Shell and tube heat exchanger

A shell-and-tube heat exchanger and heat exchanger technology, applied in the mechanical field, can solve problems such as the limitation of the agent-oil ratio, and achieve the effects of reducing the partial pressure of water vapor, reducing the coke yield, and improving the efficiency of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

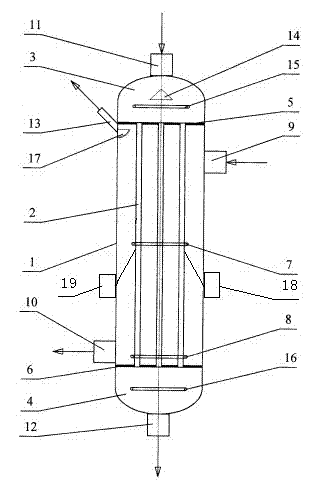

[0010] Such as figure 1 as shown in figure 1 As shown, a shell-and-tube heat exchanger consists of a shell (1), a heat exchange tube (2), an upper head (3), a lower head (4), an upper tube sheet (5), and a lower tube sheet ( 6), shell-side middle fluidization air distributor (7), shell-side lower fluidization air distributor (8), cold standby agent inlet (9), hot standby agent outlet (10), hot regeneration agent inlet ( 11), cooling regeneration agent outlet (12), hot stripping oil gas outlet (13), catalyst distribution plate (14) in the upper part of the tube pass, fluidization air distributor in the upper part of the tube pass (15), fluidization air distributor in the lower part of the tube pass (16), composed of arc-shaped baffles (17); the shell side is composed of the space between the shell (1), heat exchange tubes (2), upper tube sheet (5), and lower tube sheet (6), and the upper seal The head (3), the lower head (4) and the internal flow space of the heat exchange tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com