An improved compact waste heat-microwave high-temperature hydrothermal uninterrupted operation device and method

A high-temperature hydrothermal and operating device technology is applied in the field of microwave application technology and waste incineration fly ash disposal. The effect of uniform radiation, compact overall structure of the device and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

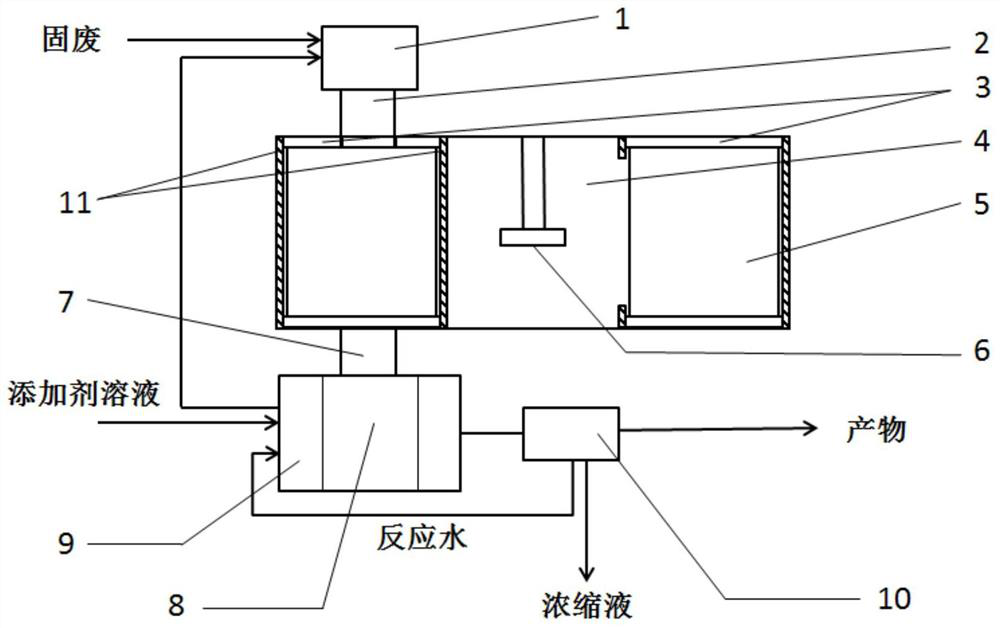

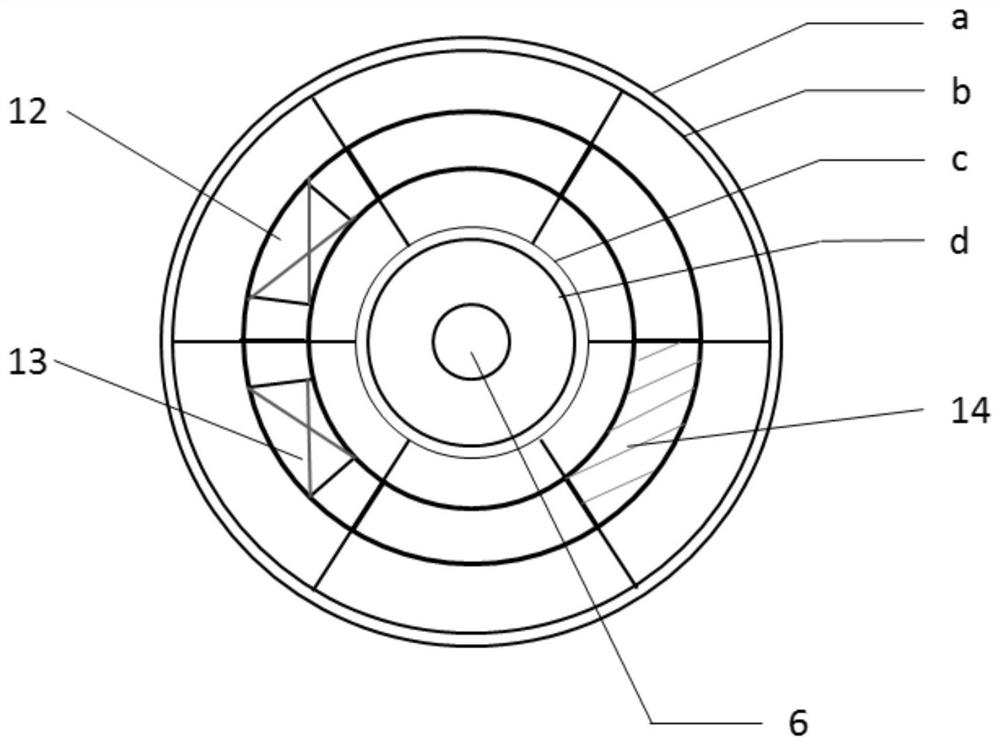

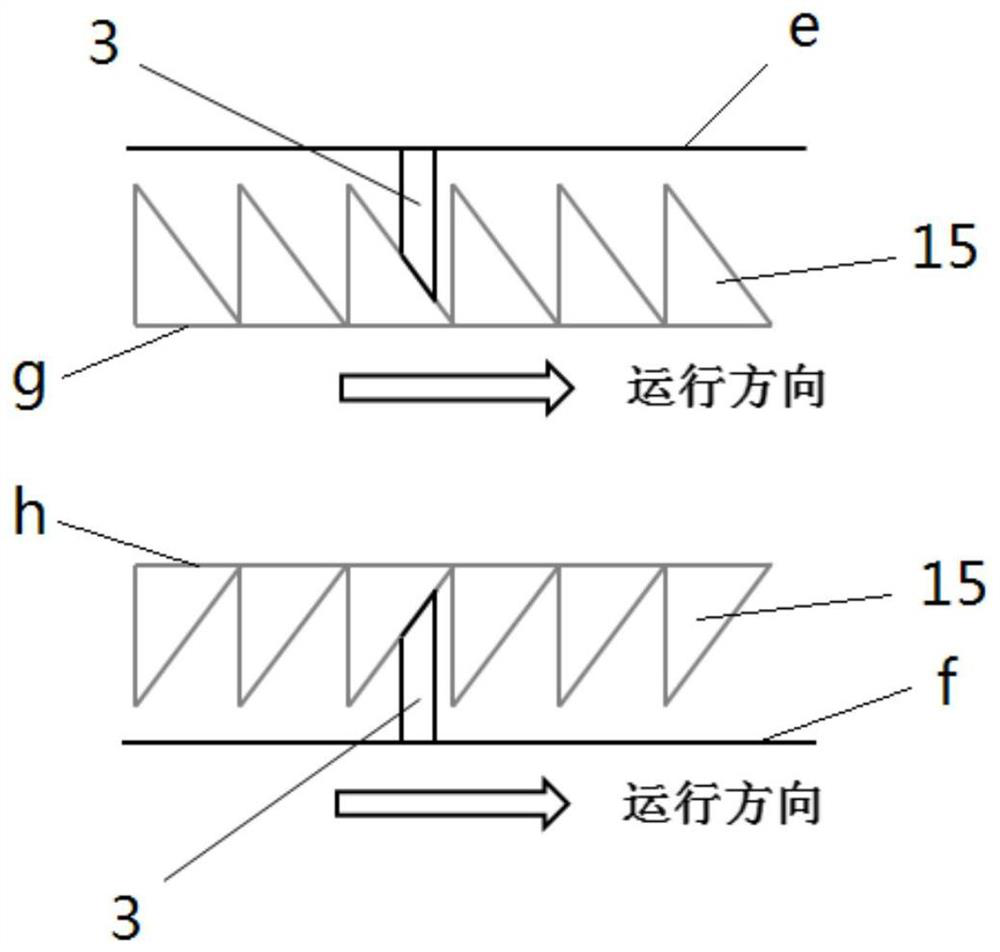

[0030] Such as figure 1 As shown, the improved compact waste heat-microwave high-temperature hydrothermal uninterrupted operation device includes an automatic sampling system 1, a microwave sealing strip 3, a microwave reaction chamber 4, a reaction vessel 5, an annular microwave transmitter 6, a sampling channel 7, and waste heat Recovery device 8 , reservoir 9 , solid-liquid separation device 10 and barrier wall 11 . Wherein the automatic sampling system 1 is provided with a solid waste automatic sampling channel and a solution automatic sampling channel 2, the outlet of the solid waste automatic sampling channel and the outlet of the solution automatic sampling channel are connected with the microwave reaction chamber 4 The sample inlet at the top is connected, and the sample outlet at the bottom of the microwave reaction chamber 4 is connected with the waste heat recovery device 8 through the sample outlet channel 7; The separation device 10 is connected; the waste heat r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com