Combustible glue for destroying unexploded bullet and preparation method and application

A technology of unexploded bombs and colloids, applied in blasting and other directions, can solve problems such as cumbersome steps, time-consuming and labor-consuming, and increase production costs, and achieve the effect of improving traditional application methods, expanding application fields, and being easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

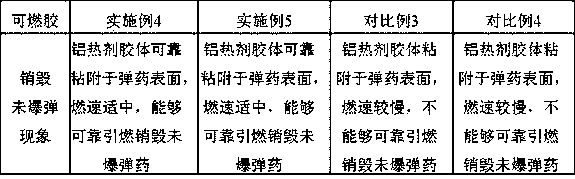

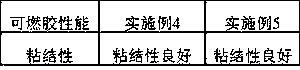

Examples

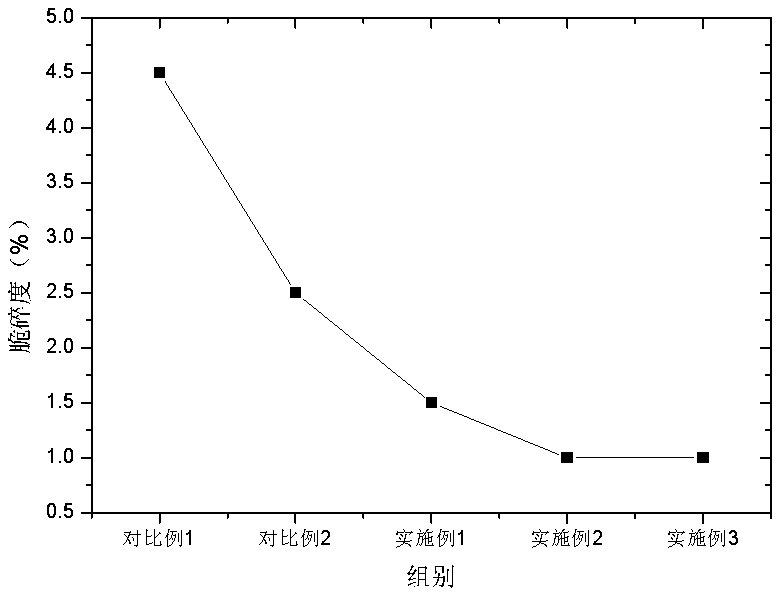

Embodiment 1

[0049]Weigh 17.9g aluminum powder and 17.5g Fe powder with a particle size of 80~140 mesh respectively 3 o 4 , 22.3gCuO, 17.6gCr 2 o 3 and 8.2gKNO 3 , put these five components into a mixer and mix evenly to obtain a mixture, put the mixture into a constant temperature box at 75°C~85°C, dry it for 2~3 hours, and take it out to obtain a composite thermite.

[0050] Put 1.8g of gelatin granules into 18.2g of water, heat it in a water bath at 70°C to 80°C while stirring with electromagnetic force, until it is completely gelatinous, and then lower it to room temperature to make an aqueous gelatin solution.

[0051] The composite thermite is added to the gelatin solution, and stirred with a mixer until the mixture is evenly mixed to prepare a bonded wet powder. Put the bonded wet powder into the wet granulation device (extrusion spheronizer) to prepare 1~2mm spherical composite thermite particles, and dry them at 75°C~85°C for 12h.

Embodiment 2

[0053] Put 2.2g of gelatin particles into 17.8g of water to make an aqueous gelatin solution; other steps are the same as in Example 1.

Embodiment 3

[0055] Put 2.6g of gelatin particles into 17.4g of water to make an aqueous gelatin solution; other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com