Automatic production line of aluminum ceiling gusset plates

An automatic production line and smallpox technology, applied in the direction of forming tools, feeding devices, positioning devices, etc., can solve the problems of increased labor costs, slow movement speed, low efficiency, etc., and achieve the effect of increasing production speed and simple and practical palletizing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

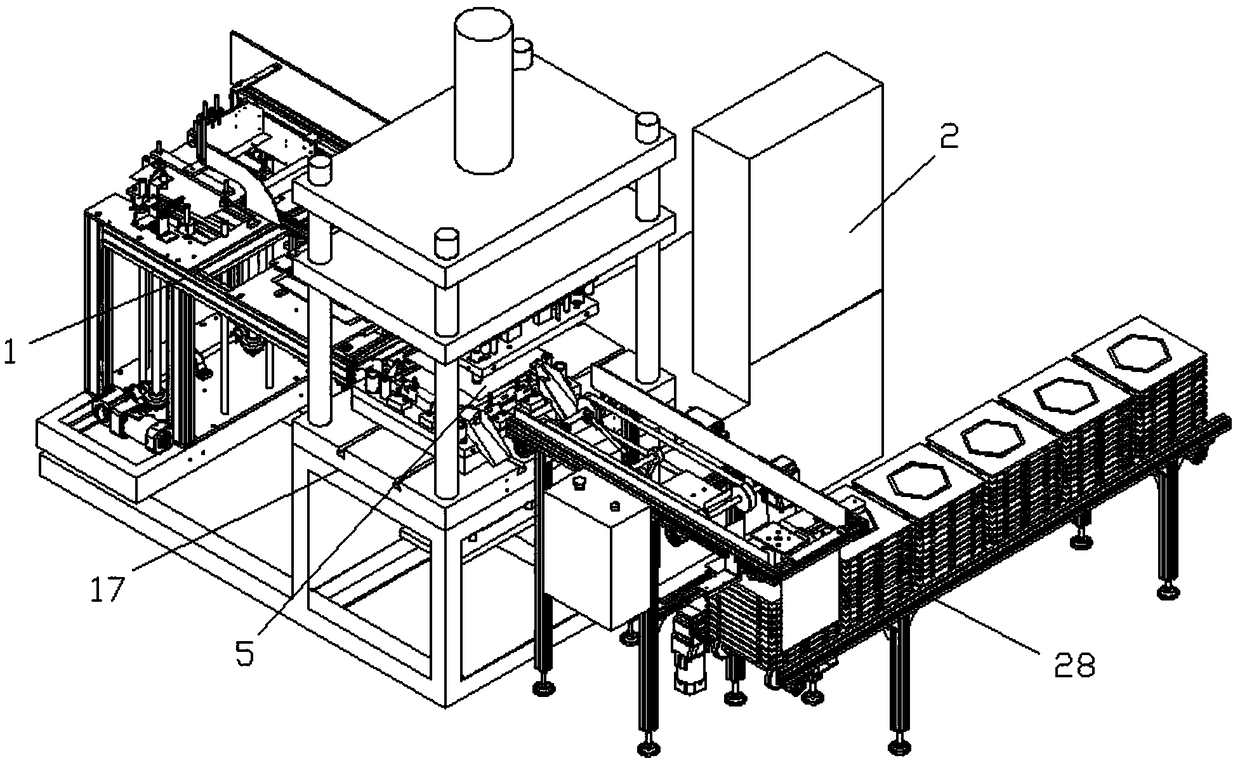

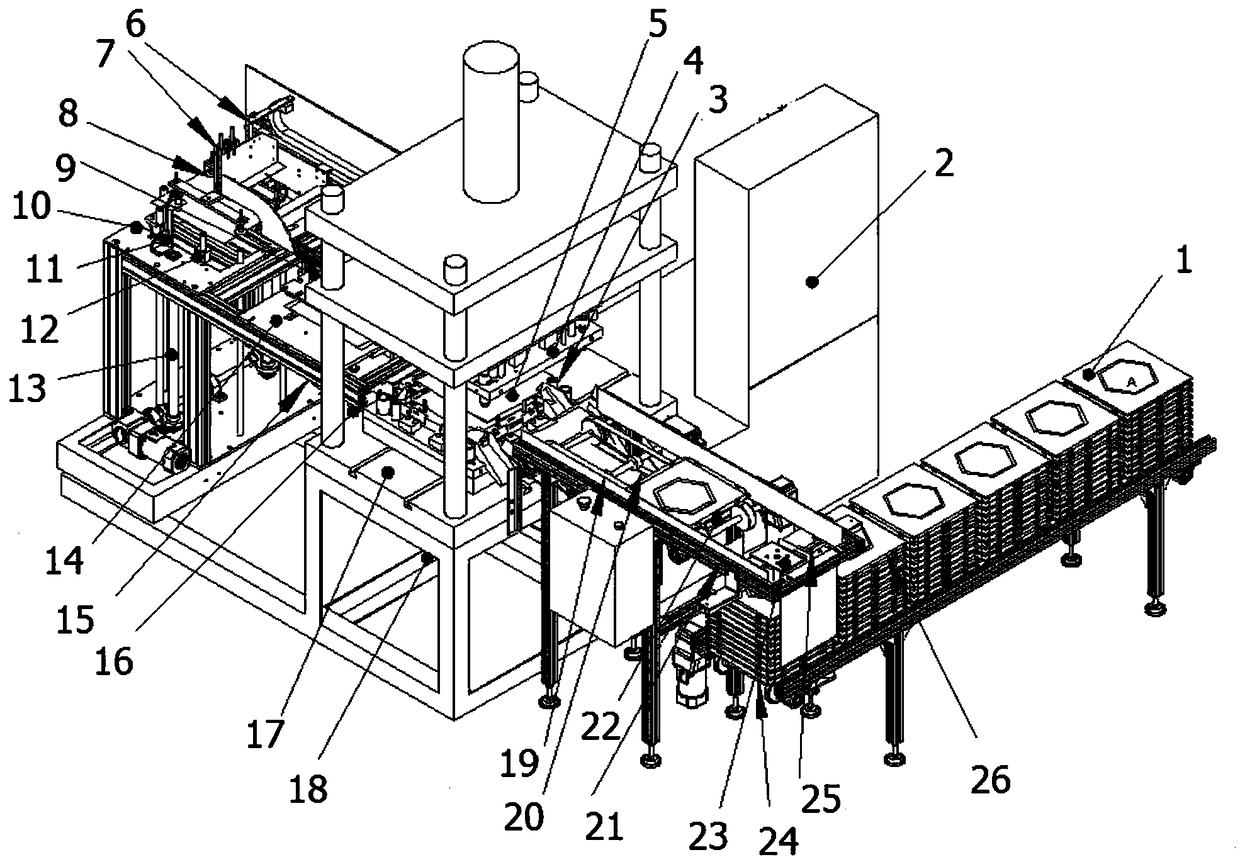

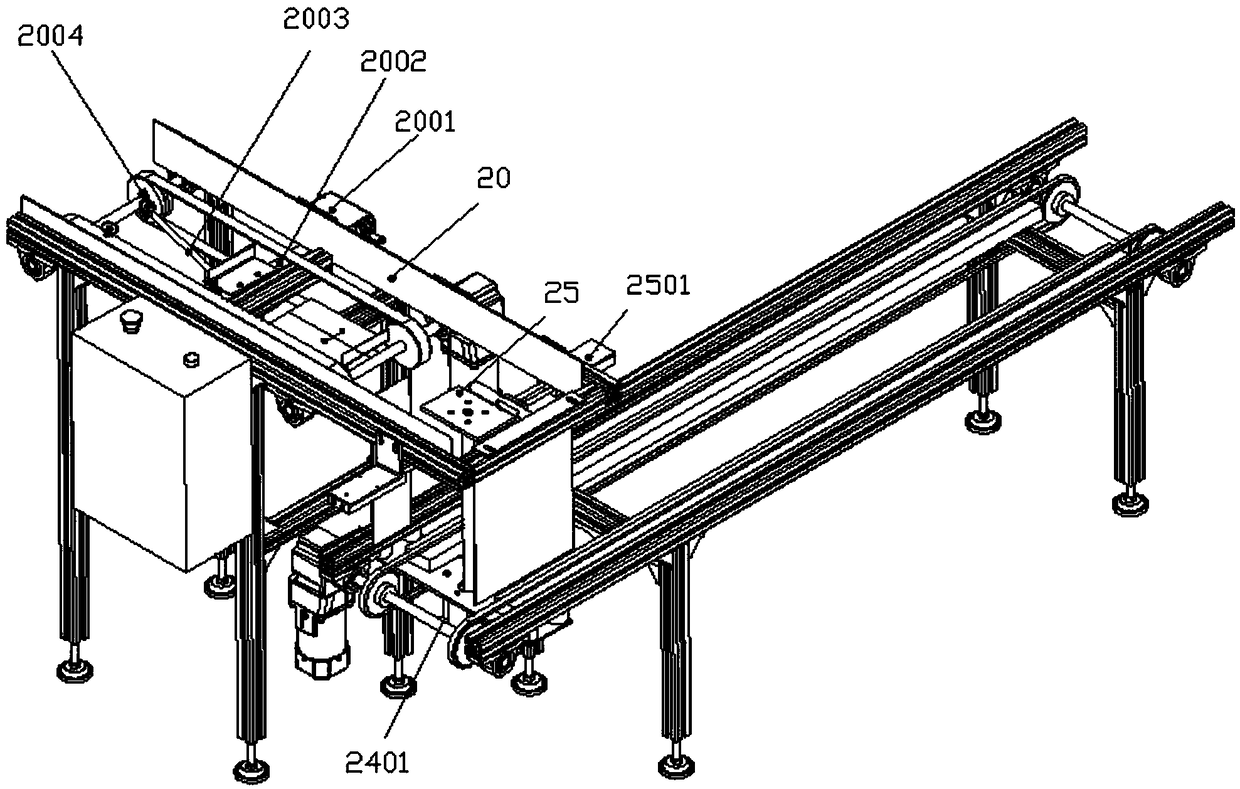

[0033] see Figure 1-10 , the present invention provides a technical solution: an automatic production line for aluminum ceiling gussets, including a feeder 1, a hydraulic press 17, a forming mold 5, a receiving machine 28 and a control electric cabinet 2, and the receiving machine 28 is provided with a finished product buffer delivery Belt 26, the finished product buffer conveyor belt 26 temporarily stores the finished product 27 to be boxed, and one end of the finished product buffer conveyor belt 26 is provided with a palletizing device 23, and the palletizing device 23 is composed of a supporting handle 25 and a lifter 24, and the finished product buffer conveyor belt 26 The front end of the front end is provided with a turning machine 22, and the turning machine 22 is composed of a turning device 20, an outlet conveyor belt 19 and a stopper 21. One end of the turning machine 22 is provided with a hydraulic press 17, and the bottom end of the hydraulic press 17 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com