Electromagnetic shielding heat conducting composition and electromagnetic shielding heat conducting gasket

An electromagnetic shielding and composition technology, which is applied in the field of thermal interface materials, can solve the problems of heat dissipation and electromagnetic interference of thermally conductive gaskets, and achieve the effects of improving thermal conductivity, good electromagnetic shielding performance, and increasing compressibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

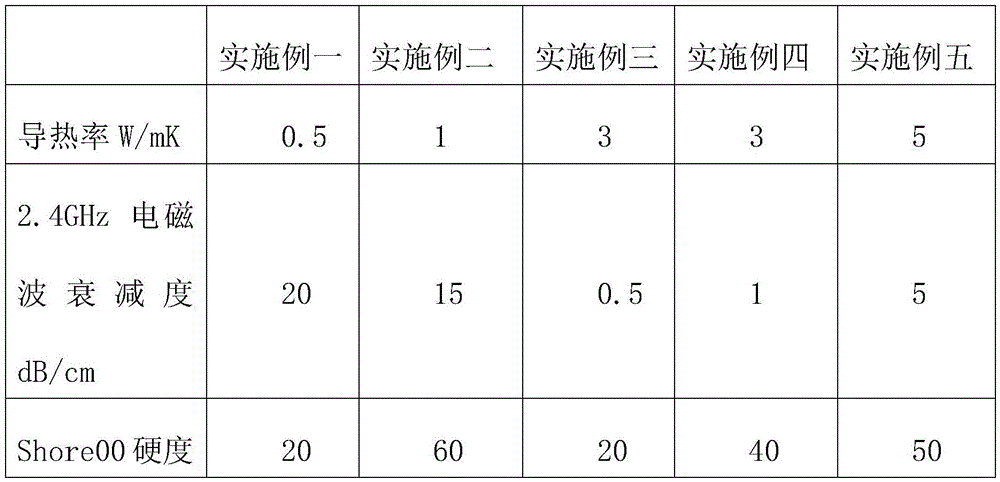

Examples

Embodiment 1

[0022] An electromagnetic shielding and heat-conducting composition, comprising the following components by mass percentage:

[0023] 10% spherical alumina powder, the average particle size of the powder particles is 150μm;

[0024] 10% spherical aluminum nitride powder, the average particle size of the powder particles is 30μm;

[0025] Fe-based magnetic powder 10%, the average particle size of the powder particles is 100μm;

[0026] Mn-Zn ferrite powder 65%, the average particle size of powder particles is 5μm;

[0027] Silicone rubber 5%.

[0028] Mix and stir the above components evenly, which can be realized by common equipment in the field such as a kneader or a mixer, to obtain an electromagnetic shielding heat-conducting composition;

[0029] The electromagnetic shielding and heat conducting composition obtained above is calendered and sliced to obtain an electromagnetic shielding and heat conducting gasket.

[0030] The thermal conductivity of the obtained elect...

Embodiment 2

[0032] An electromagnetic shielding and heat-conducting composition as described in Embodiment 1, this embodiment has the following difference: it includes the following components by mass percentage:

[0033] 10% spherical aluminum powder, the average particle size of aluminum powder particles is 50μm;

[0034] 10% spherical alumina powder, the average particle size of the powder particles is 5 μm;

[0035] Fe-Ni based powder 65%, the average particle size of powder particles is 50μm;

[0036] CuZn ferrite powder 10%, the average particle size of powder particles is 10μm;

[0037] Silicone rubber 5%.

[0038] Mix and stir the above components evenly, which can be realized by common equipment in the field such as a kneader or a mixer, to obtain an electromagnetic shielding heat-conducting composition;

[0039] The electromagnetic shielding and heat conducting composition obtained above is calendered and sliced to obtain an electromagnetic shielding and heat conducting gas...

Embodiment 3

[0042] An electromagnetic shielding and heat-conducting composition as described in Embodiments 1 and 2, this embodiment has the following differences: it includes the following components by mass percentage:

[0043] 20% spherical aluminum powder, the average particle size of powder particles is 100μm;

[0044] 20% spherical alumina powder, the average particle size of the powder particles is 1 μm;

[0045] Fe-Ni based magnetic powder 25%, the average particle size of powder particles is 60μm;

[0046] M-type flat hexagonal ferrite particles 25%, with an average particle size of 20μm;

[0047] Silicone Gel 10%.

[0048] Mix and stir the above components evenly, which can be realized by common equipment in the field such as a kneader or a mixer, to obtain an electromagnetic shielding heat-conducting composition;

[0049]The electromagnetic shielding and heat conducting composition obtained above is calendered and sliced to obtain an electromagnetic shielding and heat cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com