Shunting pressure relief device

A technology of a pressure relief device and a shunt surface, applied in the field of switch cabinets, can solve the problems of poor blocking effect of hot particles, affecting the overall size of the cabinet, insufficient ventilation rate of the pressure relief device, etc., to achieve the effect of increasing safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

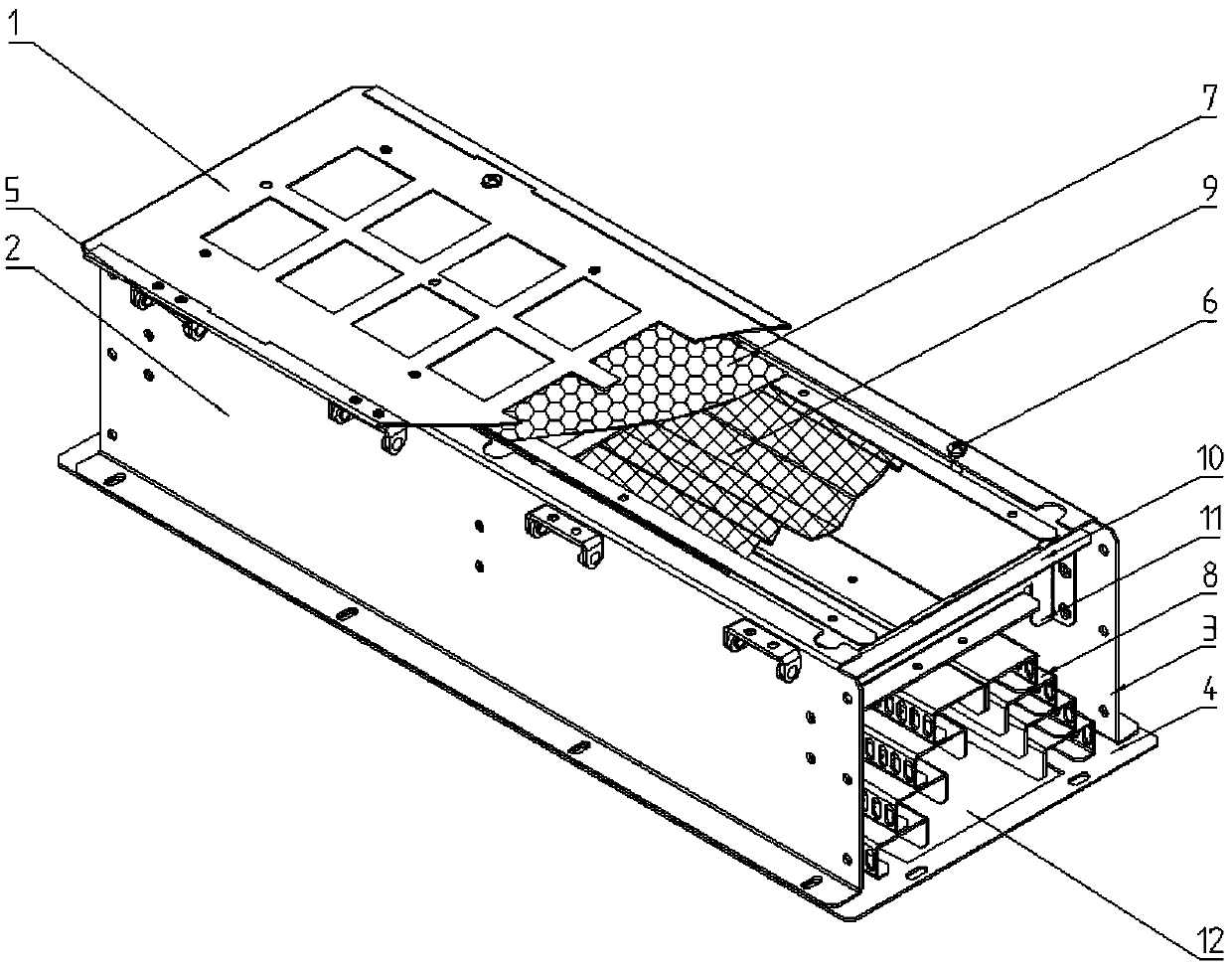

[0023] Embodiment 1, with reference to attached Figure 1-4 .

[0024] In this embodiment, the pressure-dividing device includes a housing, the housing includes a bottom plate 4, a first side plate 2, a second side plate 3 and a top plate 1, the bottom plate 4 is installed on the top of the switch cabinet, and the bottom plate 4 is provided with an inlet The air hole 12 , the top plate 1 and the first side plate 2 are rotatably connected through a hinge 5 .

[0025] The top of the first side plate 2 and the second side plate 3 is provided with inward flanging, and the bottom of the first side plate 2 and the second side plate 3 is provided with outward flanging, so that the first side plate 2 and the second The two side plates 3 form a relative Z shape, and the first side plate 2 and the second side plate 3 are fixedly installed on both sides of the bottom plate 4 by the outward flanging of the bottom respectively, and the flanging on the second side plate 3 tops is provided ...

Embodiment 2

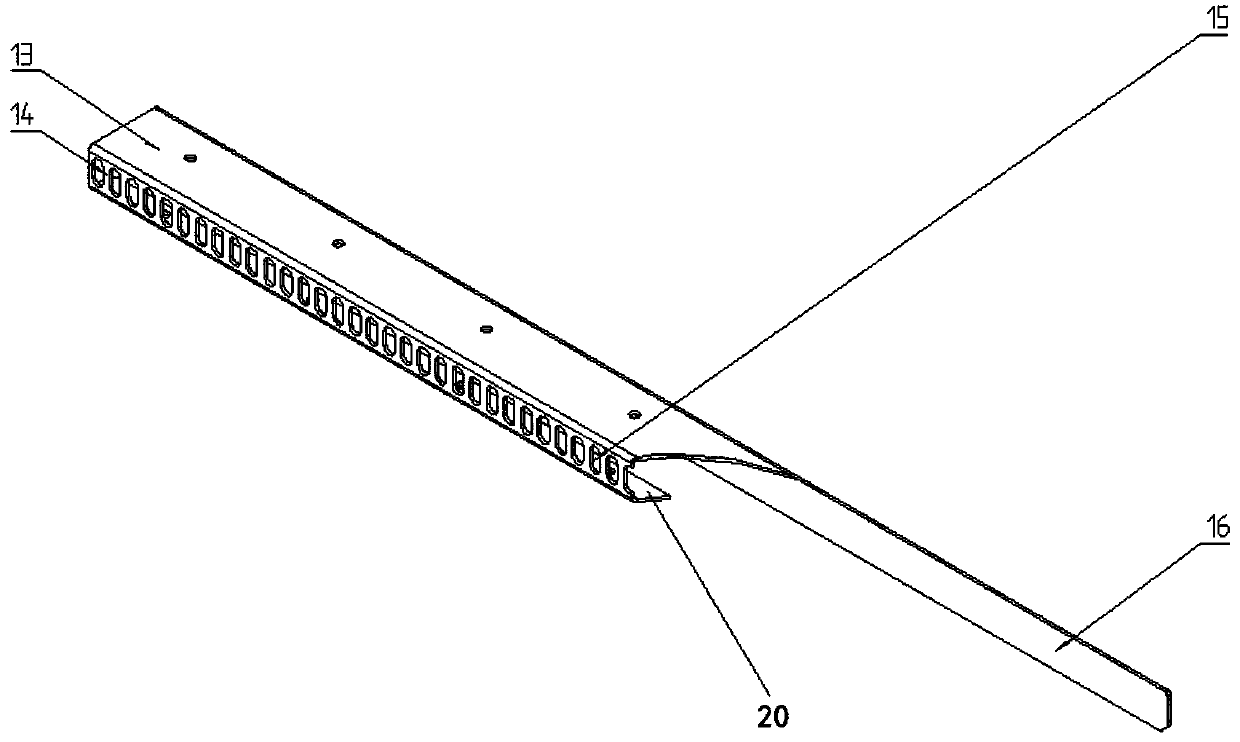

[0034] Embodiment 2, with reference to attached Figure 3-6 .

[0035] In this embodiment, the first side plate 2 and the second side plate 3 are provided with a ventilation grid 23, and the outer side of the ventilation grid 23 is arranged with a protective plate 22, and the protective plate 22 protrudes outwards. The blocking plate 21, the structure of the blocking plate 21 is consistent with the first side plate 2 and the second side plate 3, and the upper part has an inward folded edge, and the lower part has an outward folded edge, and is fixedly connected by the outward folded edge on base plate 4.

[0036] Other implementation modes of this embodiment are the same as Embodiment 1.

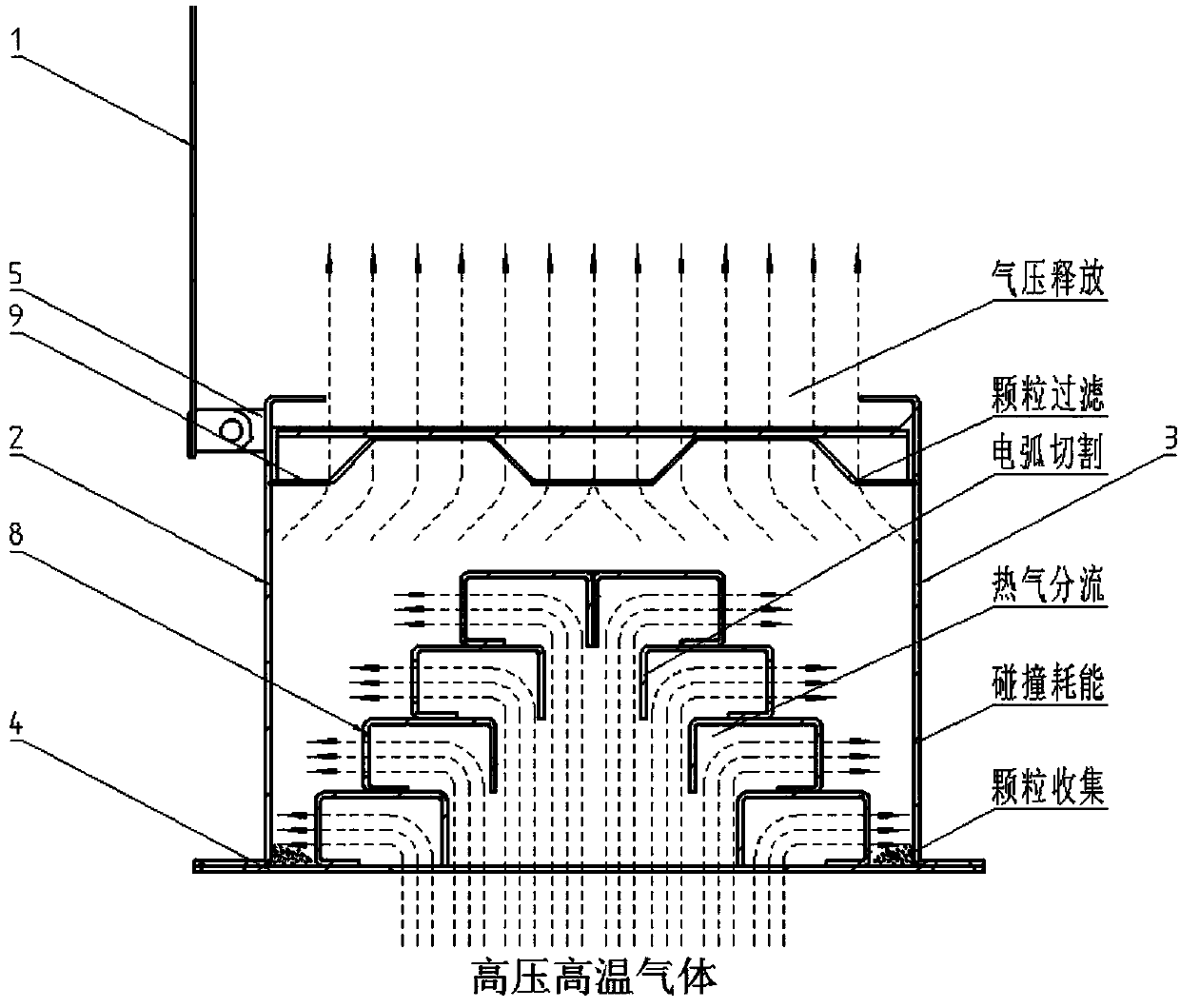

[0037] The working principle of the structure of this embodiment is as Image 6 As shown, when a large amount of high-temperature and high-pressure gas is generated at the bottom of the pressure relief device due to the arcing explosion of the switchgear, the hot gas first enters the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com