Deep dewatering device for organic gas and chloroethylene and nitrogen regenerating methods utilizing same

A deep dehydration, organic gas technology, applied in the fields of inert gas generation, chemical instruments and methods, gas treatment, etc., can solve the problems of water content difference and high production cost, and achieve the goal of reducing energy consumption, saving energy and improving product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

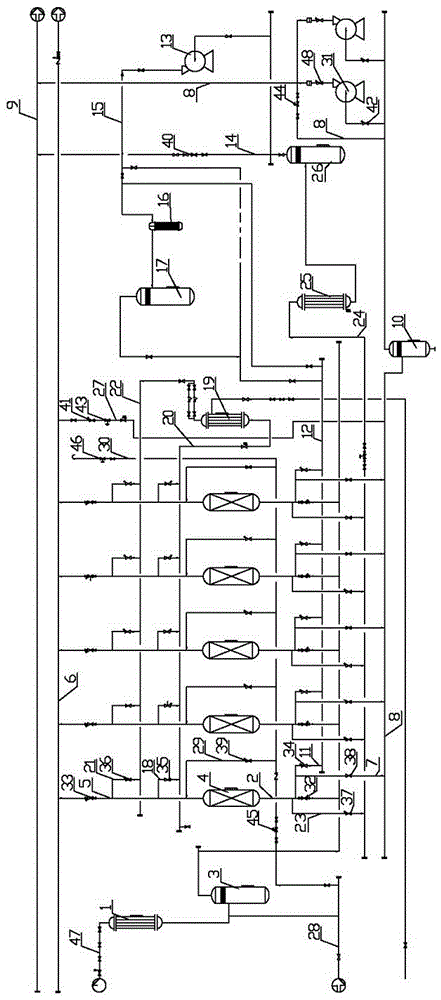

[0015] Embodiment 1, as attached figure 1 As shown, the organic gas deep dehydration device includes a feed gas cooler 1, a VCM vapor-water separator 3, at least three VCM drying adsorption towers 4, a rectification main pipe 6, a pressure drop pipe 8, a gas cabinet main pipe 9, and a pre-machine soda water Separator 10, regeneration gas main pipe 12, compressor 13, post-machine demister 16, post-machine steam-water separator 17, steam heater 19, pre-machine cooler 25 and pre-machine demister 26; 1 is connected with raw material gas pipeline 47, the outlet of raw gas cooler 1 is connected with the feed port of VCM steam-water separator 3, the gas phase outlet of VCM steam-water separator 3 is connected with the bottom feed port of each VCM dry adsorption tower 4 They are connected through raw material gas feed pipe 2, each raw gas feed pipe 2 is connected in series with a first valve 32, and the discharge port at the top of each VCM drying adsorption tower 4 is connected with ...

Embodiment 2

[0017] Embodiment 2, as the optimization of embodiment 1, as attached figure 1 As shown, the organic gas deep dehydration device also includes a nitrogen main pipe 28 and at least one vacuum pump 31, and a nitrogen feed branch pipe 29 is connected to the purified gas pipeline 5, and each nitrogen feed branch pipe 29 communicates with the nitrogen main pipe 28 , an eighth valve 39 is connected in series on each nitrogen feed branch pipe 29, a third regulating valve 45 is connected in series on the nitrogen main pipe 28 before the foremost nitrogen feed branch pipe 29, and a leak valve 45 is connected in series on the nitrogen main pipe 28. The pressure pipe 30 is connected in series with the fourth regulating valve 46 on the pressure relief pipe 30, and passes through the eleventh between the pressure-reducing pipe 8 between the pre-machine steam-water separator 10 and the second regulating valve 44 and the inlet of the vacuum pump 31. The valve 42 communicates, and the outlet ...

Embodiment 3

[0018] Embodiment 3, as attached figure 1 Shown, the vinyl chloride regeneration method carried out by the organic gas deep dehydration device of this use embodiment 1 is carried out according to the following steps, the method is carried out the statement of method with a VCM dry adsorption tower 4, the regeneration method of other VCM dry adsorption tower 4 In the same way, the regeneration gas is vinyl chloride gas: the first step is to reduce the pressure, and after the VCM drying adsorption tower 4 is saturated, close the first valve 32 and the second valve 33, and open the second regulating valve 44 and the seventh valve 38 , the crude vinyl chloride gas in the VCM drying adsorption tower 4 is sent to the gas cabinet, and after the pressure of the VCM drying adsorption tower 4 drops to 10kpa, the fifth valve 36 is closed; the second step, regeneration heating, opens the fifth valve 36, The sixth valve 37, open the ninth valve 40, simultaneously open the third valve 34 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com