Thermally stabilized bag house filters and media

一种袋式过滤器、滤袋的技术,应用在复合材料领域,能够解决缩短过滤介质使用寿命、基重受限、降低过滤器继续使用的能力等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 5

[0054] To test the thermal stability of nanofibrous webs, nanofibrous webs with a basis weight of 15 grams per square meter (gsm) were prepared using polyamide PA6 / 6 (Zytel 3218, DuPont , Wilmington, DE) nanofibers spun. The average fiber diameter is about 400 nm. Small samples (20cm x 25cm) were suspended in a forced circulation oven at 140°C. Samples are removed daily, checked for color and shrinkage, and tested for tensile strength and elongation. Table 1 lists the samples and the content of antioxidants used and the color after aging at 140 °C for 21 days. Antioxidants used were N,N'-hexamethylenebis(3,5-di-tert-butyl-4-hydroxyphenylpropanamide (Irganox 1098, Ciba, Tarrytown, NY) or copper bromide (PolyAD 1932, supplier).

[0055] Shrinkage was determined by measuring the length of one side of the sample, expressed as a percentage of the original sample length.

[0056] Table 1

[0057] sample

[0058] Antioxidant-containing samples exhibited greater resi...

Embodiment 6 to 10

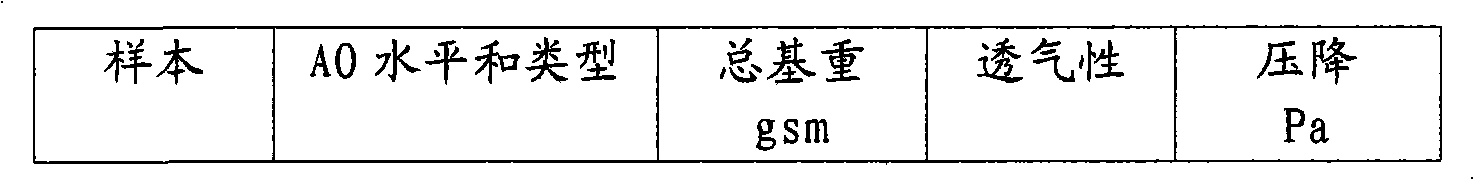

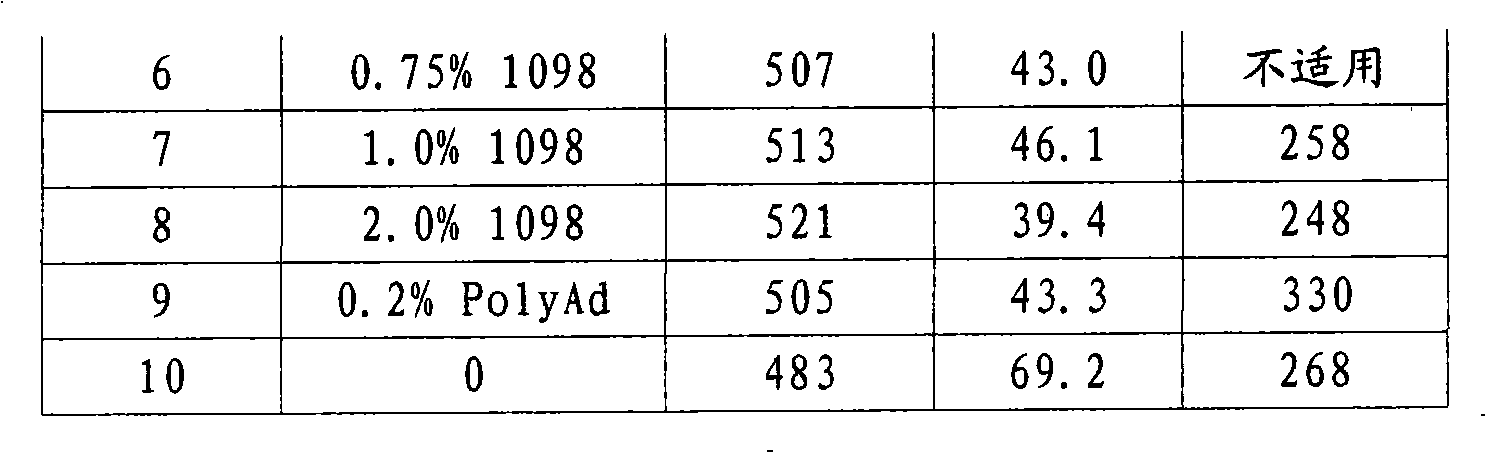

[0066] Five different nanofibrous webs were prepared with a basis weight of about 10 gsm containing 0.75%, 1%, 2% Irganox 1098, 0.2% PolyAd 1932 and no antioxidant. The average diameter is about 400 nm. The nanofibrous web was bonded to a basis weight of 14 oz / yd using the following adhesive lamination method: 2 on the polyester felt samples.

[0067] A discrete layer of polyurethane adhesive was applied to one surface of the felt using a gravure roller. The mat and nanoweb are fed into the nip of two rolls, the mat surface coated with adhesive contacts the nanoweb. The roll temperature was 144°C, the nip pressure was 40 pounds per square inch (psi), and the line speed was 3 meters per minute. The composite is rolled up and tested. A control sample without antioxidant was laminated on a commercial machine. The nip roll temperature was 290°F and the line speed was 3 meters per minute.

[0068] All samples and controls were tested by placing them in an oven at 150°C for 70...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com