Integrated residua upgrading and fluid catalytic cracking

A residual oil and logistics technology, applied in the field of integrated residual oil upgrading and fluidized catalytic cracking, can solve the problems of system overload and occupying gas space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

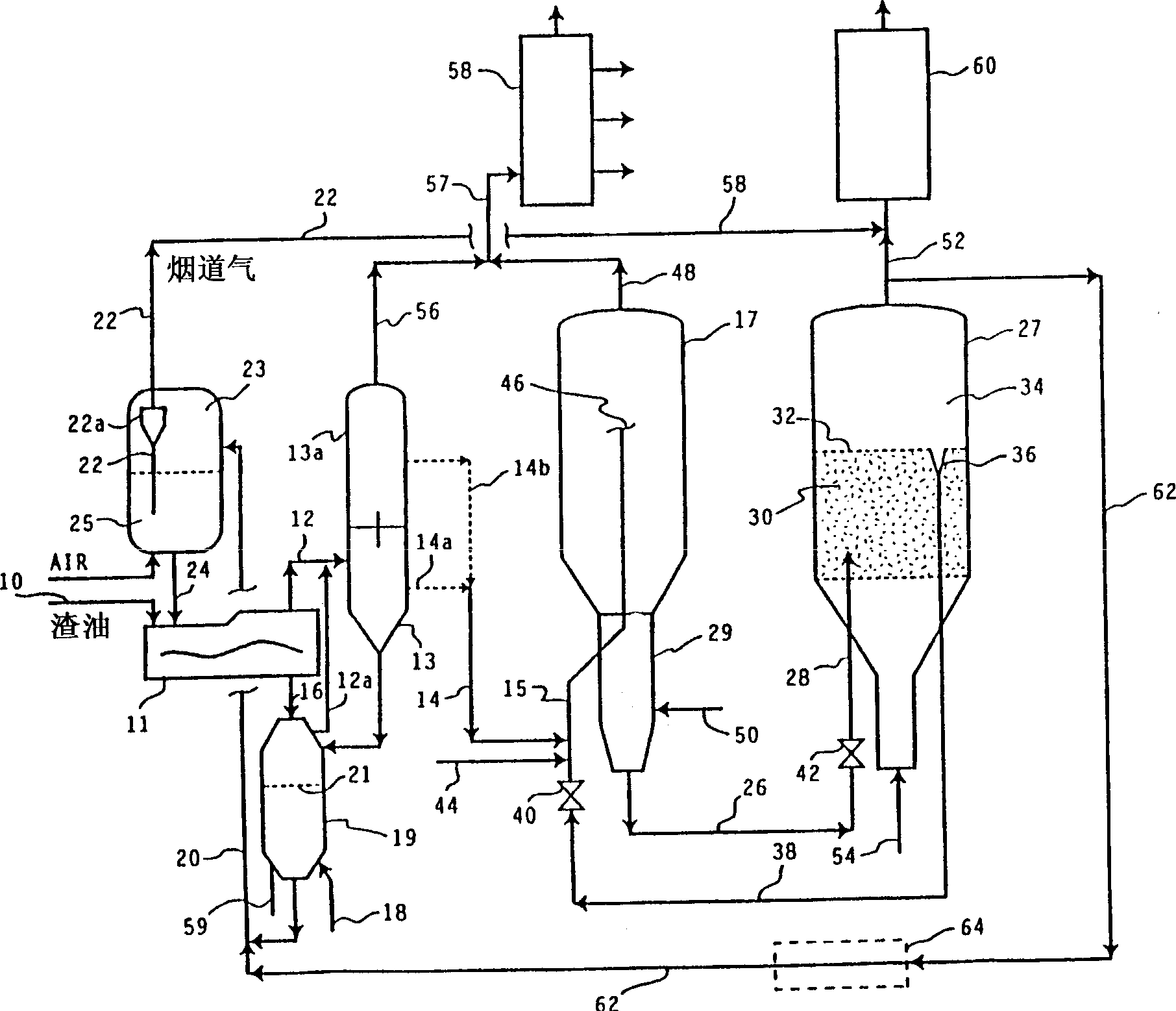

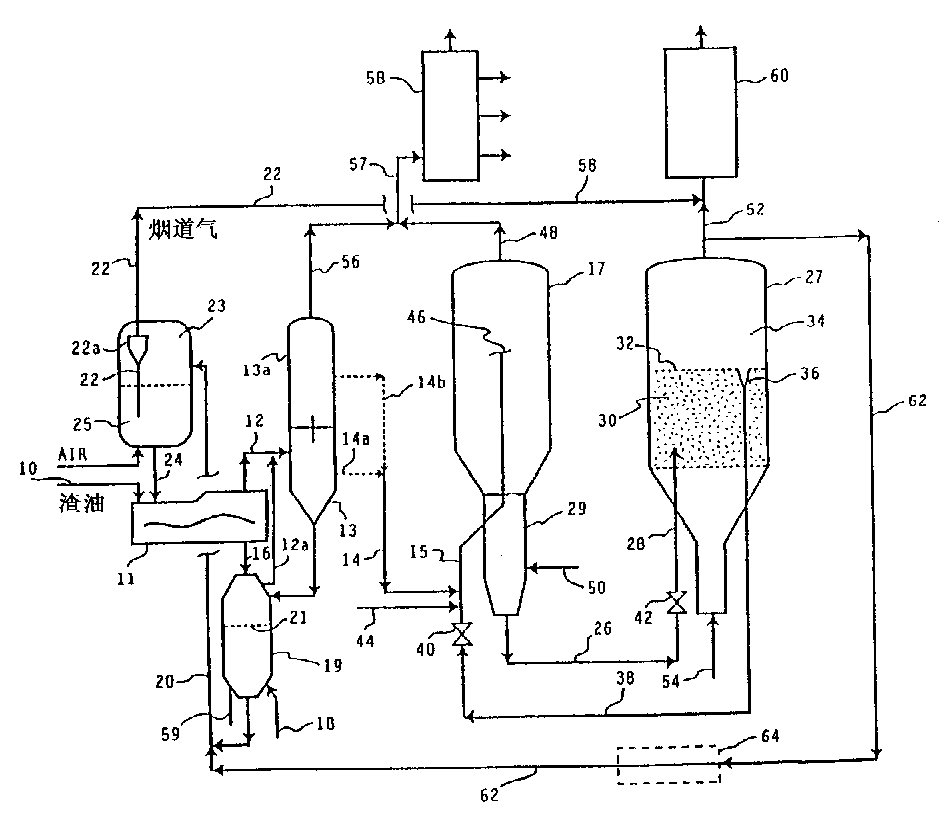

[0025] The resid feed to be upgraded according to the present invention is a petroleum fraction that is liquid under process conditions and has an average boiling point above about 480°C, preferably above about 540°C, more preferably above about 560°C. Non-limiting examples of such fractions include vacuum residues, atmospheric residues, heavy and reduced petroleum crudes, tar pitches, saphalts, bitumen, tar sands, shale Oil and coal liquefaction residue. Preferred are vacuum residues, atmospheric residues and heavy and reduced petroleum crudes. It will be appreciated that such residues may also contain minor amounts of lower boiling materials. These feeds cannot be fed to FCC units in large quantities because they generally have a high Conradson carbon content and contain undesired amounts of metal-containing components. Conradson carbon deposits on the FCC cracking catalyst and can cause excessive deactivation. Metals such as nickel and vanadium also act as catalyst poiso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com