Microwave assisted non-aqueous phase enzyme catalytic reacting device

A catalytic reaction and microwave-assisted technology, which is applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physicochemical processes using energy, etc., can solve the problems that cannot meet the fine control requirements of enzyme-catalyzed reaction temperature, etc. Realize timely display and control of temperature and even effect of microwave radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

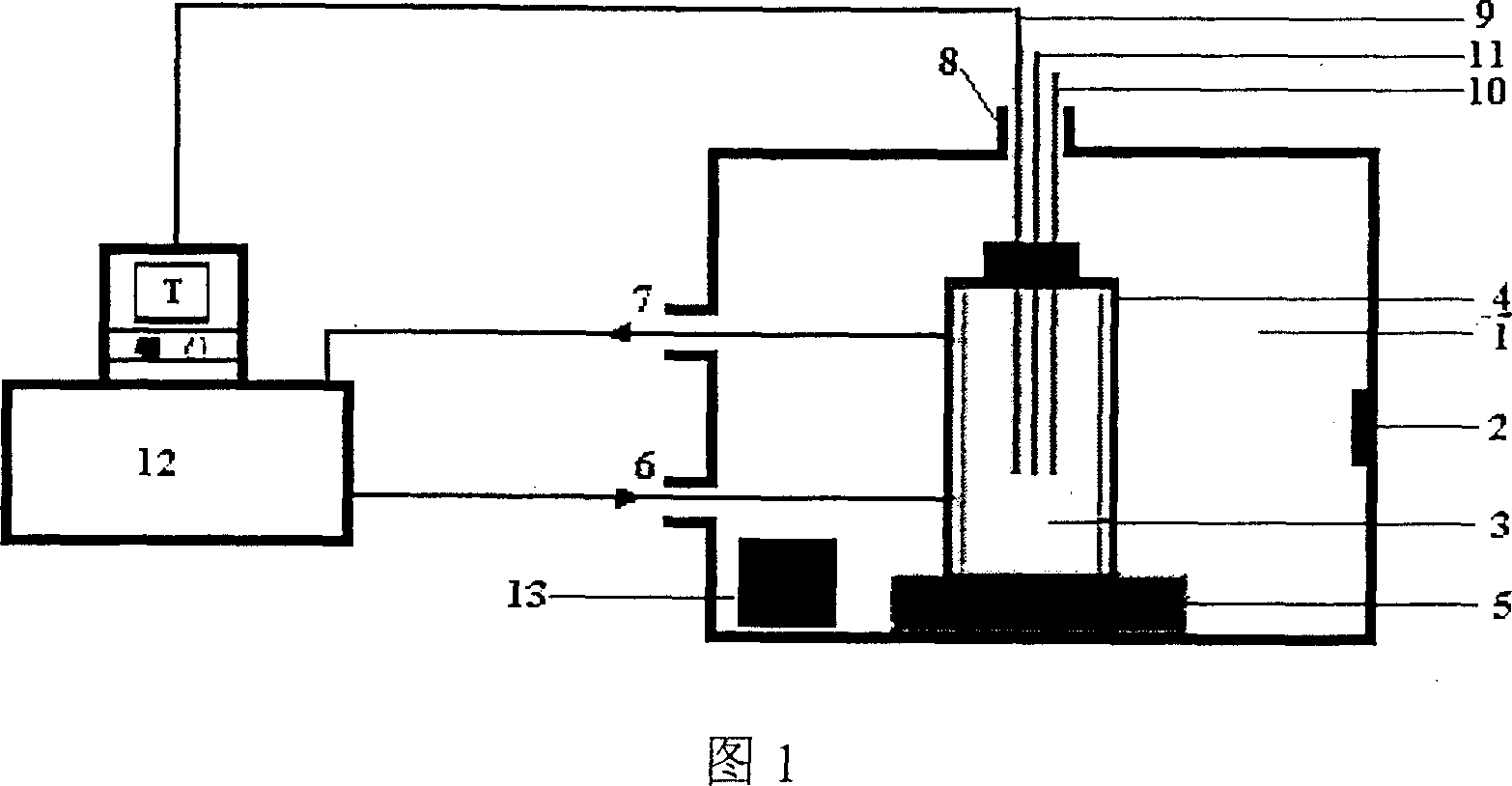

[0015] Example 1: Microwave-assisted non-aqueous enzyme catalyzed reaction device

[0016] A magnetron 2 is placed in the microwave shielding cavity 1 as an adjustable microwave emission source, and a glass reaction vessel 3 is built in the microwave shielding cavity, the reaction vessel has a jacket 4, and the reaction vessel is placed on a magnetic stirrer 5 , the magnetic stirrer is placed at the bottom of the microwave shielding cavity, and two circular holes 6 and 7 are opened on the back or side of the microwave shielding cavity as the inlet and outlet interfaces of the cooling medium. The cooling medium to be connected has a round hole on the upper part of the microwave shielding cavity, that is, the upper microwave shielding interface 8, facing the reaction vessel mouth, and a microwave shielding temperature sensor 9, an on-line sampling tube 10, a device or No gas inlet tube 11 is installed, and all openings on the microwave shielding cavity are equipped with metal sl...

Embodiment 2

[0018] Embodiment 2: microwave-assisted enzymatic synthesis of amyl octanoate

[0019] Put 3.6g of n-octanoic acid, 2.2g of n-pentanol and 0.06g of distilled water in the glass jacketed reaction vessel of the microwave reaction device, turn on the magnetic stirring to mix the reaction system evenly, set the microwave power to 200w, and set the reaction temperature to 50 ℃. Turn on the microwave reaction device, add 200 mg of immobilized lipase LRI after the reaction temperature rises to 50° C., and start timing. At different stages of the reaction, samples are taken from the sampling port of the device to measure the initial velocity of the reaction. The initial velocity of the microwave-assisted non-aqueous enzyme-catalyzed reaction was 4.2mmol / min·g; while other reaction conditions were the same, the initial velocity of the reaction in the conventional heating mode was only 1.8mmol / min·g. Microwave radiation significantly increased the initial velocity of the reaction.

Embodiment 3

[0020] Embodiment 3: microwave-assisted enzymatic synthesis of butyl octanoate

[0021] Add 1.44g n-octanoic acid, 0.74g n-butanol, 0.02g distilled water and 15mL tetrahydrofuran solvent into the glass jacketed reaction vessel of the microwave reaction device, turn on the magnetic stirring to mix the reaction system evenly, set the microwave power to 400w, and set the reaction The temperature was 55°C. Turn on the microwave reaction device, add 100 mg of immobilized lipase LRI after the reaction temperature rises to 55° C., and start timing. At different stages of the reaction, samples are taken from the sampling port of the device to measure the initial velocity of the reaction. The initial velocity of the microwave-assisted non-aqueous enzyme-catalyzed reaction was 0.76mmol / min·g; while other reaction conditions were the same, the initial velocity of the reaction in the conventional heating mode was only 0.25mmol / min·g. Microwave radiation significantly increased the initi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com