Fully-automatic loading and unloading device used in processing semiconductor chips by laser and application method thereof

A laser processing and semiconductor technology, which is applied in the field of fully automatic loading and unloading devices for laser processing semiconductor wafers, can solve problems such as poor operating efficiency and scrap rate, and achieve the effects of quality assurance, simple operation, and shortened loading and unloading time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

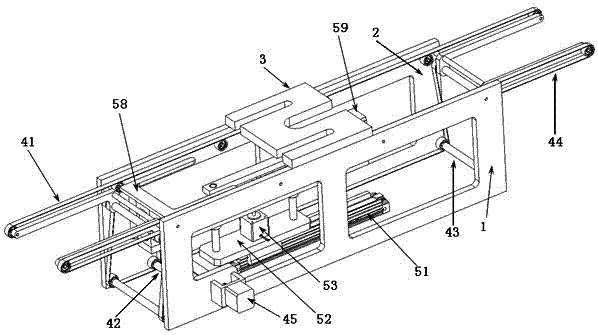

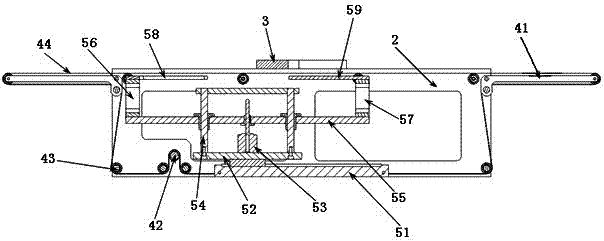

[0025] See figure 1 , figure 2 , a fully automatic loading and unloading device for laser processing semiconductor wafers, including a support frame composed of a front end plate 1 and a rear end plate 2, an M-shaped laser processing platform 3 arranged on the top of the support frame, arranged on the support frame and located at The wafer transmission mechanism below the M-shaped laser processing platform 3 and the linkage loading and unloading mechanism arranged in the support frame and below the wafer transmission mechanism;

[0026] The wafer transfer mechanism includes an idler arm 41 arranged at the top ends of the front end plate 1 and the rear end plate 2 and positioned below the level of the M-shaped laser processing platform 3, and a pulley set 42 connected between the front end plate 1 and the rear end plate 2 And idler group 43, the transmission belt 44 that is wound on pulley group 42, idler group 43 and idler arm 41 and the transmission driving device 45 that d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com