Oxide cathode

An oxide cathode and cathode technology, which is used in the manufacture of cold cathodes, solid thermionic cathodes of discharge tubes, and main electrodes of discharge tubes, etc., can solve the problems of residual emitters, geometric defects, easy ignition, etc. The effect of lifespan, increased bombardment ability, and reduced chance of ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

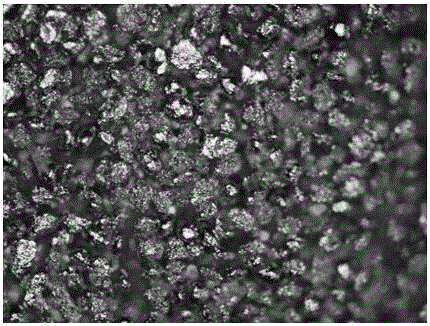

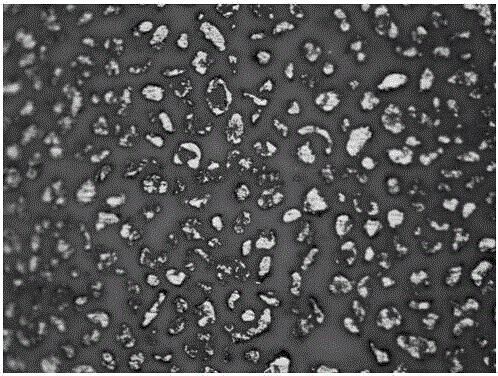

[0022] An oxide cathode: ①Reserve a geometric margin of (0.1-0.15) mm on the peripheral surface of the emission layer to make the cathode (tungsten-based) metal. Clean and degas the cathode base metal. ②Pour nickel powder 1 (purity ≥ 99.9%) with an average particle size of 40 μm (minimum not exceeding 20 μm, maximum not exceeding 60 μm) on the cathode base metal by molding. Put the cathode base metal 3 filled with nickel powder 1 together with the mold in a hydrogen furnace and sinter at a temperature of (1250±20)°C for 20 minutes (hydrogen flow rate ≥0.4L / min, dew point ≤-65°C), after cooling mold. Such as figure 2 As shown, the surface of the finished nickel sponge layer should have a geometric margin of 0.3-0.4 mm higher than the base metal (the actual size higher than the base metal should be the 0.3-0.4 mm above minus the reserved surface of the emissive layer. The difference of 0.1 ~ 0.15mm), the hole size is between (45% ~ 50%) ( figure 2 , image 3 , Figure 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com