Conveyor device

A conveying device and conveying belt technology, which is applied to conveyor objects, transportation and packaging, electrical components, etc., can solve the problems of reducing production efficiency and increasing equipment cost investment, and achieve the effect of improving production efficiency and reducing cost investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

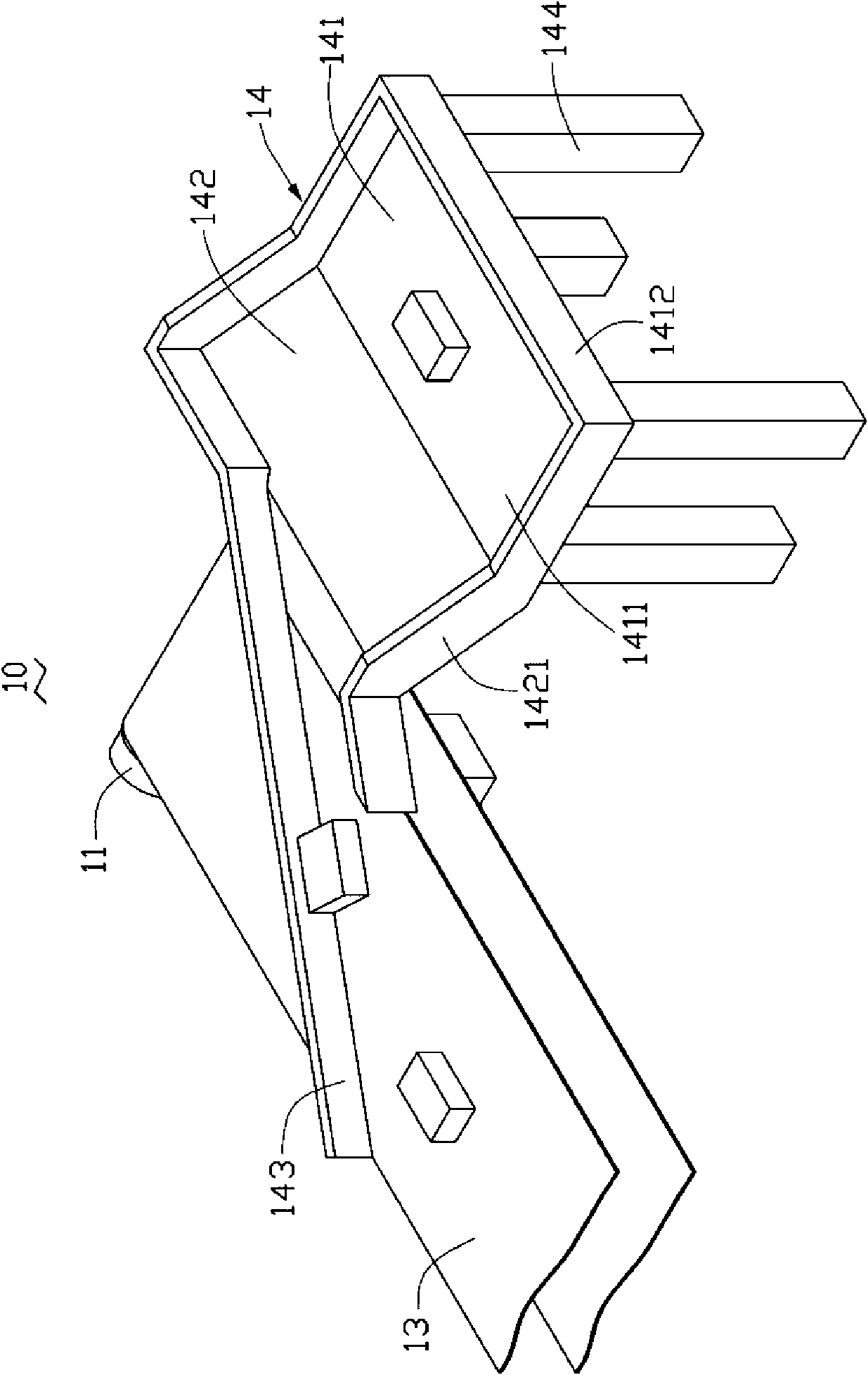

[0010] see figure 1 A preferred embodiment of the conveying device of the present invention is shown. The conveying device 10 includes a support 11 , roller shafts (not shown), a conveyor belt 13 and a wire take-up device 14 .

[0011] The support 11 can be formed by connecting several pillars to support the roller shaft 12 and the conveyor belt 13 .

[0012] The roller shaft is rotatably supported on the bracket 11 so that the conveyor belt 13 is sheathed and tensioned thereon.

[0013] The wire take-up device 14 includes a storage area 141 , a sliding plate 142 , a baffle plate 143 and four legs 144 .

[0014] The storage area 141 includes a bottom plate 1411 and a peripheral wall 1412 surrounding the bottom plate 1411 .

[0015] The sliding plate 142 is connected to the bottom plate 1411 at an obtuse angle, and two sides adjacent to the bottom plate 1411 are also provided with sidewalls 1421 . The side wall 1421 is integrally connected with the peripheral wall 1412 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com