Pressure-maintaining vacuum suction cup jig for processing sheet parts in horizontal machining center

A machining center and vacuum suction cup technology, applied in metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve problems such as affecting product quality, unstable air pressure source, reducing production efficiency, etc., to reduce clamping time, improve Production efficiency and product quality, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] combined with Figure 1-11 The notations describe the invention in detail.

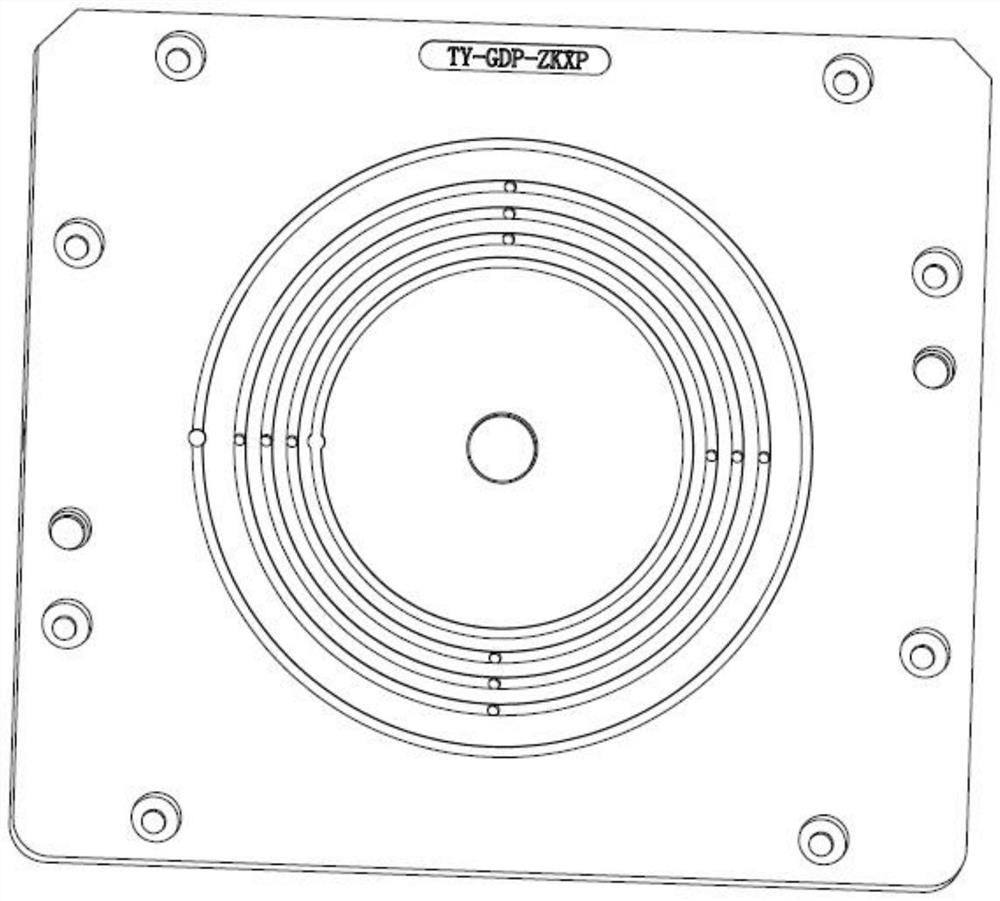

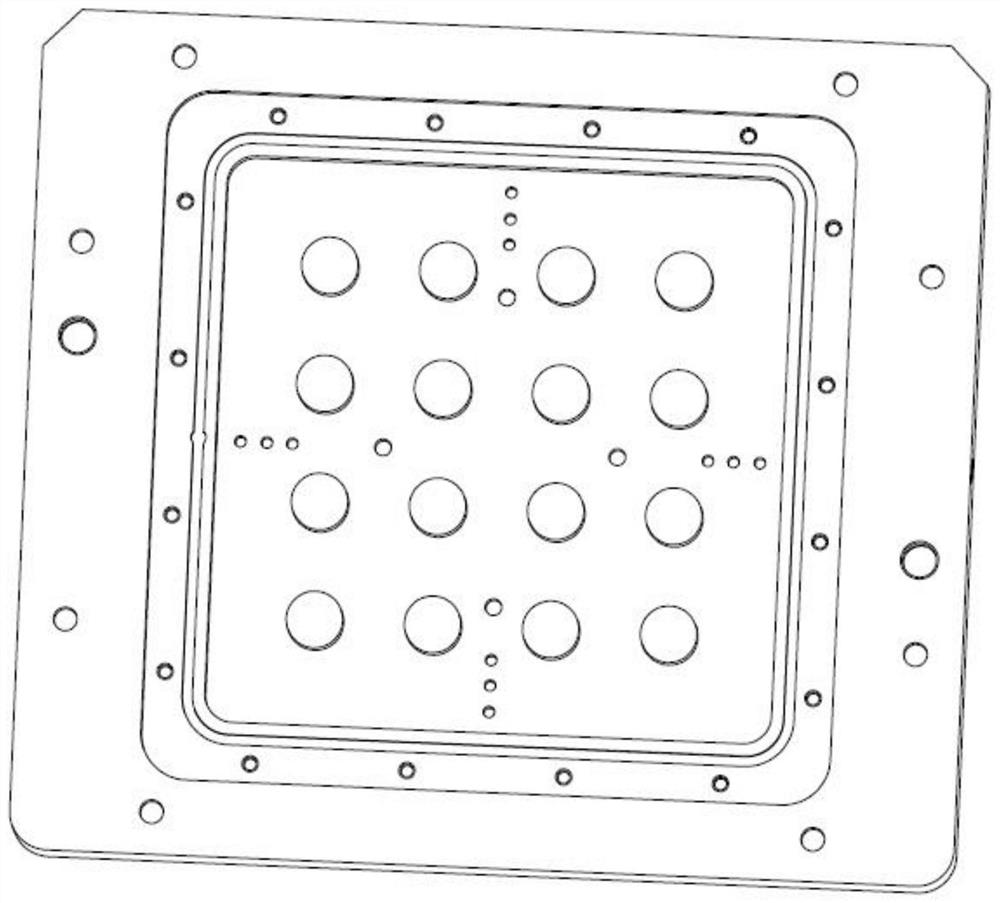

[0022] A pressure-holding vacuum suction cup fixture for processing thin plate parts in a horizontal machining center, including a vacuum adsorption platform 1, a sealing ring 2, a cover plate 3, a straight-through small ball valve 4, a pressure gauge 5, a bushing 6, a positioning pin 7, The base 8; the vacuum adsorption platform 1 is connected with the cover plate 3 through bolts and sealing rings 2; a straight-through small ball valve 4 is installed on one side wall of the vacuum adsorption platform 1; a pressure gauge 5 is installed on the other side wall of the vacuum adsorption platform 1 The vacuum adsorption platform 1 is installed on the base 8 through the positioning pin 7 and the bushing 6, and then the vacuum adsorption platform 1 and the base 8 are fixedly connected by screws.

[0023] The vacuum adsorption platform 1 is made of aluminum, and its shape and structure is a cuboid hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com