Intelligent welding and leakage-detecting device for refrigerator press cabin pipeline

A welding position and engine room technology, applied in auxiliary devices, welding equipment, metal processing, etc., can solve the problems of non-stop production line, tight manual operation time, and many welding spots, so as to reduce labor costs, improve work efficiency, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

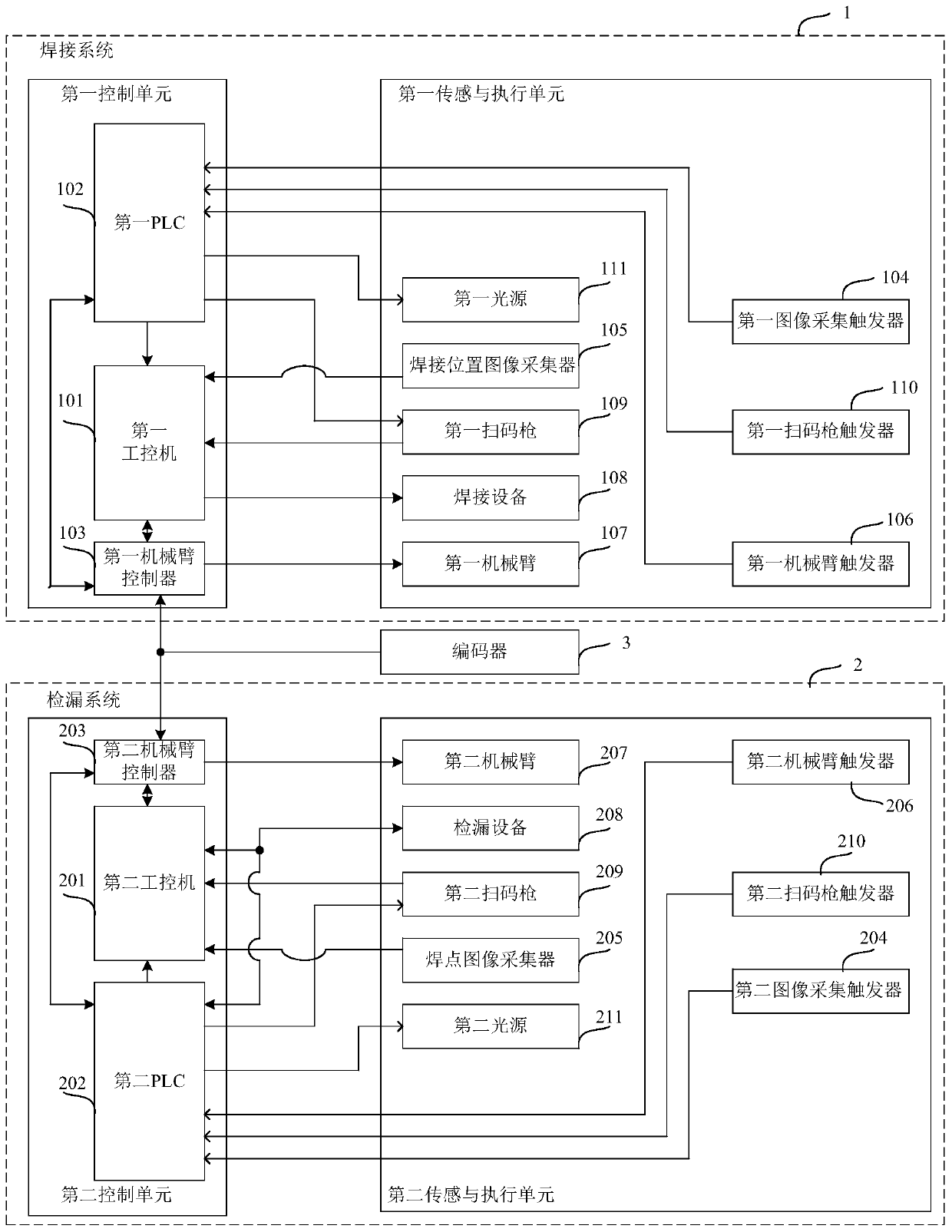

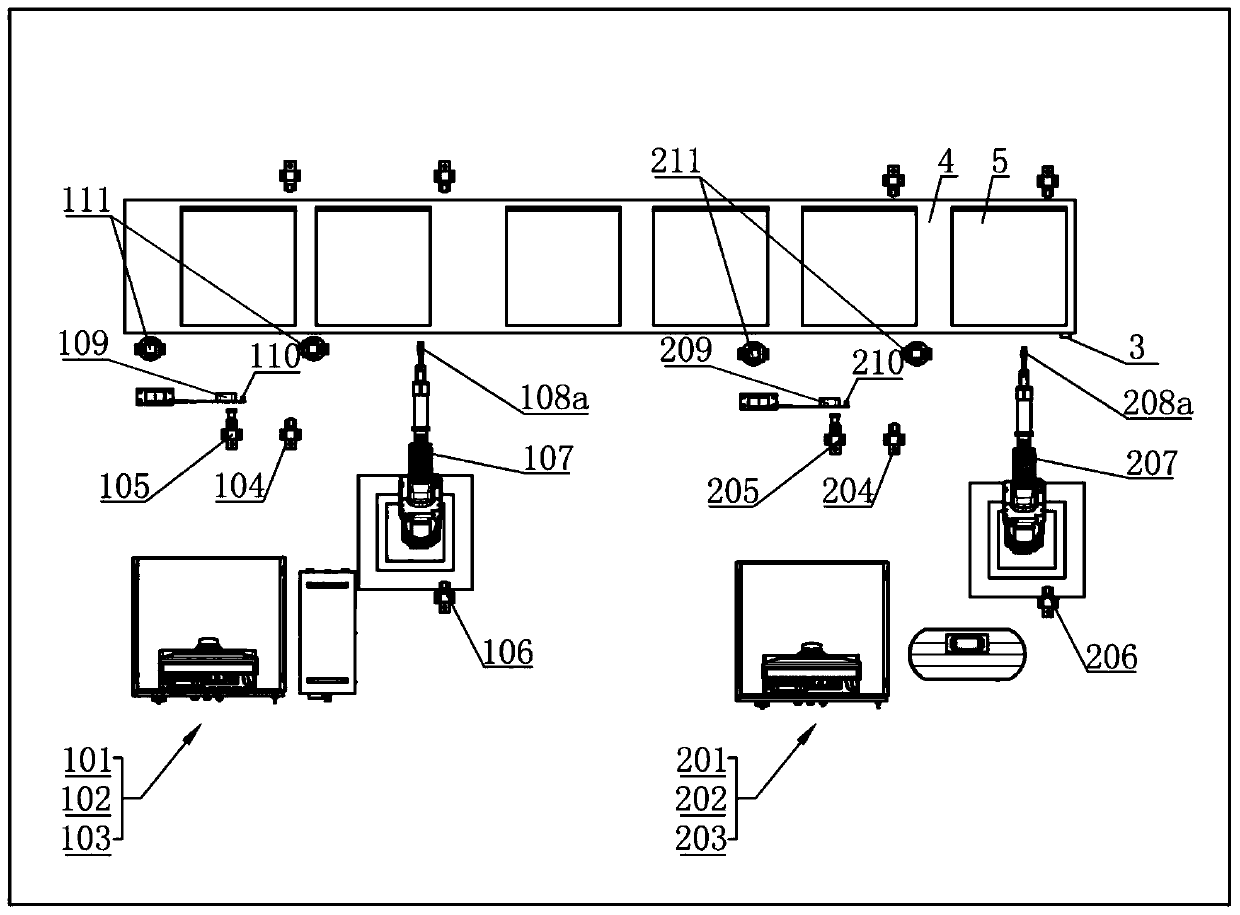

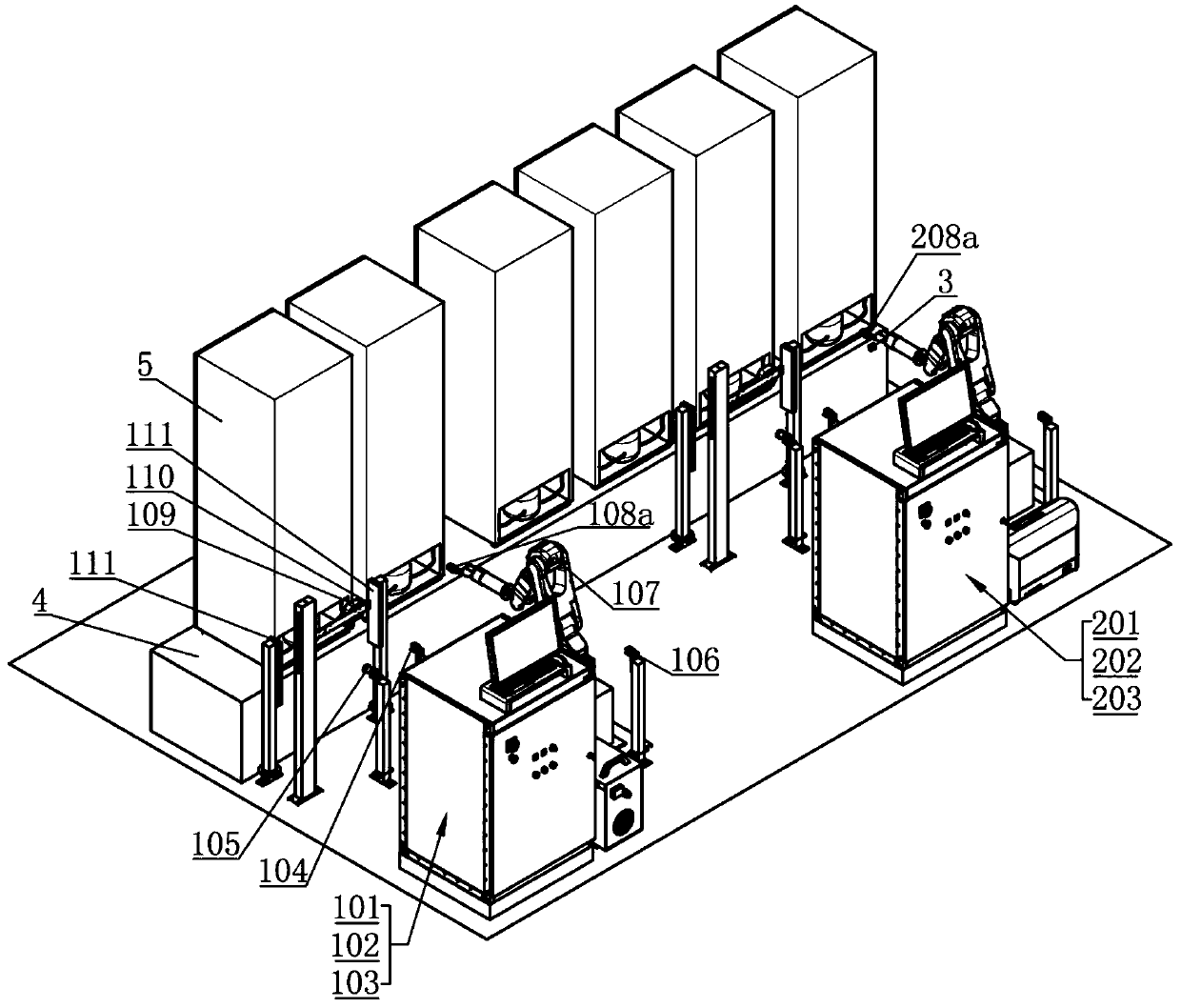

[0041] Please refer to Figure 1 to Figure 5 , the invention is an intelligent welding and leak detection device for pipelines in a compressor cabin of a refrigerator, which is used for welding pipelines in a compressor cabin 5 of a refrigerator on a production line and for leak detection of welded joints; it includes a welding system 1, a detection Leakage system 2 and encoder 3, welding system 1 and leak detection system 2 are all arranged in sequence along the transmission direction of production line conveyor belt 4, welding system 1 first welds the pipeline of refrigerator press cabin 5 on production line conveyor belt 4, and leak detection system 2 Carry out leak detection to the 5 solder joints of the refrigerator press cabin after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com