Intelligent leakage detection device for welding spot of refrigerator compressor room

A technology for solder joints and leak detection, applied in auxiliary devices, manipulators, welding equipment, etc., can solve the problems of unrealized automatic operations, tight manual operation time, increased labor costs, etc., achieve operational specifications, reduce labor costs, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

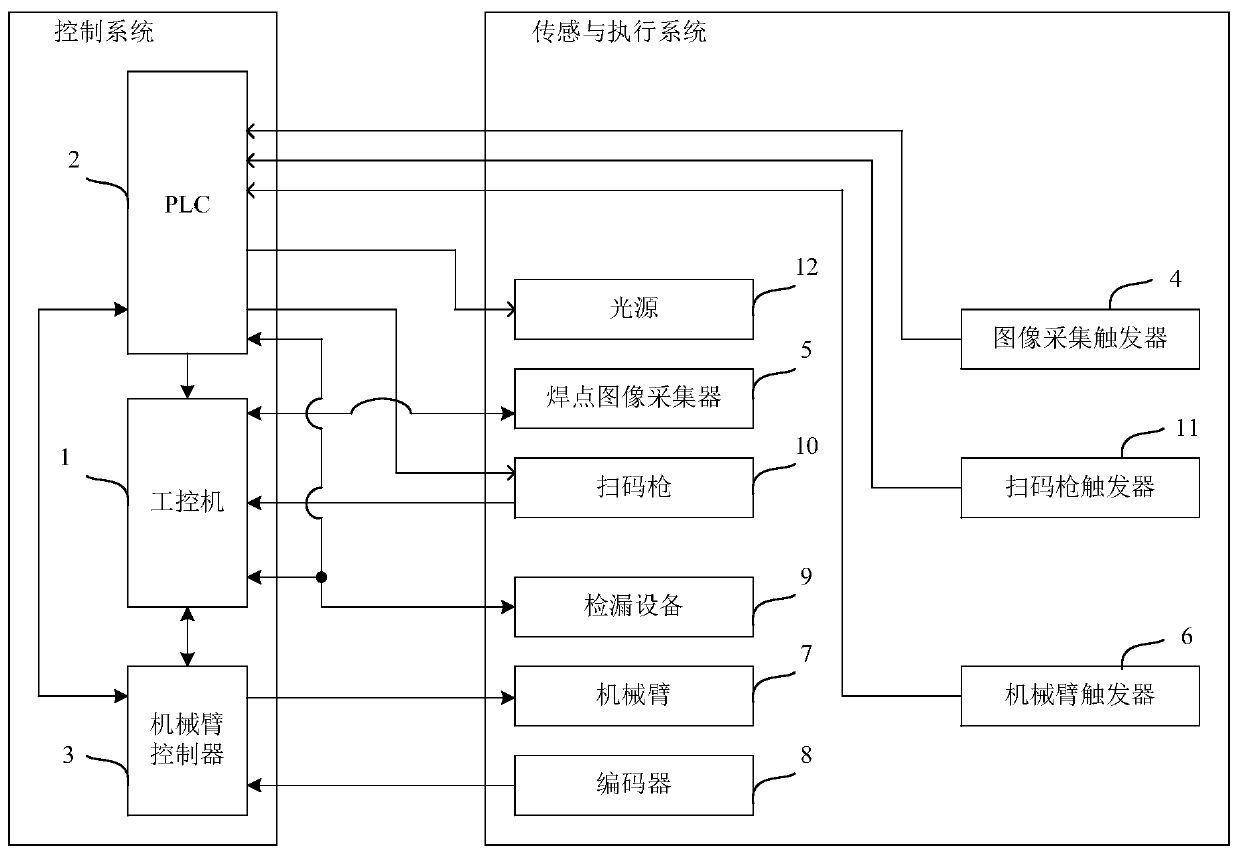

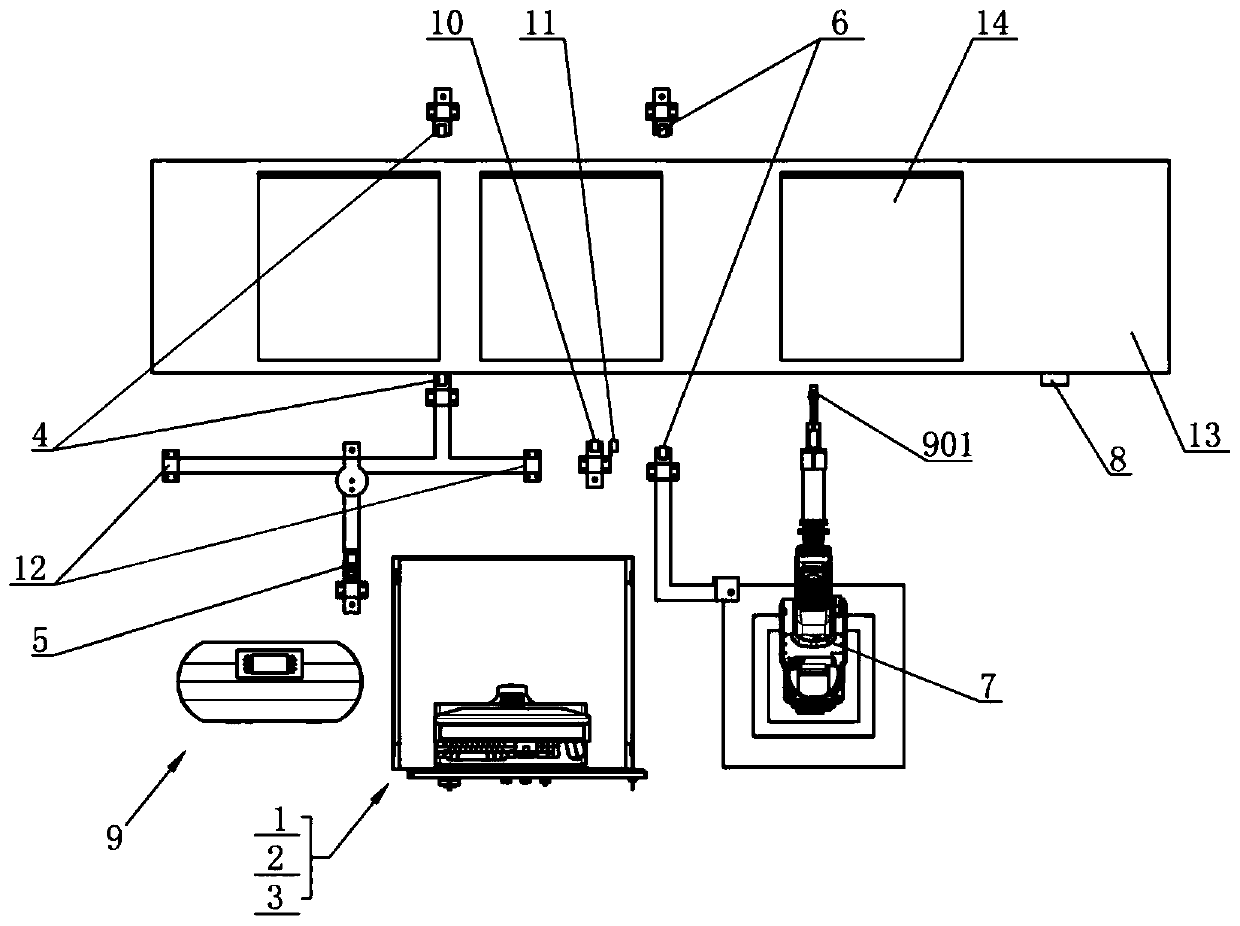

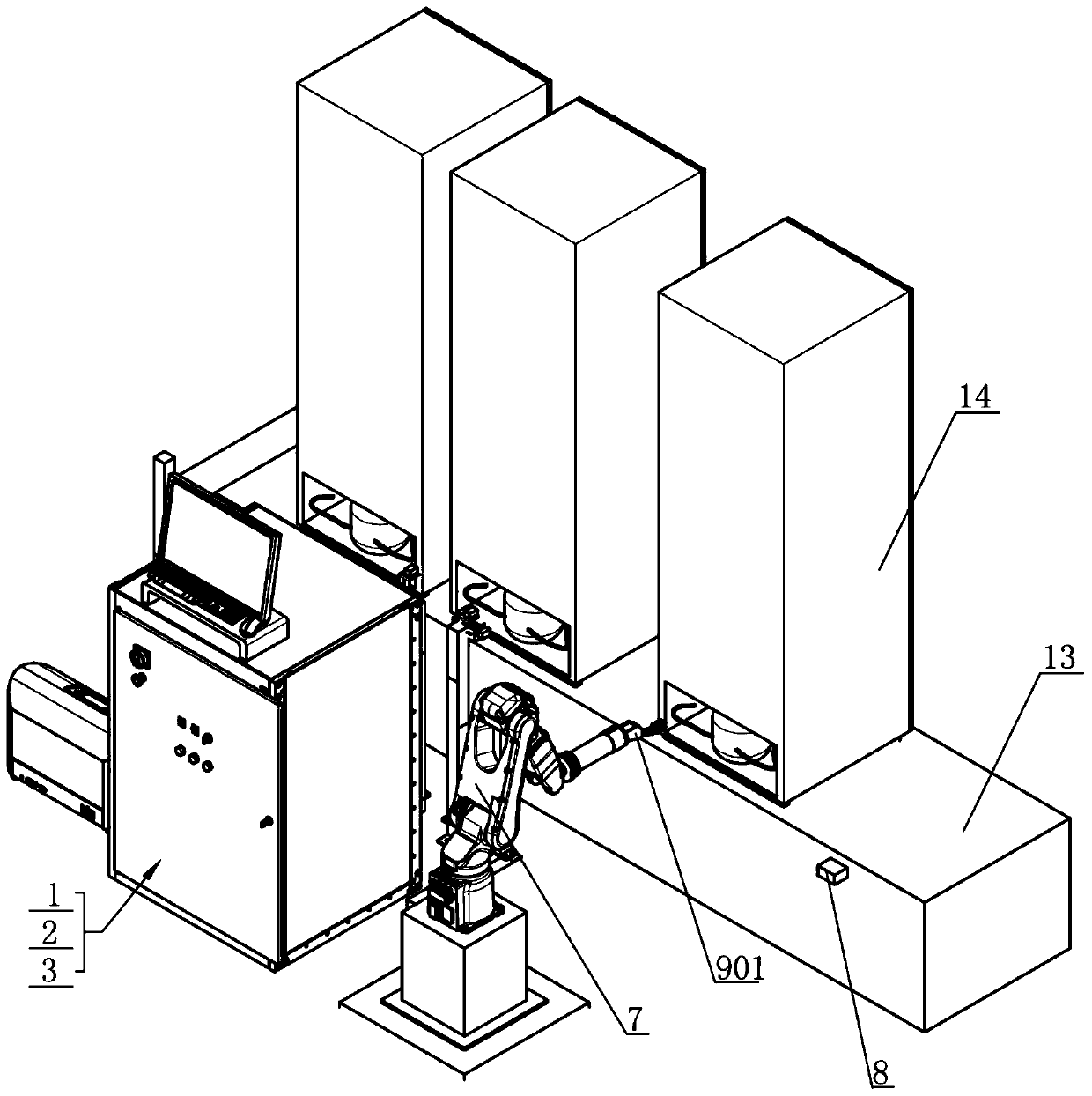

[0031] Please refer to Figure 1 to Figure 5 , the present invention is an intelligent leak detection device for the solder joints of the refrigerator press cabin, which is used for leak detection of the solder joints of the refrigerator press cabin 14 on the production line 13; the intelligent leak detection device includes a control system and a sensing and execution system; the control system includes Industrial computer 1, PLC2 connected to industrial computer 1 and robotic arm controller 3, PLC2 is electrically connected to robotic arm controller 3; the sensing and execution system includes image acquisition trigger 4, solder joint image collector 5, mechanical arm trigger device 6, mechanical arm 7, encoder 8, leak detection equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com