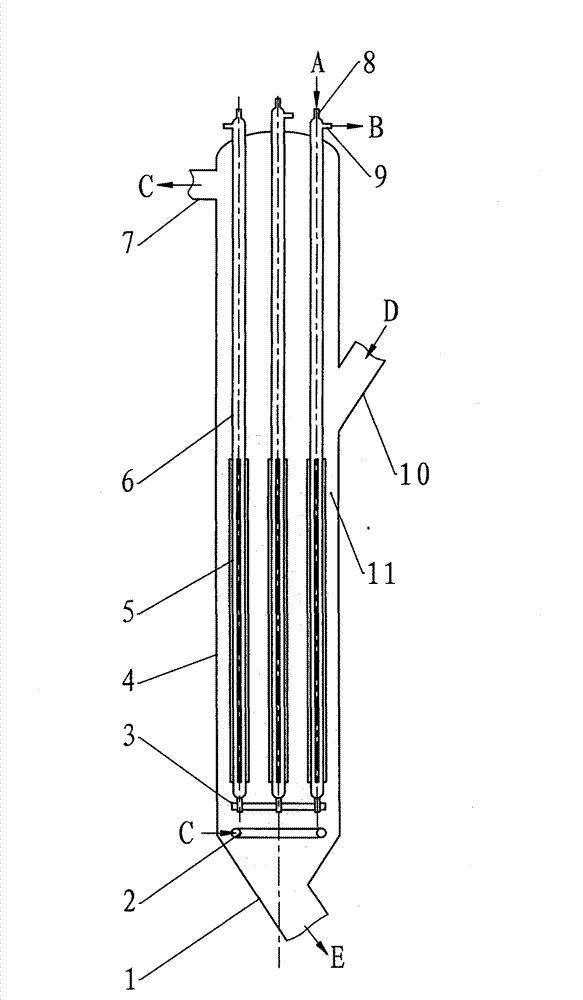

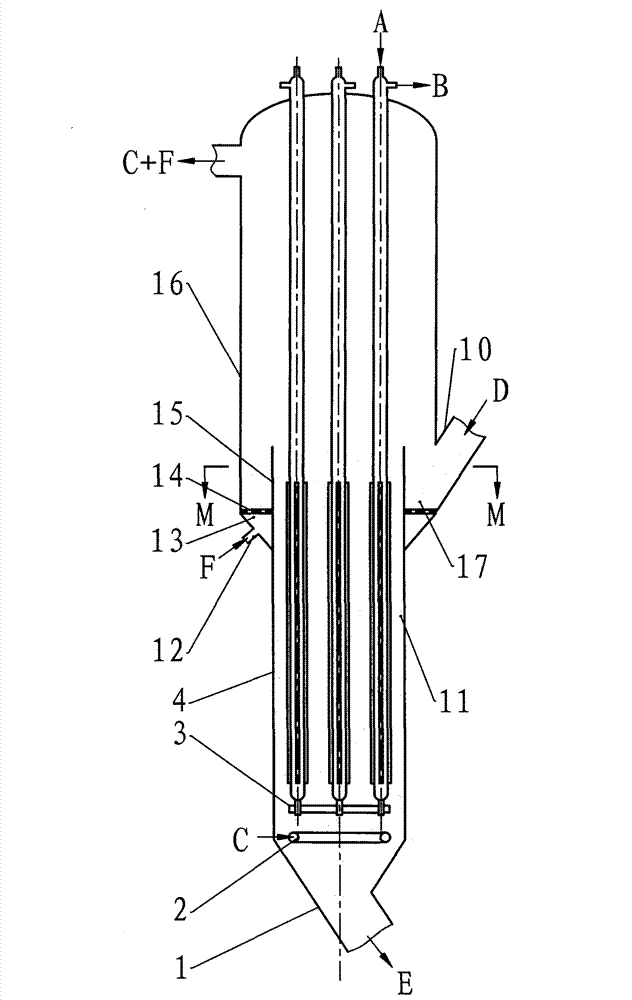

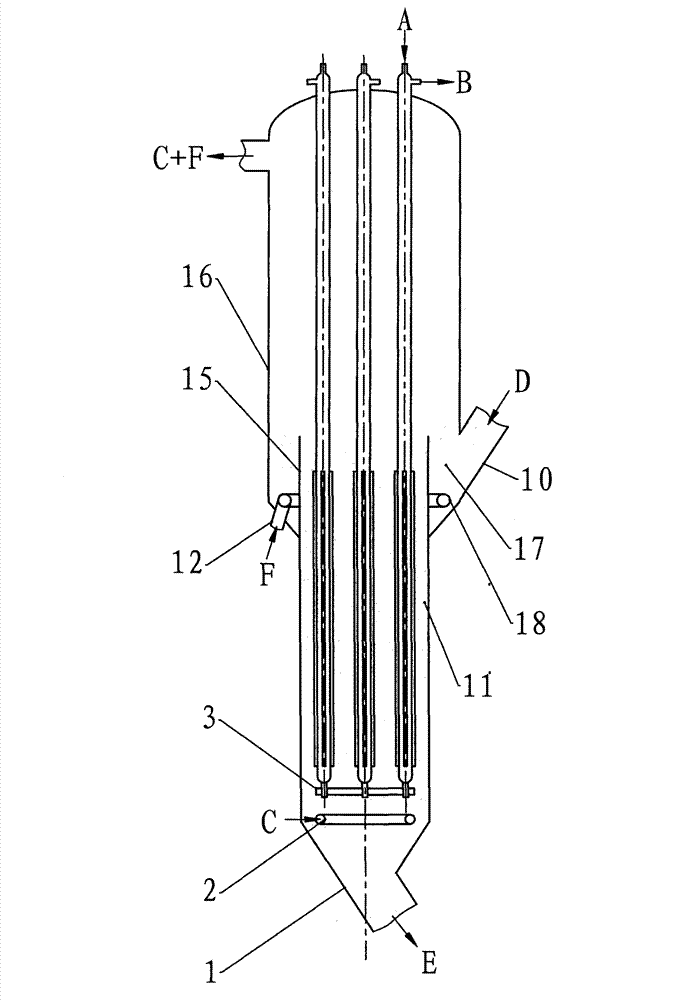

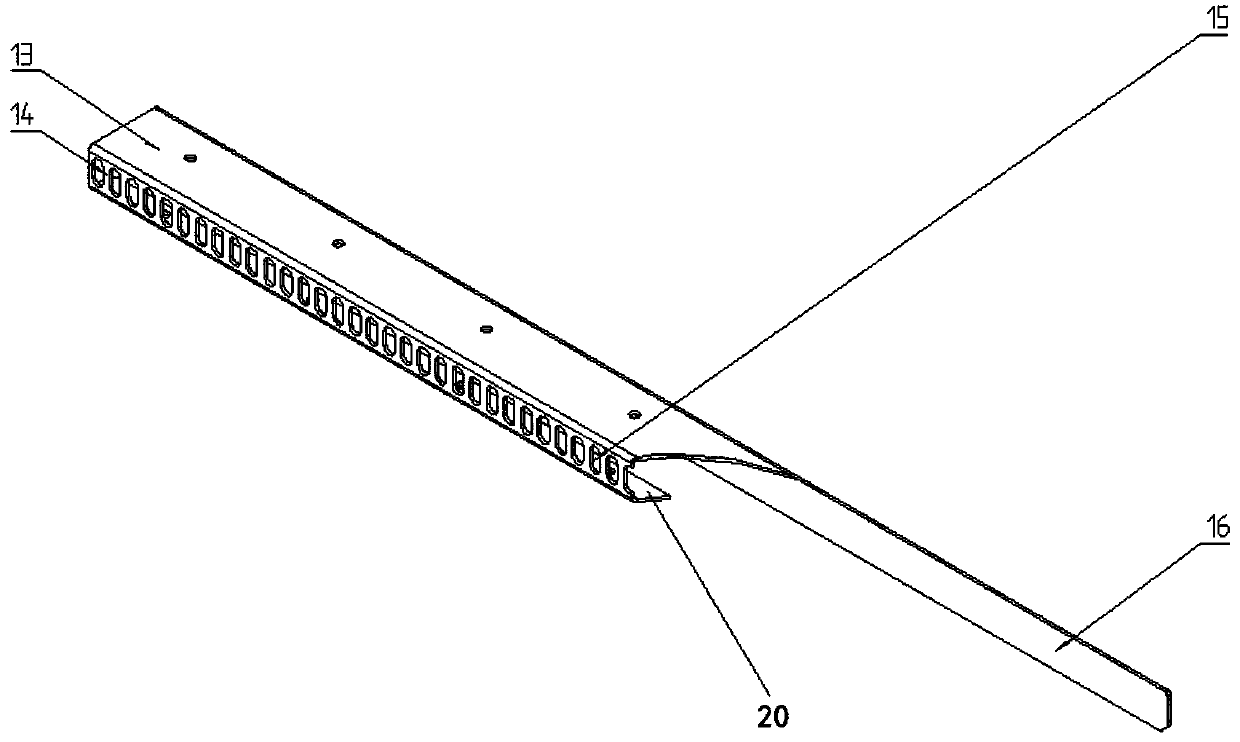

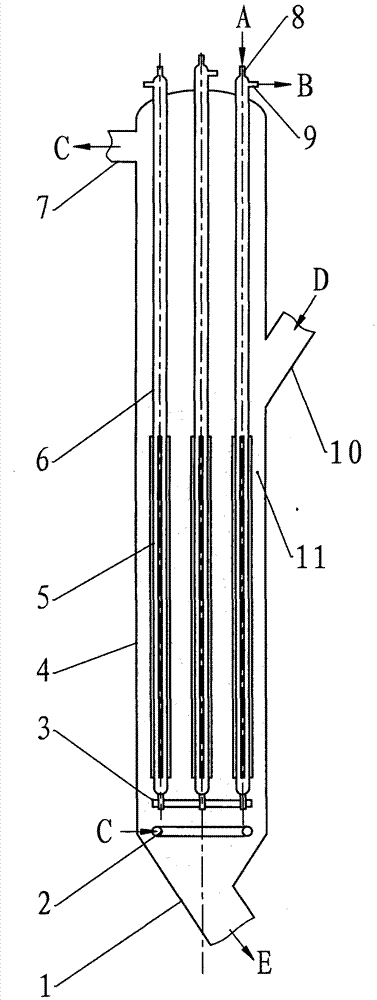

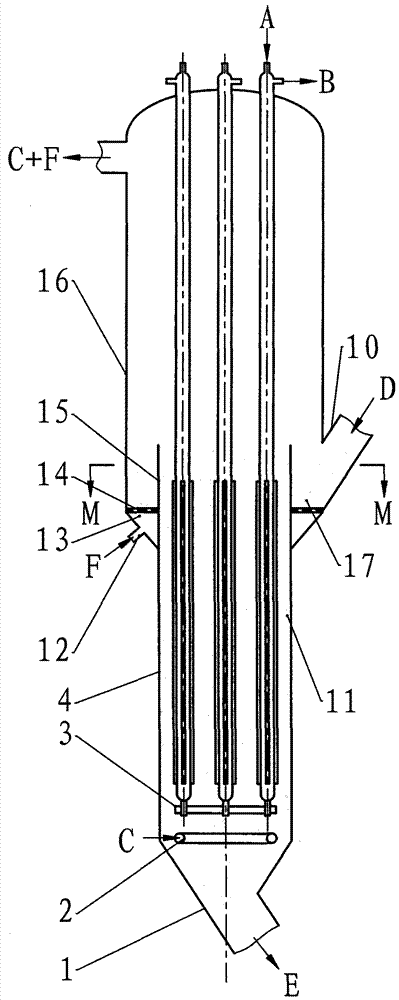

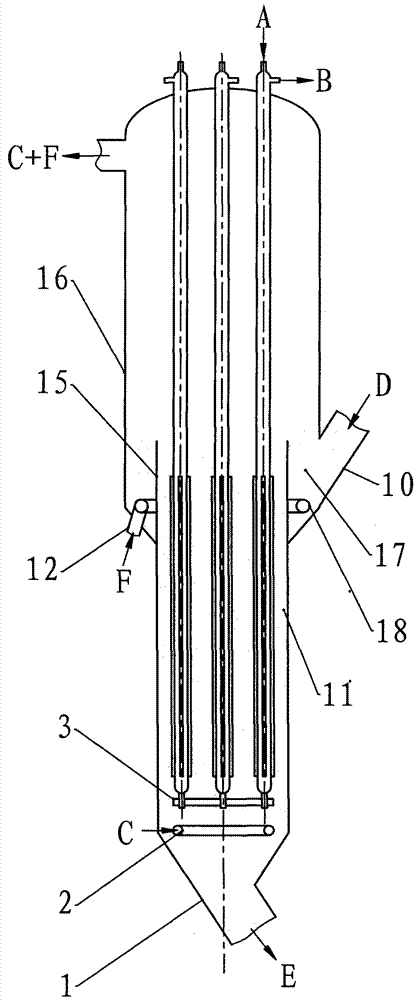

External catalytic cracking heater with pre-distributed particles

InactiveCN103113914AImprove reliabilityExtended service lifeCatalytic crackingFluidised bed heat exchangersFluidized bedEngineering

The invention discloses an external catalytic cracking heater with pre-distributed particles and is suitable for a catalytic cracking device in an oil refinery. The external catalytic cracking heater is characterized in that a plurality of unit type heat exchange tubes (6) with independent water inlets and water outlets are arranged inside an external heater (4); the heat exchange tubes (6) extend from the top to the bottom of the external heater (4), and the bottom of the external heater is provided with a guide bracket (2) which limits transverse swing of the heat exchange tubes (6); the lower parts of the heat exchange tubes (6) are immersed in a dense-phase fluidized bed (11) at the bottom of the external heater (4); hot catalyst particles entering from a catalyst inlet (10) in the middle of the external heater (4) enter an annular fluidized bed (17), and the hot particles uniformly flow into the dense-phase fluidized bed (11) from the upper edge of a side wall (15) on the inner side of the annular fluidized bed (17) or an overflow notch (19) formed in the side wall (15) on the inner side by utilizing the particle pre-distribution function of the annular fluidized bed (17); the hot particles are contacted and cooled with the side wall of the heat exchange tubes (6) and flow out of a catalyst outlet (1) at the bottom of the external heater (4) in the dense-phase fluidized bed (11); and fluidized gas in the dense-phase fluidized bed (11) is introduced from a bottom gas distributor (2), and the fluidized gas which passes through the dense-phase fluidized bed (11) and the fluidized gas in the annular fluidized bed (17) are mixed to enter a dilute phase space of a catalytic cracking device regenerator through a gas outlet (7) formed on the top of the external heater (4).

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

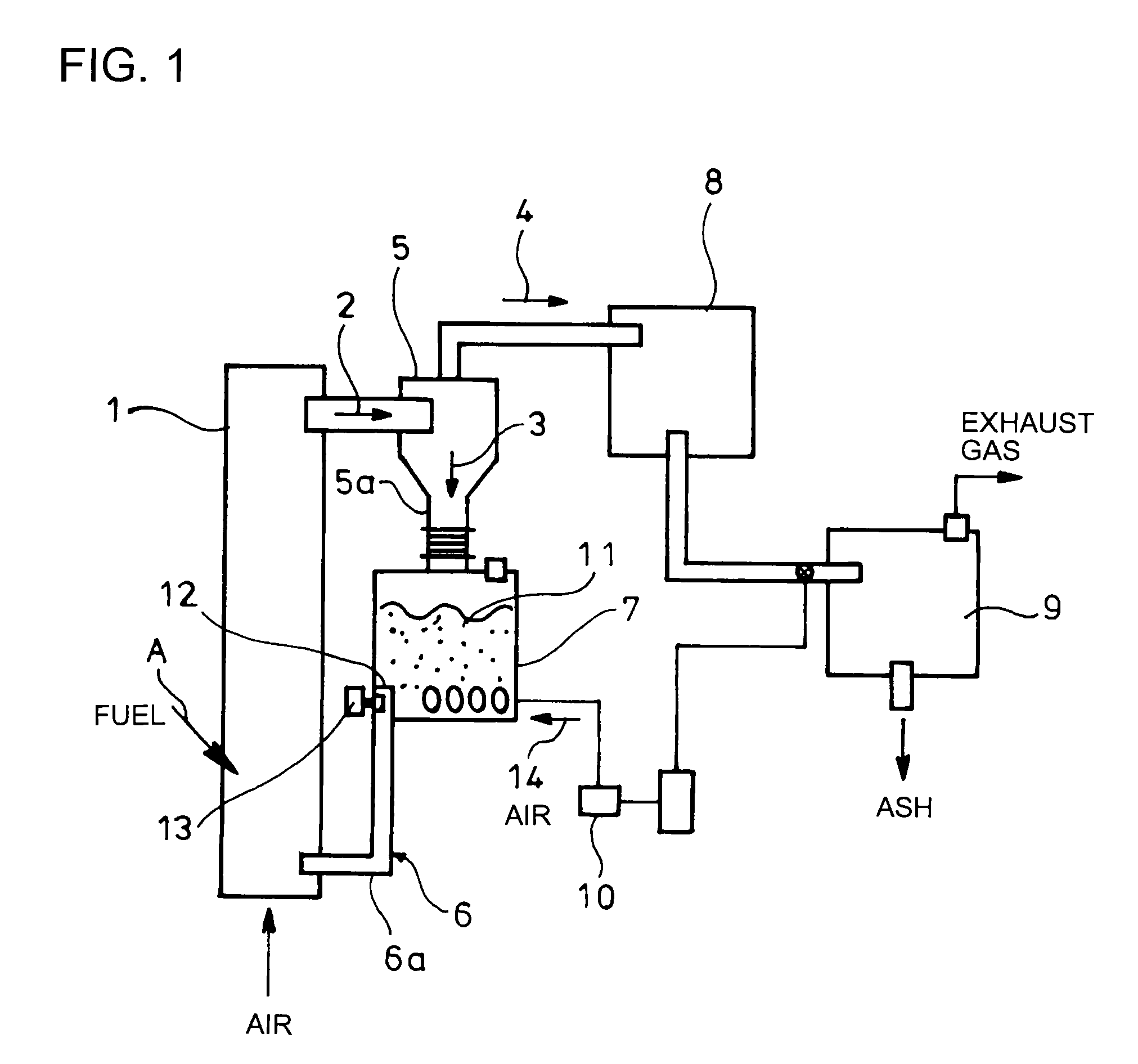

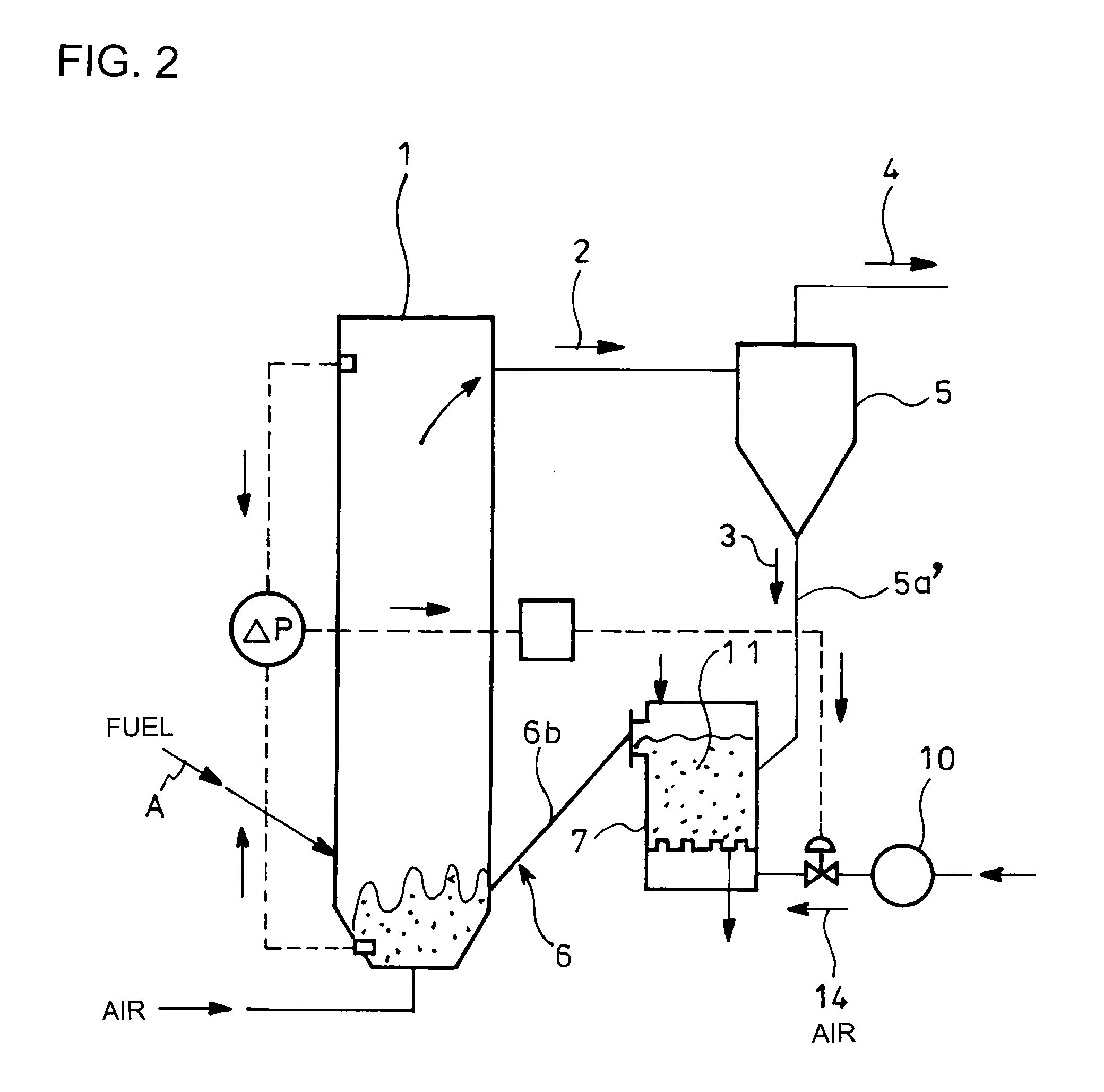

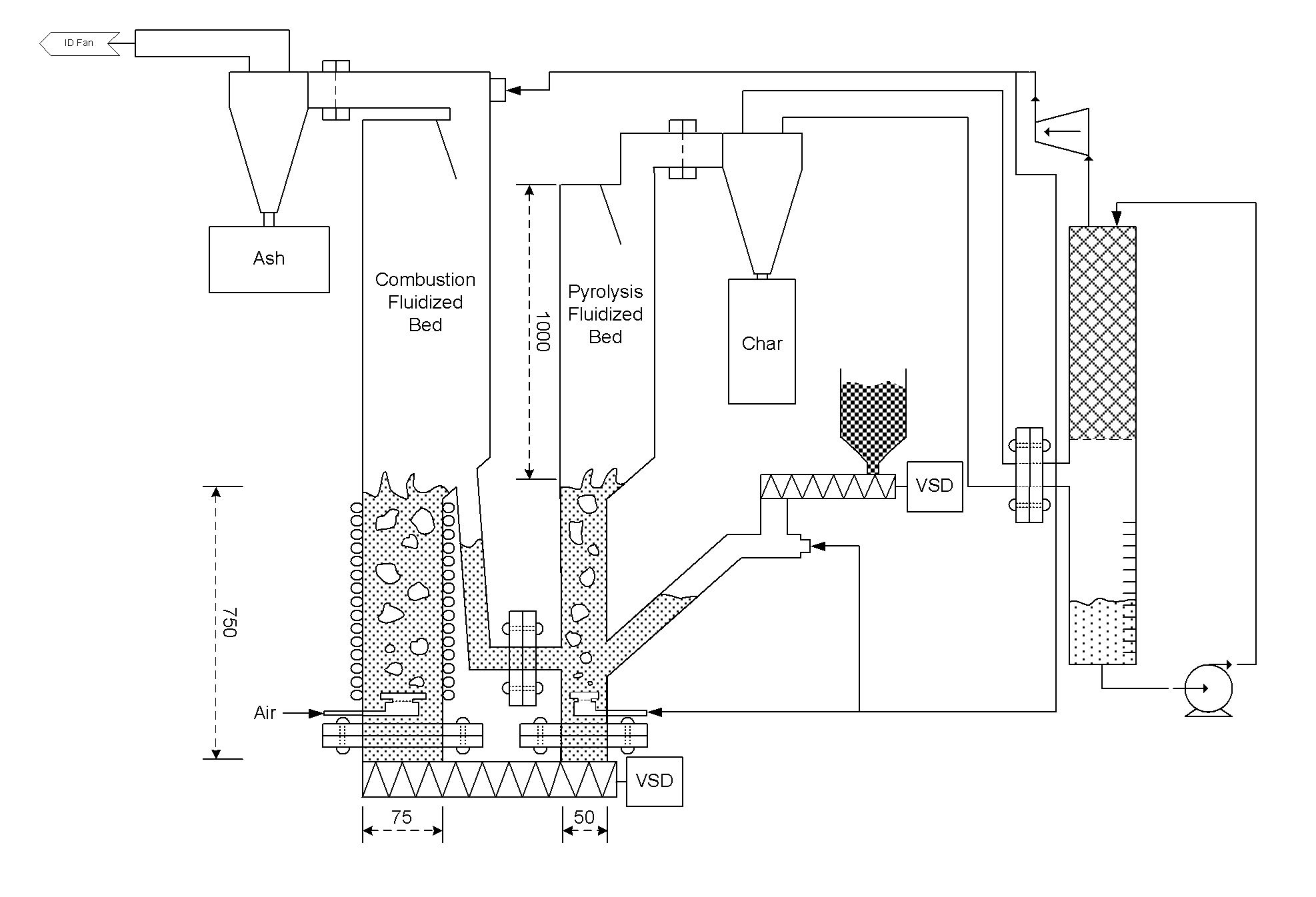

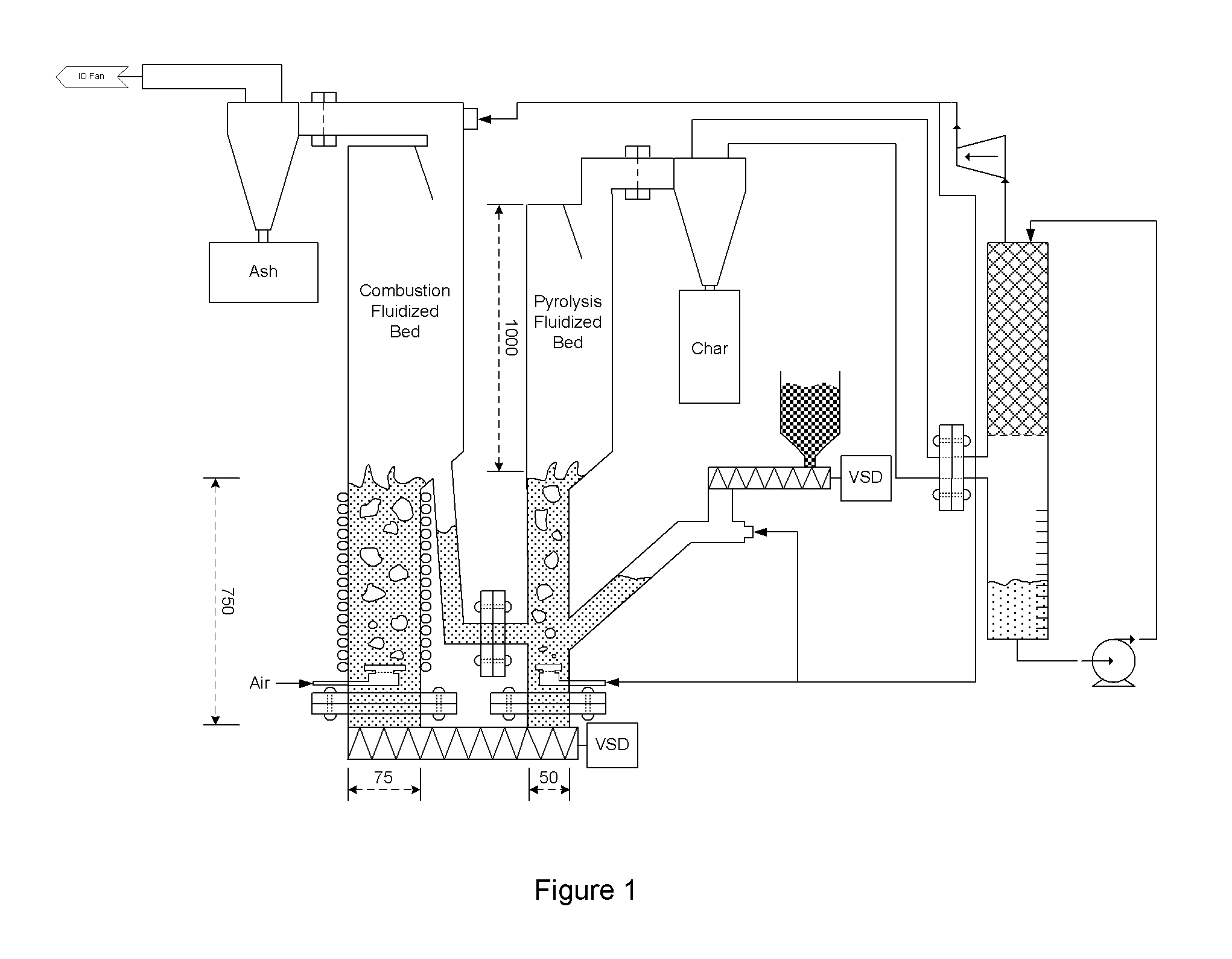

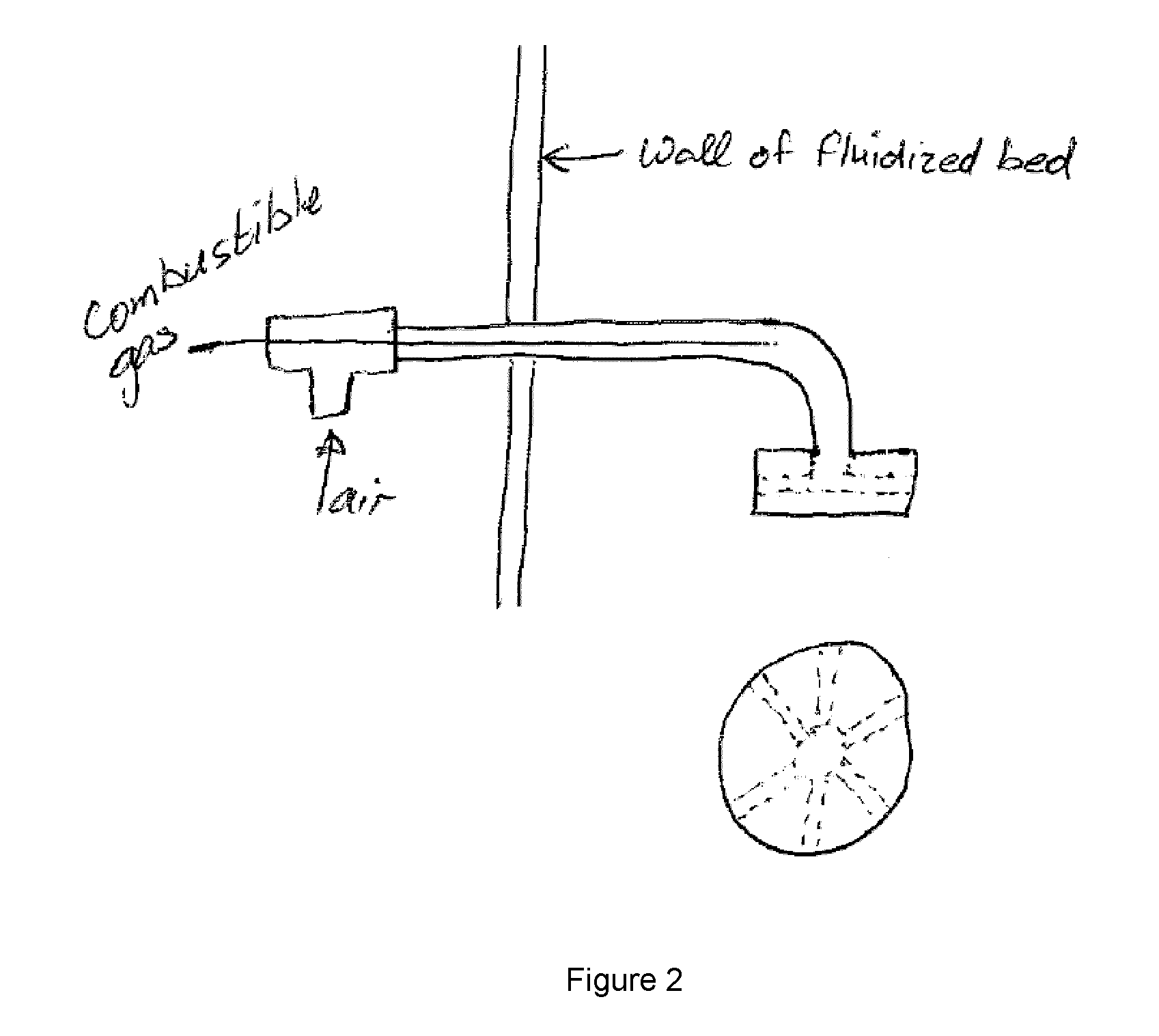

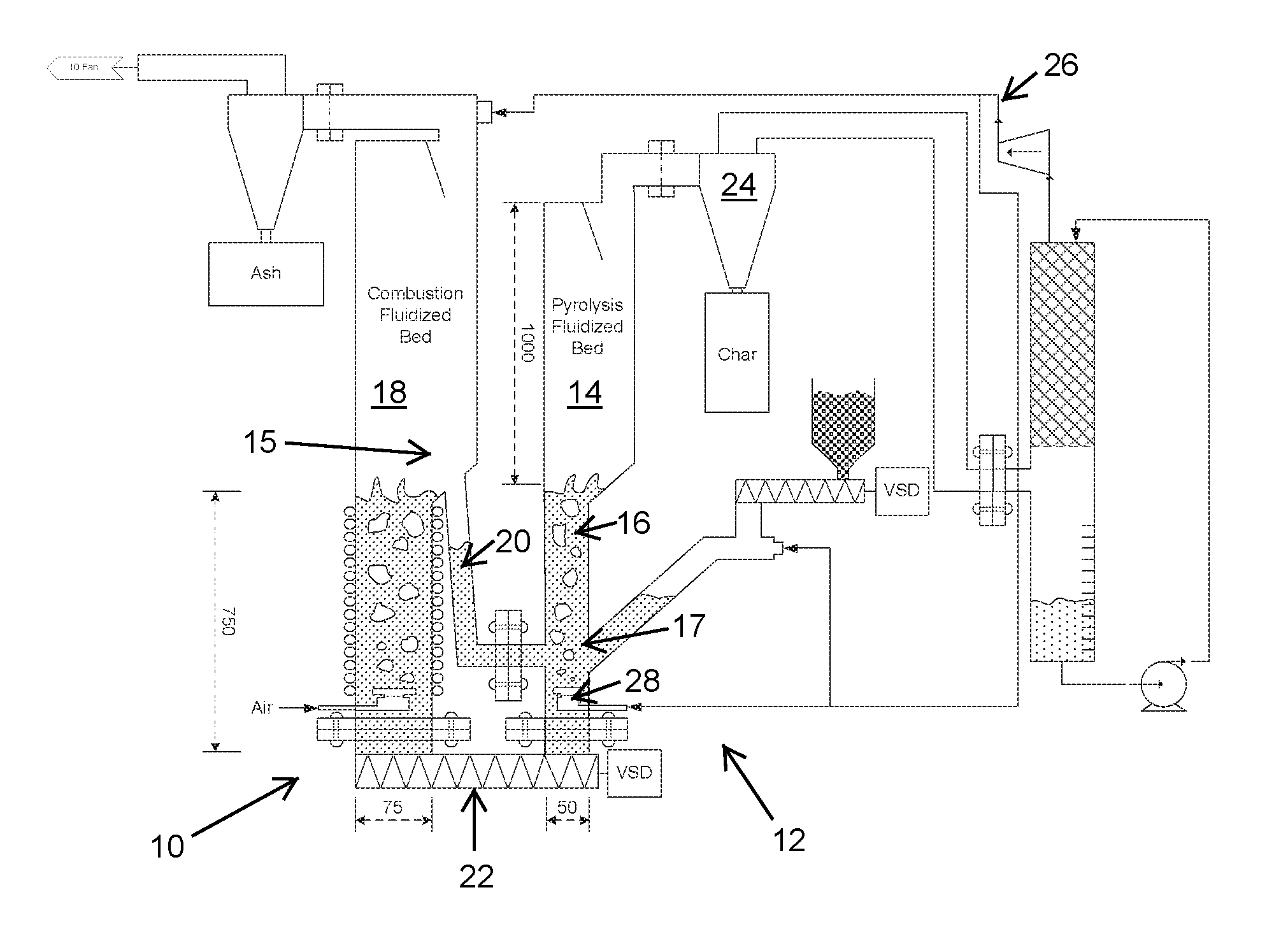

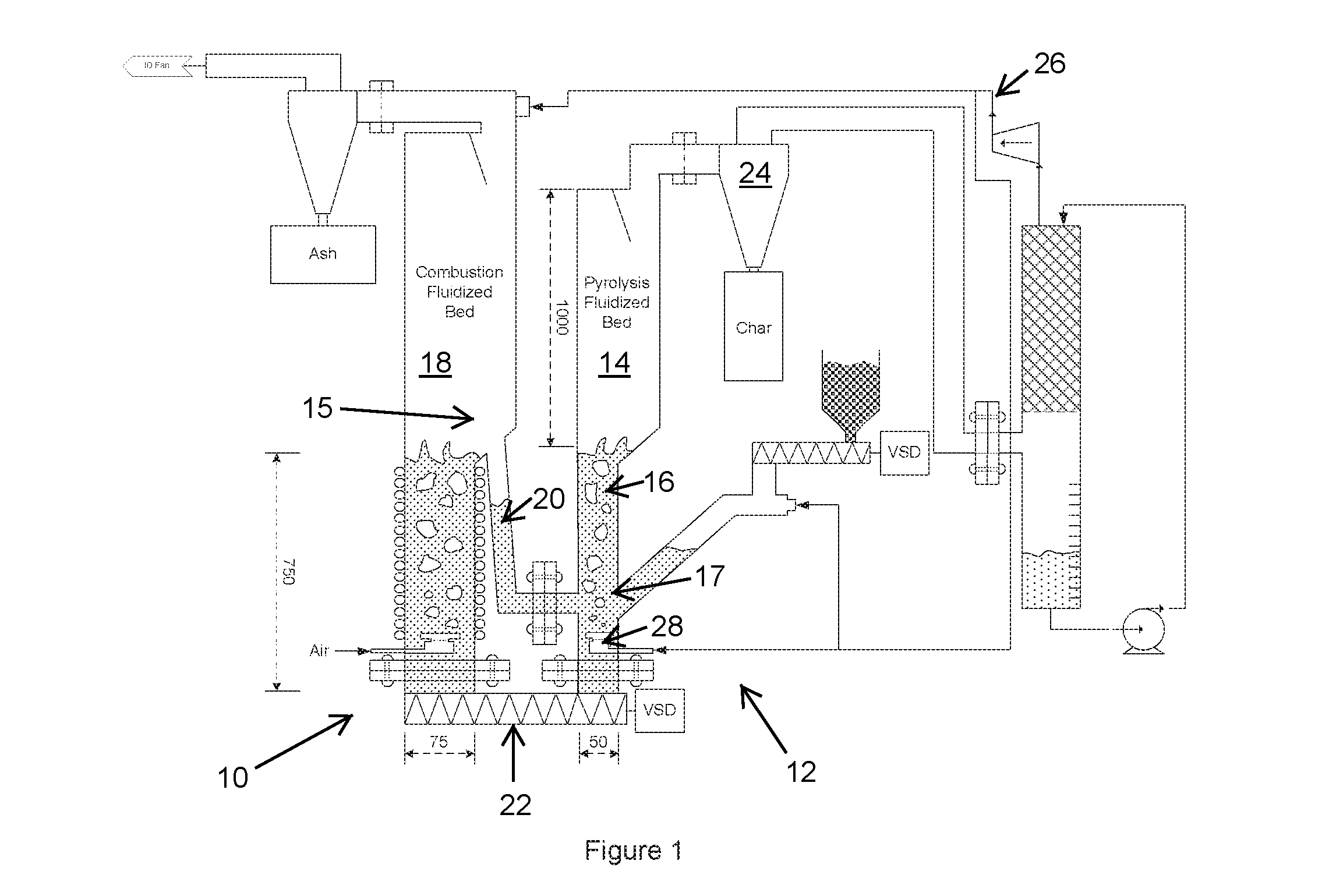

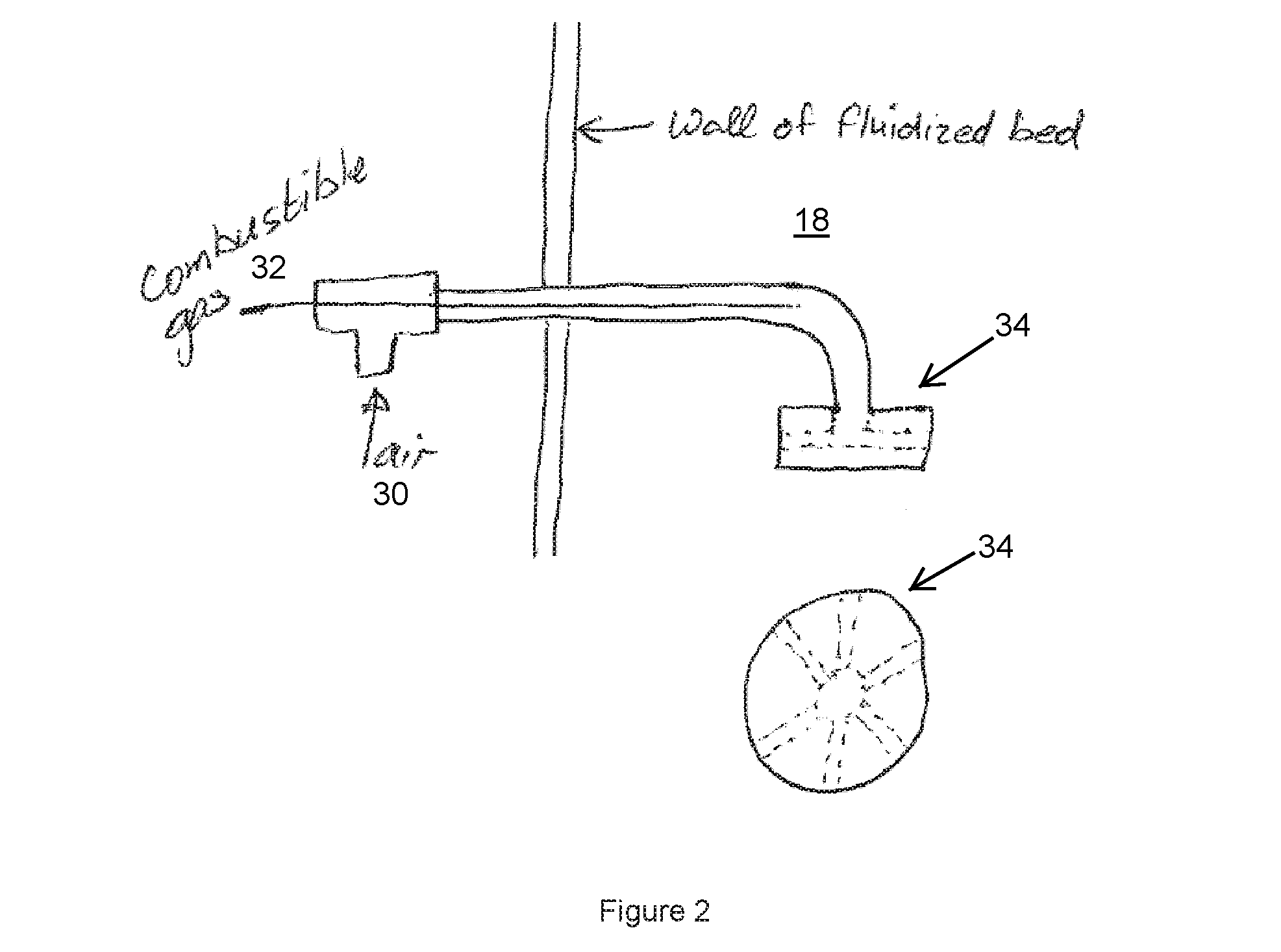

Fluidised bed pyrolysis apparatus and method

ActiveUS20140008205A1Less enthalpyIncreased superficial gas velocityFluidized bed combustionDirect heating destructive distillationCombustionFluidized bed

A carbonaceous feed pyrolysis apparatus is provided including two or more hot particle fluidised beds, and one or more positive displacement apparatus for the transfer of hot particles between two or more of the beds, wherein one or more of the fluidised beds contains a combustion zone. A bio-oil production process is also provided, including pyrolysis of a carbonaceous bio-mass using two or more fluidized beds, including a first combustion zone carried out in one or more combustion fluidized beds in which a particulate material is fluidized and heated, and a second pyrolysis zone carried out in one or more pyrolysis fluidized beds in which the hot particles heated in the combustion zone are used for pyrolysis of the bio-mass.

Owner:UNIVERSITY OF PRETORIA +1

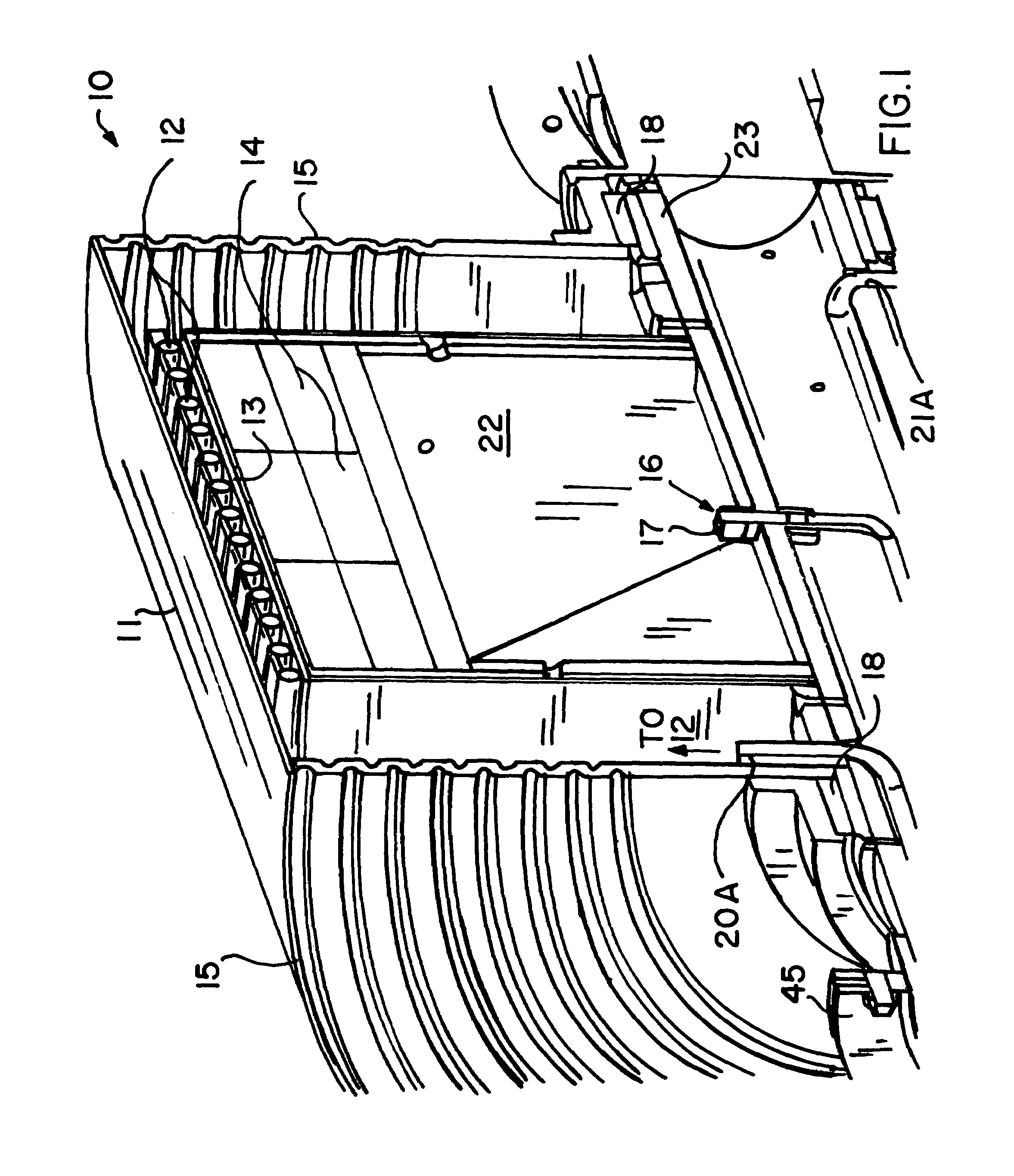

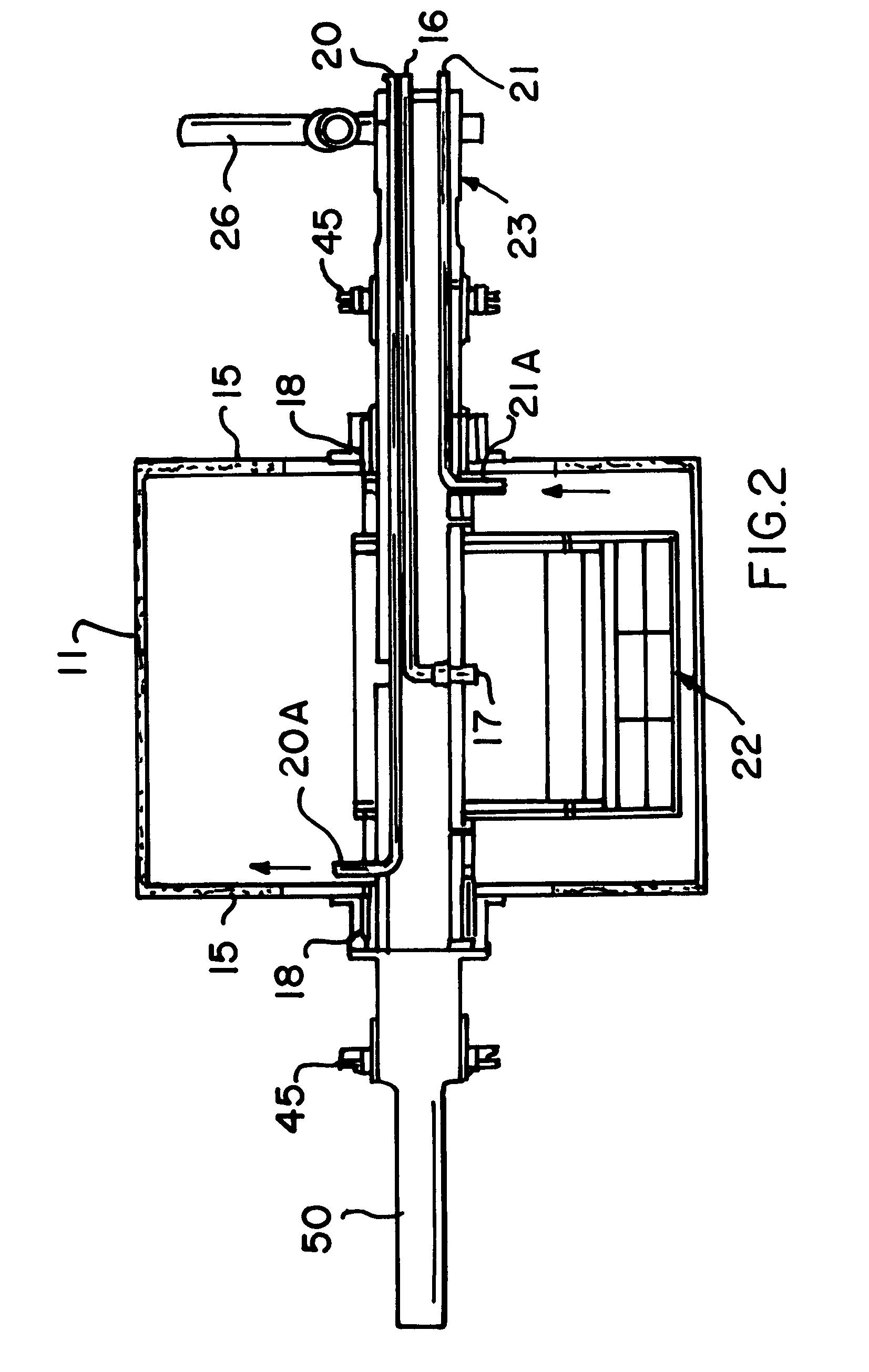

Hot magnetic separator process and apparatus

ActiveUS7478727B2Improve cooling effectReduce oxidationMagnetic separationSortingMagnetic separatorEngineering

System and method for a continuous process for separating particles according to their magnetic properties such as Curie point includes a feed of hot particles having different magnetic properties on a moving surface spaced above a stationary magnetic assembly. The temperature of the bed of particles is controlled to enable selective separation of different factions of particles based upon the temperature of the particles. The magnets are maintained substantially below their Curie point. Gaseous nitrogen is fed into and from the inside of the magnetic assembly to enhance the cooling of the magnetic assembly and to inhibit oxidation. The gas exits through high temperature bearings to inhibit debris therein. A thermal shield is placed between the moving surface and the magnets and below tubes carrying a cooling fluid to maintain magnets substantially below their Curie point. The entire process is contained with an inert gas-purged cabinet.

Owner:METSO OUTOTEC (FINLAND) OY

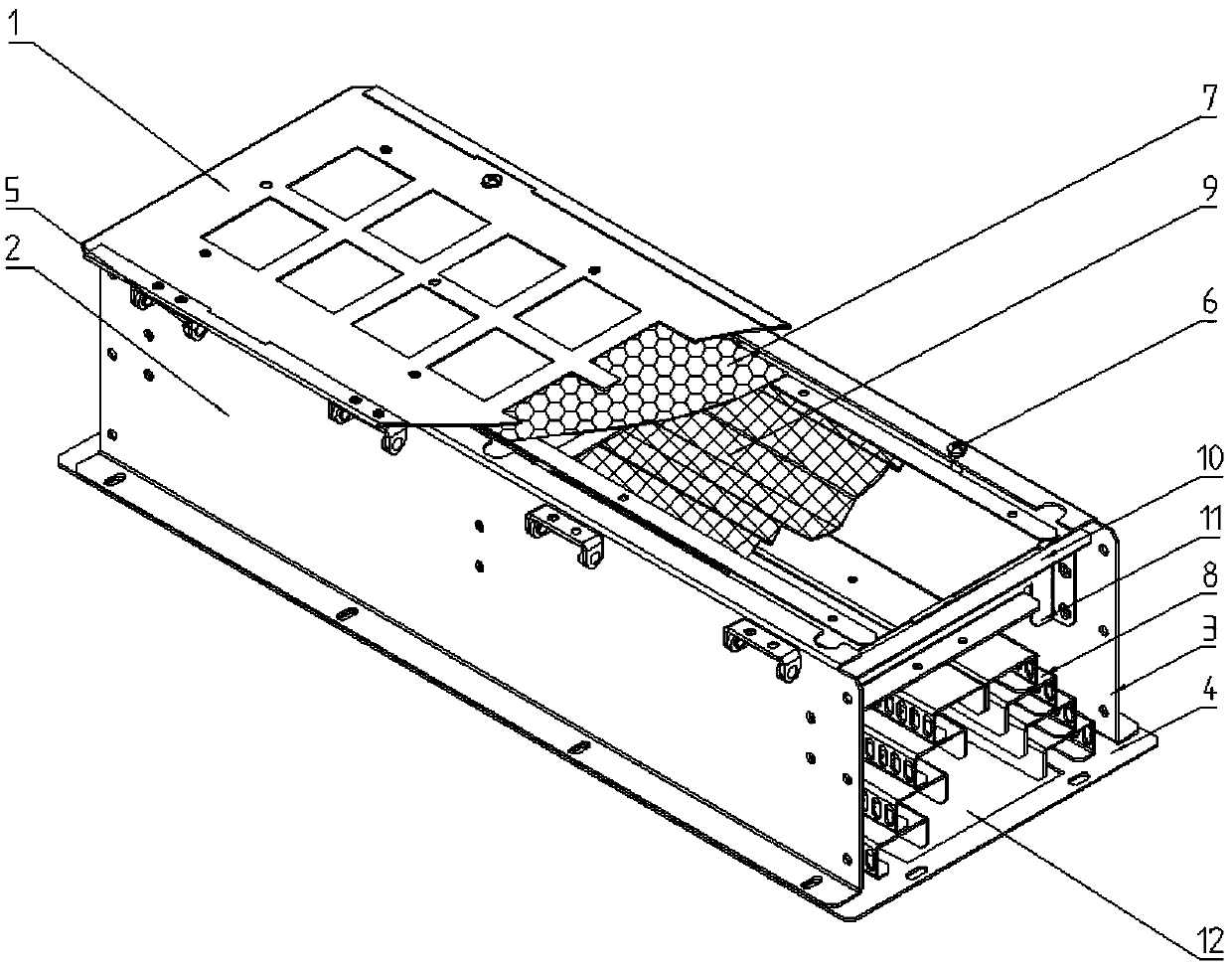

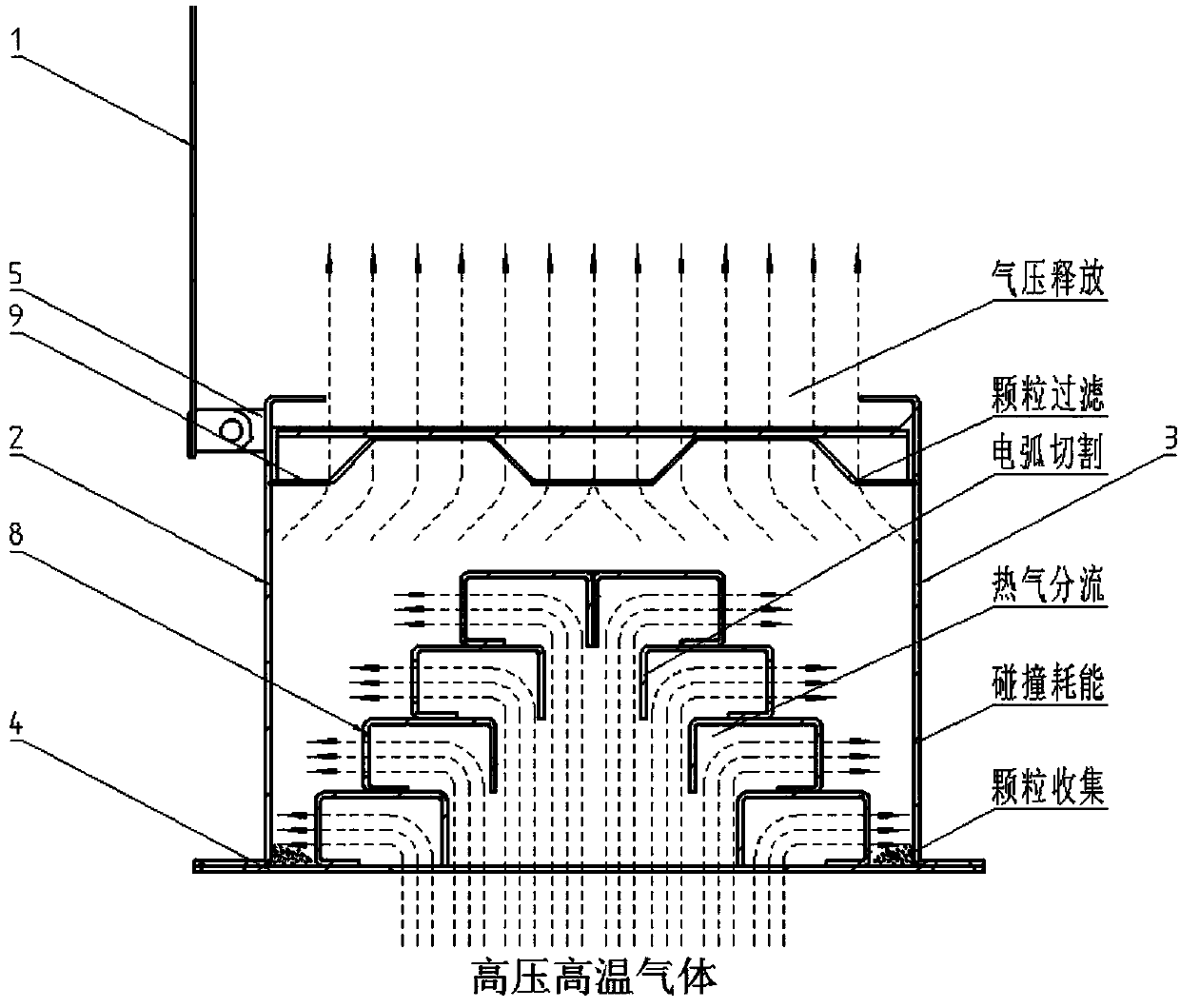

Shunting pressure relief device

PendingCN107910790APlay a diversion roleEffective filteringSwitchgear arrangementsSubstation/switching arrangement cooling/ventilationEngineeringTower

The invention provides a shunting pressure relief device comprising a housing. A tower-shaped pressure relief structure is arranged in the housing and comprises a shunting guide plate stacked in a tower shape. The shunting guide plate comprises a shunting surface and a ventilating surface. Ventilation holes are arranged on the ventilating surface. After the effect of the shunting pressure relief device, the energy of hot air is consumed and hot particles are filtered out, thereby greatly improving the safety of a switch cabinet and not influencing the external dimensions of the switch cabinet.

Owner:WECOME GRP

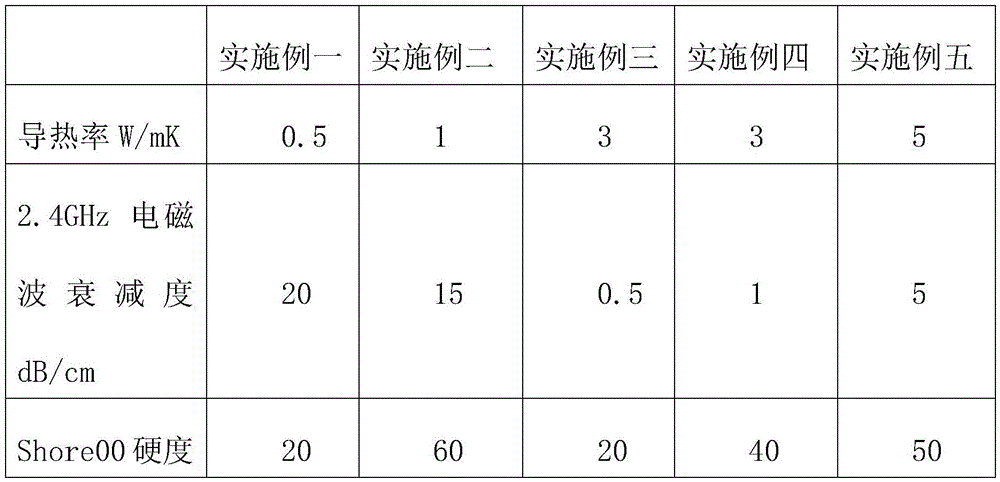

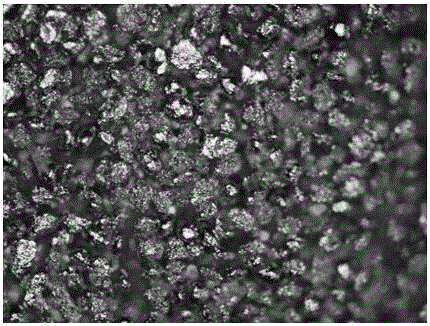

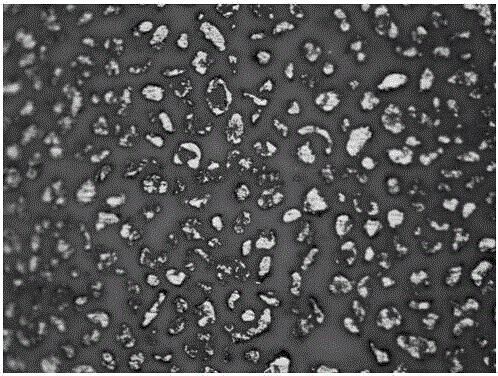

Electromagnetic shielding heat conducting composition and electromagnetic shielding heat conducting gasket

The invention relates to an electromagnetic shielding heat conducting composition, prepared from the following components in percent by mass: 10-30% of first heat conducting particles, 10-30% of second heat conducting particles, 5-10% of matrix and the balance of magnetic particles. The electromagnetic shielding heat conducting composition has the advantages that by matching the first heat conducting particles and the second heat conducting particles with different particle sizes, filling amount of the heat conducting particles in a polysiloxane matrix material is improved, thereby building an efficient heat conducting network, and improving the heat transfer rate; by filling the magnetic particles into the components, magnetic retardation of the composition can be improved, electromagnetic waves penetrating through the composition can be effectively attenuated, the magnetic particles are irregular in shape and different in size, gaps among the heat conducting particles can be further filled, a compression rate is increased, thermal conductivity is effectively improved, and well electromagnetic shielding performance and excellent radiating effect can be realized under the premise of low hardness.

Owner:PINGHU ALLIED IND

Oxide cathode

ActiveCN105244244AImprove job stabilityExtend working lifeDischarge tube solid thermionic cathodesCold cathode manufactureHydrogenDecomposition

The invention provides an oxide cathode, which particularly comprises the following steps: preparing a cathode-based metal, and reserving a geometric margin on the peripheral surface of an emission layer; pouring nickel powder onto the cathode-based metal by a molding method and putting the entire cathode-based metal together with a mold into a hydrogen furnace for sintering into a nickel sponge layer, reserving a certain geometric margin on the prepared nickel sponge layer, filling the nickel sponge layer with alkali earth metal carbonate, mechanically compacting an emission surface of a cathode emission layer, and removing the residual geometric margin; carrying out pre-decomposition on the oxide cathode before pipe filling; and clamping the oxide cathode on a chuck of a lathe, turning the emission layer and the peripheral surface, removing the residual geometric margin, and then wiping away all particles attached to the cathode surface. The cathode surface provided by the invention becomes smooth, regular, bright and clean; a hot particle emission angle is reduced; deformation of emission electron density distribution is limited; the particle bombardment resistance of the cathode is improved; the sparking probability of the cathode emission surface is reduced; the work stability of the cathode is improved; and the lifetime of the cathode is prolonged.

Owner:甘肃虹光电子有限责任公司

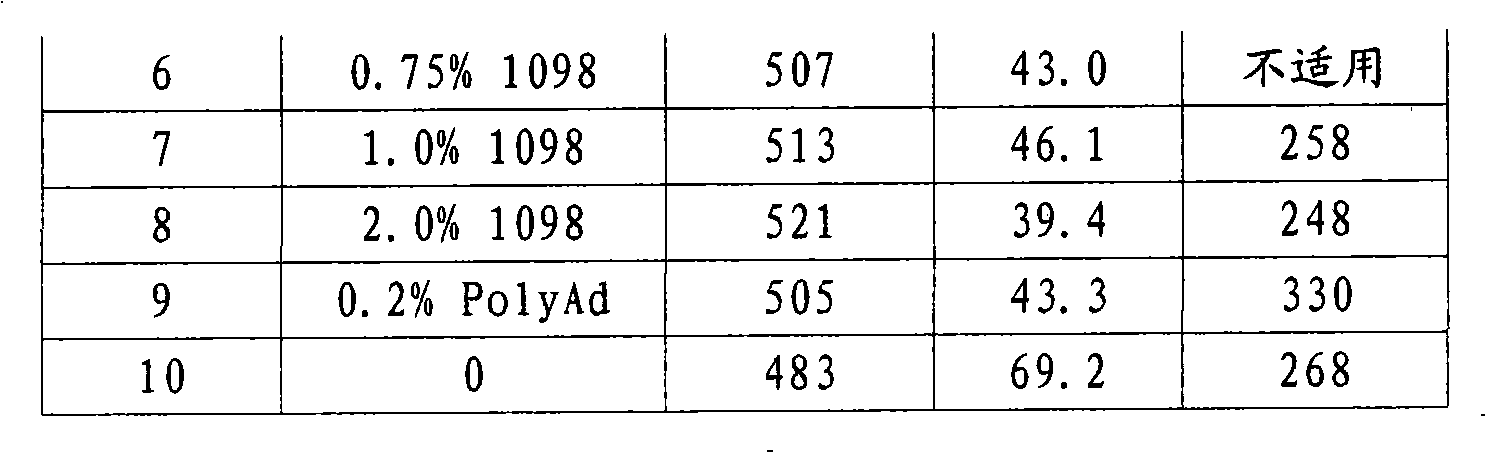

Thermally stabilized bag house filters and media

A bag filter having a support structure clothed in a filter bag. The cloth of the filter bag is a composite of at least one substrate layer and at least one nanoweb bonded thereto in a face-to-face relationship. The nanoweb is positioned at the surface of the filter bag first exposed to the hot particle laden gas stream and can have a basis weight of greater than about 0.1 gsm.

Owner:CUMMINS FILTRATION IP INC

An external heat extractor for catalytic cracking with particle predistribution

InactiveCN103113914BImprove reliabilityExtended service lifeFluidised bed heat exchangersParticulatesFluidized bed

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

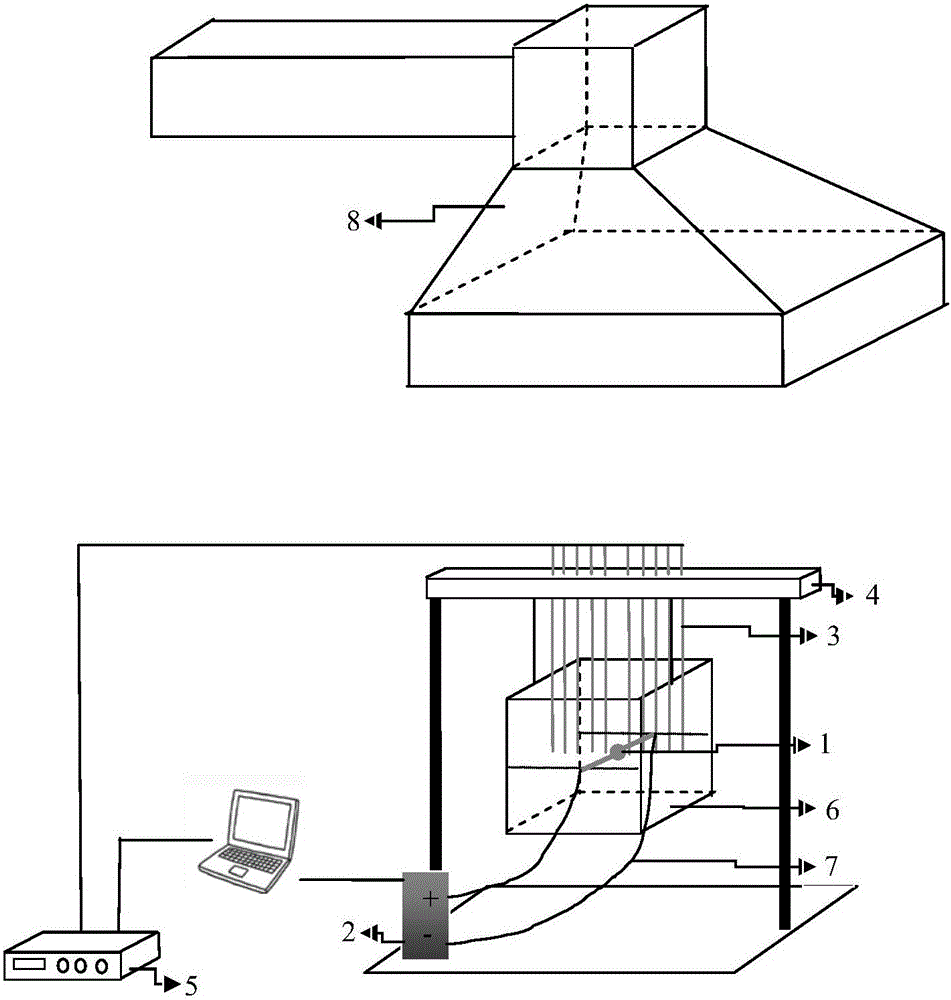

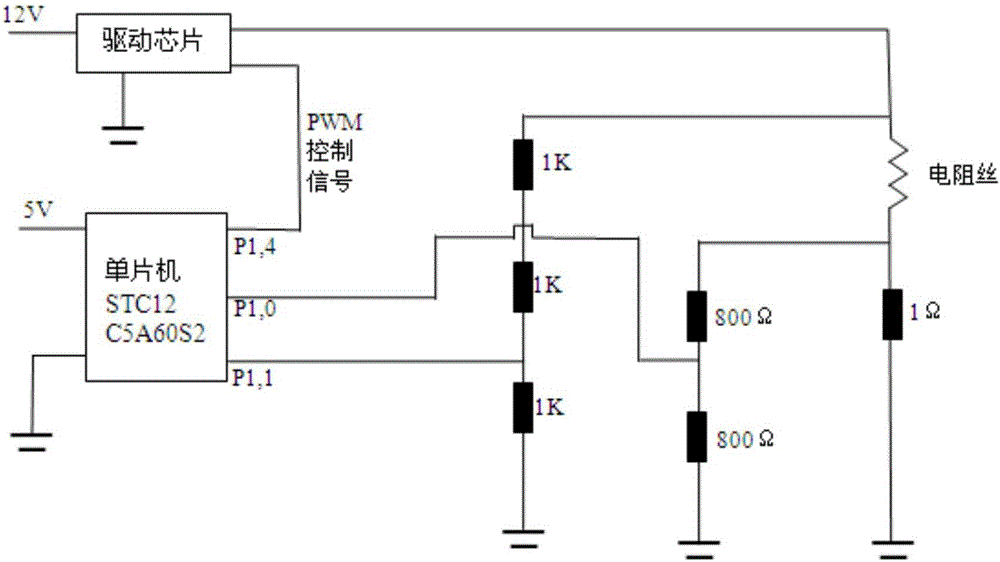

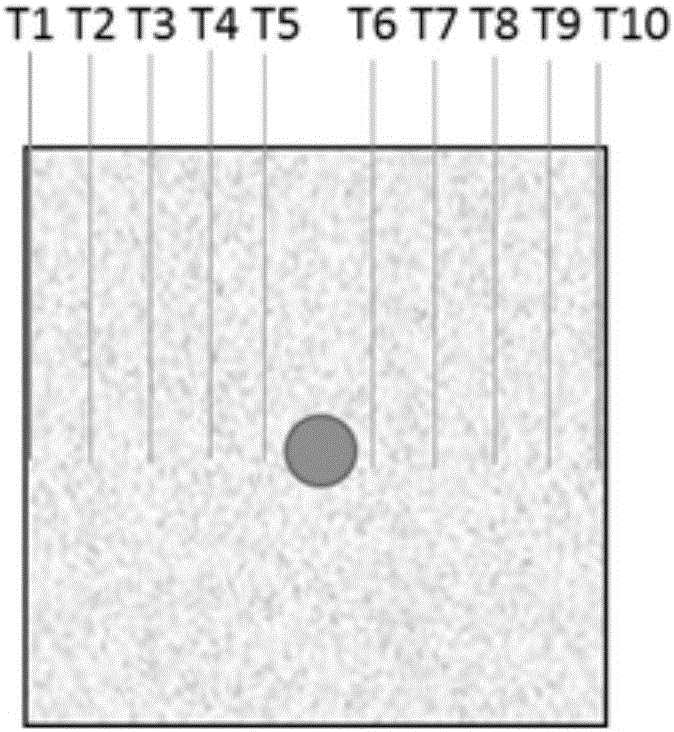

Testing device for combustion performance of stacked materials under constant-power heating effect of spherical metal hot particles

The invention discloses a device for testing the combustion performance of accumulated materials under the heating action of constant power spherical metal hot particles, which includes a circuit for outputting power and real-time adjustment and feedback to the heat source power, a cubic metal mesh basket containing the accumulated materials, and a thermocouple for collecting temperature data and data collectors and fume hoods. The metal mesh basket is fixed on the bracket at a certain distance from the ground by iron hooks. The metal hot particles are located in the center of the metal mesh basket. Thermocouples for collecting temperature data are arranged symmetrically on both sides of the center of the hot particles in the horizontal direction. temperature data. A fume collecting hood is arranged above the support. By testing the combustion performance of combustible accumulation materials under the heating of spherical metal thermal particles with constant power, the ignition time of accumulation materials, the critical power for combustion behavior, and the speed of smoldering propagation can be obtained under the heating conditions of different sizes and different constant power metal thermal particles. Temperature, so as to provide reference for fire safety precautions of piled materials and new detection methods for fire safety of piled materials.

Owner:UNIV OF SCI & TECH OF CHINA

Bag house filters and media

A bag filter having a support structure clothed in a filter bag. The cloth of the filter bag is a composite of at least one substrate layer and at least one nanoweb bonded thereto in a face-to-face relationship. The nanoweb is positioned at the surface of the filter bag first exposed to the hot particle laden gas stream and can have a basis weight of greater than about 2 gsm.

Owner:DUPONT SAFETY & CONSTR INC

Thermally stabilized bag house filters and media

A bag filter having a support structure clothed in a filter bag. The cloth of the filter bag is a composite of at least one substrate layer and at least one nanoweb bonded thereto in a face-to-face relationship. The nanoweb is positioned at the surface of the filter bag first exposed to the hot particle laden gas stream and can have a basis weight of greater than about 0.1 gsm.

Owner:CUMMINS FILTRATION IP INC

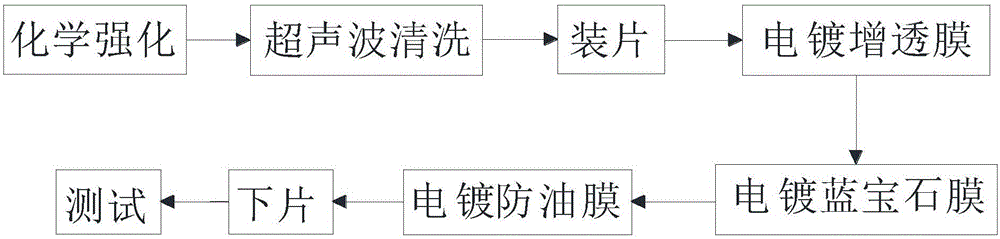

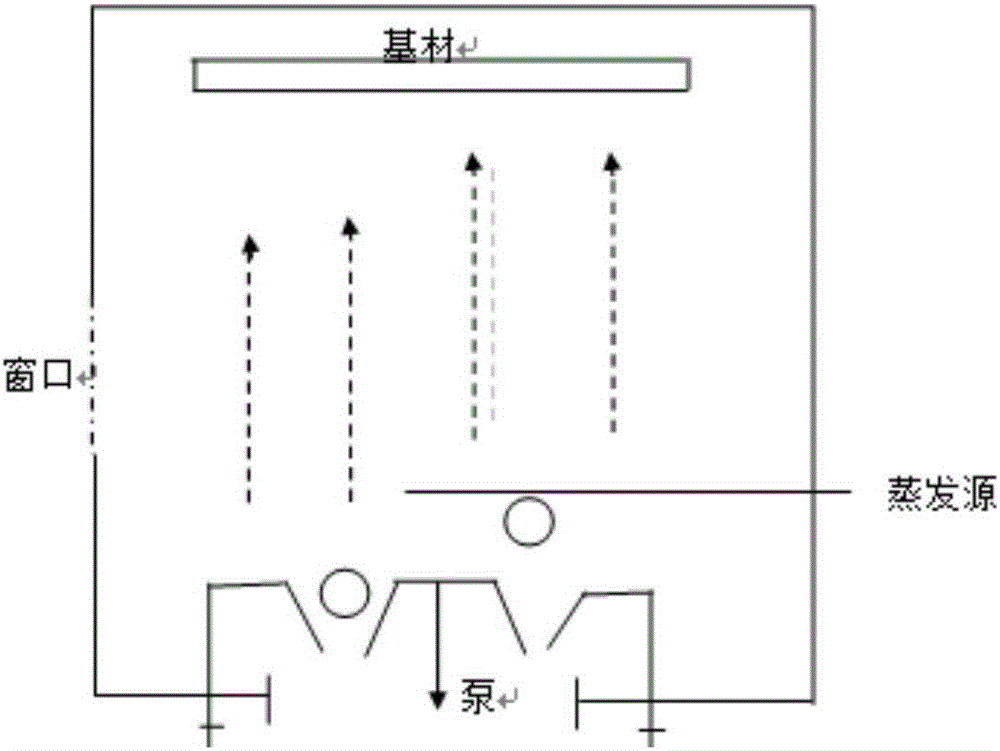

Manufacturing process of electroplating anti-reflection sapphire film onto cell phone cover plate

InactiveCN106495502AMake up for the lack of low light transmittanceImprove yieldCoatingsTelephone set constructionsMicrowaveGas phase

The invention relates to a manufacturing process of electroplating an anti-reflection sapphire film onto a cell phone cover plate, wherein the process includes the processes of: surface reinforcement of glass, ultrasonic cleaning, vacuum electroplating, vacuum gas phase film plating and microwave hot-particle gas-phase deposition. By electroplating the anti-reflection sapphire film onto a common glass plate, the glass plate is comparable with sapphire glass in hardness, and meanwhile, the defect of low light transmittance of the sapphire is overcome. The product, compared with the sapphire, is also greatly improved in yield. The creative technology can replace a simple sapphire process. The product is convenient and quick to process and has better advantages than the sapphire in cost.

Owner:WINTEK CHINA TECH LTD

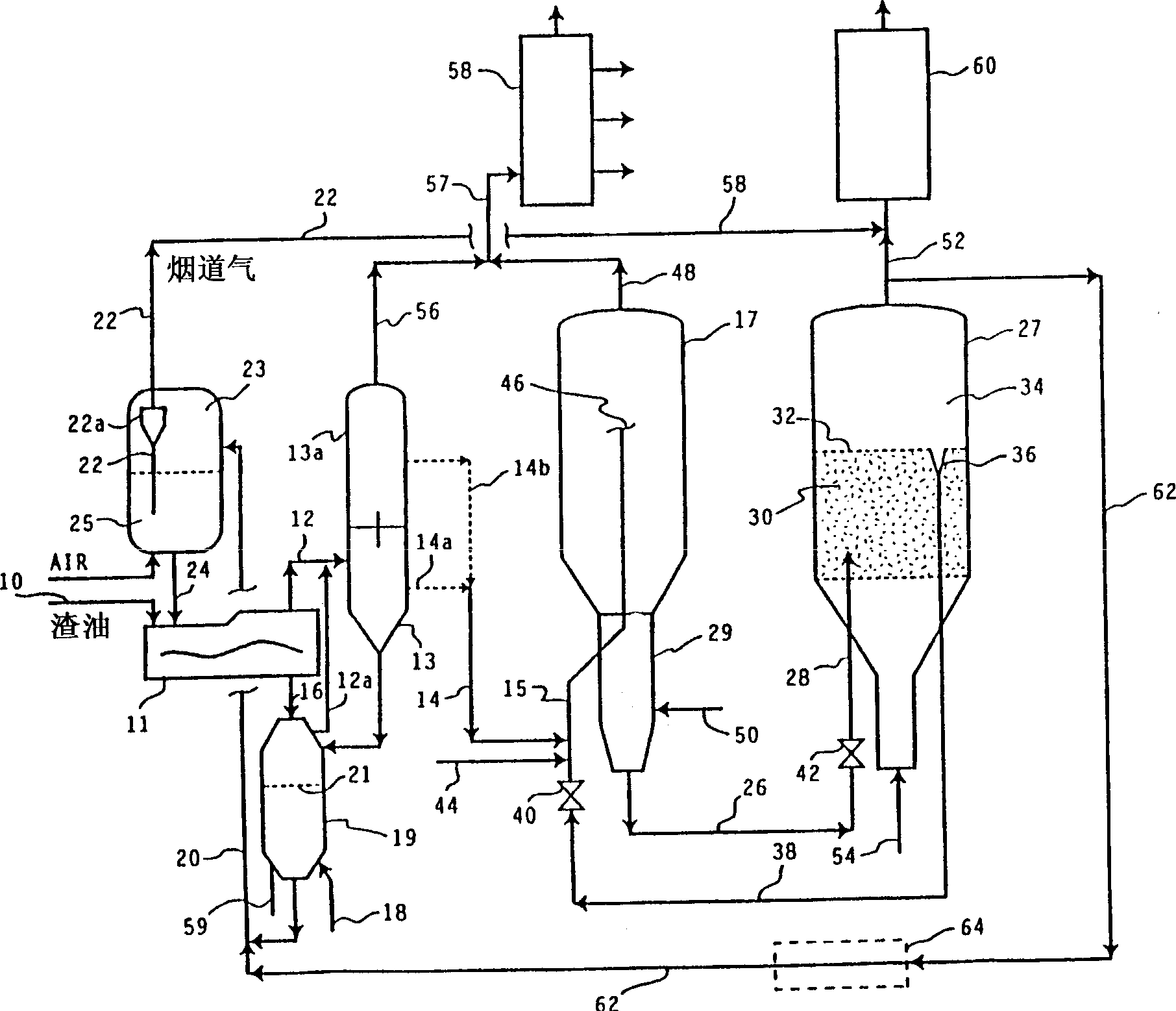

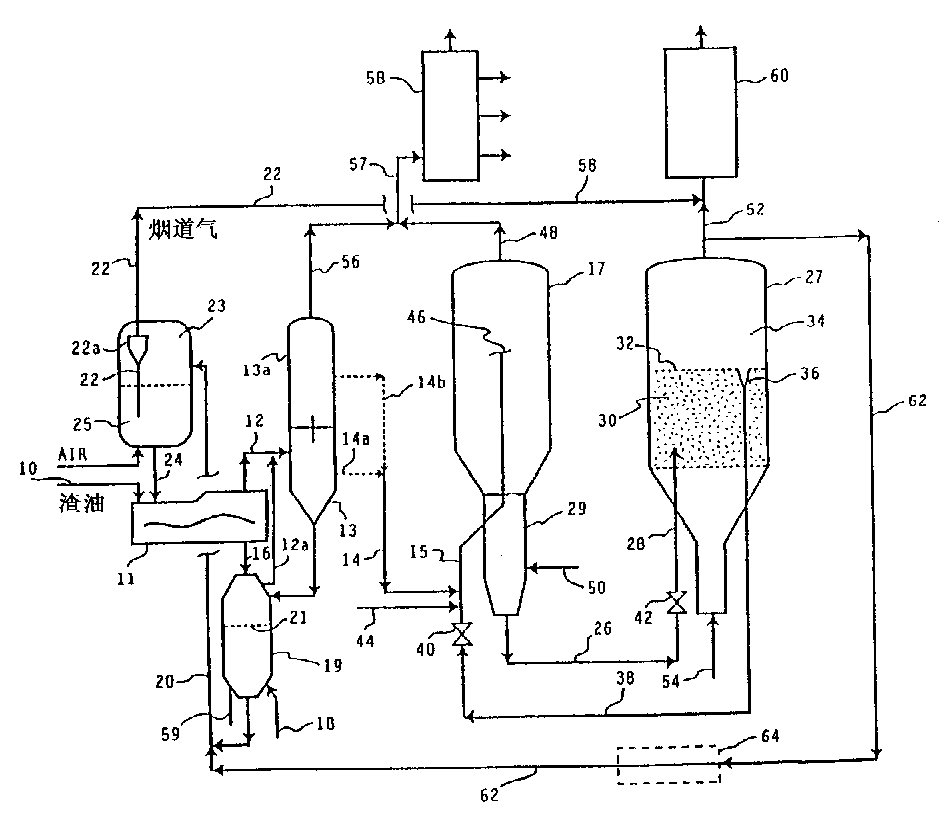

Integrated residua upgrading and fluid catalytic cracking

InactiveCN1264415AThermal non-catalytic crackingTreatment with plural serial cracking stages onlyFlue gasContact time

A residuum feedstock is upgraded in a short vapor contact time thermal process unit (11) comprised of a horizontal moving bed of fluidized hot particles and is then fed to a fluid catalytic cracking reactor (17). Hot flue gases from the fluid catalytic cracking regenerator (27) are used to circulate solid particles and to provide process heat to the thermal process unit (11).

Owner:EXXON RES & ENG CO

Preparation method for loading nanoparticle composite fiber through thermal spray adhesion method

InactiveCN105696309AHigh load rateReduce manufacturing costFibre treatmentEnergy based wastewater treatmentNanoparticleGranularity

The invention relates to a preparation method of composite fiber, in particular to a preparation method for loading nanoparticle composite fiber through a thermal spray adhesion method.The method includes the following steps of firstly, heating, by mass, 1-25 parts of nanoparticles including but not limited to titanium dioxide, silicon dioxide, calcium oxide, magnesium oxide and apatite with granularity of about 50-200 nm to 80-120 DEG C; secondly, putting, by mass, 5-120 parts of synthesis fiber in a container, and putting the container in an oven at a temperature of 70-110 DEG C; thirdly, spraying hot particles obtained in the first step into the container along with hot gas flow, and cooling to obtain the required composite fiber after circulating is conducted in the container for 1-5 hours.The production cost is low, high-amount loading of nanoparticles can be achieved, and the highest loading rate can reach 10% of the weight of synthesis fiber.

Owner:HANGZHOU TONG KING ENVIRONMENT TECH CO LTD

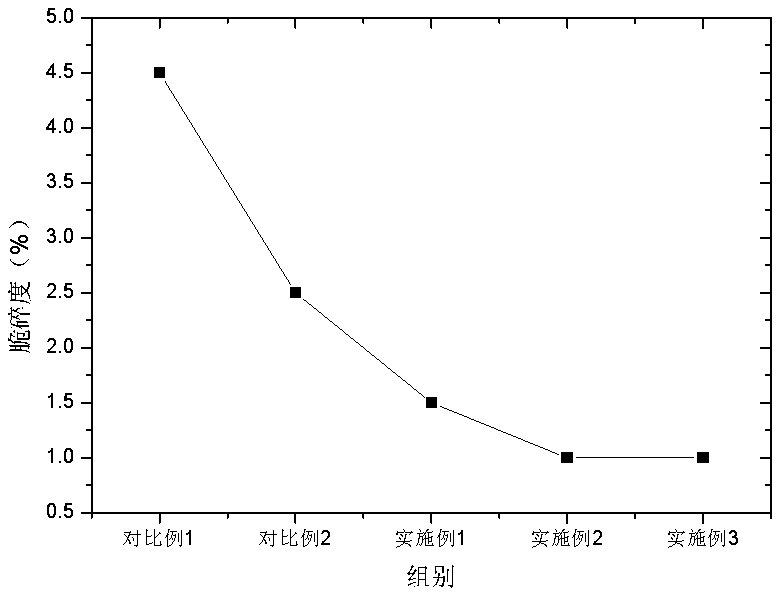

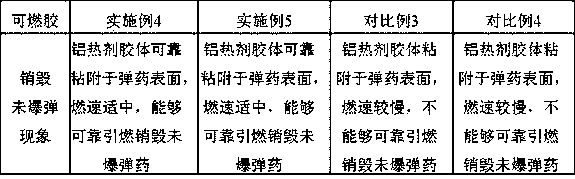

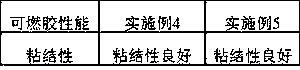

Combustible glue for destroying unexploded bullet and preparation method and application

InactiveCN109186391AImprove traditional application methodsSimple methodBlastingNitrile rubberAdhesive

The invention provides a combustible glue for destroying an unexploded bullet and a preparation method and application. The combustible glue for destroying the unexploded bullet comprises a colloidalbinder and a composite aluminothermic agent particle, the mass ratio of the colloidal binder and the colloidal binder to the composite aluminothermic agent particle is 15-20:100, and the combustible glue for destroying the unexploded bullet is prepared by coating a colloid binder on the outer surface of the composite aluminothermic agent particles less than or equal to 3 mm; the colloid adhesive comprises 23-30 wt% of liquid nitrile rubber, 18-23 wt% of KNO3, 43-57 wt% of collodion and 2-4 wt% of Mg powder. The preparation method comprises the following steps that firstly, the composite aluminum heat agent powder is prepared into particles, and then the outer surface of the composite aluminum hot particle is coated with a colloidal binder to prepare the combustible glue. The preparation method is simple and convenient, the operation is easy, the aluminum powder in the composite aluminum heat agent is in close contact with the oxide, the reaction spreading rate is increased, the reaction is more stable, the burning capacity is enhanced, the traditional application mode of the composite aluminum heat agent is improved, the limitation of the mold is eliminated, and the application field of the composite aluminum heat agent is expanded.

Owner:ARMY ENG UNIV OF PLA

Fluidised bed pyrolysis apparatus and method

ActiveUS9580657B2More throughputLess endothermicProductsFluidized bed combustionCombustionFluidized bed

A carbonaceous feed pyrolysis apparatus is provided including two or more hot particle fluidized beds, and one or more positive displacement apparatus for the transfer of hot particles between two or more of the beds, wherein one or more of the fluidized beds contains a combustion zone. A bio-oil production process is also provided, including pyrolysis of a carbonaceous bio-mass using two or more fluidized beds, including a first combustion zone carried out in one or more combustion fluidized beds in which a particulate material is fluidized and heated, and a second pyrolysis zone carried out in one or more pyrolysis fluidized beds in which the hot particles heated in the combustion zone are used for pyrolysis of the bio-mass.

Owner:UNIV OF PRETORIA +1

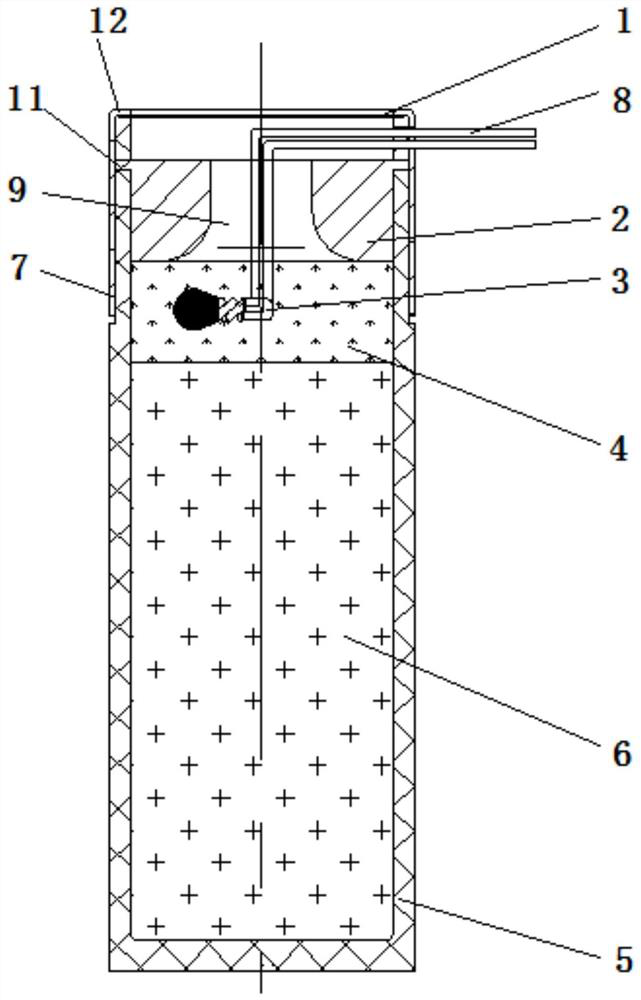

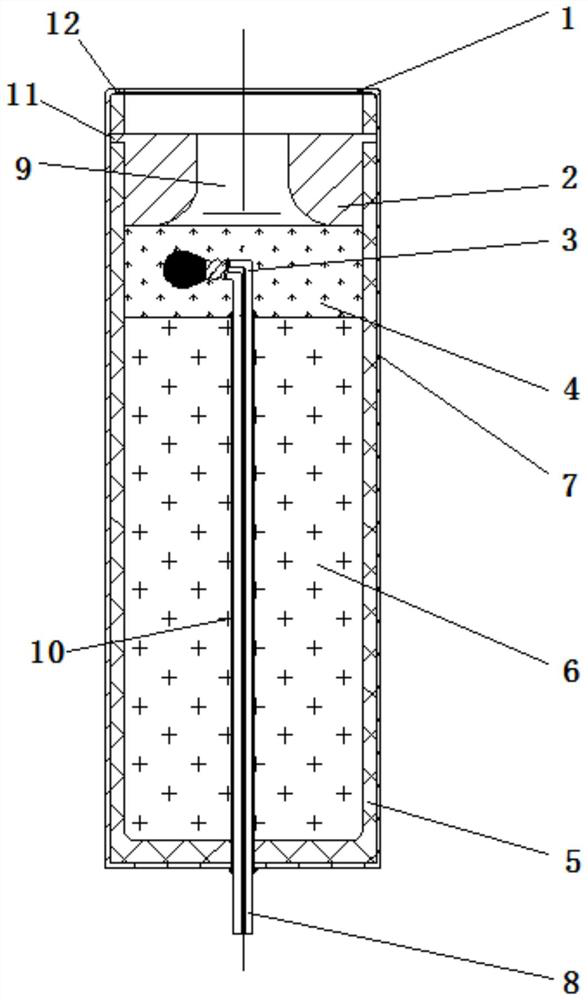

System and Method of Heating a Tool with Electromagnetic Radiation

A system and method of heating a tool with electromagnetic radiation aims to harness the dialectic heating effect of radio waves on metallic nanoparticles to generate controllable, user-safe, highly variable heat with the use of a specific supporting structure. It is considered that the method may be applied to a variety of existing assemblies, such as a knife, a cooking pot, a jacket, and other embodiments. The system of the present invention provides at least one tool body, at least one suspension mechanism, and a plurality of photothermal particles. Furthermore, at least one portable electromagnetic (EM) wave generator is provided, wherein the portable EM wave generator either is integrated into the tool body, or is positioned adjacent to the tool body, wherein the portable EM wave generator includes a manual on / off switch. The overall process allows for controlled generation of heat within a variety of physical objects.

Owner:ANSON JONATHAN ROSS

Uniform particle heating method

InactiveCN100554924CLow costExperimental data is reliableEngine testingPreparing sample for investigationGas cylinderHot particle

A method for uniformly heating particles relates to a method for uniformly heating particles. It solves the problem that the actual engine test run is expensive to measure the performance of high-temperature particles, and the particle distribution and temperature characteristics are uncontrollable. The steps of its method are as follows: Weigh the particles with a diameter of 1-500 μm, put the particles into the particle screening and uniform distribution device, start the power supply, preheat the particles, measure the temperature in the furnace body through a thermocouple; The falling particles from the leakage hole of the moving plate are screened, evenly distributed, and heated; the nozzle of the working medium is aimed at the furnace body through the lifting device, and after the gas valve of the gas cylinder is opened, the gas is ejected upward to suspend the screened particles. The transmittance, absorption coefficient and particle size distribution of the particles are obtained, and the motor is turned off. The invention has the advantages of cost reduction, controllable particle distribution and temperature characteristics, and reliable experimental data for in-depth research on physical properties of high-temperature particle spectral characteristics.

Owner:HARBIN INST OF TECH

A lightweight, high-power, particle-rich propellant ignition device

The invention discloses a light-weight, high-power, and particle-rich propellant ignition device, which solves the problems of high development and test costs of the existing ignition device, long development period, and easy damage to the thrust chamber caused by the remains of the ignition device after ignition. The ignition device mainly includes an ignition head, an initial charge, a main charge, a shell, a nozzle and a sealing diaphragm. After the ignition head of the ignition device is energized and detonated, the initial charge is ignited, and then the main charge is ignited. The high-temperature gas generated breaks through the sealing diaphragm through the nozzle to produce a continuous and stable flame output rich in hot particles, thereby realizing the engine. Ignition of thrust chamber propellant.

Owner:XIAN AEROSPACE PROPULSION INST +1

A hot-air-microwave combined processing method for bamboo shoot particles

The invention relates to a hot wind and microwave combined processing method for bamboo shoot particles. The hot wind and microwave combined processing method comprises the following steps: preprocessing, blanching, coating film, drying through spouted combination of microwave and hot wind, and packaging. Compared with the prior art, the hot wind and microwave combined processing method for the bamboo shoot particles has the advantages that compared with spouted sectional cooperation of the microwave and hot wind, the spouted combination drying based on the microwave and the hot wind can be used for further improving the dewatering rate; the drying time can be greatly shortened; meanwhile, the quality of the dewatered bamboo shoot particles also can be improved so as to solve the problems of complex sectional drying processes and unevenness for heating the materials. In addition, the technology of coating film, and the technology of coating film and seasoning are added into the spouted combination drying process of the microwave and the hot wind for the first time, so that the collision and breakage problems caused by spouting the dry materials can be avoided, and the finished product ratio of product can be improved; further, a layer of protection film can be formed on the surfaces of the bamboo shoot particles coated with films, so that the inner water stream can be avoided and the swelling degree of the product can be improved; meanwhile, seasonings are added into a film coating liquid, so that a bamboo shoot particle snack food with special flavor can be developed.

Owner:ZHEJIANG WANLI UNIV

Preparation of surface reinforced Raman active substrate of large area micro-nano dendritical structure array

InactiveCN101281133BHighly sensitive SERS activitySuitable for testingDecorative surface effectsRaman scatteringBasementMicro nano

The invention discloses a preparation method for increasing raman activity of a basement in a surface of a large area of a micro-nano tree structure array, which firstly prepares a large area of a silicon micron cylinder array; a nanometer assembling technology is used for producing a nanometer stick in the silicon micron cylinder array. then a three-dimensional ordered periodic micro-nano structure array is obtained; and various appearance of metal nano-particles are embedded into the three-dimensional ordered periodic micro-nano structure array by using a way of a hydro-thermal synthesis method. A SERS activity basement of the invention can achieve homogenization from a centimeter grade to a large area. The invention designs SERS activity hot-particles on the three-dimensional ordered micro-nano structure, and assembles increasing effect of antenna, the increasing effect of metal / semiconductor intersection and the increasing effect of a gap into one body, then high sensitivity of the SERS activity is obtained, and the SERS activity hot-particles is firmly embedded into the tree micro-nano structure, then the invention is not only applicable for a SERS test of trace liquid-phaseanalyte, but also for the SERS test of trace gaseous-phase analyte.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com