Preparation method for loading nanoparticle composite fiber through thermal spray adhesion method

A nanoparticle and composite fiber technology, which is applied in fiber treatment, energy wastewater treatment, textiles and papermaking, etc., can solve the problems of difficult recycling of nanomaterials, secondary pollution, etc., and achieve the effect of low production cost and high load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

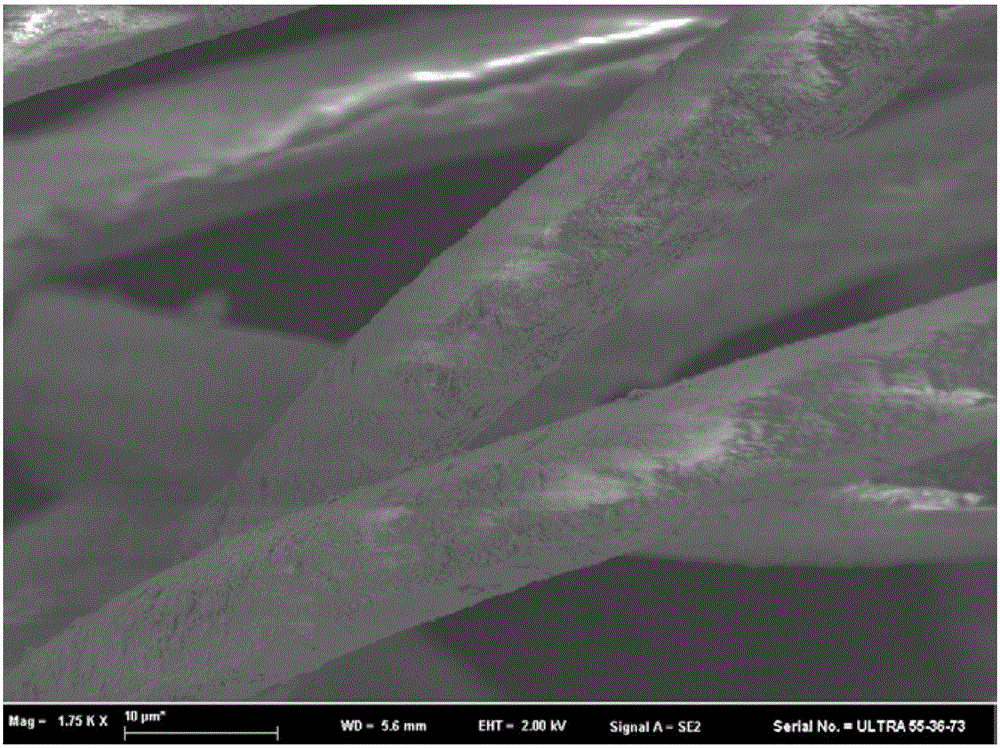

Image

Examples

Embodiment 1

[0019] A preparation method for loading nanoparticle composite fibers by thermal spray bonding, comprising the following steps:

[0020] 1) According to the number of parts by mass, 1 part of nanoparticles with a particle size of about 50nm is heated to 80 degrees, and the nanoparticles are titanium dioxide, silicon dioxide, calcium oxide, magnesium oxide or apatite;

[0021] 2) According to the number of parts by mass, 5 parts of synthetic fibers are placed in a container, and the container is placed in an oven at 70 degrees;

[0022] 3) The hot particles obtained in step 1) are sprayed into the container along with the hot air flow, and circulated in the container for 1 hour and then cooled to obtain the desired composite fiber.

Embodiment 2

[0024] A preparation method for loading nanoparticle composite fibers by thermal spray bonding, comprising the following steps:

[0025] 1) According to the number of parts by mass, 25 parts of nanoparticles with a particle diameter of about 200nm are heated to 120 degrees, and the nanoparticles are titanium dioxide, silicon dioxide, calcium oxide, magnesium oxide or apatite;

[0026] 2) According to the number of parts by mass, 120 parts of synthetic fibers are placed in the container, and the container is placed in an oven at 110 degrees;

[0027] 3) The hot particles obtained in step 1) are sprayed into the container along with the hot air flow, and circulated in the container for 5 hours and then cooled to obtain the desired composite fiber.

Embodiment 3

[0029] A preparation method for loading nanoparticle composite fibers by thermal spray bonding, comprising the following steps:

[0030] 1) According to the number of parts by mass, 17 parts of nanoparticles with a particle diameter of about 125nm are heated to 100 degrees, and the nanoparticles are titanium dioxide, silicon dioxide, calcium oxide, magnesium oxide or apatite;

[0031] 2) According to the number of parts by mass, 65 parts of synthetic fibers are placed in a container, and the container is placed in a 90-degree oven;

[0032] 3) The hot particles obtained in step 1) are sprayed into the container along with the hot air flow, and circulated in the container for 2.5 hours and then cooled to obtain the desired composite fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com