Testing device for combustion performance of stacked materials under constant-power heating effect of spherical metal hot particles

A constant power, testing device technology, applied in the direction of material thermal development, etc., to achieve the effect of stable output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0021] The device for testing the combustion performance of piled materials under the heating action of constant power spherical metal thermal particles of the present invention, its preferred specific implementation method is:

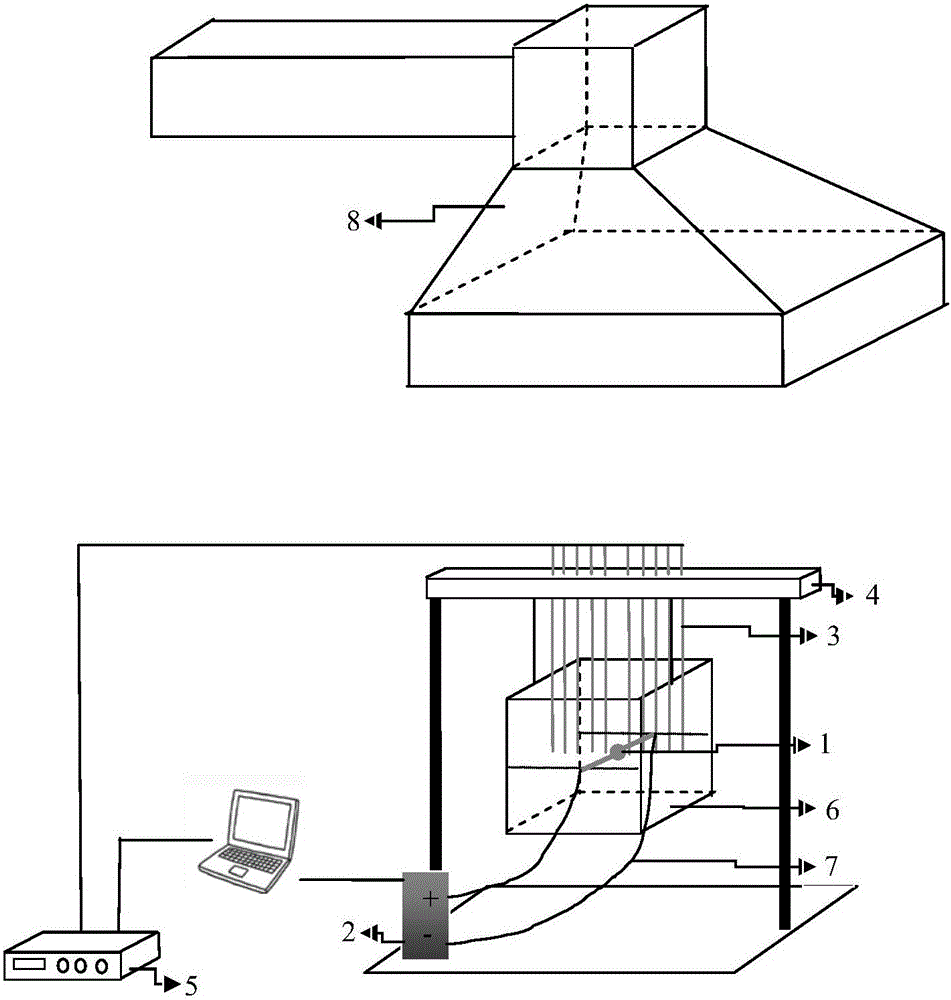

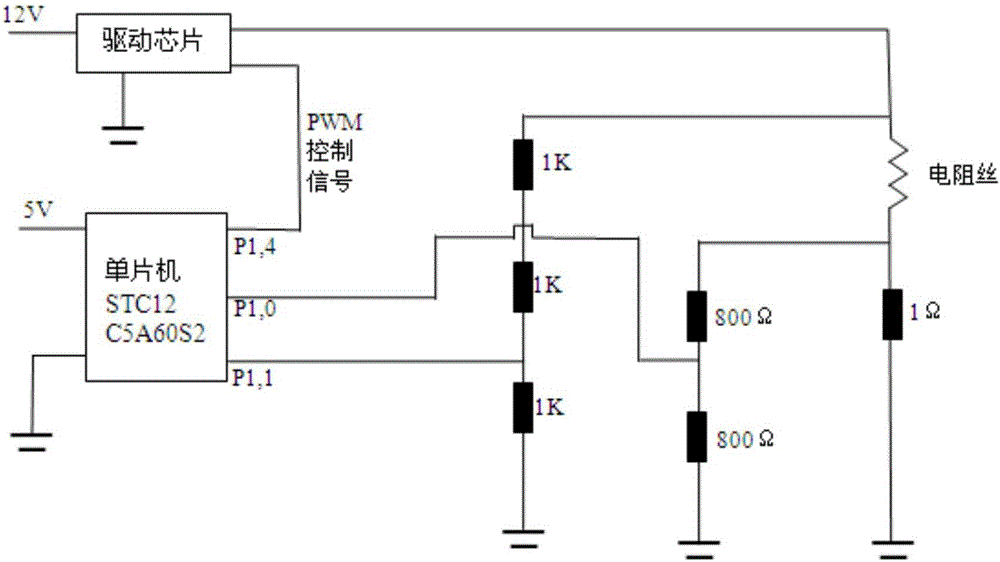

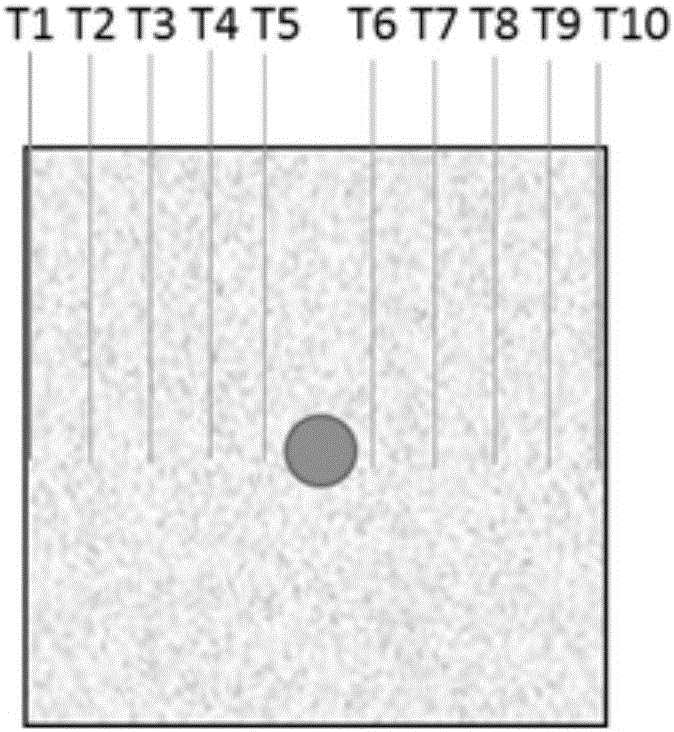

[0022] Including output power and real-time adjustment feedback circuit for heat source power, cubic metal mesh basket for accumulating materials, thermocouple and data acquisition instrument for collecting temperature data, and fume collection hood. The metal mesh basket is fixed on a bracket at a certain distance from the ground by iron hooks. The metal hot particles are located in the center of the metal mesh basket. Thermocouples are arranged symmetrically on both sides of the center of the hot particles in the horizontal direction. The temperature data is collected by the data acquisition instrument. There is a sm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com