Patents

Literature

41results about How to "Achieve non-stop operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

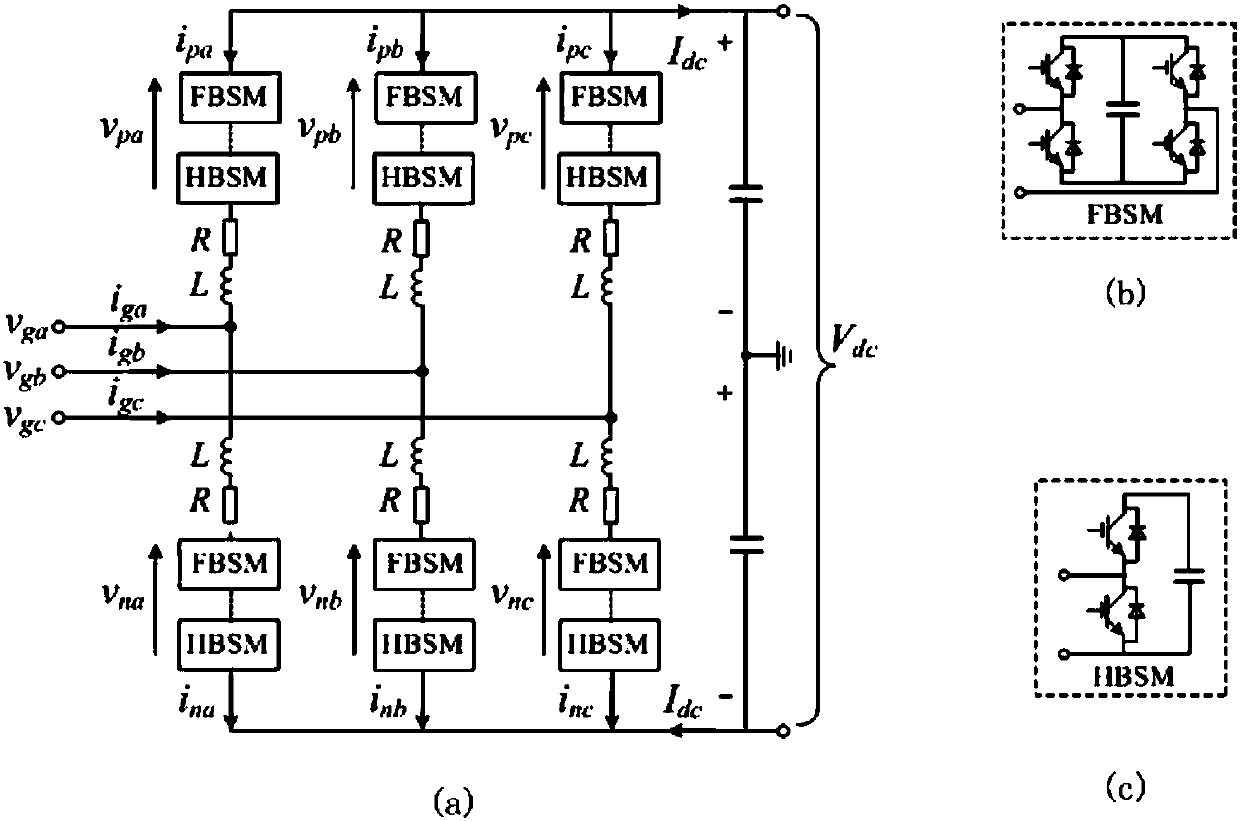

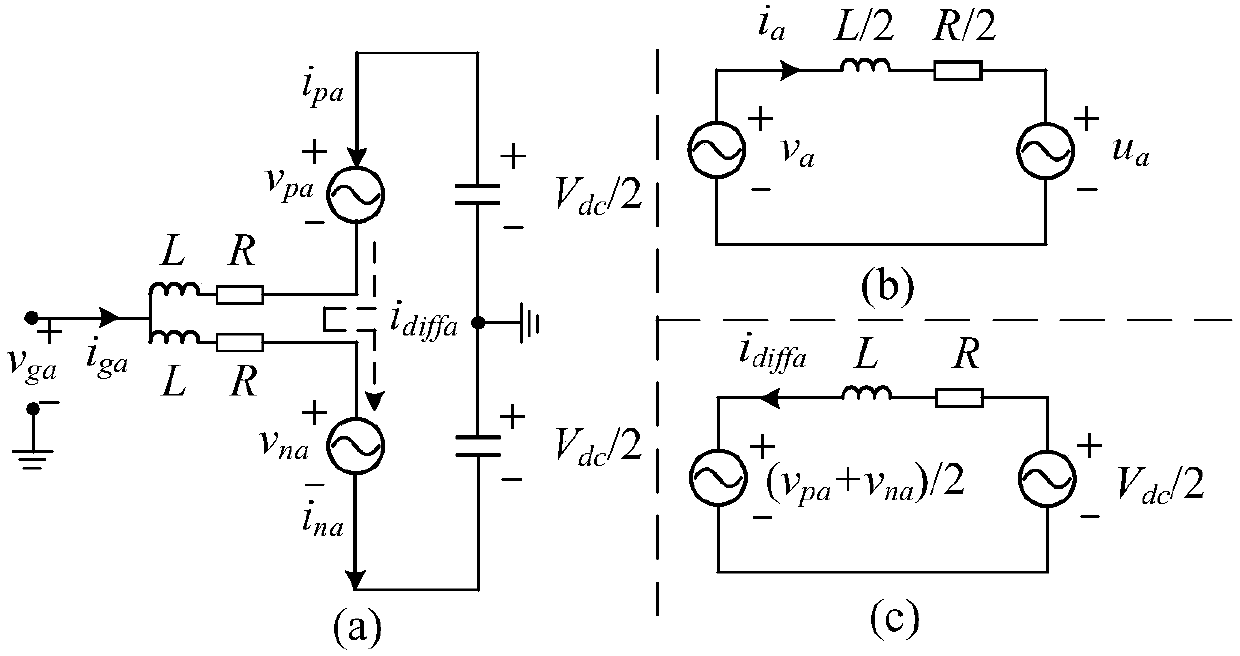

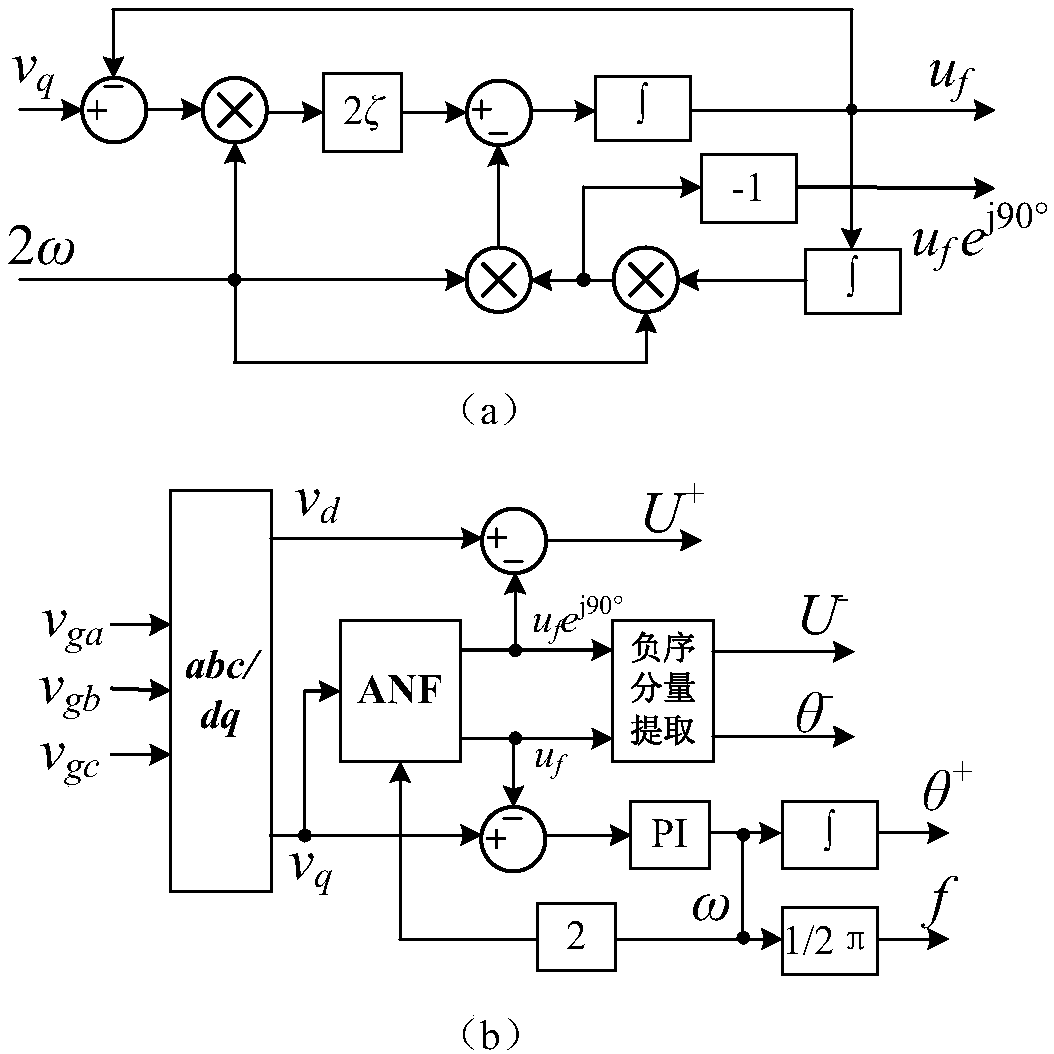

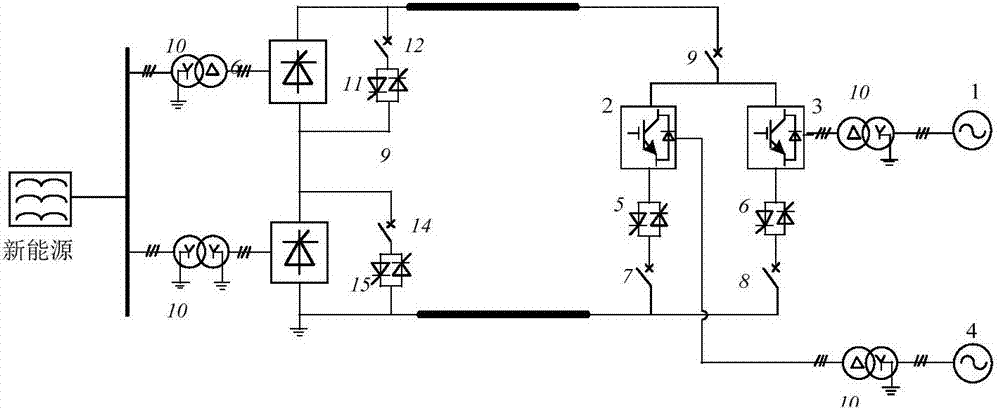

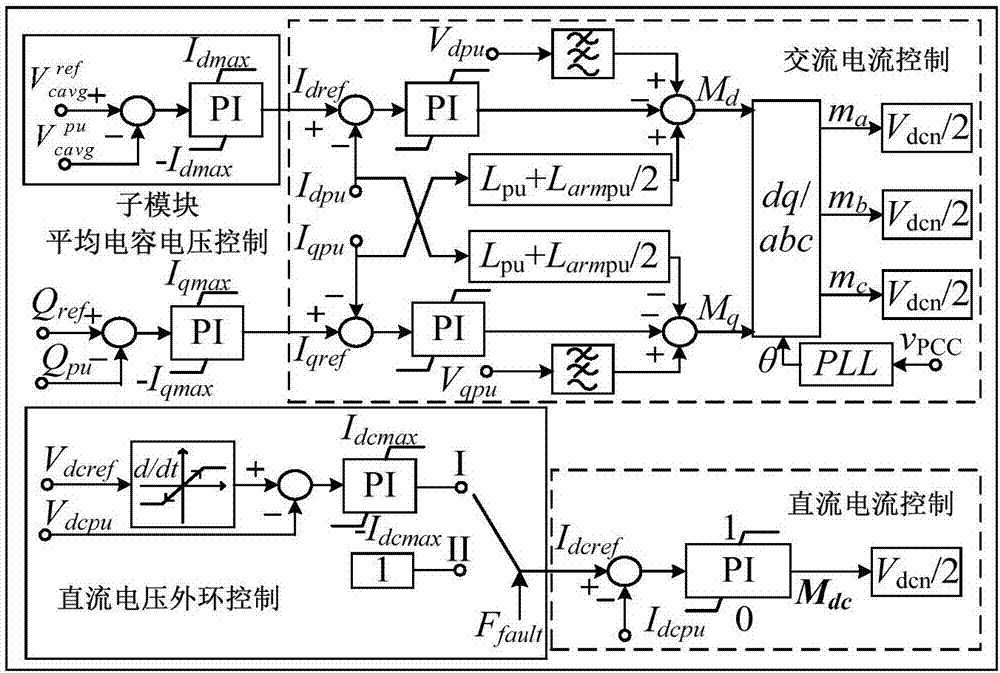

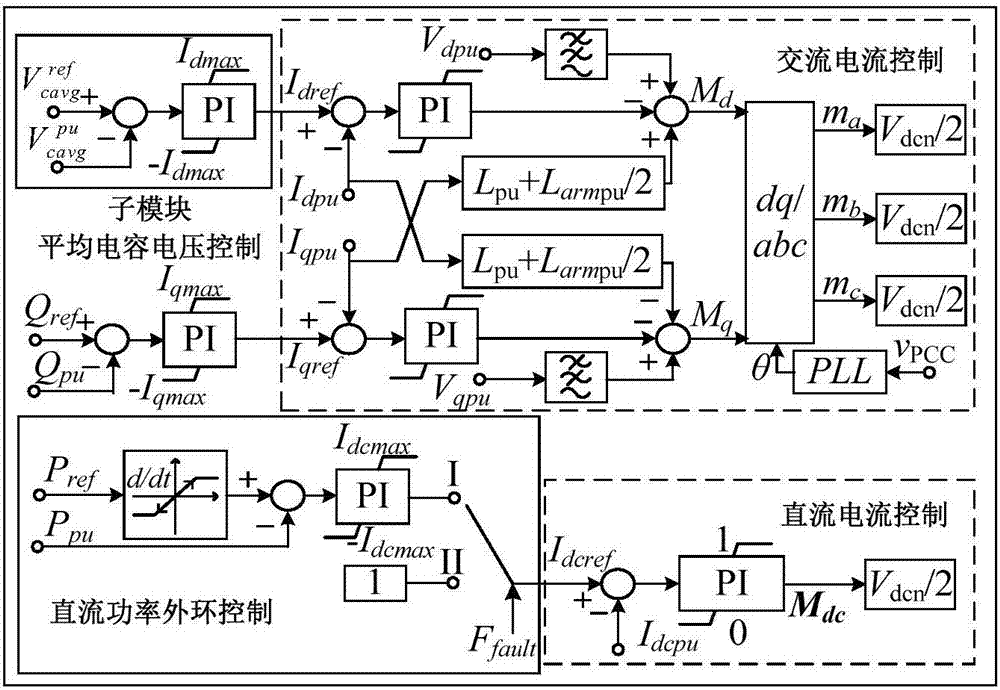

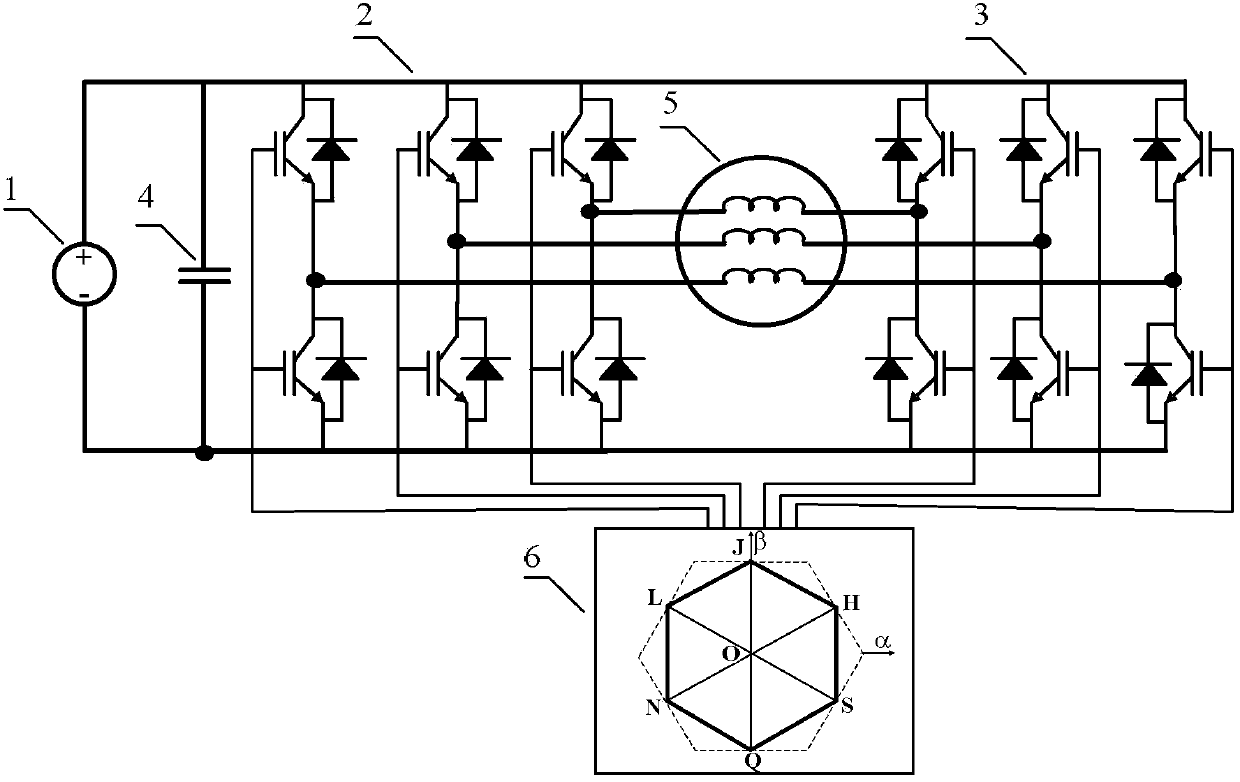

Control method and control system for hybrid MMC uninterrupted operation

ActiveCN107834830AAvoid overvoltage and overcurrentAchieve non-stop operationAc-dc conversionPolyphase network asymmetry elimination/reductionDc currentControl system

The invention discloses a control method and a control system for hybrid MMC uninterrupted operation. The control method comprises the following steps: acquiring the alternating current output voltagereference values of each phase of upper and lower bridge arms, acquiring a direct current voltage reference value, acquiring the negative sequence frequency-doubled circulating current restraint reference voltage of each phase of upper and lower bridge arms, acquiring the zero sequence circulating current compensating potential reference value, and generating a driving signal. The control systemcomprises an alternating current control device, a direct current control device, a negative sequence circulating current restraint control device and a driving signal synthesis device which are usedfor acquiring the alternating current output voltage reference values of each phase of upper and lower bridge arms, the direct current voltage reference value, the negative sequence frequency-doubledcirculating current restraint reference voltage of each phase of upper and lower bridge arms, the zero sequence circulating current compensating potential reference value and the driving signal. Alternating current positive and negative sequence current can be uniformly controlled, alternating current negative sequence current and bridge arm zero sequence ring current are restricted, direct current side current is controlled, and uninterrupted operation is finally realized.

Owner:HUAZHONG UNIV OF SCI & TECH +1

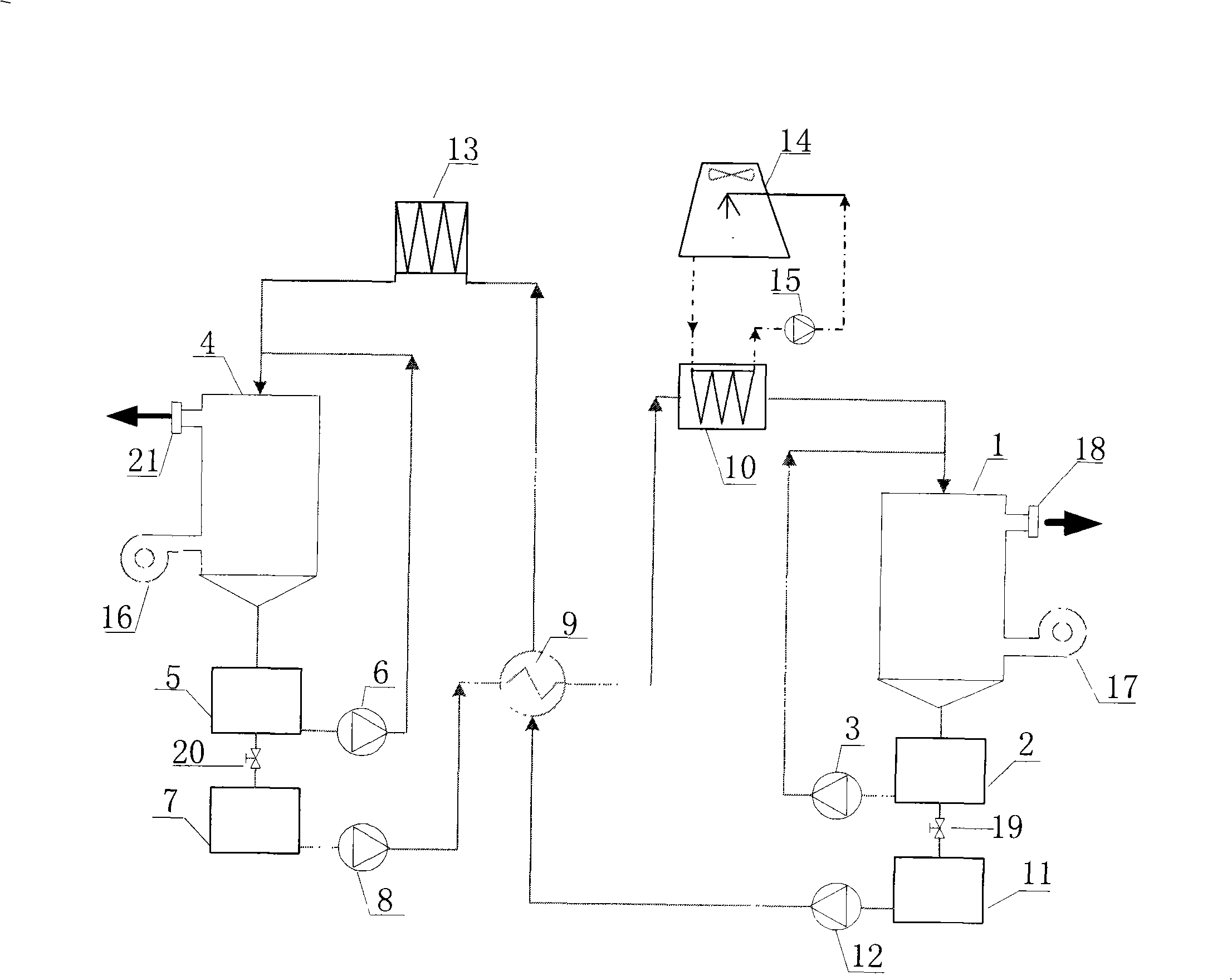

Solution dehumidification device driven by low-temperature smoke gas

InactiveCN101537303AAddress underutilizationSave waterDispersed particle separationCooling towerMoisture absorption

The invention discloses a solution dehumidification device driven by low-temperature smoke gas, comprising a solution dehumidifier, a solution regenerator, a flue heater, a heat exchanger, a solution cooler, a concentrated solution trough, a diluted solution trough, a cooling tower, a water pump, a fan, a concentrated solution internal circulation pump, a concentrated solution external circulation pump, a diluted solution internal circulation pump, a diluted solution external circulation pump, a valve, an air inlet and an air outlet. The device takes a moisture-absorption solution as a dehumidizer to remove the water in the air; and the dehumidified air can be used for industrial combustion or used as the new air of an air conditioning system; and the device utilizes the low-temperature smoke gas exhausted by an industrial furnace as the heat source of the solution regenerator and drives the whole device to run by heating the solution with the flue heater. The device has the advantages of recovering the residual heat of the low-temperature smoke gas, saving energy resource, having high heat recovery rate and strong dehumidification capability, and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

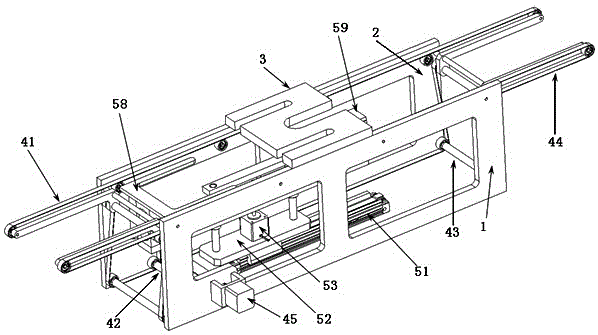

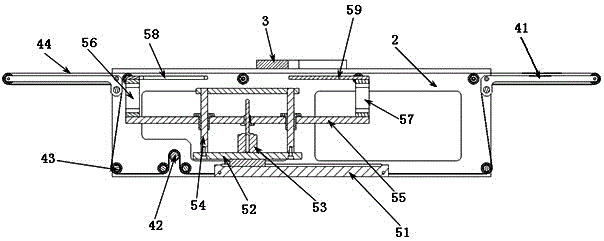

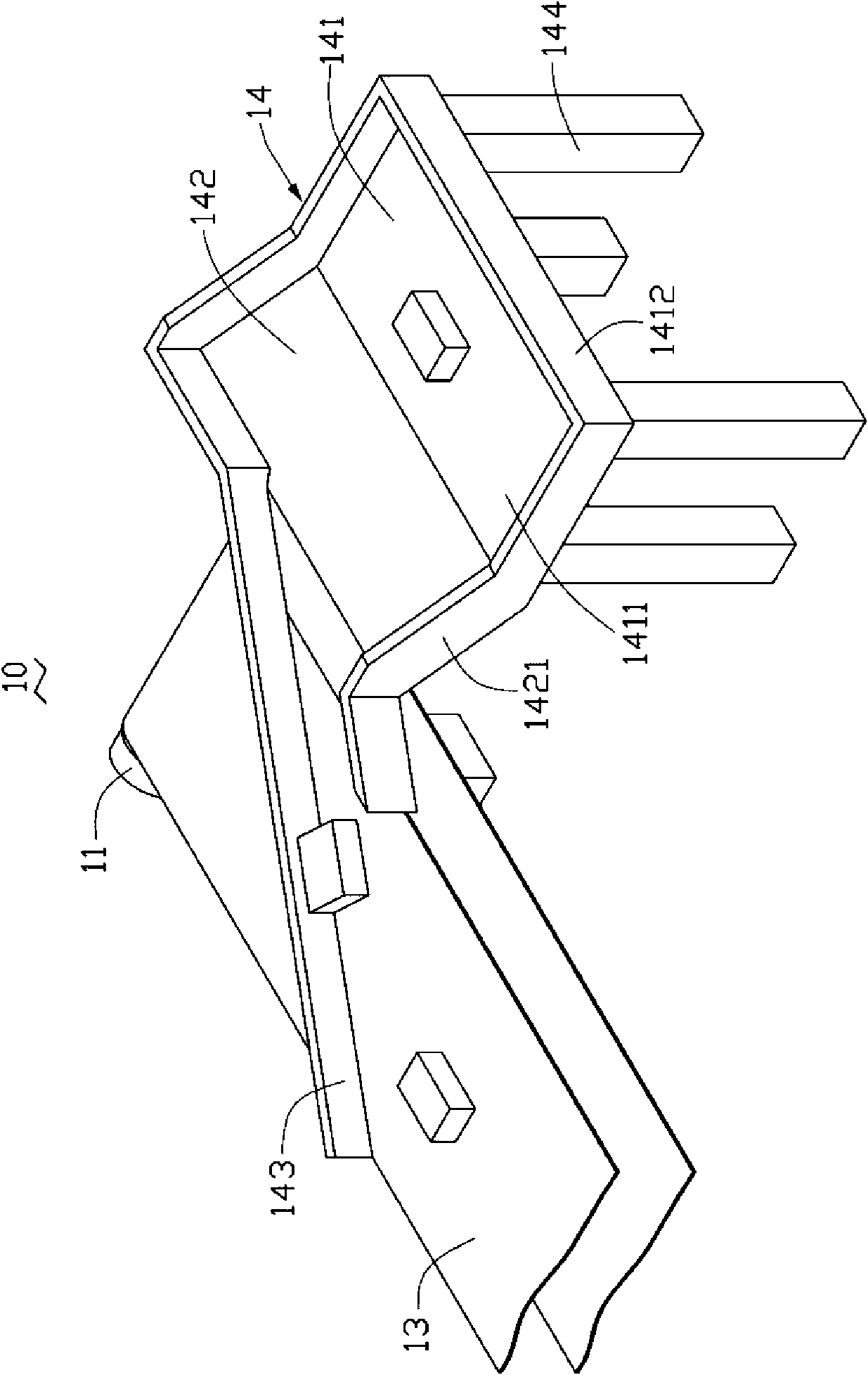

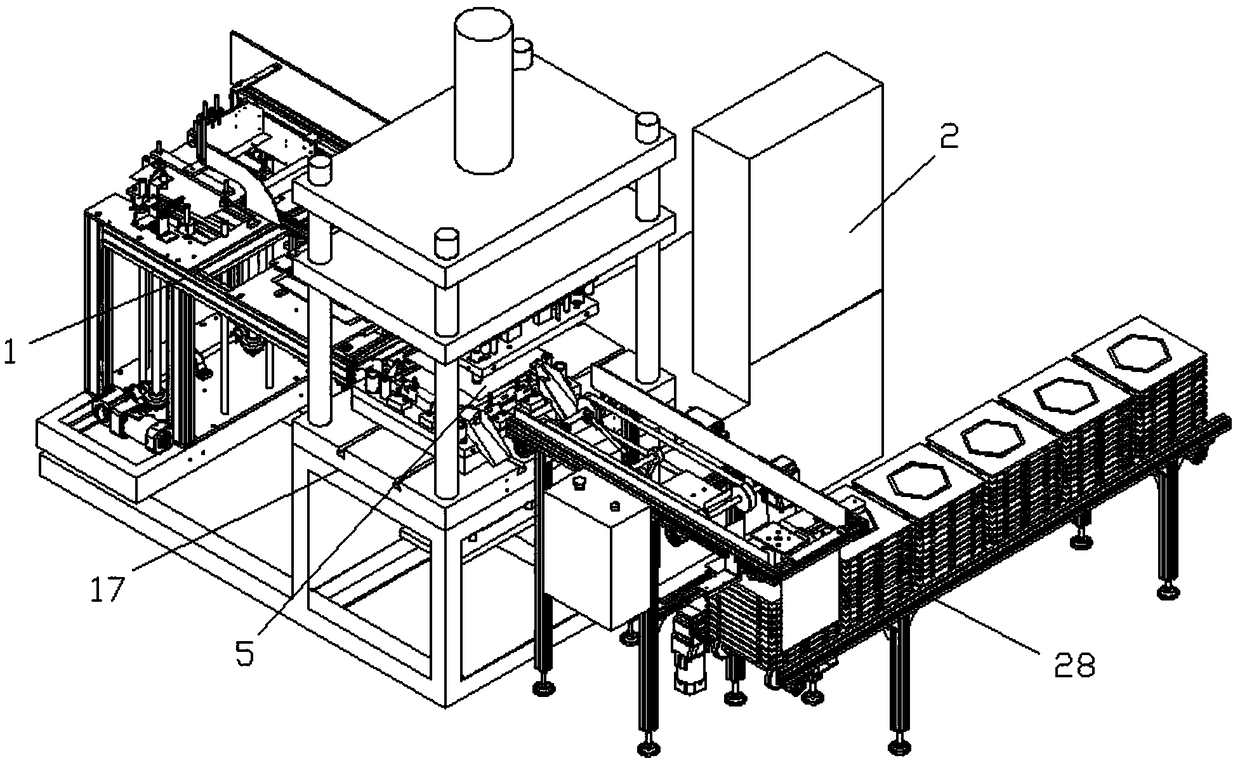

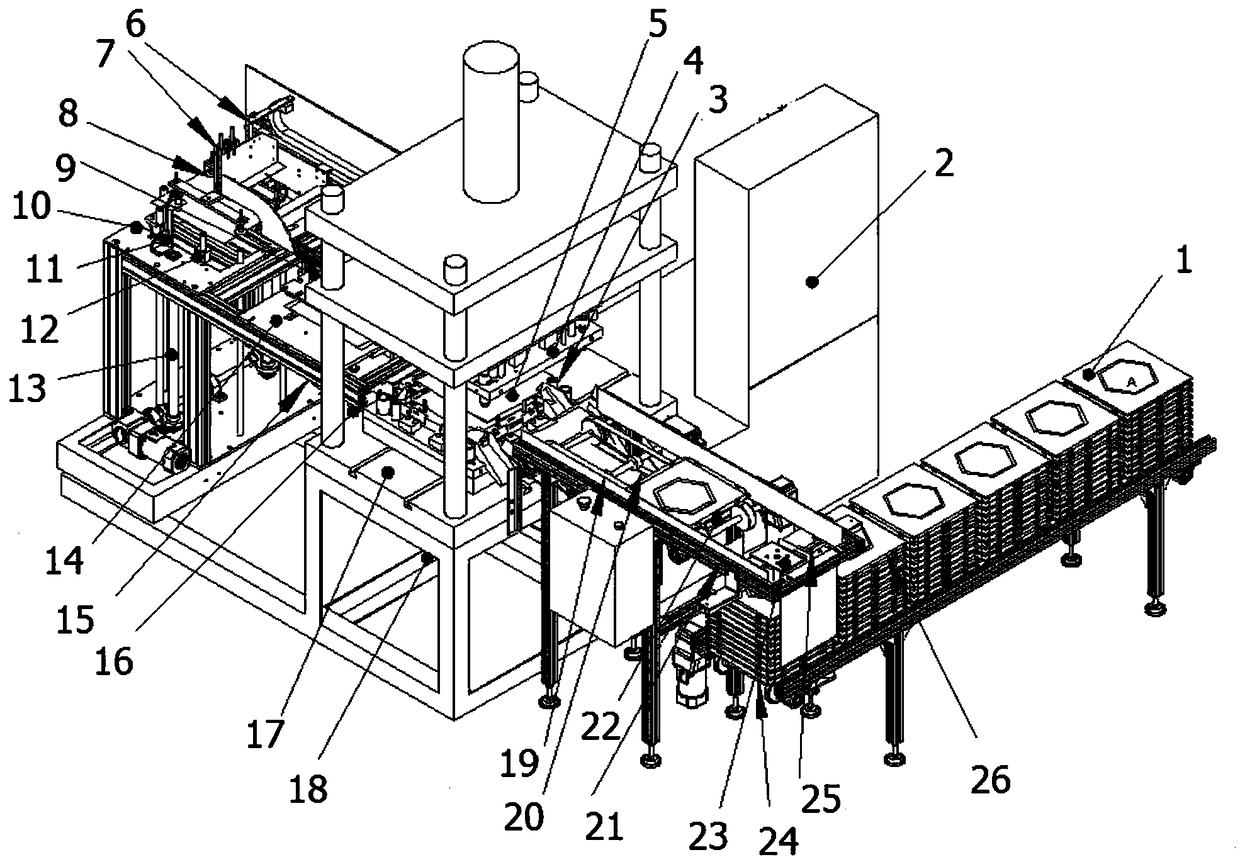

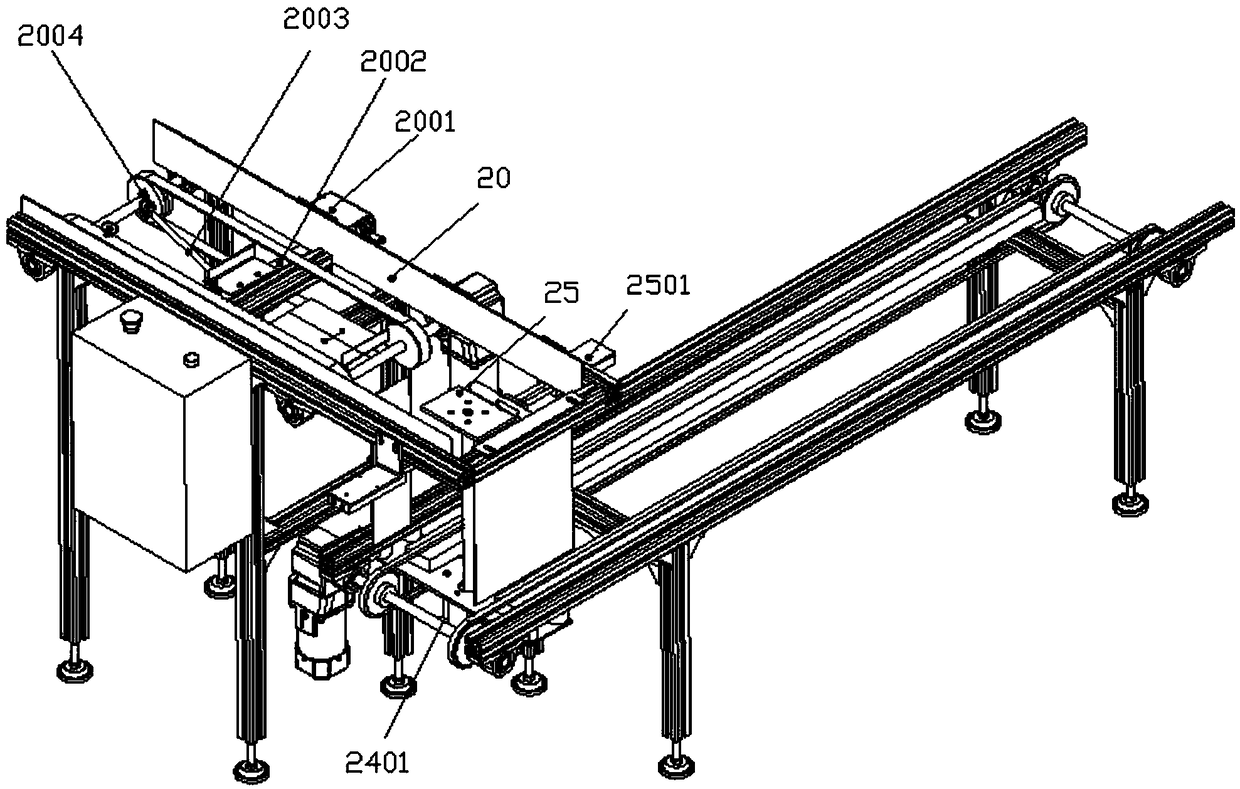

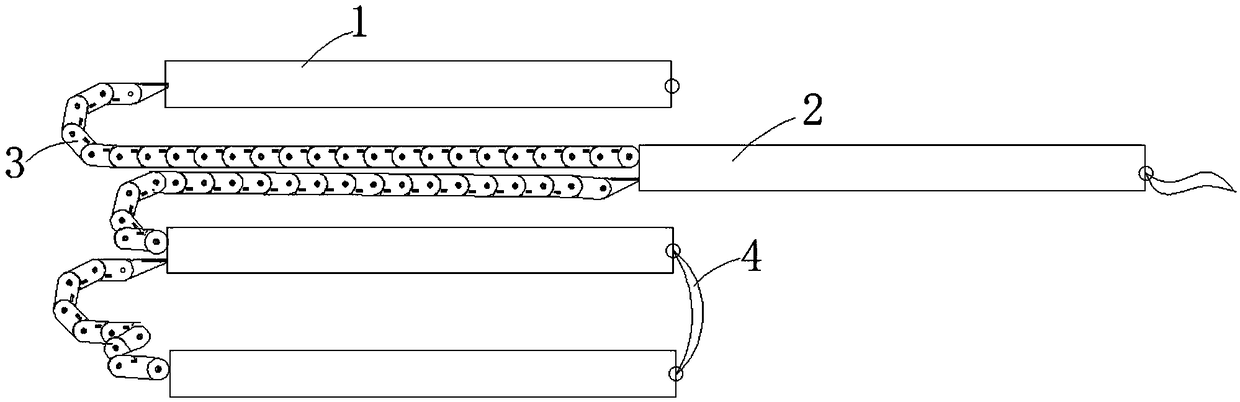

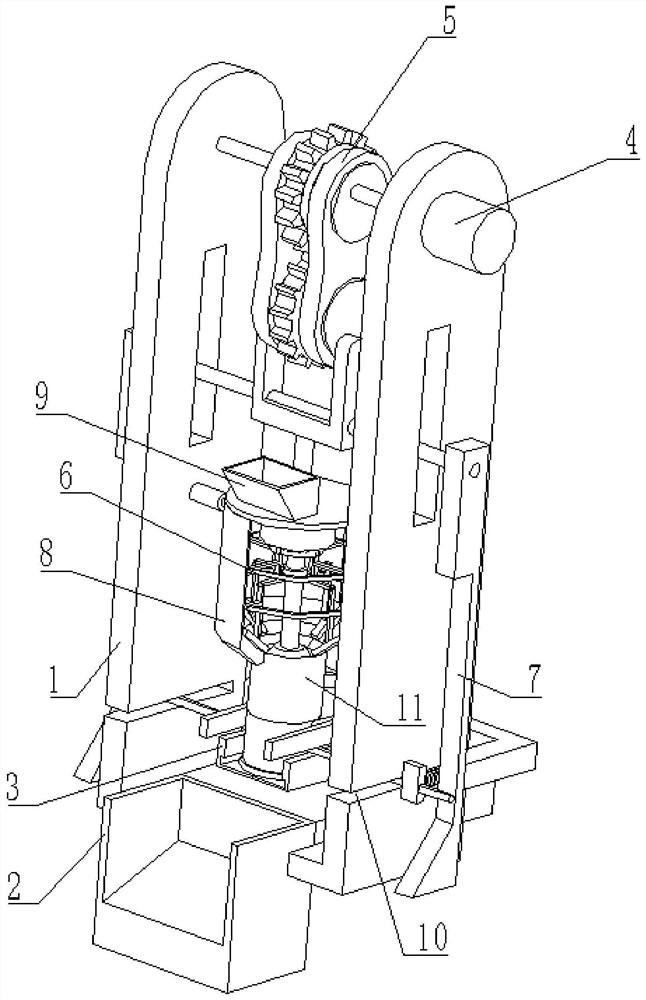

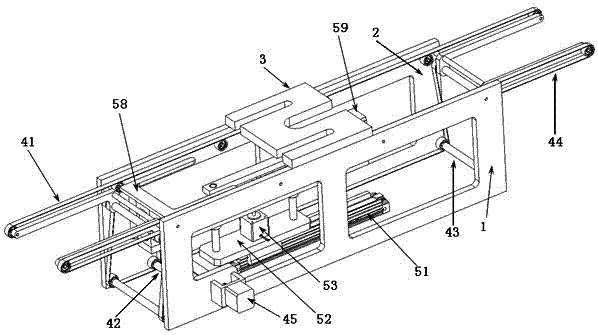

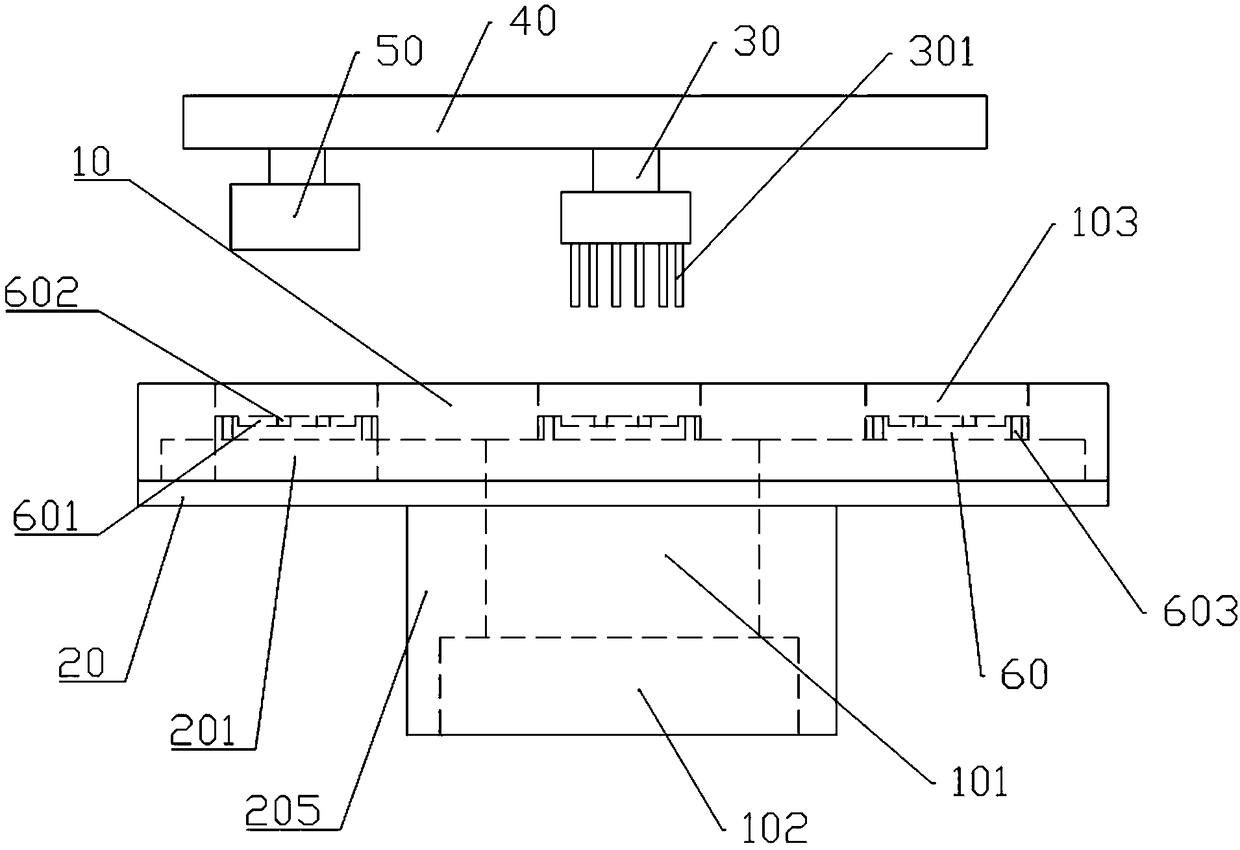

Fully-automatic loading and unloading device used in processing semiconductor chips by laser and application method thereof

ActiveCN102723302AEasy to operateImprove efficiencyLaser beam welding apparatusConveyor partsLaser processingSemiconductor chip

The invention discloses a fully-automatic loading and unloading device used in processing semiconductor chips by laser and an application method thereof. The fully-automatic loading and unloading device used in processing semiconductor chips by laser comprises a support frame, a laser processing platform, a chip transmission mechanism, and a linkage loading and unloading mechanism, wherein the laser processing platform is arranged on the top end of the support frame, the chip transmission mechanism is arranged on the support frame and located below the laser processing platform, and the linkage loading and unloading mechanism is arranged in the support frame and located below the chip transmission mechanism. The fully-automatic loading and unloading device of the invention has the advantages that human operation is not needed in loading and unloading processes and the loading and unloading processes are performed simultaneously, which improves production efficiency and rate of finished products, avoids pollution to the chips caused by direct contact of workers with the chips, improves the quality of the products, realizes seamless linkage between the current working procedure and the previous and the next working procedures at the same time, and omits a step of workpiece transportation by human labor between two working procedures.

Owner:HEFEI ZHICHANG PHOTOELECTRIC TECH

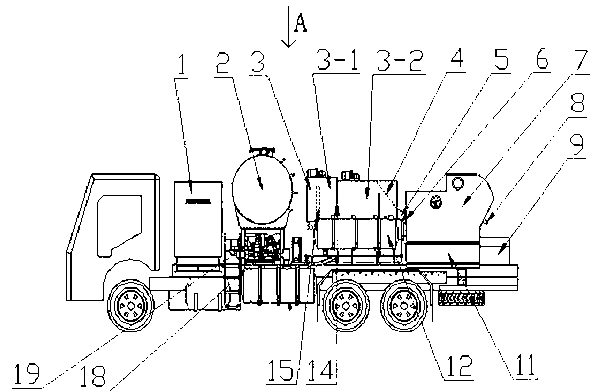

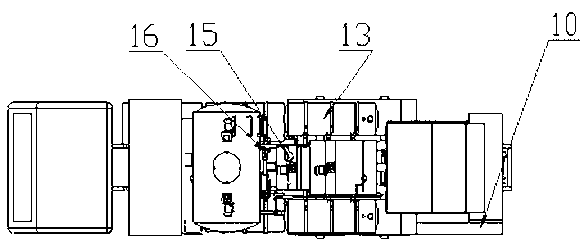

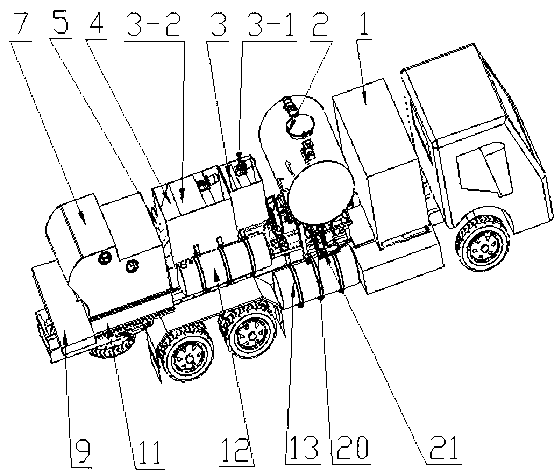

All-digital intelligent mobile septic tank sewage disposal device

InactiveCN103183461AStir wellFully integratedSludge treatment by de-watering/drying/thickeningItem transportation vehiclesElectrical controlSewage treatment

The invention discloses an all-digital intelligent mobile septic tank sewage disposal device. The all-digital intelligent mobile septic tank sewage disposal device comprises an electrical control system, a stirring box, a flocculant tank, a sewage suction pipe and the like, and is characterized in that a cam pump is arranged on the sewage suction pipe, an outlet of the cam pump is communicated with the stirring box through a pipeline, the sewage suction pipe communicated with an inlet of the cam pump is communicated with the flocculant tank through the pipeline, the all-digital intelligent mobile septic tank sewage disposal device is provided with a squeezer and a conveyor, which are sequentially connected with the stirring box, a sewage discharge port of the stirring box is connected with a feed port of the squeezer through the pipeline, and a discharge port of the squeezer is connected with the conveyor. The all-digital intelligent mobile septic tank sewage disposal device disclosed by the invention can realize full-automatic operation and management through the electrical control system, has a plurality of advantages of simple structure, convenience in movement, low energy consumption, no pollution during the disposal process, short disposal time, great disposal capacity and the like, can solve the technical difficult problems of dehydration, deodorization and sterilization of sewage in a septic tank, as well as incapability of utilizing the sewage and further has very extensive practicality.

Owner:杨渊博

Cascade converter valve, DC power transmission system and control method thereof

ActiveCN107968588ARealize asynchronous interconnectionAvoid Power ImbalancesElectric power transfer ac networkDc-ac conversion without reversalHybrid typeTransformer

The invention discloses a cascade converter valve, a DC power transmission system and a control method thereof. The cascade converter valve is provided with a high voltage valve group and a low voltage valve group which are connected in series in the DC side. The high voltage valve group is a first converter. The low voltage valve group comprises a second converter and a third converter which areconnected in parallel. At least one of the converters is a hybrid multilevel output converter. The AC side of the first converter and the AC side of the third converter are connected in parallel through a transformer to form the first AC end of the cascade converter valve. The AC side of the second converter forms the second AC end of the cascade converter valve. The cascade converter valve has multiple working modes and AC system access modes, high-voltage, high-capacity and long-distance DC power transmission and receiving AC network hierarchical access and asynchronous partition interconnection can be simultaneously realized under the premise of reducing the total manufacturing cost and area occupation of the DC system and thus the system stability and reliability can be enhanced. The cascade converter valve is suitable for the electric power system of multiple DC feed-in points.

Owner:HUAZHONG UNIV OF SCI & TECH +1

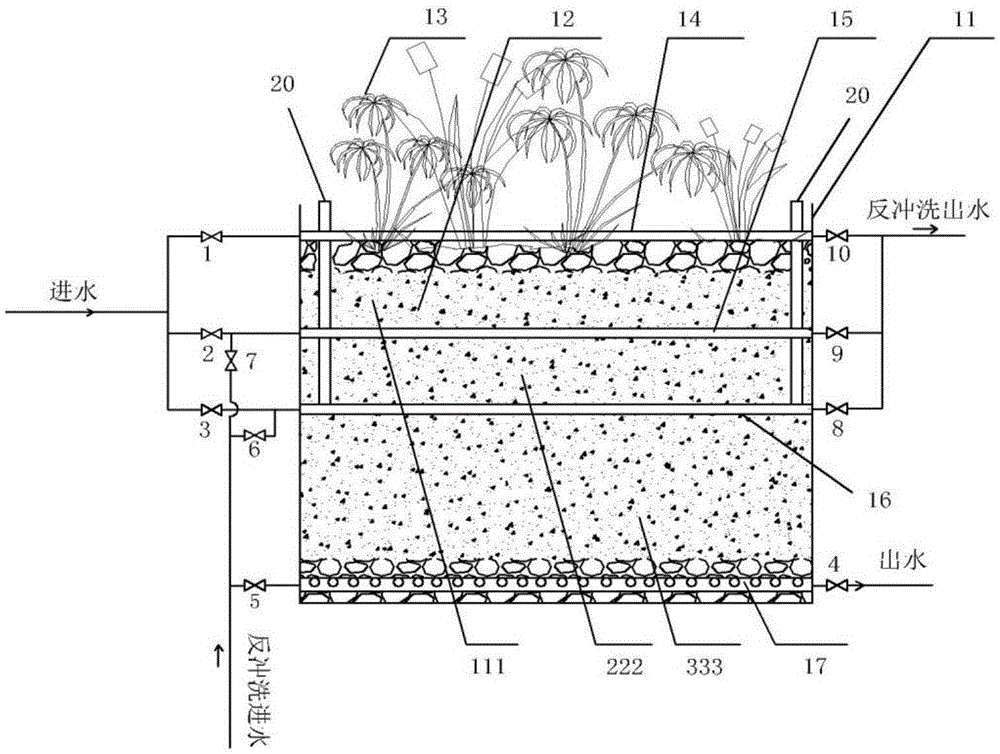

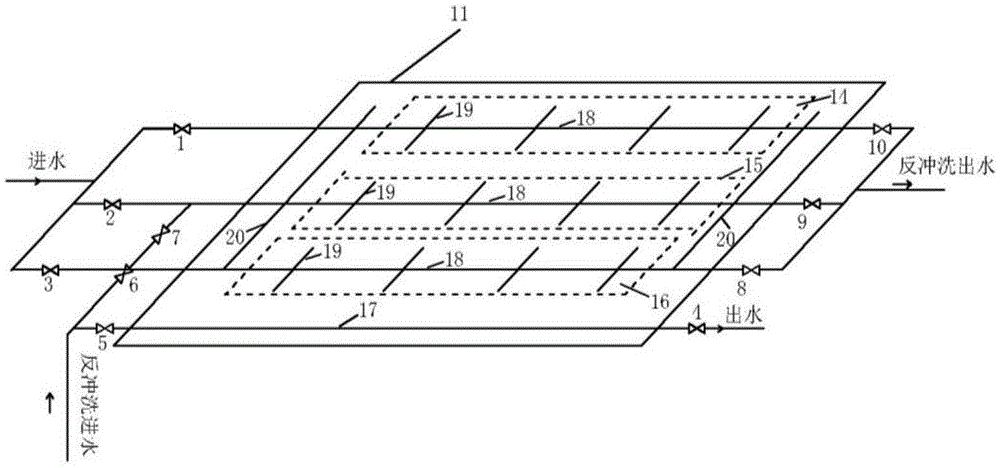

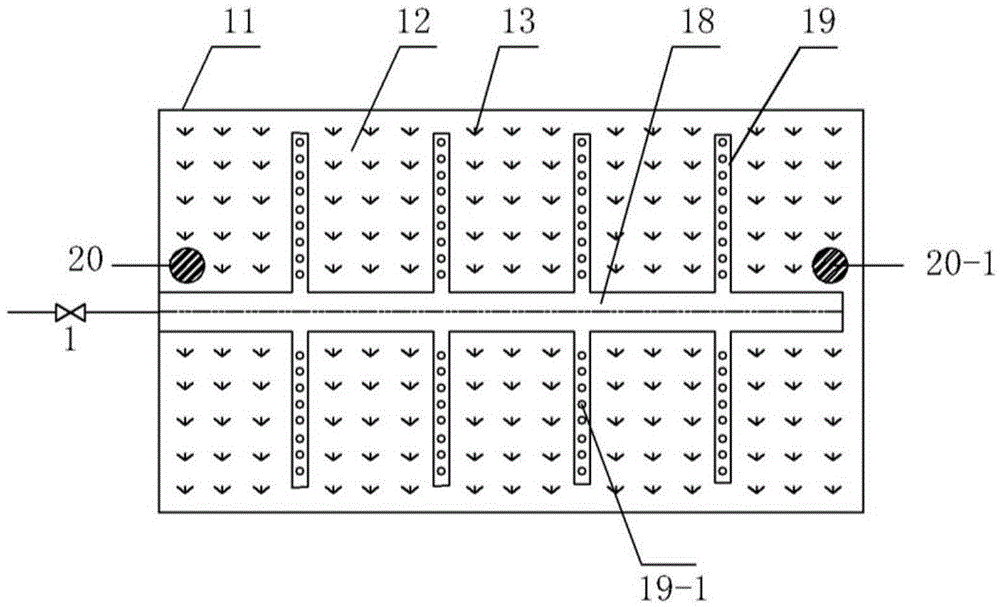

Anti-blocking water distribution and back-flushing method and device for constructed wetland

ActiveCN105600938AAlleviate concentrated blockageExtended service lifeSpecific water treatment objectivesSustainable biological treatmentFlushing timeConstructed wetland

The invention discloses an anti-blocking water distribution and back-flushing method and device for a constructed wetland. Water distribution pipes are arranged in layers on the surface layer of the constructed wetland and inside filler and connected with an incoming water source through valves respectively; the water distribution pipe in the filler is connected with an air pipe through an intermediate pipe; and the top of the air pipe is communicated with the atmosphere. When the device runs in the wetland, constant water distribution is realized layer by layer from top to bottom by controlling the on / off of the valves, and the yielding water is collected and discharged by a water-out pipe at the bottom of the wetland; and in back flushing, the water-out and distribution pipes are used as back-flushing layered water feed and collection pipes. The parameters such as back-flushing strength and back-flushing time are set according to the actual blocking degree of each layer of the wetland, and the back-flushing water is discharged nearby; the phenomenon that the filler close to the water distribution positions is easily blocked together in the constructed wetland can be effectively solved, the filler of each layer is fully utilized, and the service life is prolonged; due to the back-flushing way, the back-flushing efficiency is improved, the distribution of back-flushing water is optimized, and the operation is simple; and since an additional back-flushing pipe is not needed, the cost is lowered.

Owner:INST OF AQUATIC LIFE ACAD SINICA

Conveyor device

InactiveCN101652058AAchieve non-stop operationReduce installationElectrical componentsConveyor partsEngineeringConveyor belt

The invention provides a conveyor device, comprising a conveyor belt and a wind-up device. The wind-up device comprises a storage area and a baffle, the baffle is arranged at the position corresponding to the storage area above the conveyor belt and used for leading conveying objects into the storage area.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

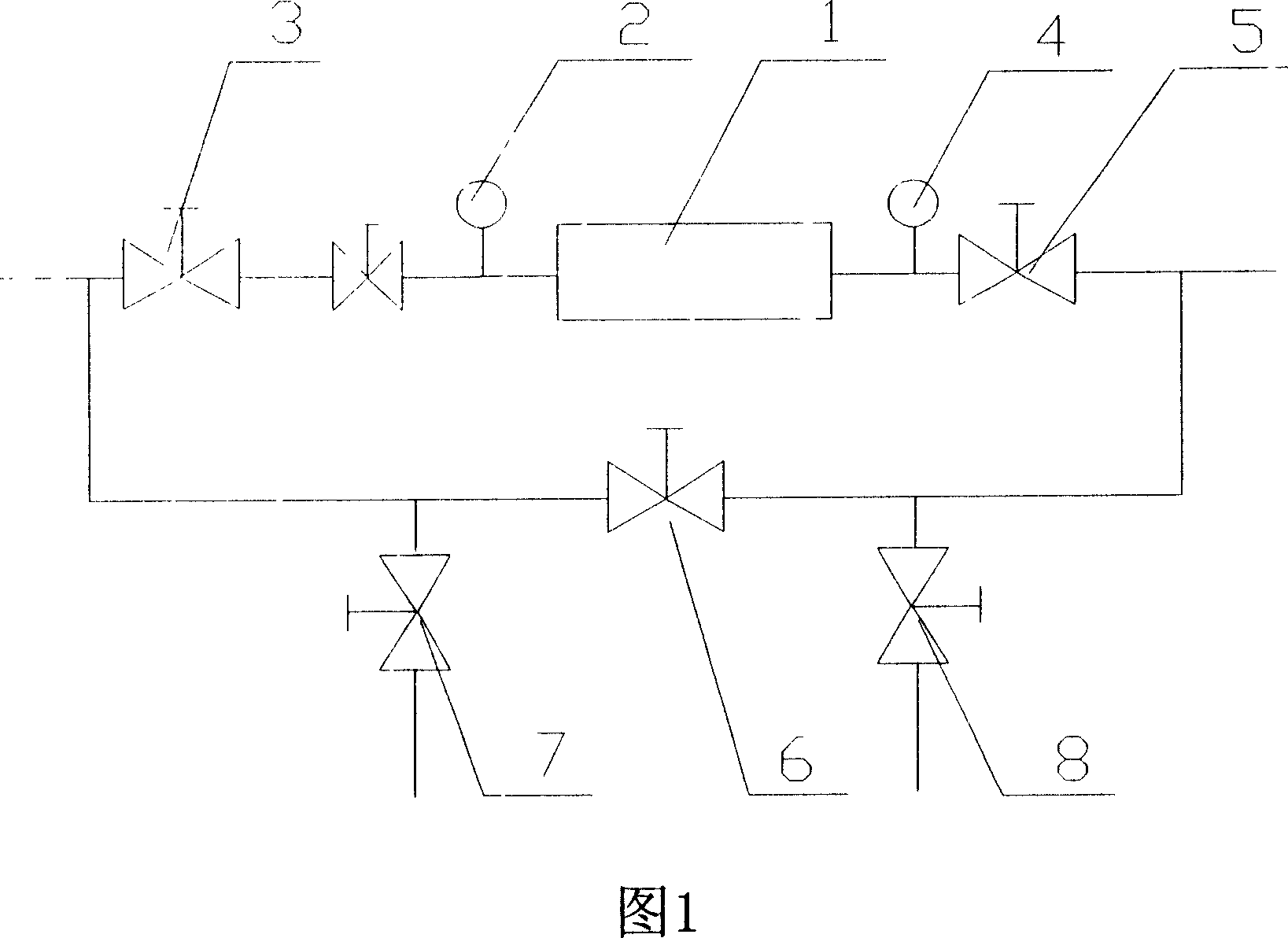

Secondary filter for water-cooling system of proton equipment

An accurate filter unit for the cooling system of proton apparatus is composed of accurate filter, front and back valves, pressure meter before filter, pressure meter after filter, by-pass valve for ensuring normal running even if the accurate filter is damaged or blocked, detecting valve and discharging valve.

Owner:吕迎智 +1

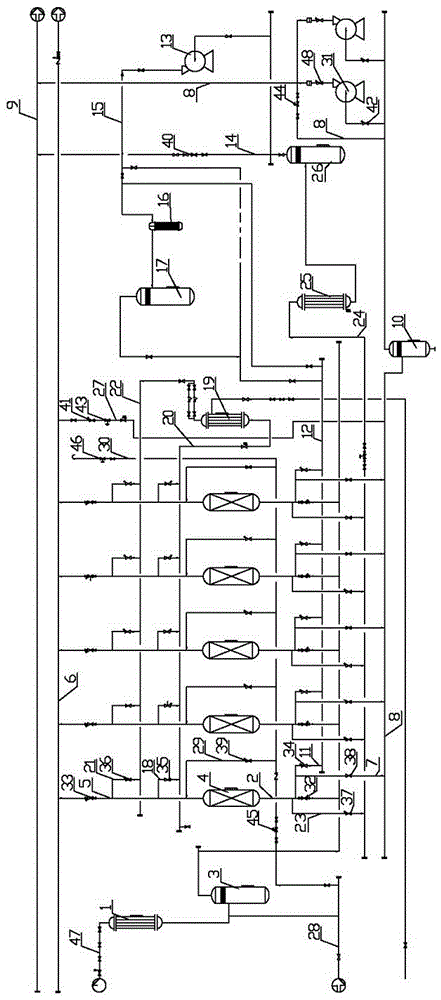

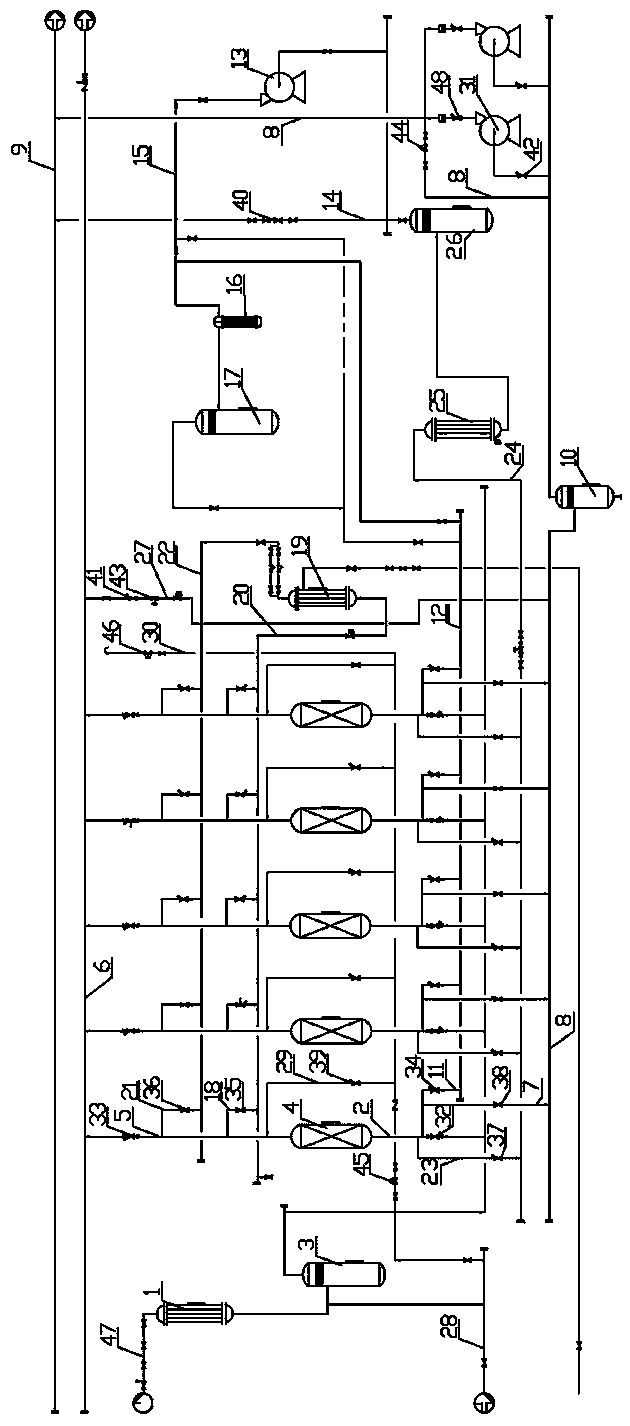

Deep dewatering device for organic gas and chloroethylene and nitrogen regenerating methods utilizing same

ActiveCN106582218AAvoid problems such as cumulative quality degradationImprove product qualityGas treatmentChemical industryDecompositionPolyvinyl chloride

The invention relates to the technical field of chloroethylene monomer drying and provides a deep dewatering device for organic gas and chloroethylene and nitrogen regenerating methods utilizing the same. The deep dewatering device comprises a feed gas cooler, a VCM steam-water separator, at least three VCM dry adsorption towers, a de-rectification header pipe, a depressurization pipe, a gasometer header pipe, a before-machine steam-water separator, gas regeneration header pipe, a compressor, an behind-machine demister, an behind-machine steam-water separator, a steam heater, before-machine cooler and a before-machine demister. According to the chloroethylene and nitrogen regenerating methods utilizing the deep dewatering device for the organic gas, the problems that meta-acid of a rectification system and accumulated quality declining of vinyl chloride monomers are caused by feed gas chloroethylene decomposition under the high temperature are avoided. The water content of the vinyl chloride monomers produced through a treatment calcium carbide method can be controlled below 150 mg / Kg. Therefore, by adoption of the deep dewatering device for the organic gas and the chloroethylene and nitrogen regenerating methods utilizing the same, the polyvinyl chloride product quality can be effectively improved, and the deep dewatering device for the organic gas and the chloroethylene and nitrogen regenerating methods utilizing the same particularly play an important role in product upgrading and high-quality resin producing; and meanwhile, energy can be effectively saved, energy consumption can be effectively lowered, and continuous operation can be achieved.

Owner:新疆圣雄氯碱有限公司

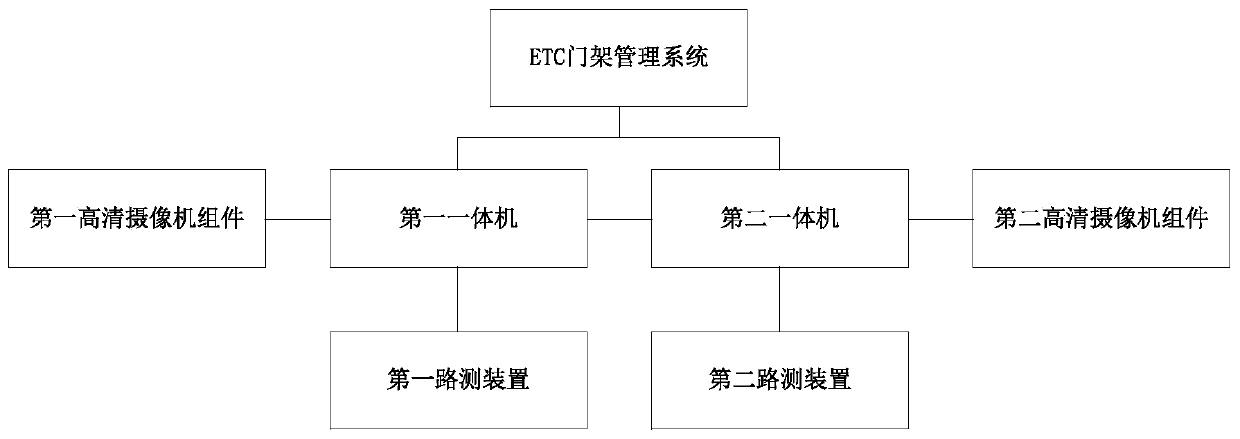

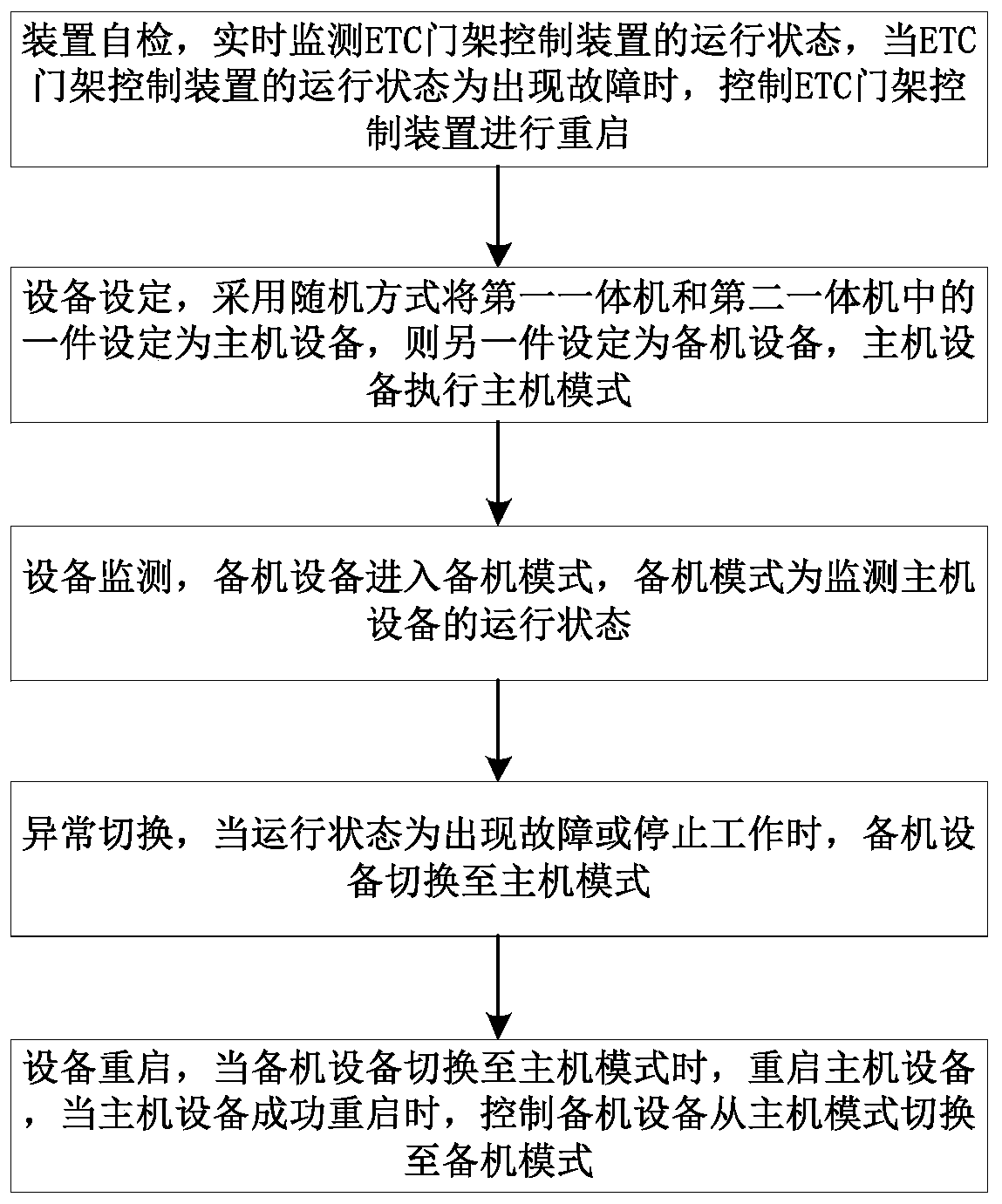

ETC (Electronic Toll Collection) portal control device for realizing uninterrupted operation and control method of ETC (Electronic Toll Collection) portal control device

The invention provides an ETC (Electronic Toll Collection) portal control device for realizing uninterrupted operation. The ETC portal control device comprises a first all-in-one machine, a second all-in-one machine, a first drive test device, a second drive test device, a first high-definition camera assembly comprising a plurality of first high-definition cameras, a second high-definition cameraassembly comprising a plurality of second high-definition cameras, and an ETC portal management system; the first drive test device and the second drive test device are both connected with the firstall-in-one machine and the second all-in-one machine; the first high-definition cameras and the second high-definition cameras are both connected with the first all-in-one machine and the second all-in-one machine; the first all-in-one machine and the second all-in-one machine both establish communication connections with the ETC portal management system; the first all-in-one machine and the second all-in-one machine are connected through a network cable; and when a vehicle to be tested passes through the ETC portal control device, the first drive test device or the second drive test device communicates with a vehicle-mounted unit of the vehicle to be tested. With the ETC (Electronic Toll Collection) portal control device for realizing uninterrupted operation of the invention adopted, theuninterrupted operation of an ETC portal can be realized.

Owner:GUANGZHOU HUAGONG INFORMATION SOFTWARE

Automatic production line of aluminum ceiling gusset plates

PendingCN109433928AIncrease production speedPalletizing device is simple and practicalShaping toolsMetal-working feeding devicesAluminiumEngineering

The invention discloses an automatic production line of aluminum ceiling gusset plates. The automatic production line comprises a feeding machine, a hydraulic machine, a forming die, a material collecting machine and a control electric cabinet, wherein a finished product buffer conveying belt is arranged on the material collecting machine, a finished product to be packed is temporarily stored on the finished product buffer conveying belt, a stacking device is arranged at one end of the finished product buffer conveying belt, the stacking device is composed of a supporting hand and a lifter. According to the automatic production line, two sensors are adopted; the two sensors are fixed above a stock bin; two probes of the two sensors are installed at a right angle, so that the blocking whensheet materials are sucked up is avoided, an air cylinder and an uninterrupted stacking device are adopted in the lower cylinder of the hydraulic machine, the supporting hand adopts a standard two-axis or three-axis air cylinder, or a self-made pneumatic device with guide is adopted; a lifting speed reducer is simple and practical, the production line forming process really realizes unmanned operation; the stock bin sheet materials are kept orderly, and the failure rate is low; the production speed is high, the production efficiency is high, and the rejection rate is low; and the finished products are stacked according to the preset number, and manual counting of operators is not needed.

Owner:佛山市能地智能科技有限公司

Single-supply open-coil winding permanent magnet synchronous motor driving system for electric vehicles

InactiveCN102882459BReduce in quantityReduce volumeAC motor controlVector control systemsCapacitancePermanent magnet synchronous motor

Owner:SOUTHEAST UNIV

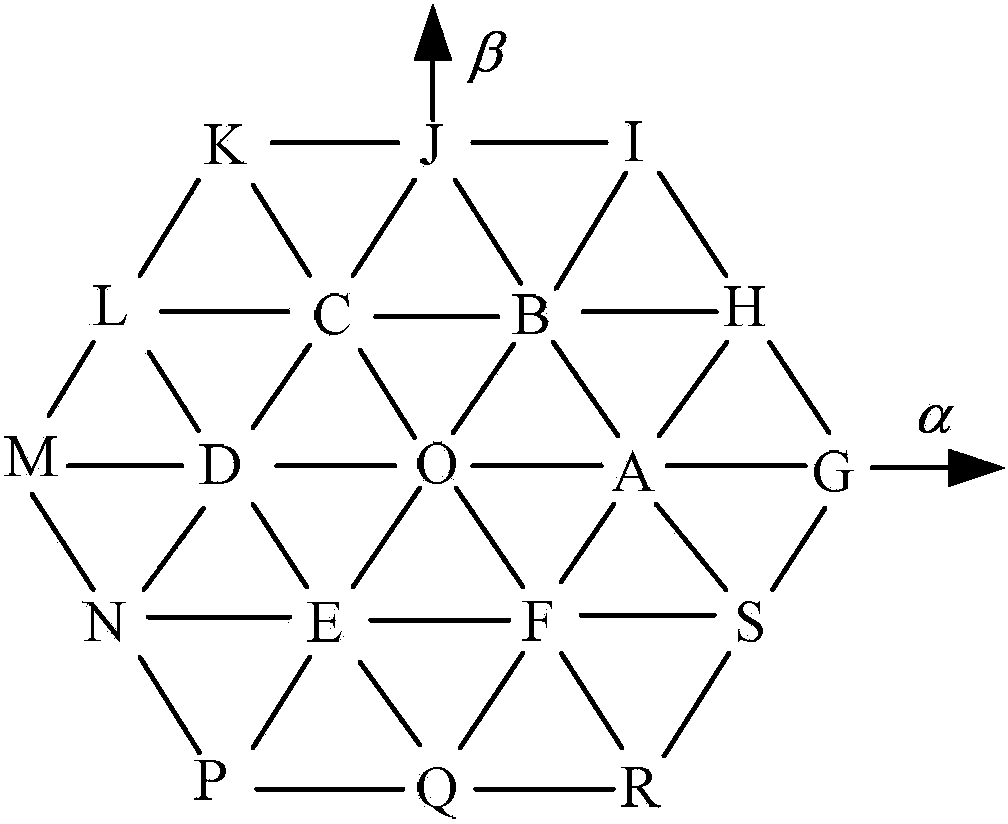

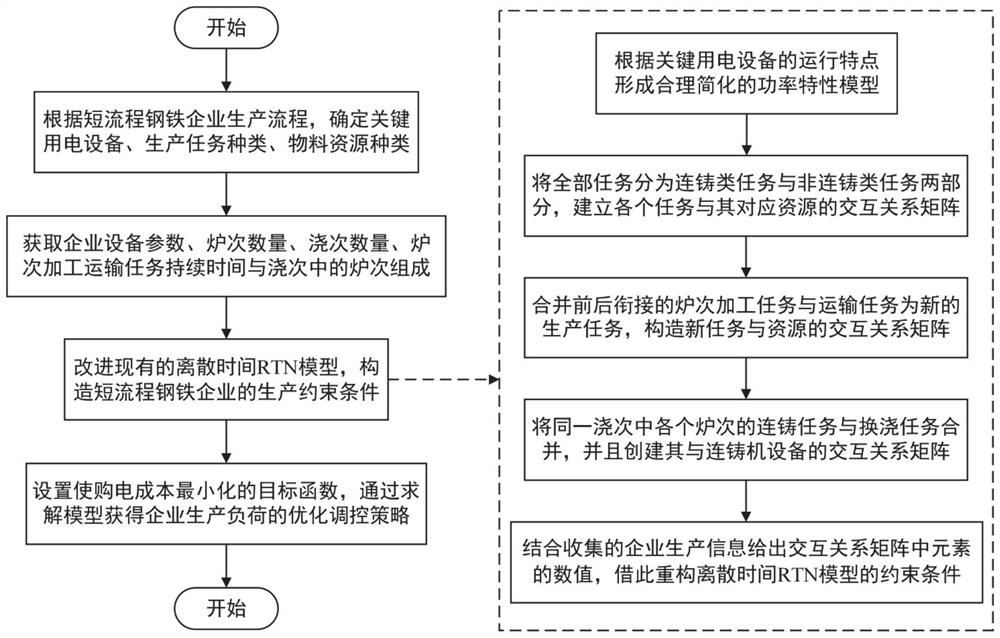

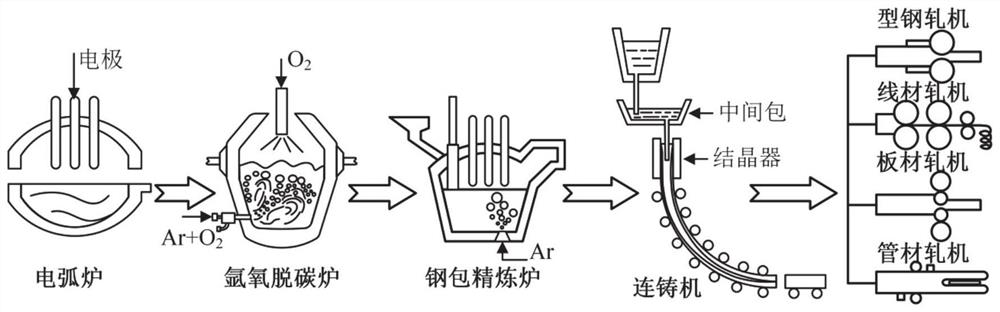

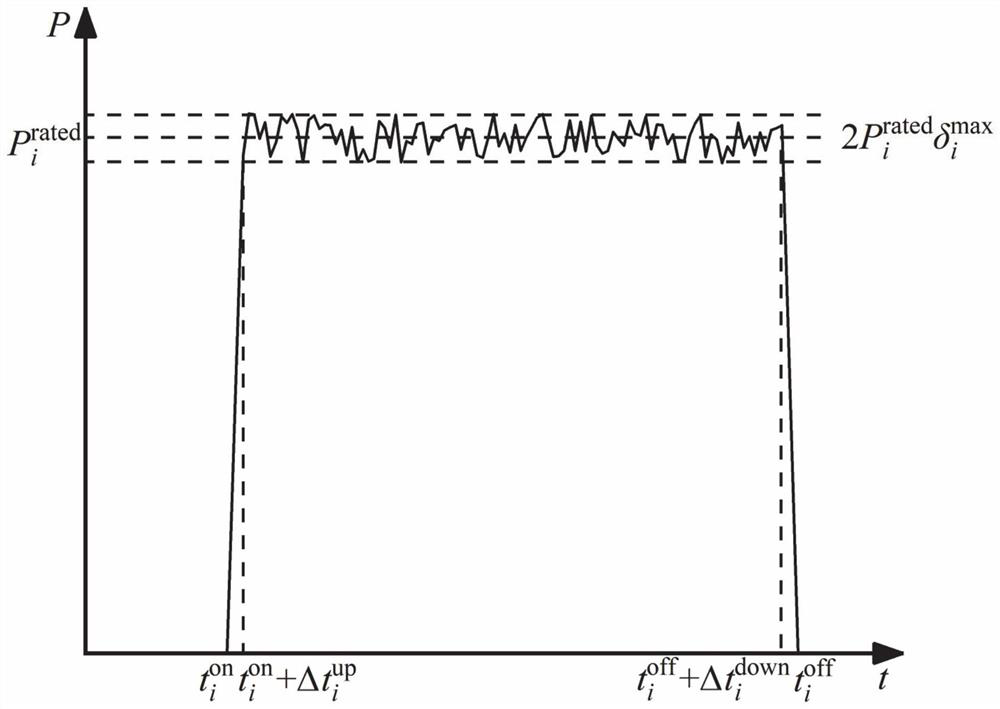

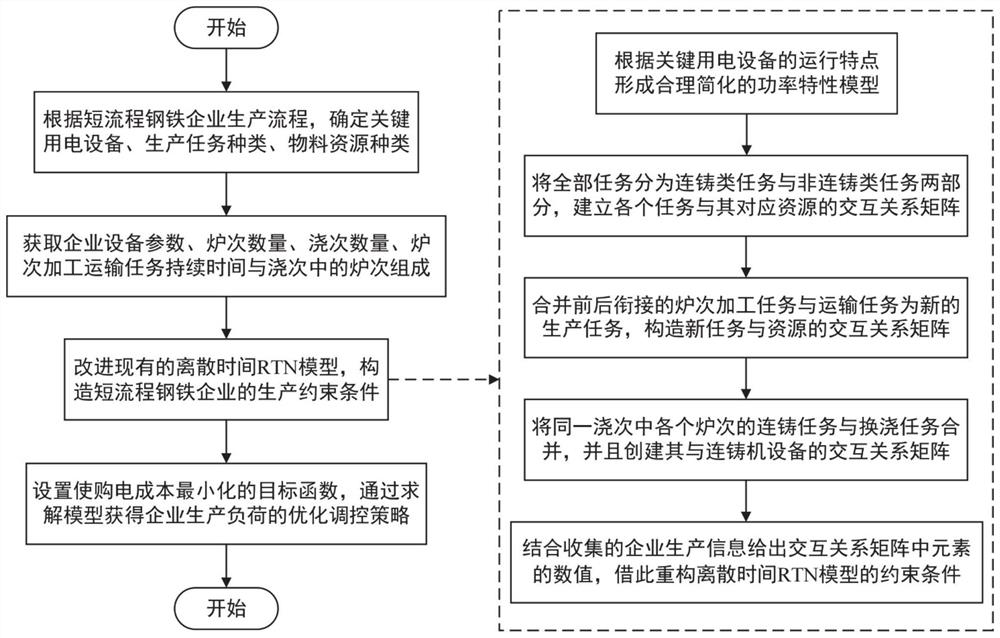

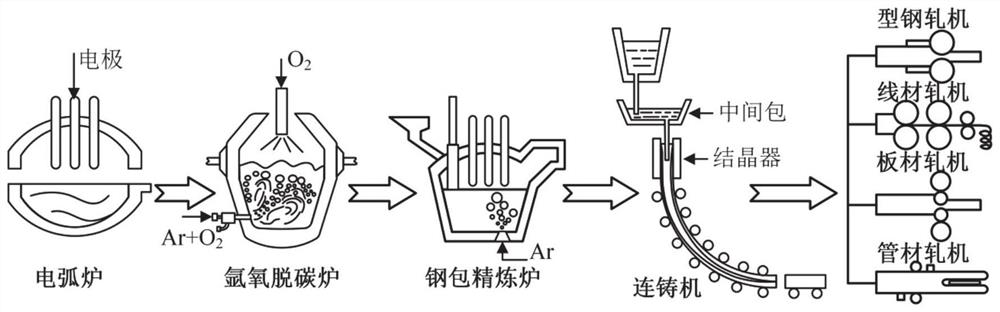

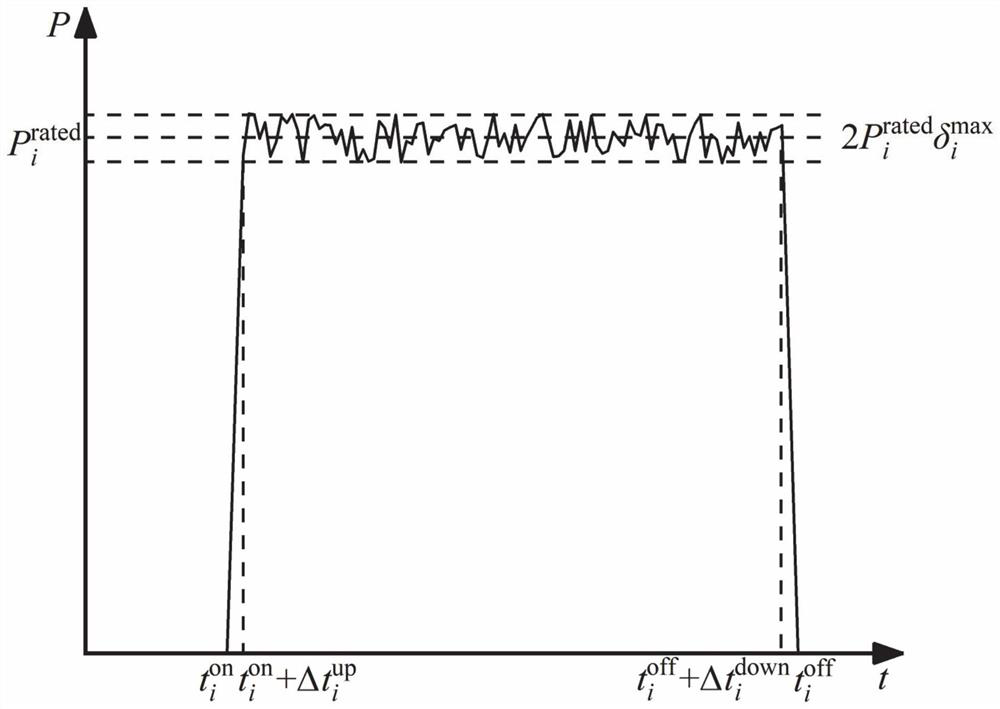

Short-process iron and steel enterprise load optimization regulation and control method and system considering process limitation

ActiveCN111769555ACorrection and refinement of waiting time constraintsHigh engineering practical valuePower network operation systems integrationLoad forecast in ac networkLoad optimizationPower usage

The invention provides a short-process iron and steel enterprise load optimization regulation and control method and system considering process limitation. The method comprises the following steps ofobtaining enterprise equipment parameters, the number of heat times, the number of casting times, the duration of a heat time machining and transporting task and heat time composition in the casting times; reconstructing a discrete time RTN model based on the obtained data, and constructing a production constraint condition of a short-process iron and steel enterprise; and setting an objective function for minimizing the electricity purchasing cost, and obtaining an optimized regulation and control strategy of the enterprise production load through the objective function and a production constraint condition solving model, namely the specific starting and stopping times of different individuals in various key electric equipment. According to the invention, the electric energy consumption and the production task are accurately combined together on the premise of ensuring that the process limitation of the iron and steel enterprise is strictly satisfied, so that the load optimization regulation and control strategy formulated by taking the minimum power purchase cost of the enterprise as the target has practical operability and the economic benefit of the enterprise is improved at the same time.

Owner:SHANDONG UNIV +1

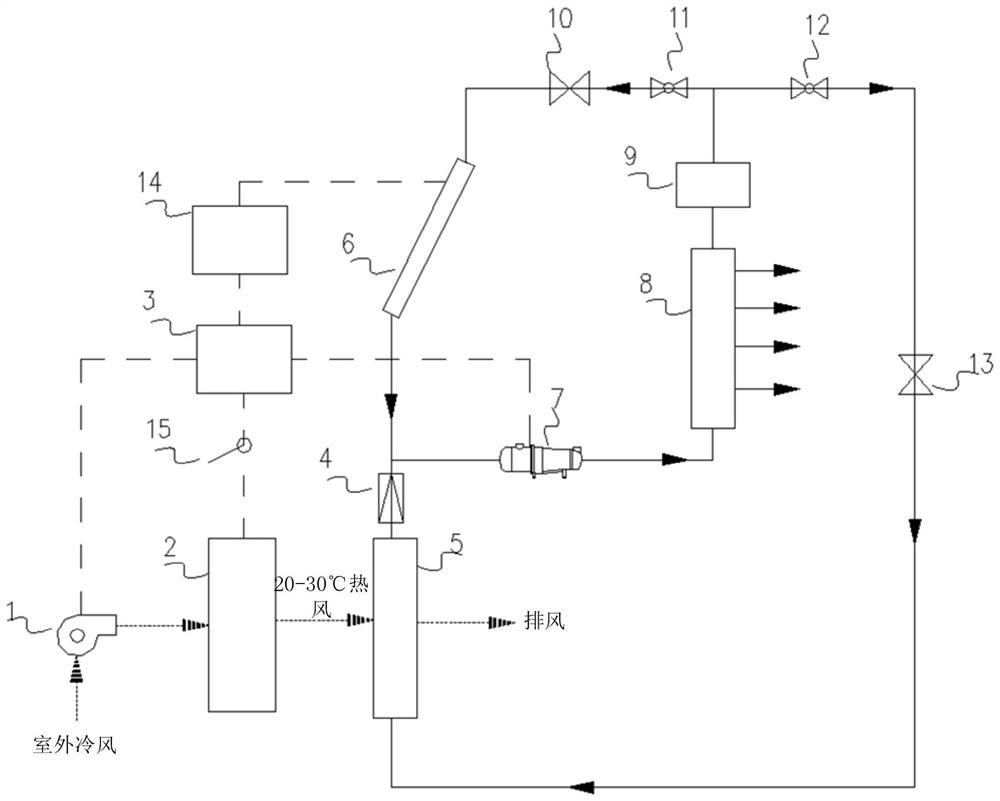

Zero-energy-consumption uninterrupted operation solar heating system

ActiveCN112710023AAchieve non-stop operationSolar heating energyBatteries circuit arrangementsElectric energyEngineering

The invention belongs to the technical field of heating equipment, and particularly relates to a zero-energy-consumption uninterrupted operation solar heating system. The zero-energy-consumption uninterrupted operation solar heating system comprises a heat pump system, a solar photovoltaic system and a heat storage system which are connected with one another, wherein the heat pump system is used for supplying heat by utilizing the heat of the solar photovoltaic system or the heat storage system; the solar photovoltaic system is used for converting solar energy into electric energy so as to heat the heat storage system and converting the solar energy into heat energy so as to supply heat to the heat pump system; and the heat storage system is used for converting the electric energy of the solar photovoltaic system into heat to supply heat to the heat pump system. According to the zero-energy-consumption uninterrupted operation solar heating system provided by the embodiment of the invention, indoor heating can be achieved by arranging the heat pump system, heat can be provided for the heat pump system by arranging the solar photovoltaic system, and heat can be stored by arranging the heat storage system so as to supply heat to the heat pump system.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

Metal powder extrusion forming method

The invention relates to the technical field of powder processing, and discloses a metal powder extrusion forming method, which adopts an extrusion forming device comprising a rack; a guide plate is fixedly connected to the bottom of the rack; a fixed sliding plate is fixedly connected to the interior of the rack; a pushing mechanism is arranged on the surface of the rack. a motor is connected tothe right side of the rack through bolts; an extrusion mechanism is arranged at an output end of the motor; a box body is fixedly connected to the inner wall of the rack; and a mixing mechanism is arranged in the box body. According to an extrusion device capable of achieving automatic feeding, an extrusion hammer can be driven to conduct extrusion forming on powder in the vertical position in thevertical movement process of a connecting frame, when the extrusion hammer moves upwards, powder is provided for a gap flowing out of the gap to enter a cavity, automatic feeding is conducted every time, materials fed every time are basically consistent, and the same quality effect of each extrusion can be well ensured, and the overall quality of the product is improved.

Owner:张君

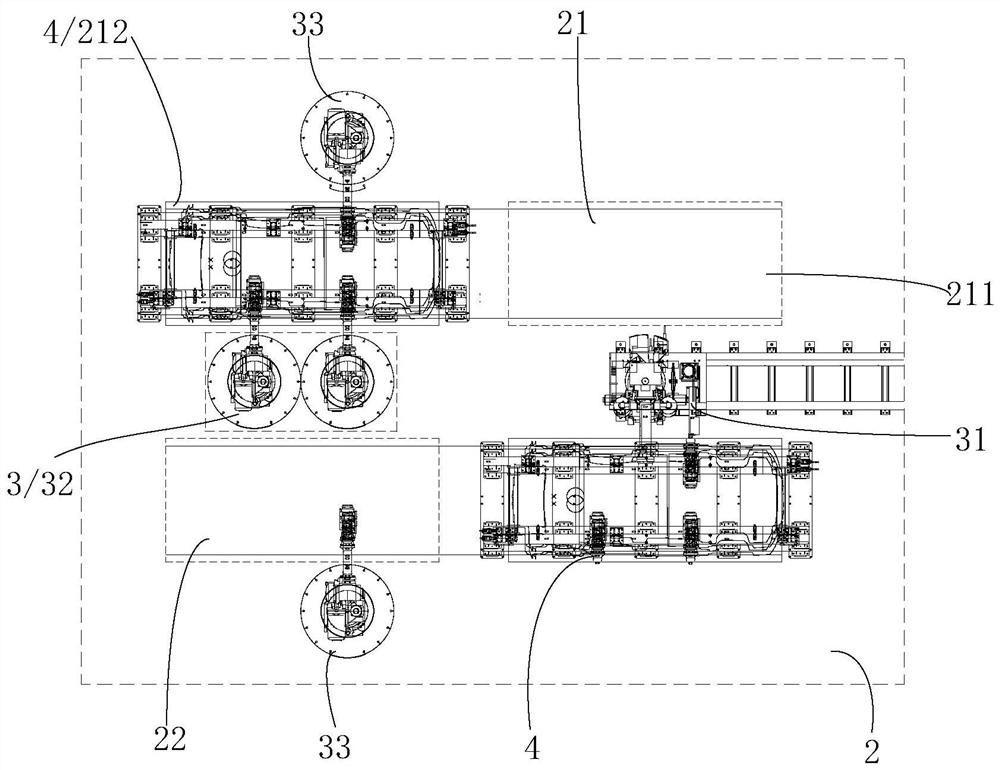

Welding production line and production process

PendingCN112658519AIncrease profitAchieve non-stop operationWelding/cutting auxillary devicesAuxillary welding devicesProduction lineIndustrial engineering

The invention provides a welding production line and a production process. The comprises a rack and a moving device, wherein the rack is provided with a material storage station and a welding station which are sequentially arranged in the conveying direction, the moving device is movably arranged on the rack in the conveying direction so as to be provided with a first working position close to the material storage station and a second working position close to the welding station, the material storage station comprises an on-line station and an off-line station which are arranged on the two sides of the moving device in the conveying direction correspondingly, the welding station comprises a first welding station and a second welding station which are arranged on the two sides of the moving device in the conveying direction correspondingly, so that when the moving device moves from the first working position to the second working position, to-be-welded parts on the on-line station are conveyed to one of the first welding station and the second welding station, and when the moving device moves from the second working position to the first working position, a welding assembly on one of the first welding station and the second welding station is conveyed to the off-line station, so that the welding efficiency of the welding production line is improved.

Owner:DONGFENG LIUZHOU MOTOR

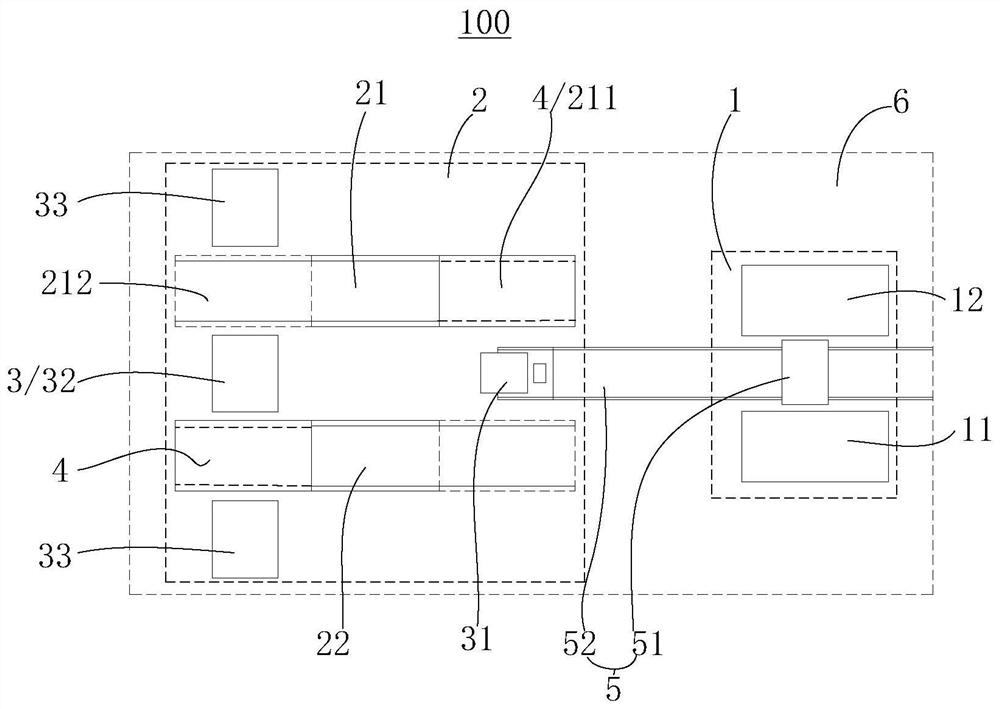

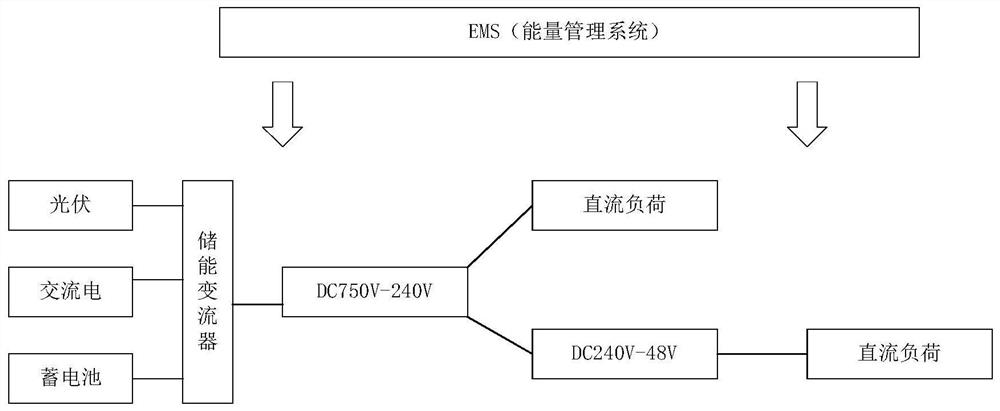

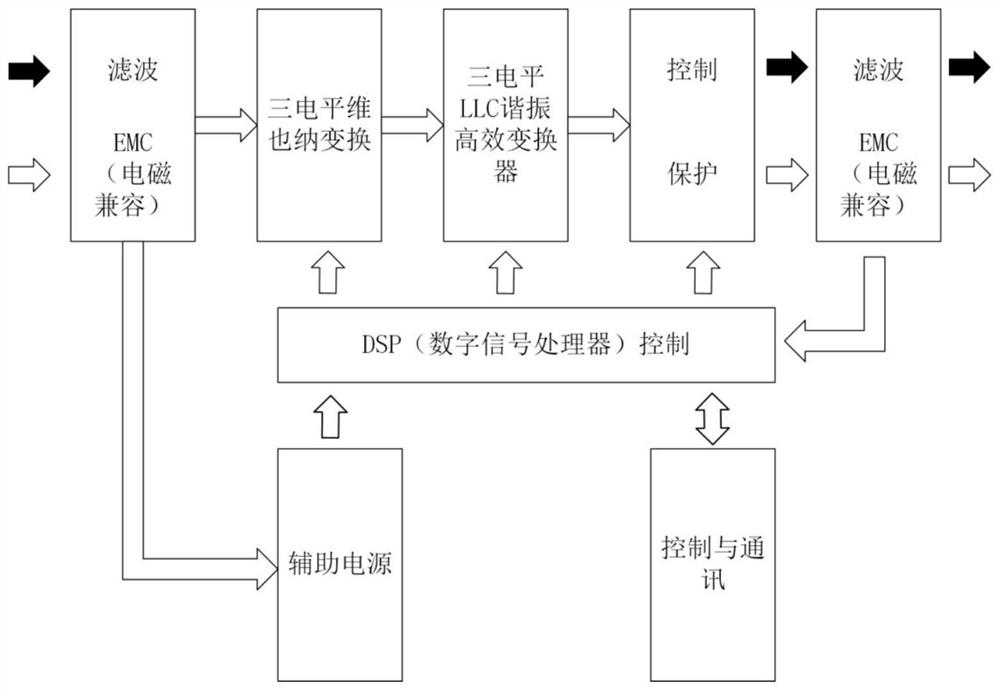

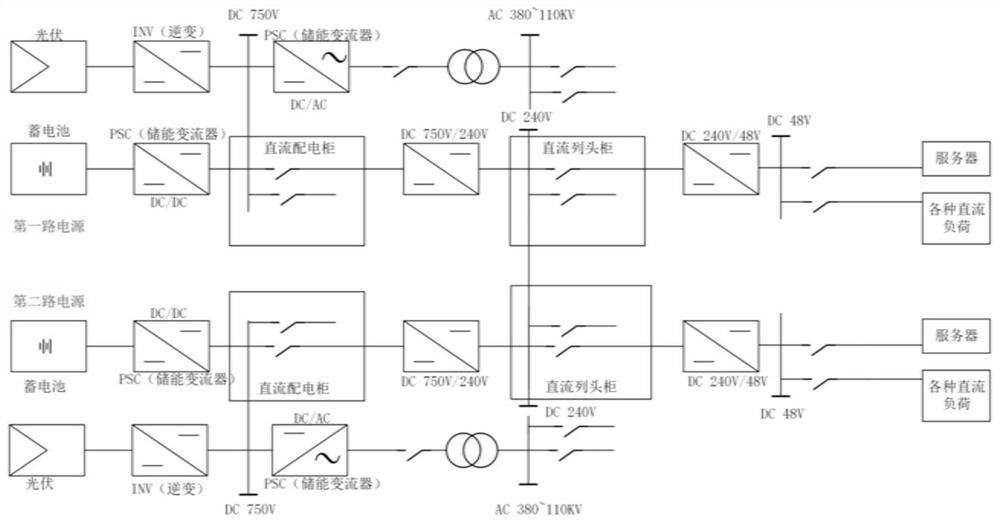

Modular data center system based on direct-current bus

PendingCN112117753AImprove stability and reliabilityImprove reliabilityThree-or-more-wire dc circuitsDc source parallel operationElectric energyServer

The invention discloses a modular data center system based on a direct-current bus. The system is characterized in that the system comprises a power input module, a DC / DC power conversion module, a power distribution module, and an EMS system, wherein the power supply input module is divided into photovoltaic input, alternating current input and storage battery input; three paths of power suppliesare uniformly converted into direct current through the energy storage converter PSC, and the direct current is input into the DC / DC power conversion module; the DC / DC power conversion module is subjected to DCDC conversion twice; and the power distribution module is used for distributing power to each DC load in the data center. The modular data center system is uniformly allocated by a superiorEMS, uses various modes such as an alternating current power supply, photovoltaic power generation and a storage battery as power supplies to form complementary input, and converges into a direct current bus for electric energy transmission; the direct current is transmitted to a server of a data center and each direct current load in the data center through direct current conversion and power distribution of each power module.

Owner:INFORMATION & COMM BRANCH OF STATE GRID JIANGSU ELECTRIC POWER +1

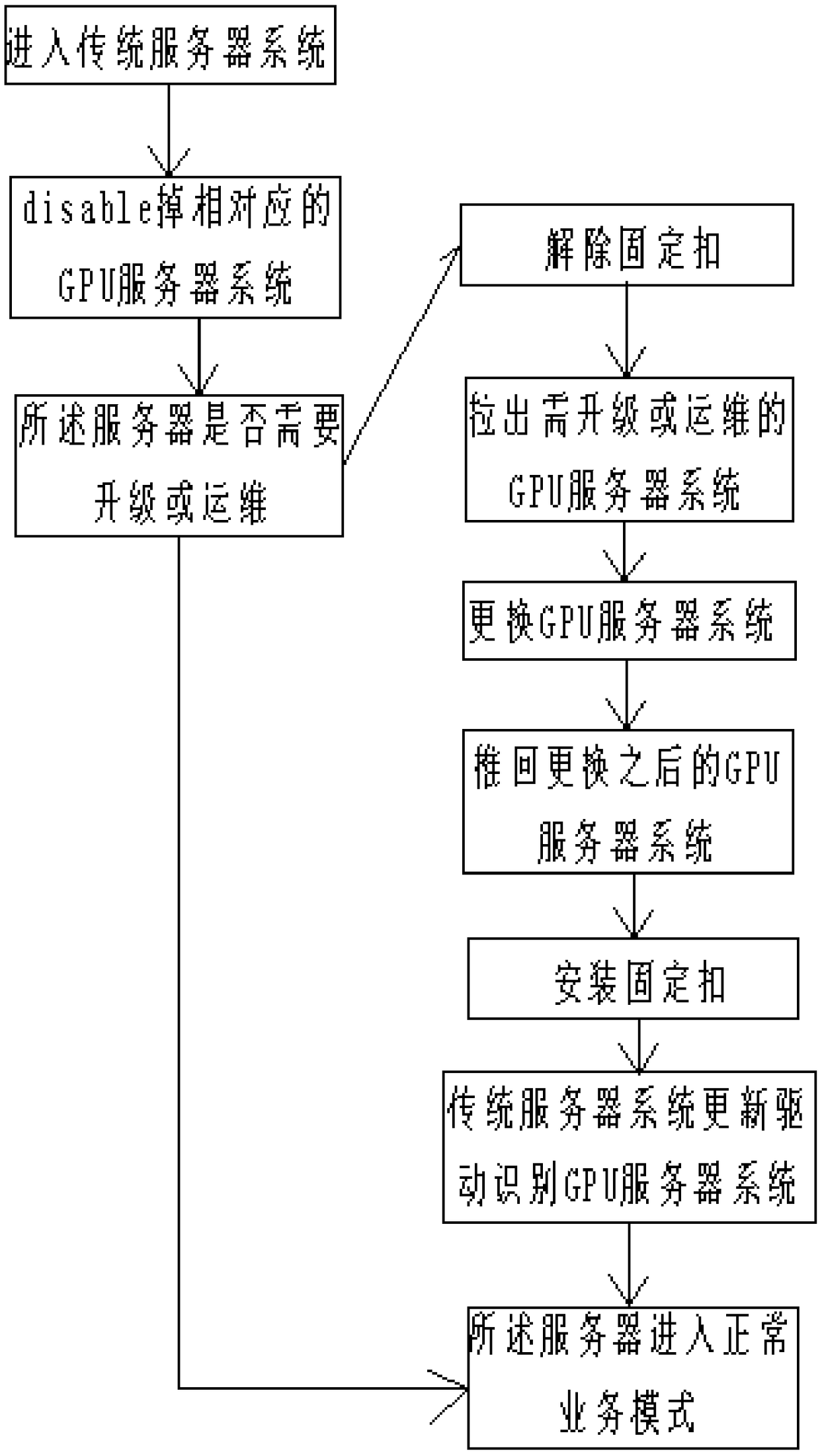

Server subjected to optimization design and maintenance method

InactiveCN108762818AEnsure coherenceImprove structural firmnessCasings/cabinets/drawers detailsBootstrappingContinuous operationServer system

The invention discloses a server subjected to optimization design and a maintenance method. According to the server subjected to the optimization design, a traditional server system and a GPU serversystem are arranged in a layered mode according to function modules, and the number of layers is more than one, so that the whole server can be stretched freely under the condition of continuous operation; a tank chain used for pulling the traditional server system or the GPU server system is arranged on one side of each layer except the top layer, so that the arrangement continuity between the layers is guaranteed, and the loss of parts is avoided during layer pulling; and a fixing buckle is arranged on the other side of each layer, so that the structure firmness of the server subjected to the optimization design is enhanced.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

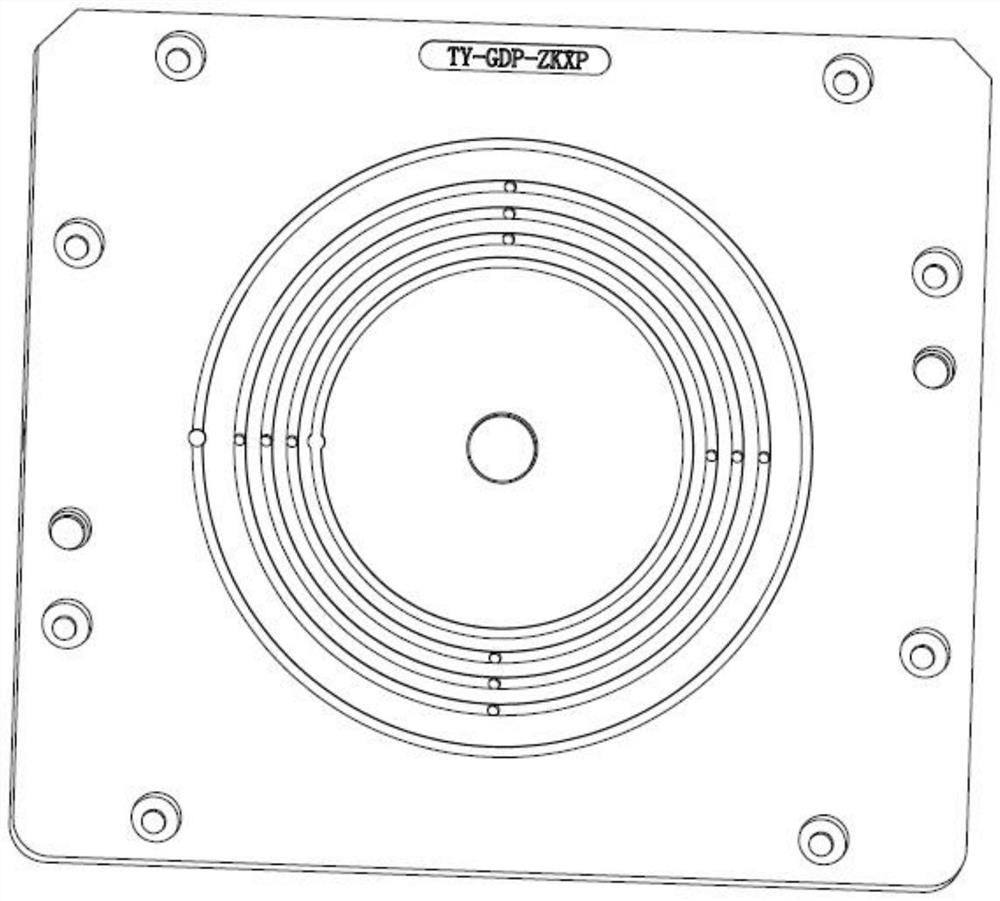

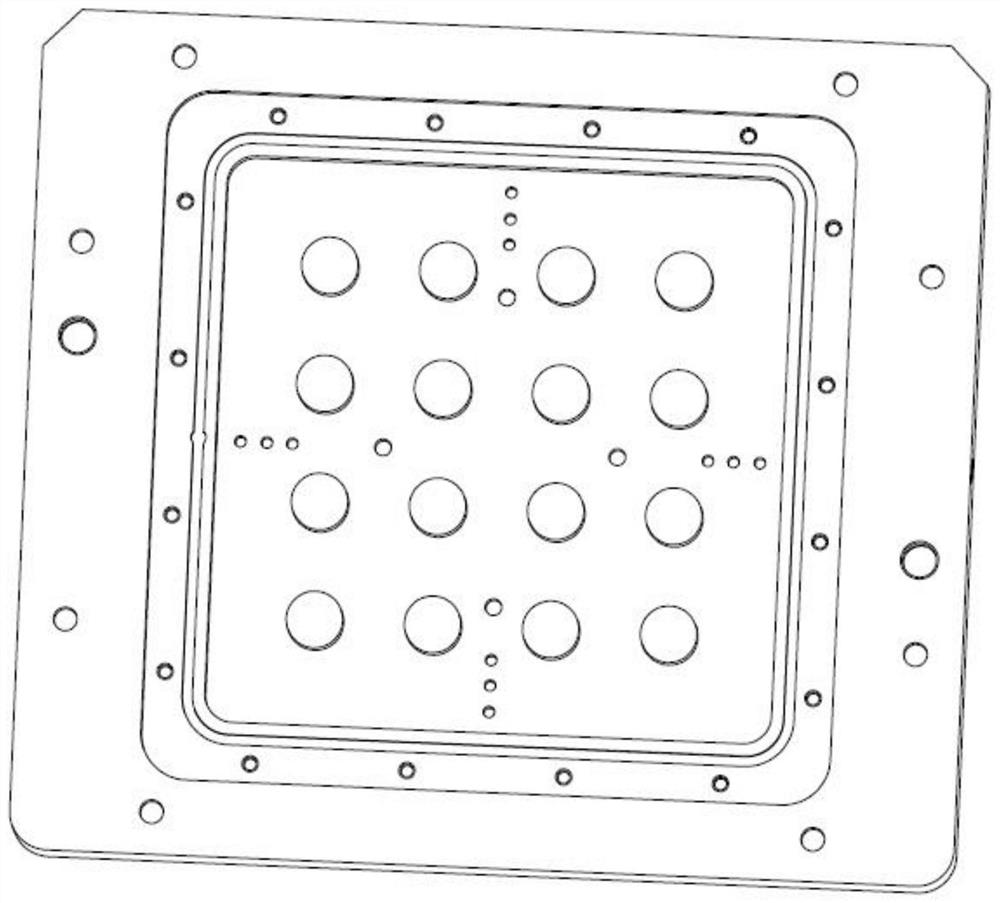

Pressure-maintaining vacuum suction cup jig for processing sheet parts in horizontal machining center

InactiveCN111644875AReduce setup timeReduce the number of clampingPositioning apparatusMetal-working holdersEngineeringMachine tool

The invention provides a pressure-maintaining vacuum suction cup jig for processing sheet parts in a horizontal machining center. The pressure-maintaining vacuum suction cup jig comprises a vacuum adsorption platform, a sealing ring, a cover plate, a straight-through small ball valve, a pressure gauge, a bushing, a positioning pin, and a base; the vacuum adsorption platform is connected with the cover plate through a bolt and the sealing ring; the straight-through small ball valve is installed on one sidewall of the vacuum adsorption platform; the pressure gauge is installed on the other sidewall of the vacuum adsorption platform; the vacuum adsorption platform is installed on the base through the positioning pin and the bushing; and then the vacuum adsorption platform is fixedly connectedwith the base by adopting screws. The pressure-maintaining vacuum suction cup jig provided by the invention greatly reduces the clamping time and the clamping number, realizes uninterrupted operationof the machine tool, and improves the production efficiency and product quality by virtue of continuous machining of the parts.

Owner:SHENYANG FORTUNE PRECISION EQUIP CO LTD

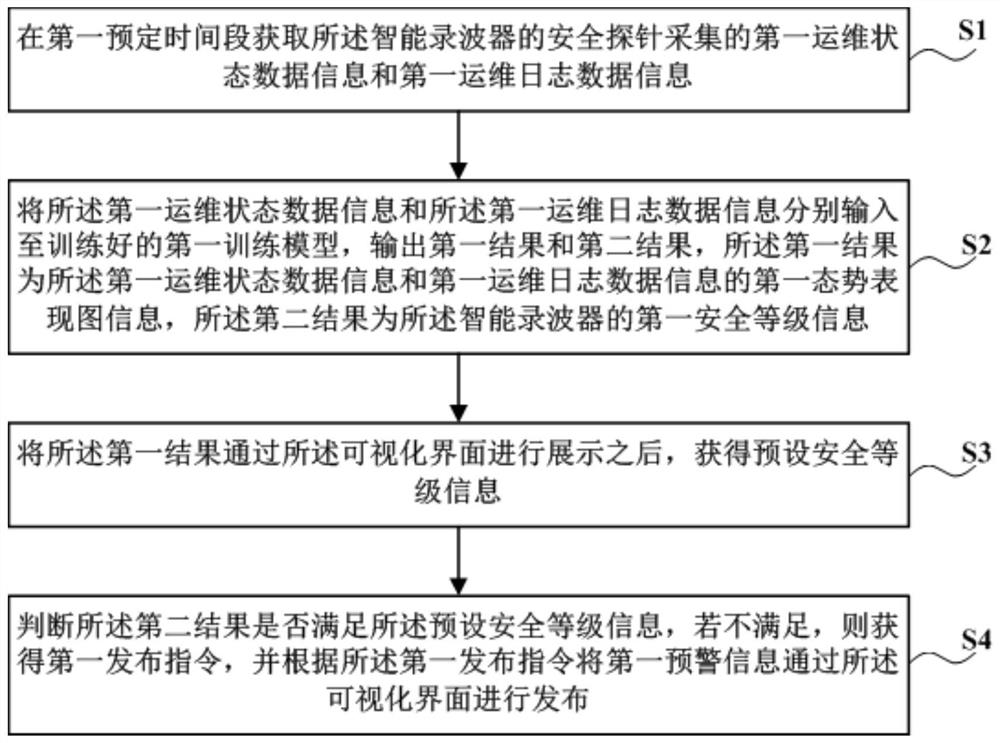

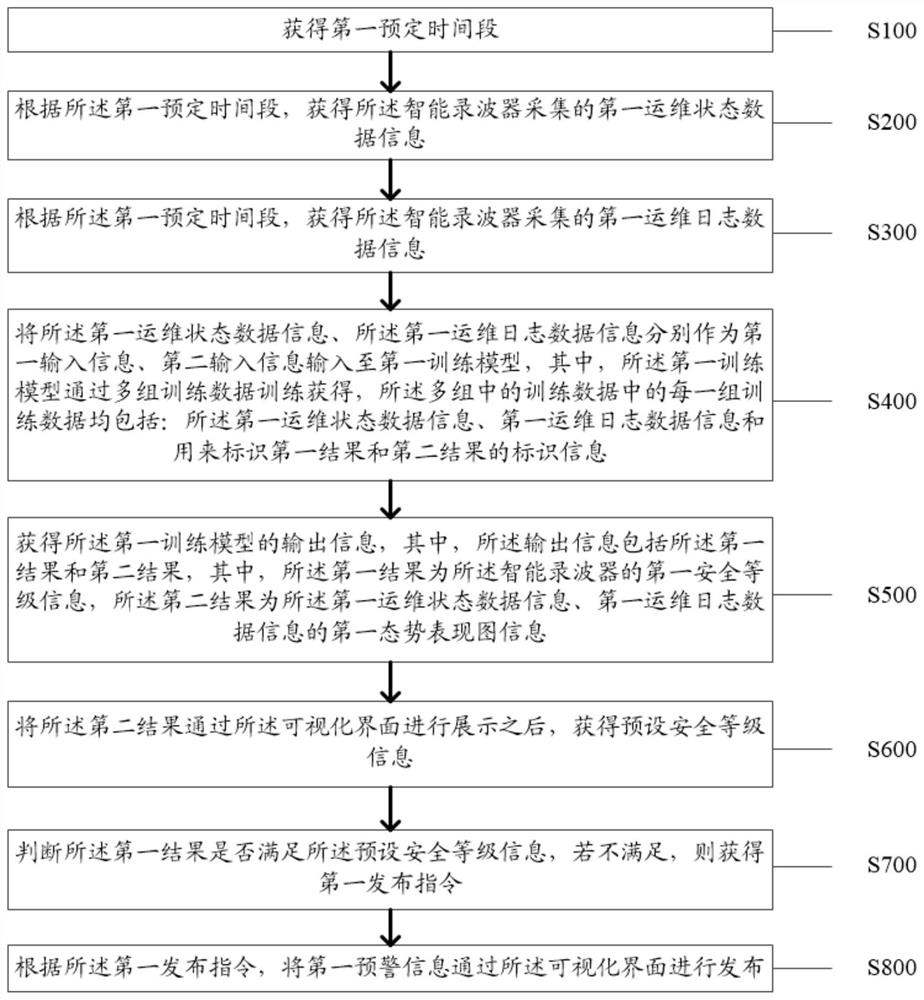

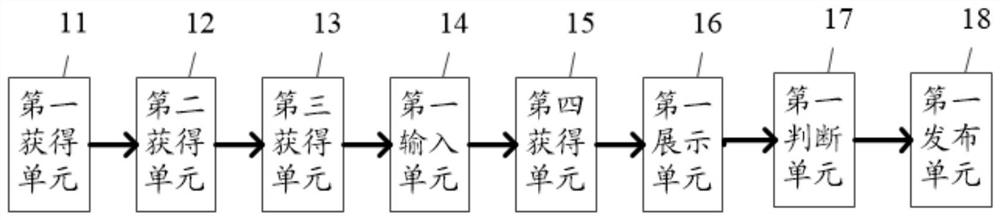

Operation and maintenance safety monitoring method and system for intelligent wave recording master station and computer readable storage medium

PendingCN112764852AVisualize the security situationRealize visualizationMeasurement devicesMachine learningData informationReliability engineering

The invention discloses an operation and maintenance safety monitoring method and system for an intelligent wave recording master station and a computer readable storage medium, and the method comprises the steps: obtaining a first preset time period; obtaining first operation and maintenance state data information and first operation and maintenance log data information collected by the intelligent oscillograph according to a first preset time period; inputting the first operation and maintenance state data information and the first operation and maintenance log data information into a first training model as first input information and second input information respectively; obtaining output information of the first training model; after the second result is displayed through a visual interface, acquiring preset security level information; judging whether the first result meets preset security level information or not, and if not, obtaining a first issuing instruction; and issuing the first early warning information through a visual interface according to the first issuing instruction. According to the invention, the technical problem that the remote operation and maintenance safety monitoring of the intelligent oscillograph by the intelligent wave recording main station cannot be visually mastered in real time is solved.

Owner:SHENZHEN POWER SUPPLY BUREAU

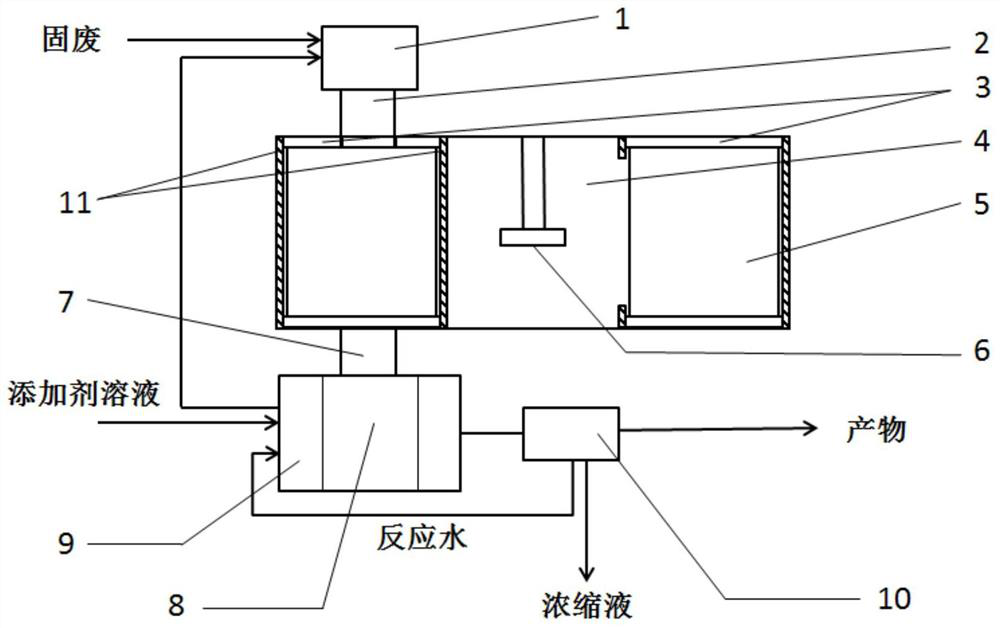

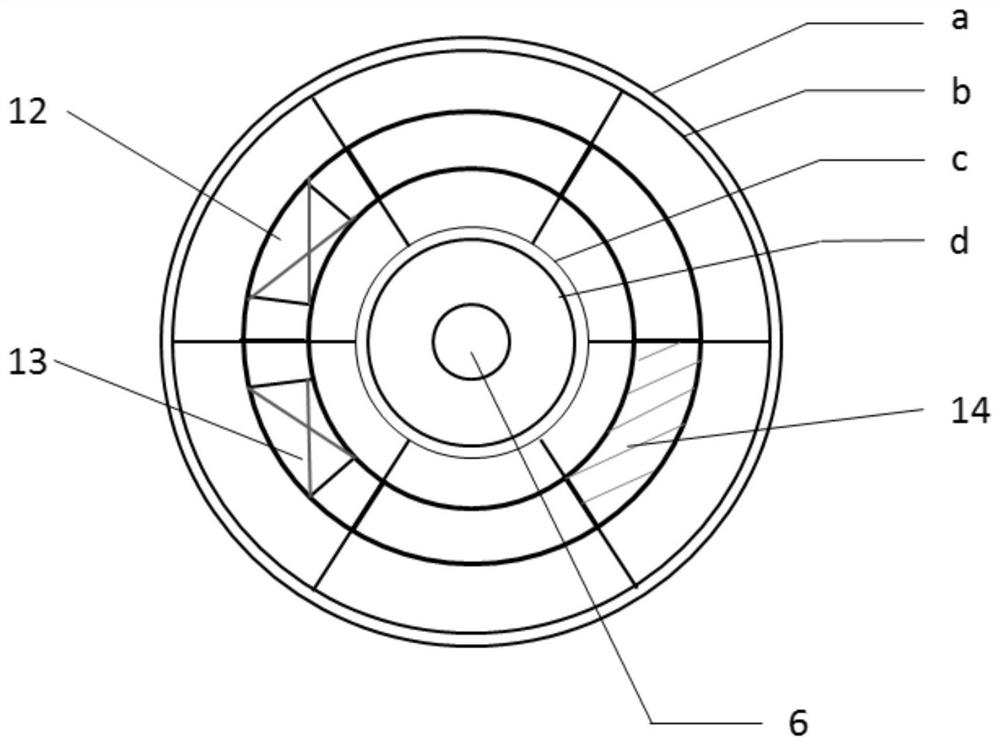

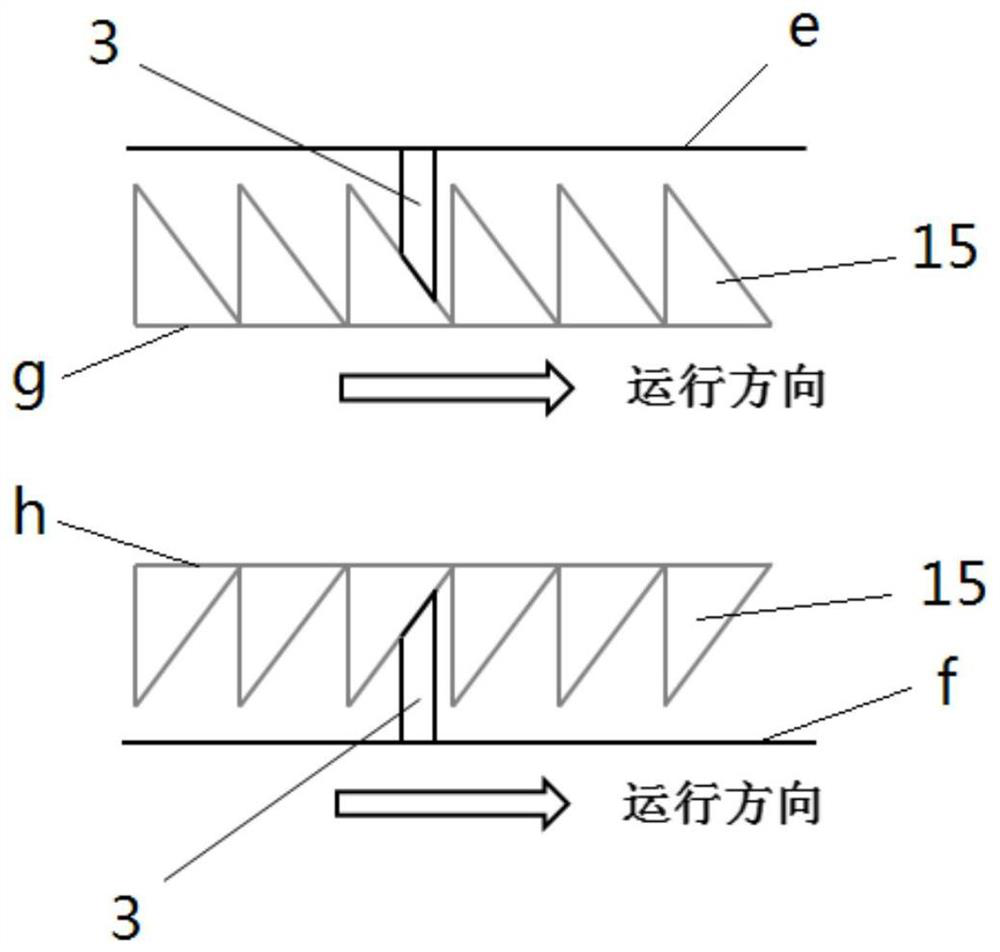

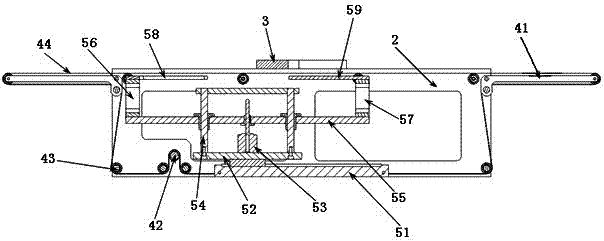

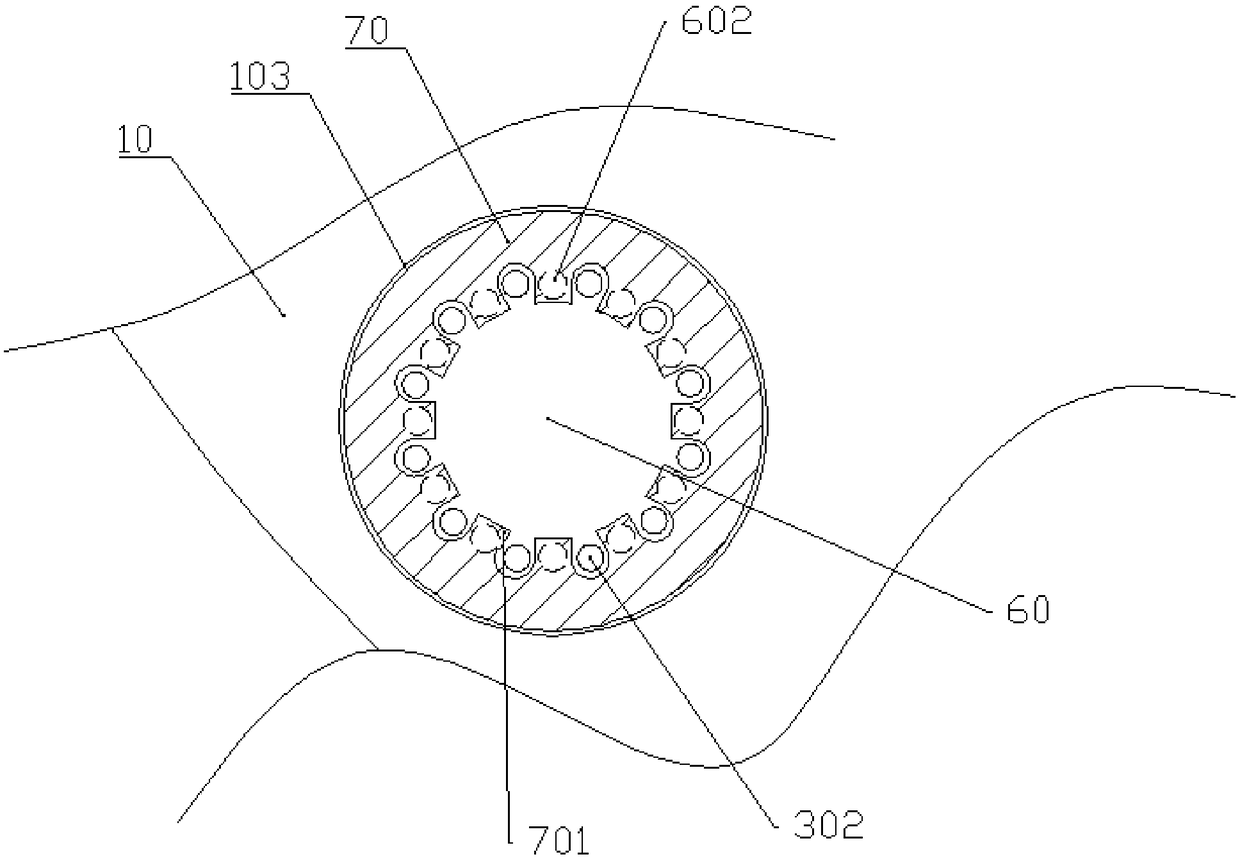

An improved compact waste heat-microwave high-temperature hydrothermal uninterrupted operation device and method

ActiveCN110743896BUniform microwave radiationMicrowave radiation stableSolid waste disposalTransportation and packagingThermodynamicsLight sensing

The invention discloses an improved compact waste heat-microwave high-temperature hydrothermal uninterrupted operation device and method. By arranging the microwave launcher and the reaction vessel in a ring, the heating rate and the stability of the temperature field in the microwave field are realized, which improves the stability of the microwave continuous operation system; at the same time, the ring track setting improves the compactness of the system and reduces the footprint area, space utilization is more reasonable. The opening and closing of the inlet and outlet of the reaction vessel is controlled by light sensing, combined with the automatic sampling system of gravity sensing-flow control, truly realizing the uninterrupted operation of the microwave high-temperature hydrothermal process. By recovering and utilizing the waste heat of the product after the reaction, the energy consumption and reaction time during the microwave heating period are reduced. In addition, the top and bottom of the reaction vessel are both designed to have zigzag planes, combined with the retractable sealing strip at the entrance and exit of the device, to avoid microwave leakage. The device is compact and reasonable, and is suitable for microwave high-temperature hydrothermal application of waste incineration fly ash and other solid waste.

Owner:NANJING INST OF TECH

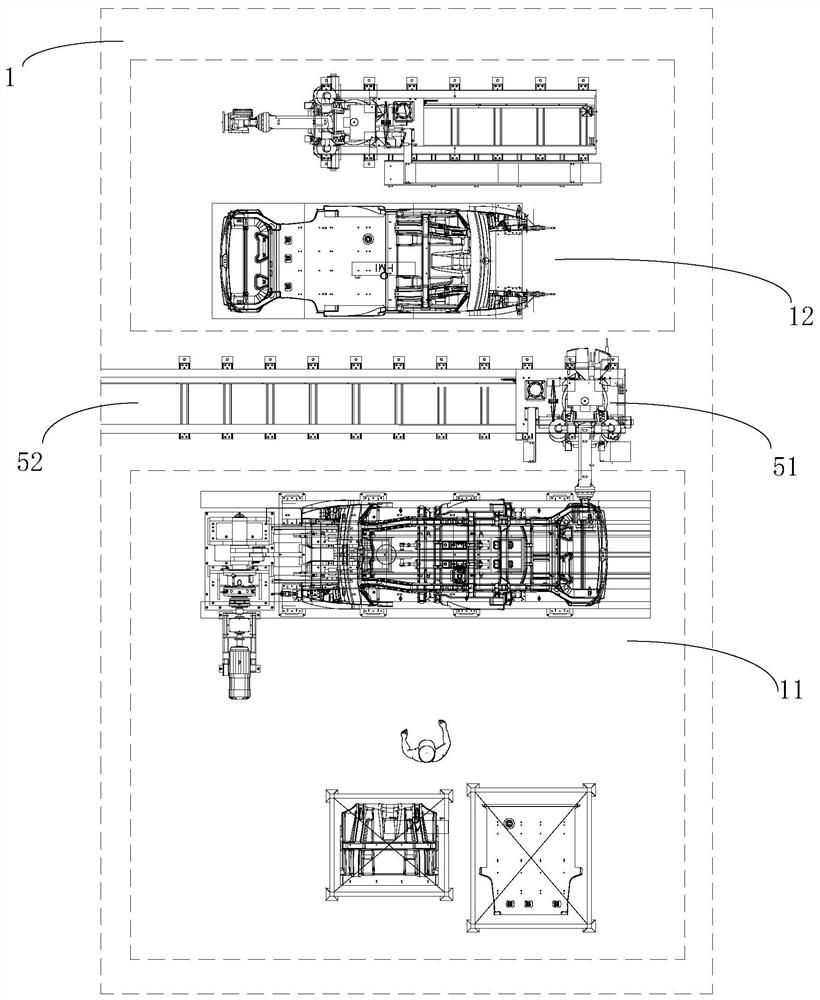

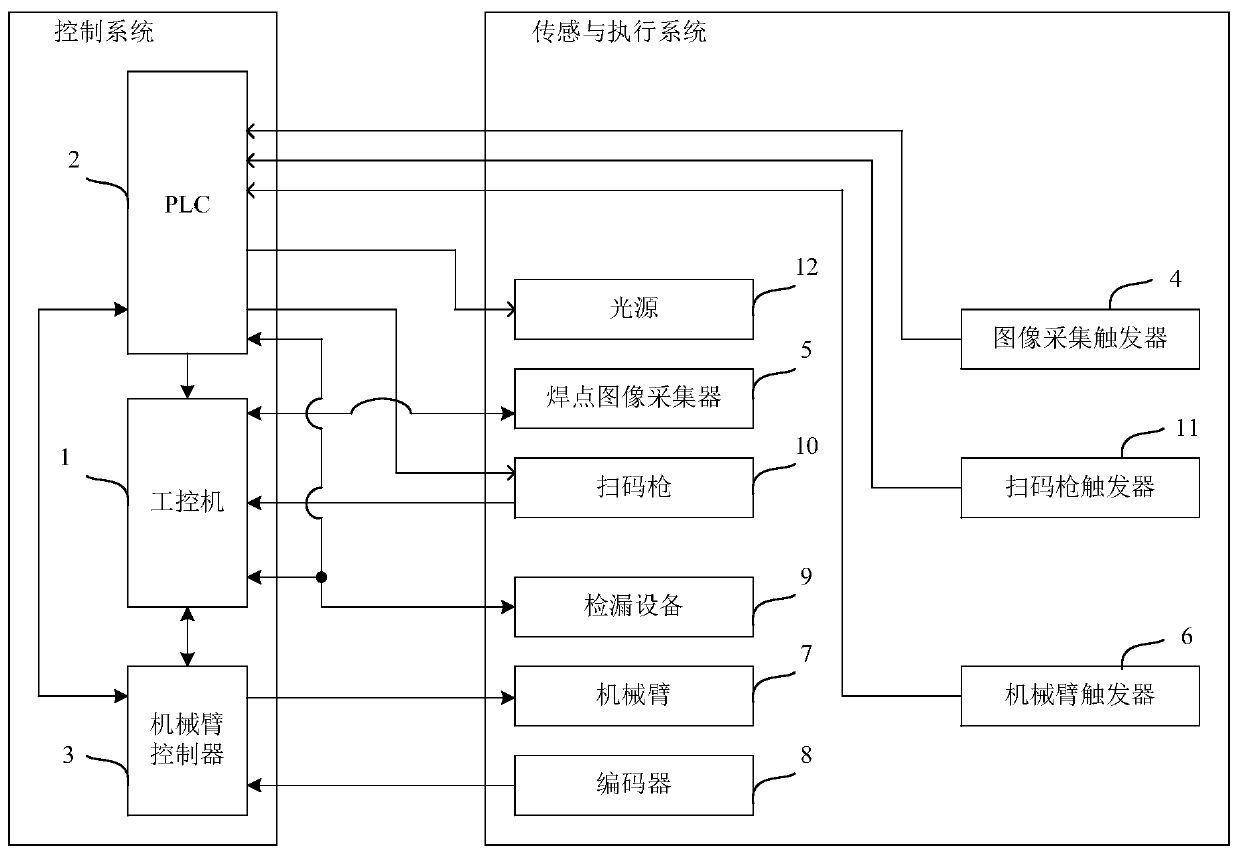

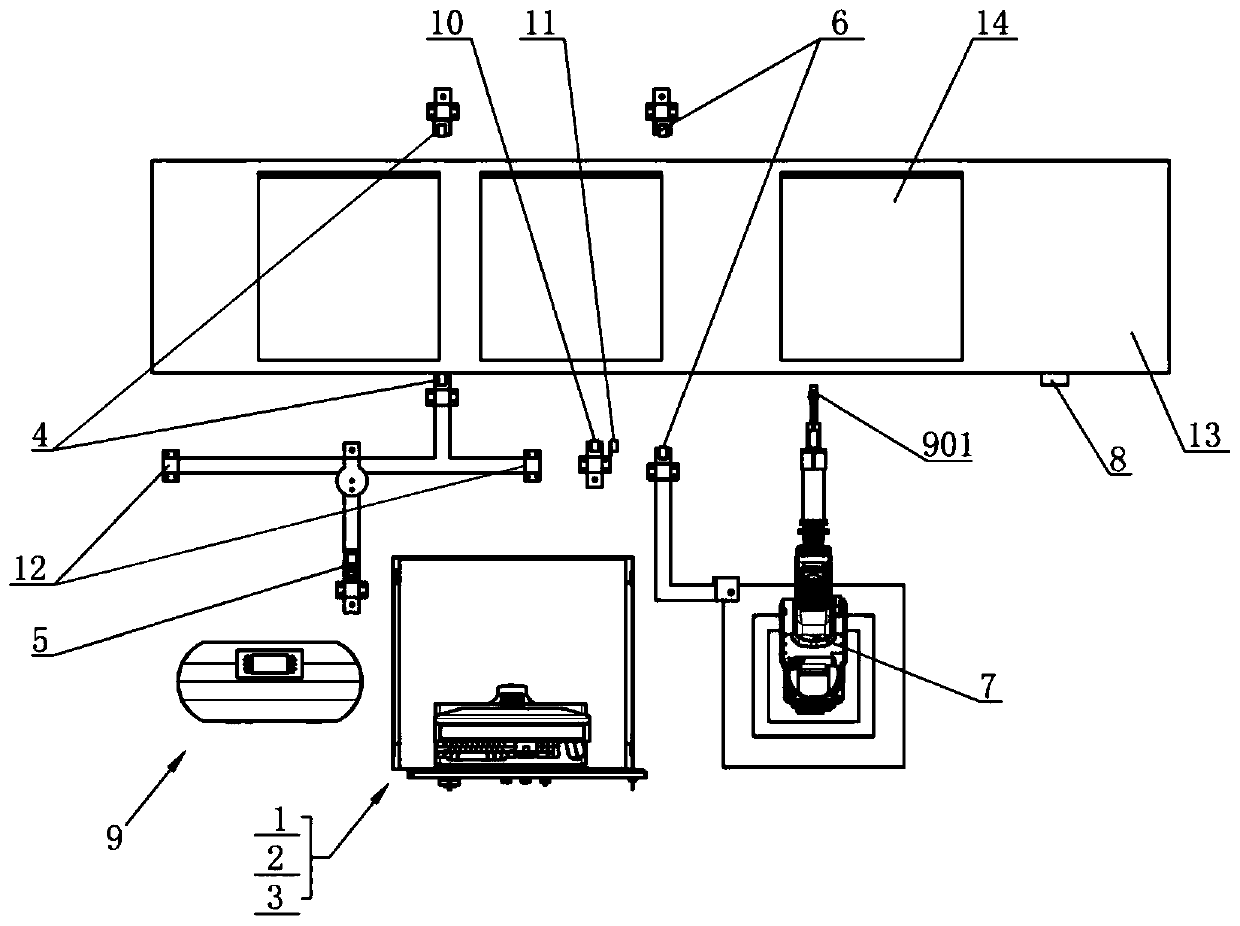

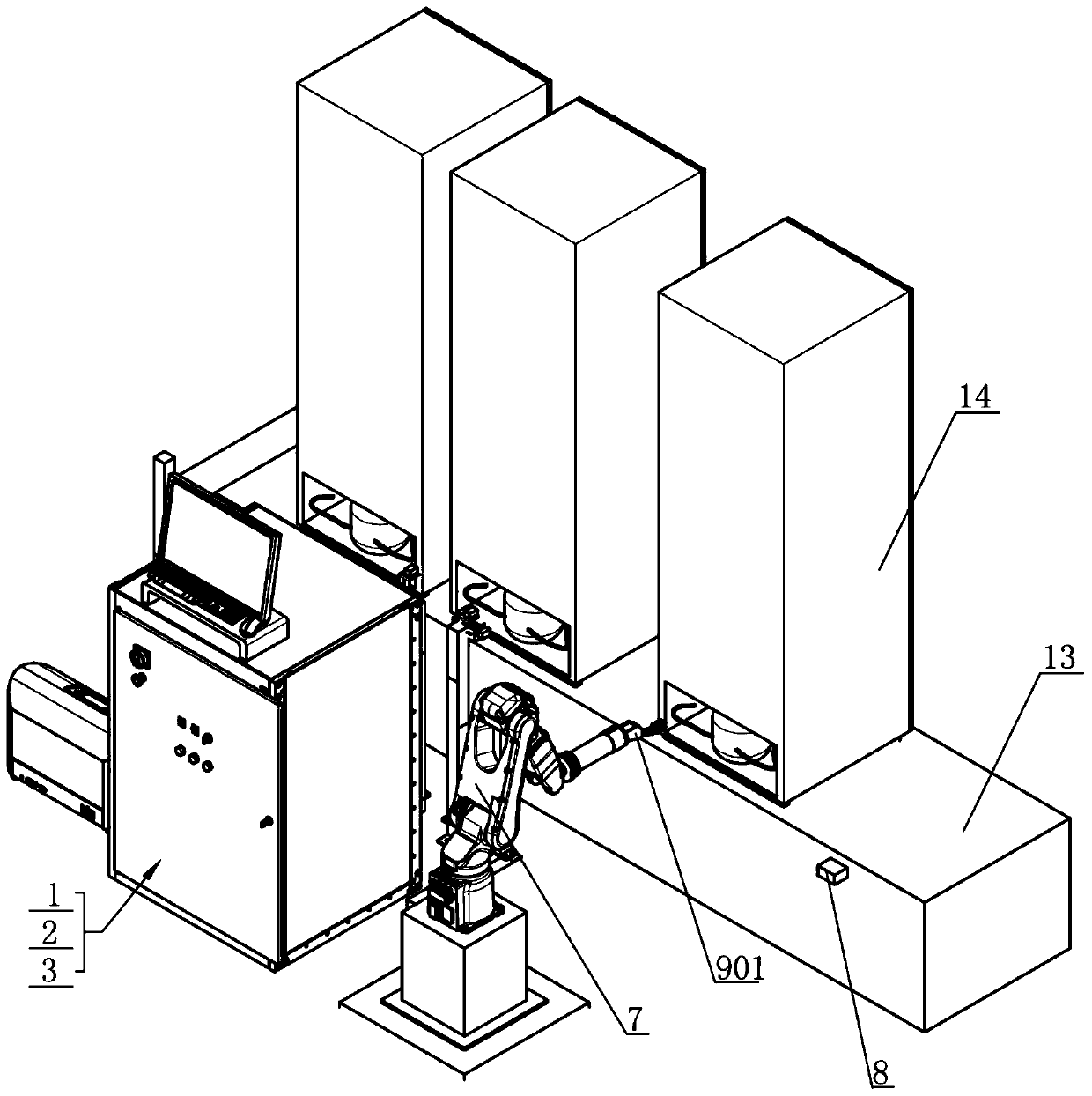

Intelligent leakage detection device for welding spot of refrigerator compressor room

PendingCN111250906AAvoid situations such as leaving the factory unqualifiedImprove stabilityProgramme-controlled manipulatorWelding/cutting auxillary devicesProduction lineControl system

The invention relates to the field of leakage detection, and in particular relates to an intelligent leakage detection device for a welding spot of a refrigerator compressor room. The intelligent leakage detection device is characterized by comprising a control system and a sensing and execution system, wherein the control system comprises an industrial personal computer, a PLC connected to the industrial personal computer and a mechanical arm controller, and the PLC is electrically connected to the mechanical arm controller; the sensing and execution system comprises an image collection trigger, a welding spot image collector, a mechanical arm trigger, a mechanical arm, an encoder and leakage detection equipment; the welding spot image collector and the mechanical arm are arranged on oneside of a production line driving belt in sequence on the conveying direction of a production line, the image collection trigger corresponds to the welding spot image collector in position, and the mechanical arm trigger corresponds to the mechanical arm in position; the encoder is arranged on the production line driving belt; and the leakage detection equipment is used for obtaining the detectionon and off signals of the industrial personal computer to complete the welding spot detection of the refrigerator compressor room, judge whether a leakage point exists and feed back the leakage pointinformation to the industrial personal computer. The intelligent leakage detection device effectively reduces the omission ratio, improves the production efficiency, and reduces the labor cost.

Owner:南京英格伯格智能装备有限公司

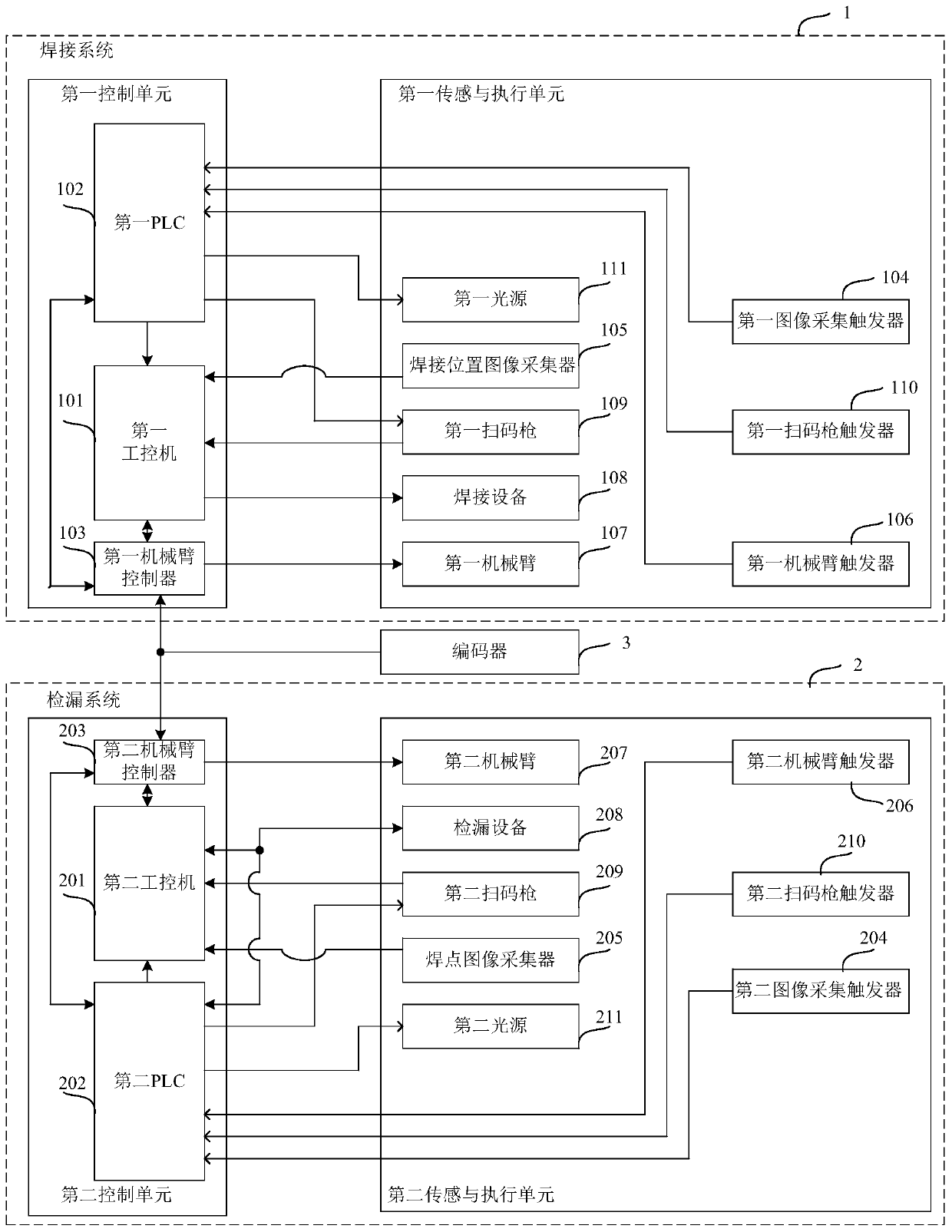

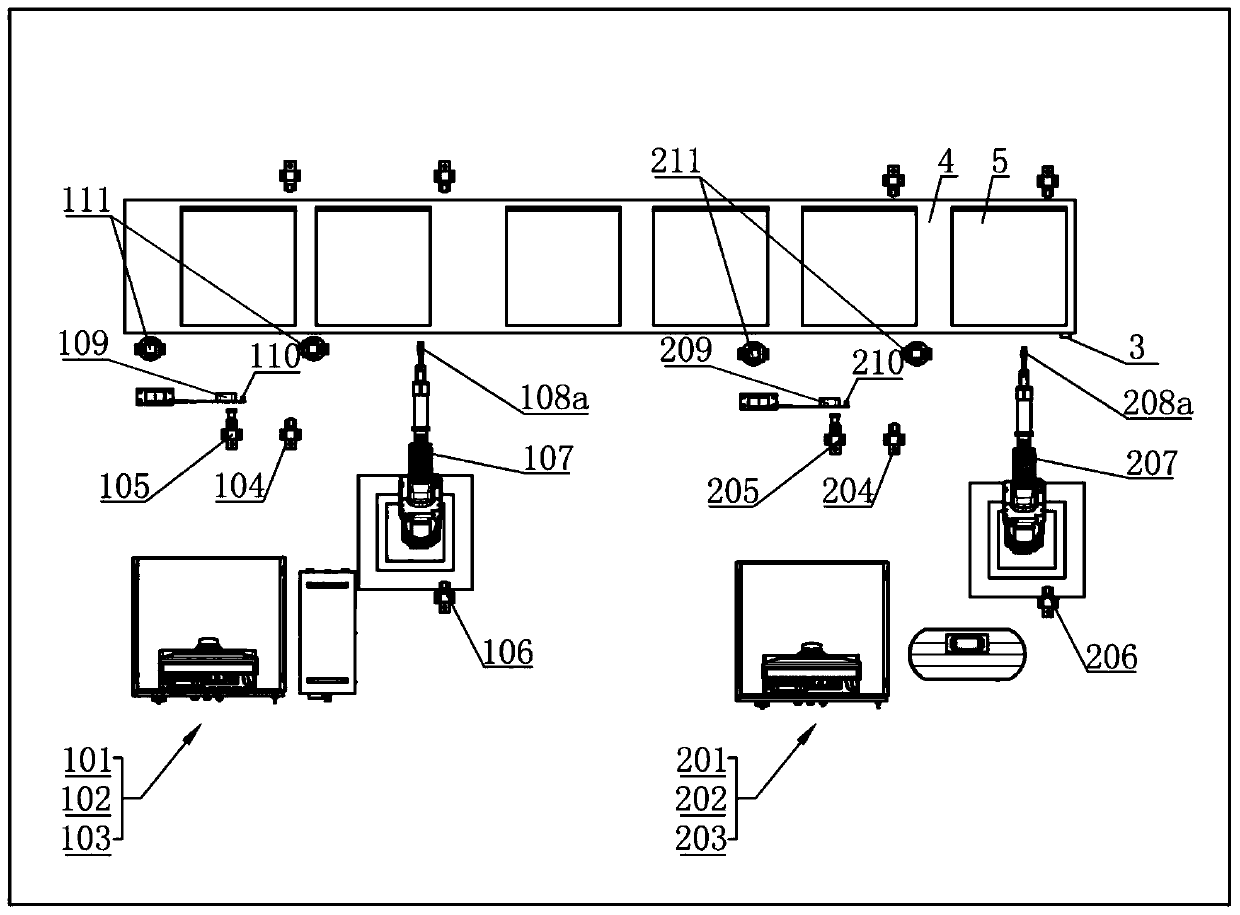

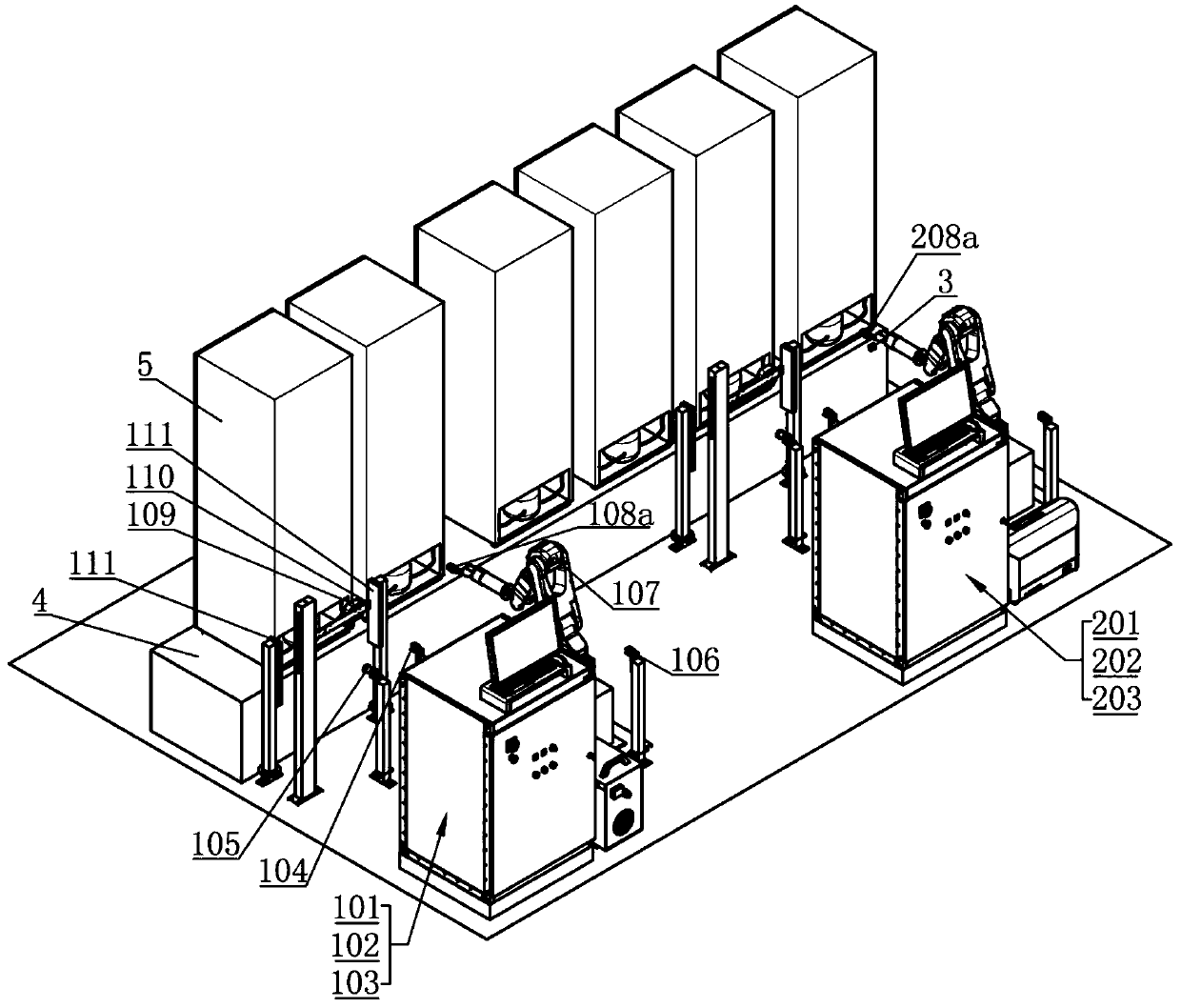

Intelligent welding and leakage-detecting device for refrigerator press cabin pipeline

PendingCN111230245AAvoid situations such as leaving the factory unqualifiedCode of PracticeMetal working apparatusSoldering auxillary devicesProduction lineIcebox

The invention relates to the field of welding and leakage-detecting, in particular to an intelligent welding and leakage-detecting device for a refrigerator press cabin pipeline. The intelligent welding and leakage-detecting device is characterized by comprising a welding system, a leakage-detecting system and a code, wherein the coder is arranged on a production line conveyor belt; the welding system comprises a first industrial controller, a first PLC and a first mechanical arm controller, which are connected to the first industrial controller, a first image acquisition trigger, a welding position image acquirer, a first mechanical arm trigger, a first mechanical arm and welding equipment; and the leakage-detecting equipment comprises a second industrial controller, a second PLC and a second mechanical arm controller, which are connected to the second industrial controller, a second image acquisition trigger, a welding point image acquirer, a second mechanical arm trigger, a second mechanical arm and leakage-detecting equipment. The intelligent welding and leakage-detecting device can improve welding quality, improves production efficiency and reduces labor cost.

Owner:南京英格伯格智能装备有限公司

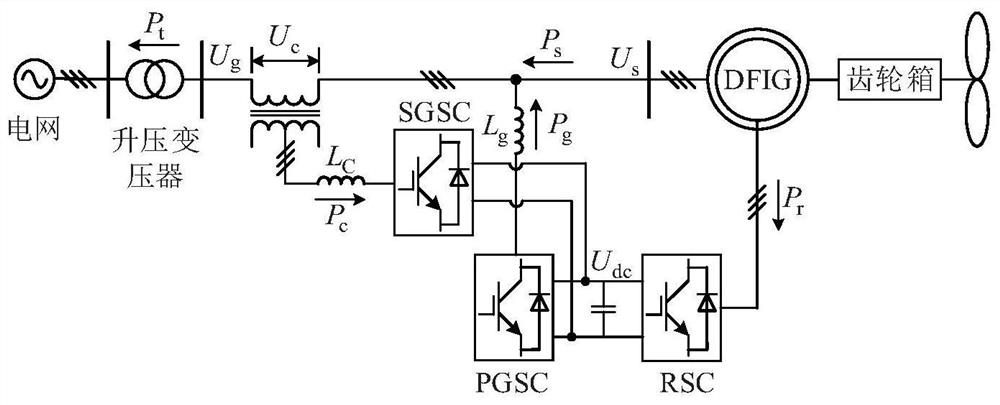

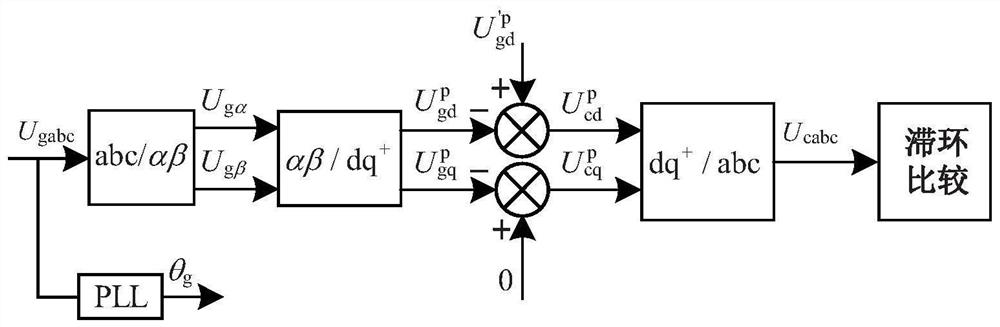

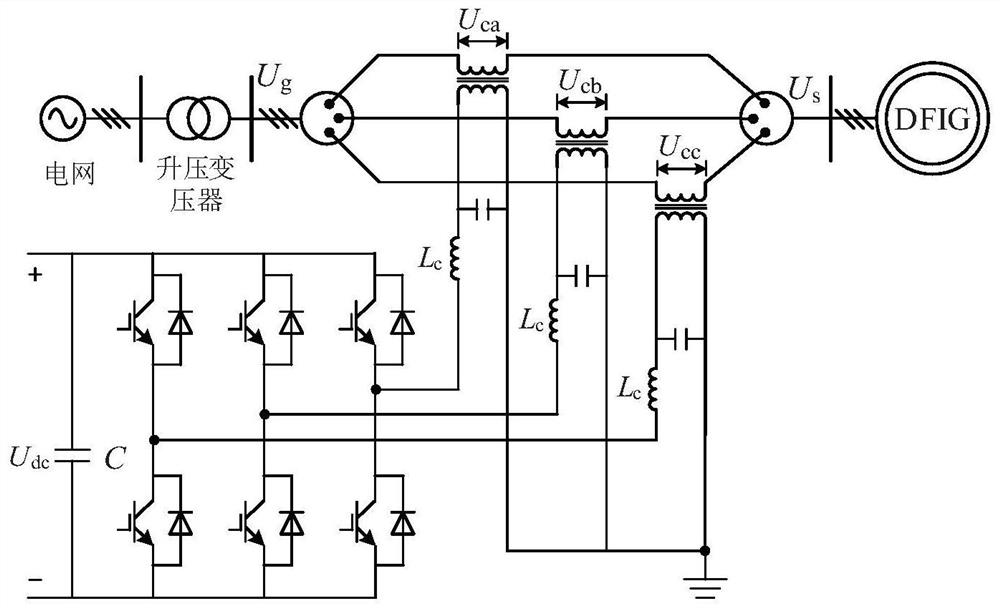

A ride-through operation method of dfig system under symmetrical voltage fault

ActiveCN109256798BImprove anti-interference abilityReduce adverse effectsSingle network parallel feeding arrangementsWind energy generationControl theoryMechanical engineering

The invention discloses a method for running through a DFIG system under voltage symmetrical faults. The grid side of the DFIG system is provided with a series grid-side converter. The running method includes: when a symmetrical fault occurs in the grid voltage, obtain The positive sequence component of the stator voltage is calculated by using the positive sequence component of the grid voltage and the stator voltage to obtain the compensation voltage that the series grid side converter should output; the stator voltage and the parallel grid side converter are compensated by using the compensation voltage that the series grid side converter should output The AC voltage keeps the stator voltage, rotor voltage, stator current, and rotor current in the state before the fault, and at the same time keeps the AC voltage of the parallel-connected side converter unchanged, thereby stabilizing the DC bus voltage. The invention overcomes the bad influence caused by the fault voltage of the power grid on the doubly-fed wind power generation system, prevents the wind generator set from disconnecting from the power grid when the power grid voltage fails, and maintains grid-connected operation.

Owner:HUAZHONG UNIV OF SCI & TECH

Organic gas deep dehydration device and vinyl chloride regeneration method and nitrogen regeneration method using it

ActiveCN106582218BAvoid problems such as cumulative quality degradationImprove product qualityGas treatmentChemical industryDecompositionPolyvinyl chloride

The invention relates to the technical field of chloroethylene monomer drying and provides a deep dewatering device for organic gas and chloroethylene and nitrogen regenerating methods utilizing the same. The deep dewatering device comprises a feed gas cooler, a VCM steam-water separator, at least three VCM dry adsorption towers, a de-rectification header pipe, a depressurization pipe, a gasometer header pipe, a before-machine steam-water separator, gas regeneration header pipe, a compressor, an behind-machine demister, an behind-machine steam-water separator, a steam heater, before-machine cooler and a before-machine demister. According to the chloroethylene and nitrogen regenerating methods utilizing the deep dewatering device for the organic gas, the problems that meta-acid of a rectification system and accumulated quality declining of vinyl chloride monomers are caused by feed gas chloroethylene decomposition under the high temperature are avoided. The water content of the vinyl chloride monomers produced through a treatment calcium carbide method can be controlled below 150 mg / Kg. Therefore, by adoption of the deep dewatering device for the organic gas and the chloroethylene and nitrogen regenerating methods utilizing the same, the polyvinyl chloride product quality can be effectively improved, and the deep dewatering device for the organic gas and the chloroethylene and nitrogen regenerating methods utilizing the same particularly play an important role in product upgrading and high-quality resin producing; and meanwhile, energy can be effectively saved, energy consumption can be effectively lowered, and continuous operation can be achieved.

Owner:新疆圣雄氯碱有限公司

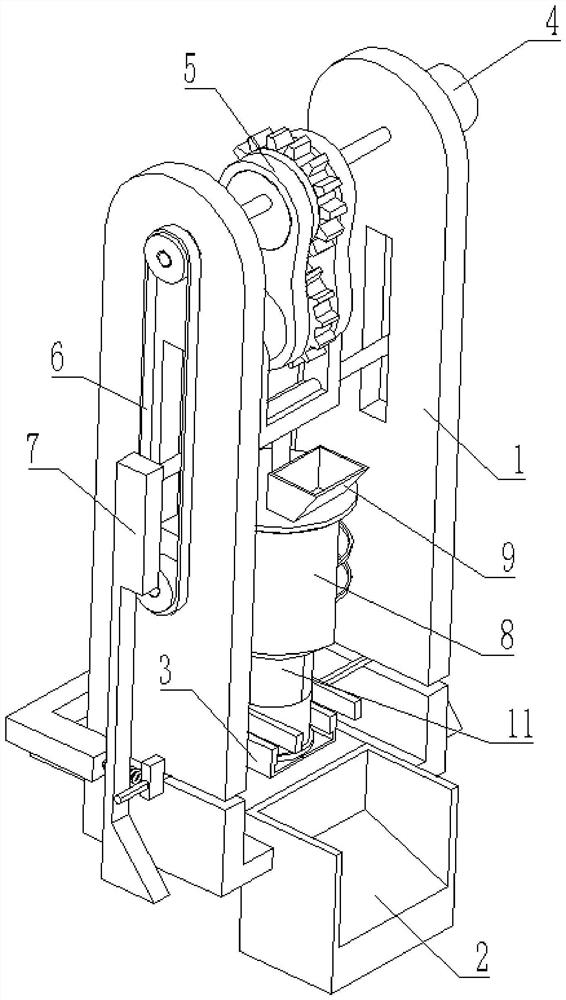

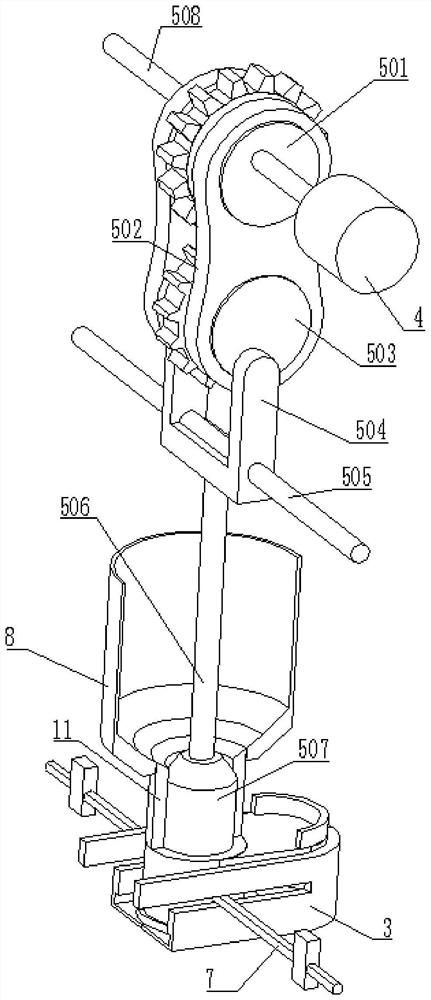

Extrusion device capable of automatically feeding and discharging

The invention relates to the technical field of powder processing, and discloses an extrusion device capable of automatically feeding and discharging. The extrusion device comprises a rack, wherein the bottom of the rack is fixedly connected with a material guide plate; the inner part of the rack is fixedly connected with a fixed slide plate; a material pushing mechanism is arranged on the surfaceof the rack; the right side of the rack is connected with a motor through a bolt; the output end of the motor is equipped with an extrusion mechanism; the inner wall of the rack is fixedly connectedwith a box body; and a mixing mechanism is arranged inside the box body. According to the extrusion device capable of automatically feeding and discharging disclosed by the invention, during the up-and-down movement of a connecting frame, an extrusion hammer can be driven to perform extrusion forming on powder up and down; when the extrusion hammer moves upwards, a flowing-out gap provides powderinto a cavity, so that automatic feeding is performed each time, and materials fed each time are basically consistent, and therefore, the same quality effect of extrusion each time can be guaranteed very well, the consistency of product quality can be guaranteed very well, and the integral quality of a product is improved.

Owner:张君

Load optimization and control method and system for short-process iron and steel enterprises considering process constraints

ActiveCN111769555BCorrection and refinement of waiting time constraintsHigh engineering practical valuePower network operation systems integrationLoad forecast in ac networkLoad optimizationBusiness enterprise

This disclosure proposes a load optimization control method and system for short-process iron and steel enterprises that take into account process constraints, including the following steps: obtaining enterprise equipment parameters, number of heats, number of castings, duration of processing and transportation tasks of furnaces, and Composition of furnaces; Reconstruct the discrete-time RTN model based on the obtained data, and construct the production constraints of short-process iron and steel enterprises; set the objective function to minimize the cost of electricity purchase, and obtain the production load of the enterprise through the objective function and the solution model of production constraints The optimal control strategy, that is, the specific start and stop times of different individuals in various key electrical equipment. This disclosure accurately combines power consumption and production tasks under the premise of ensuring that the iron and steel enterprise's process restrictions are strictly satisfied, so that the load optimization control strategy formulated with the goal of minimizing the enterprise's electricity purchase cost has practical operability while improving the efficiency of the enterprise. economic benefits.

Owner:SHANDONG UNIV +1

Fully-automatic loading and unloading device used in processing semiconductor chips by laser and application method thereof

ActiveCN102723302BEasy to operateImprove efficiencyConveyor partsLaser beam welding apparatusLaser processingSemiconductor chip

The invention discloses a fully-automatic loading and unloading device used in processing semiconductor chips by laser and an application method thereof. The fully-automatic loading and unloading device used in processing semiconductor chips by laser comprises a support frame, a laser processing platform, a chip transmission mechanism, and a linkage loading and unloading mechanism, wherein the laser processing platform is arranged on the top end of the support frame, the chip transmission mechanism is arranged on the support frame and located below the laser processing platform, and the linkage loading and unloading mechanism is arranged in the support frame and located below the chip transmission mechanism. The fully-automatic loading and unloading device of the invention has the advantages that human operation is not needed in loading and unloading processes and the loading and unloading processes are performed simultaneously, which improves production efficiency and rate of finished products, avoids pollution to the chips caused by direct contact of workers with the chips, improves the quality of the products, realizes seamless linkage between the current working procedure and the previous and the next working procedures at the same time, and omits a step of workpiece transportation by human labor between two working procedures.

Owner:HEFEI ZHICHANG PHOTOELECTRIC TECH

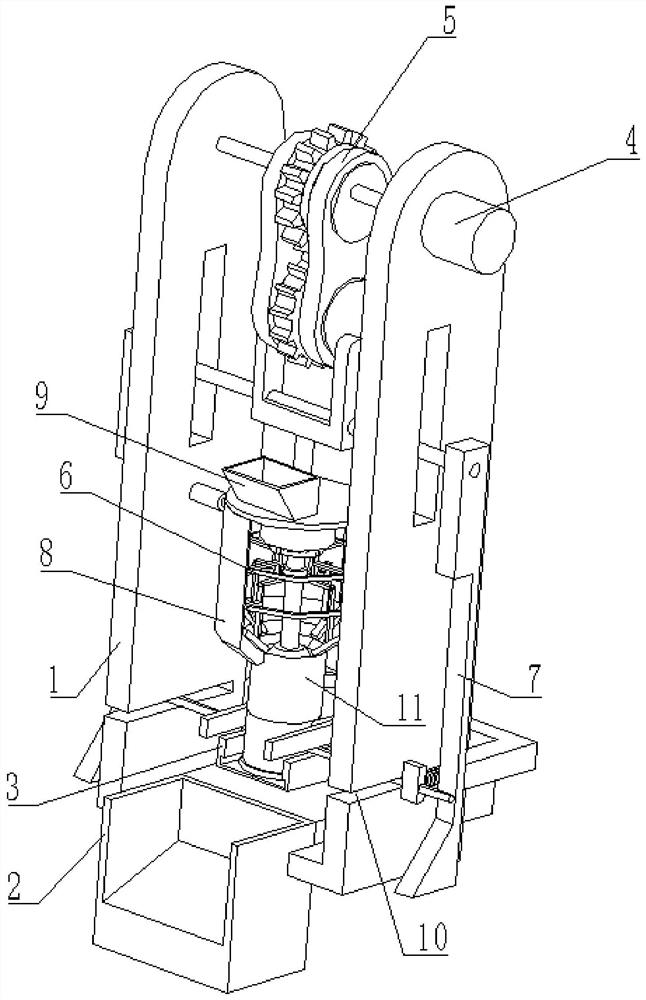

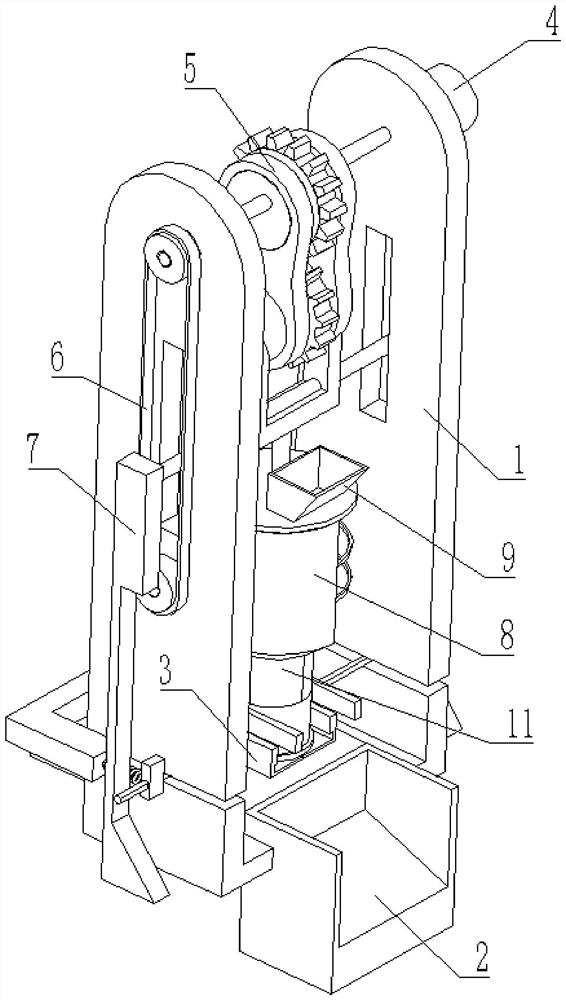

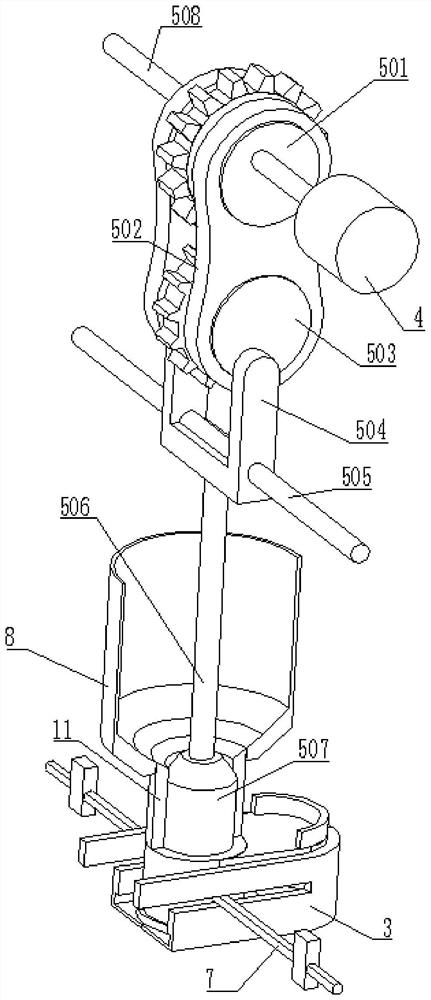

Transfer processing unit for internally toothed lock washers

ActiveCN107413972BAlignment process is quick and easyAlignment is simple and convenientMetal-working feeding devicesStripping-off devicesEngineeringMechanical engineering

The invention relates to the field of part machining and particularly discloses a conveying machining device for internal tooth locking washers. According to the device, a calibration stamping mechanism is adopted, and before stamping of the internal tooth locking washers is started, the positions of the internal tooth locking washers can be calibrated through driving levers and a rotatable extending-and-contracting rod; and it is guaranteed that a stamping portion of each internal tooth locking washer can be subjected to stamping precisely, furthermore, stamping quality of the internal tooth locking washers is improved, and the stamping defective rate of the internal tooth locking washers is lowered. By means of the conveying device, the internal tooth locking washers can be aligned with a stamping head and jacking rods, and stamping efficiency of the internal tooth locking washers is improved.

Owner:CHONGQING YOUBO MACHINERY MFG

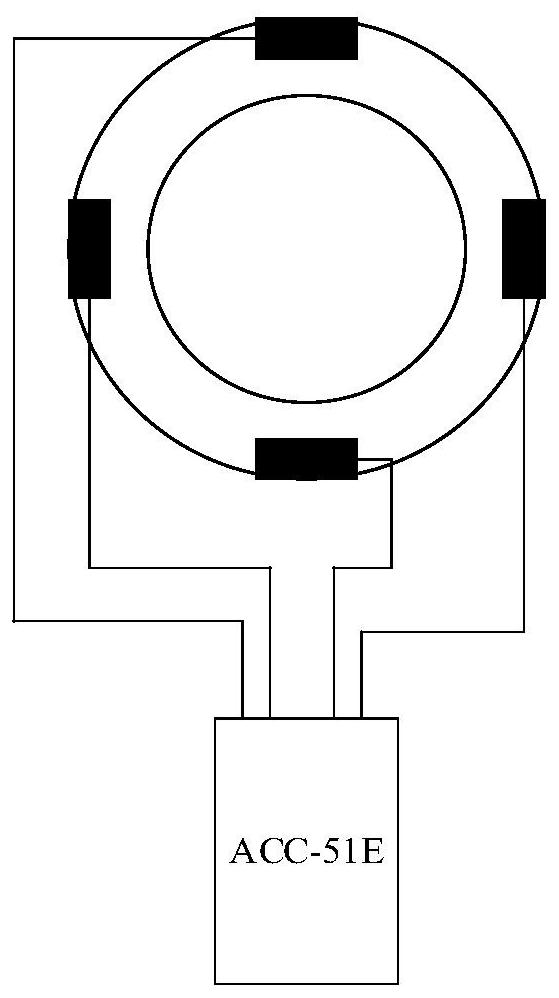

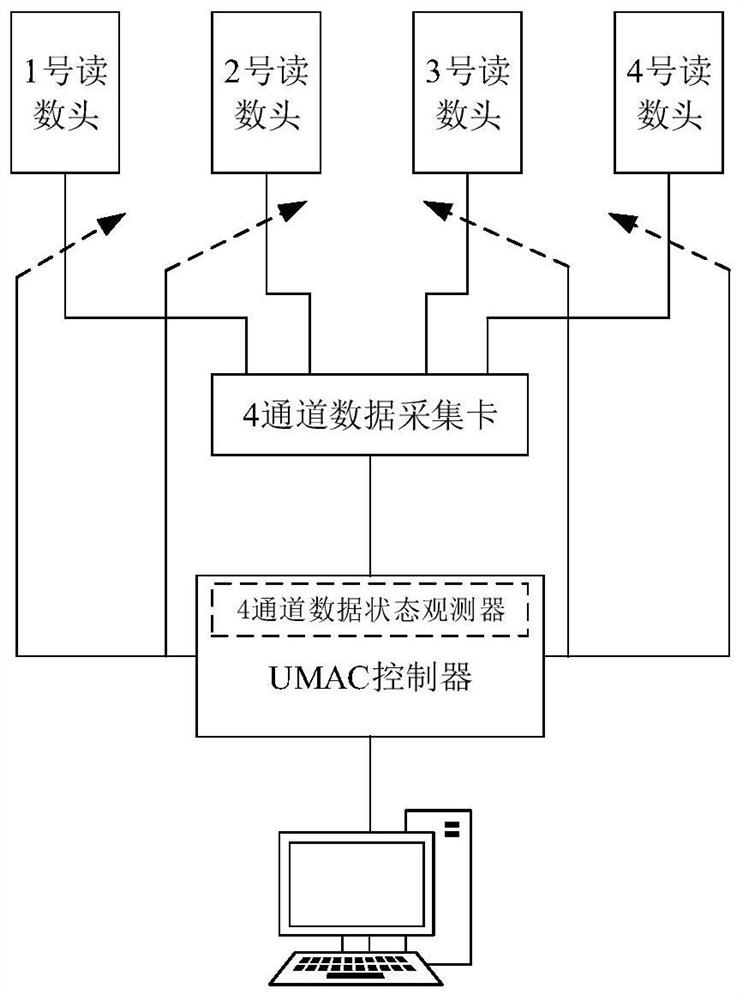

Applicable to the method of automatically shielding the fault reading head of position sensor in extreme environment

Applicable to the method of automatically shielding the faulty reading head of the position sensor in extreme environments: preset the corresponding rules for the output data of the faulty reading head; the controller has a built-in four-channel data state observer, which detects the variable values corresponding to the four When the signal appears the preset characteristics in the corresponding rules of the preset fault reading head output data, the data masking algorithm is executed; the program is written according to the preset fault characteristics and data masking algorithm, and the automatic masking of the faulty reading head data is realized without affecting the operation of the equipment . The present invention also includes related software design schemes, and the program is written according to the principle of the four-channel data state observer designed above. The invention realizes the automatic shielding of the faulty reading head data of the grating position sensor in the extreme environment, and is used for the fault diagnosis and isolation of the multi-reading head grating angle measuring device.

Owner:NANJING INST OF ASTRONOMICAL OPTICS & TECH NAT ASTRONOMICAL OBSE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com