A hot-air-microwave combined processing method for bamboo shoot particles

A technology of combined processing and granulation, which is applied in the field of snack food processing, can solve the problems of uneven microwave drying, complicated drying process, and increased puffing degree, and achieve the effects of overcoming the complexity of segmented drying process, shortening the drying time, and increasing the puffing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

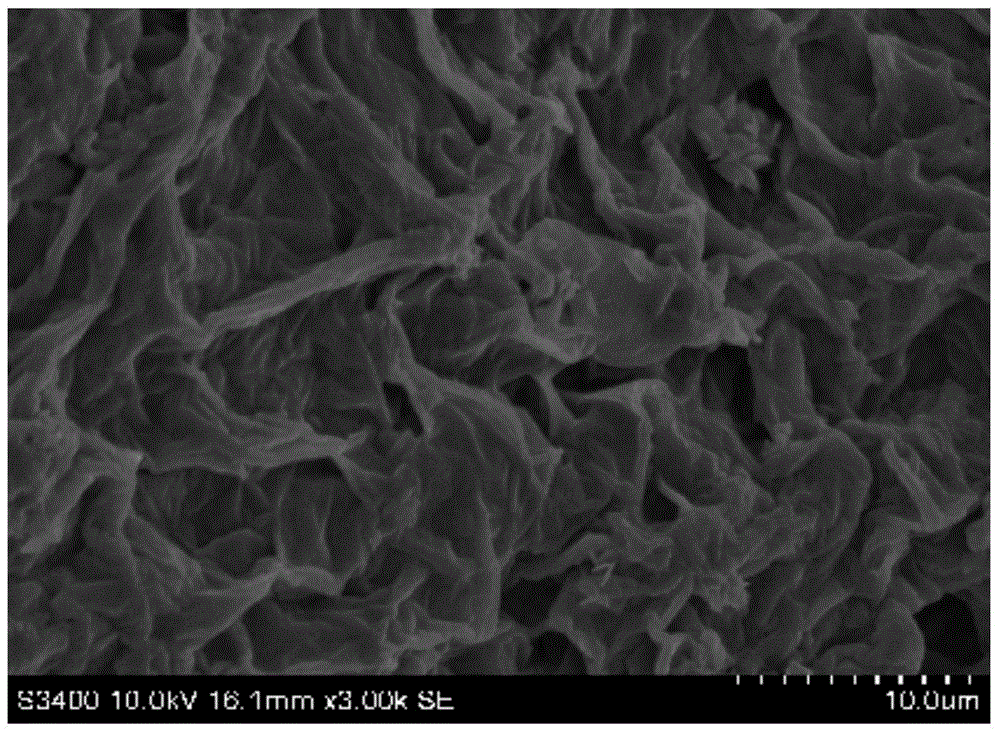

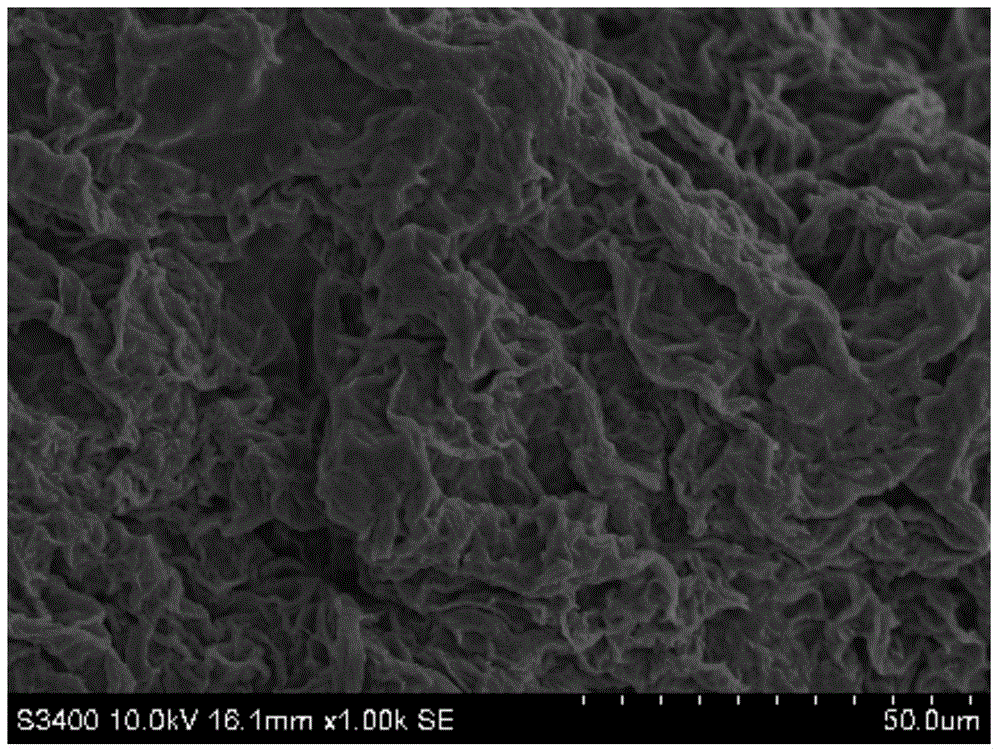

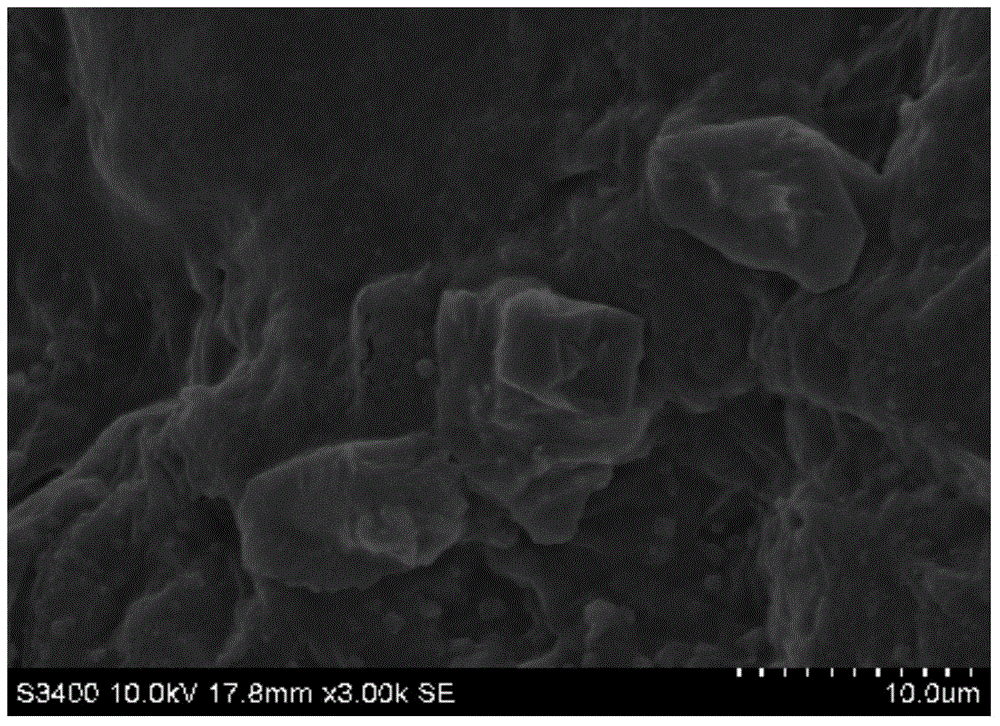

Image

Examples

Embodiment 1

[0024] The specific steps of drying and processing bamboo shoots into snack food are as follows:

[0025] (1) Pretreatment: Shell the bamboo shoots, wash them, and cut them into granules of 10×10×10 mm.

[0026] (2) Blanching: Appropriate blanching temperature and time can inactivate enzyme activity and reduce microbial content. The specific method is to blanch with 90°C water for 5 minutes, and cool and store. At this time, the initial moisture content (wet basis) of bamboo shoot particles is 92.5%.

[0027] (3) Coating film: In order to prevent the material from colliding with the wall of the dryer during spraying and causing rupture and loss, a protective film is coated on the surface of the bamboo shoot particles to prevent shattering. At the same time, seasoning is added to the protective film coating solution. The specific operation is as follows: soak the bamboo shoot particles in the coating solution for 30 minutes, take them out and drain them, so that a layer of pr...

Embodiment 2

[0030] The specific steps of drying and processing bamboo shoots into snack food are as follows:

[0031] (1) Pretreatment: Shell the bamboo shoots, wash them, and cut them into granules of 12×12×12mm.

[0032] (2) Blanching: Appropriate blanching temperature and time can inactivate enzyme activity and reduce microbial content. The specific method is to blanch with 95°C water for 4 minutes, then cool and store. At this time, the initial moisture content (wet basis) of bamboo shoot particles is 91.5%.

[0033] (3) Coating film: In order to prevent the material from colliding with the wall of the dryer during spraying and causing rupture and loss, a protective film is coated on the surface of the bamboo shoot particles to prevent shattering. At the same time, seasoning is added to the protective film coating liquid. The specific operation is as follows: soak the bamboo shoot particles in the coating solution for 35 minutes, take them out and drain them, so that a layer of prot...

Embodiment 3

[0037] The specific steps of drying and processing bamboo shoots into snack food are as follows:

[0038] (1) Pretreatment: Shell the bamboo shoots, wash them, and cut them into granules of 15×15×15mm.

[0039] (2) Blanching: Appropriate blanching temperature and time can inactivate enzyme activity and reduce microbial content. The specific method is to blanch with 100°C water for 5 minutes, and cool and store. At this time, the initial moisture content (wet basis) of bamboo shoot particles is 92%.

[0040] (3) Coating film: In order to prevent the material from colliding with the wall of the dryer during spraying and causing rupture and loss, a protective film is coated on the surface of the bamboo shoot particles to prevent shattering. At the same time, seasoning is added to the protective film coating liquid. The specific operation is as follows: soak the bamboo shoot particles in the coating solution for 30 minutes, take them out and drain them, so that a layer of protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com