Dry particle mixing device

A mixing device, dry particle technology, applied in mixers, mixing methods, solid and solid mixing, etc., can solve problems such as poor mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

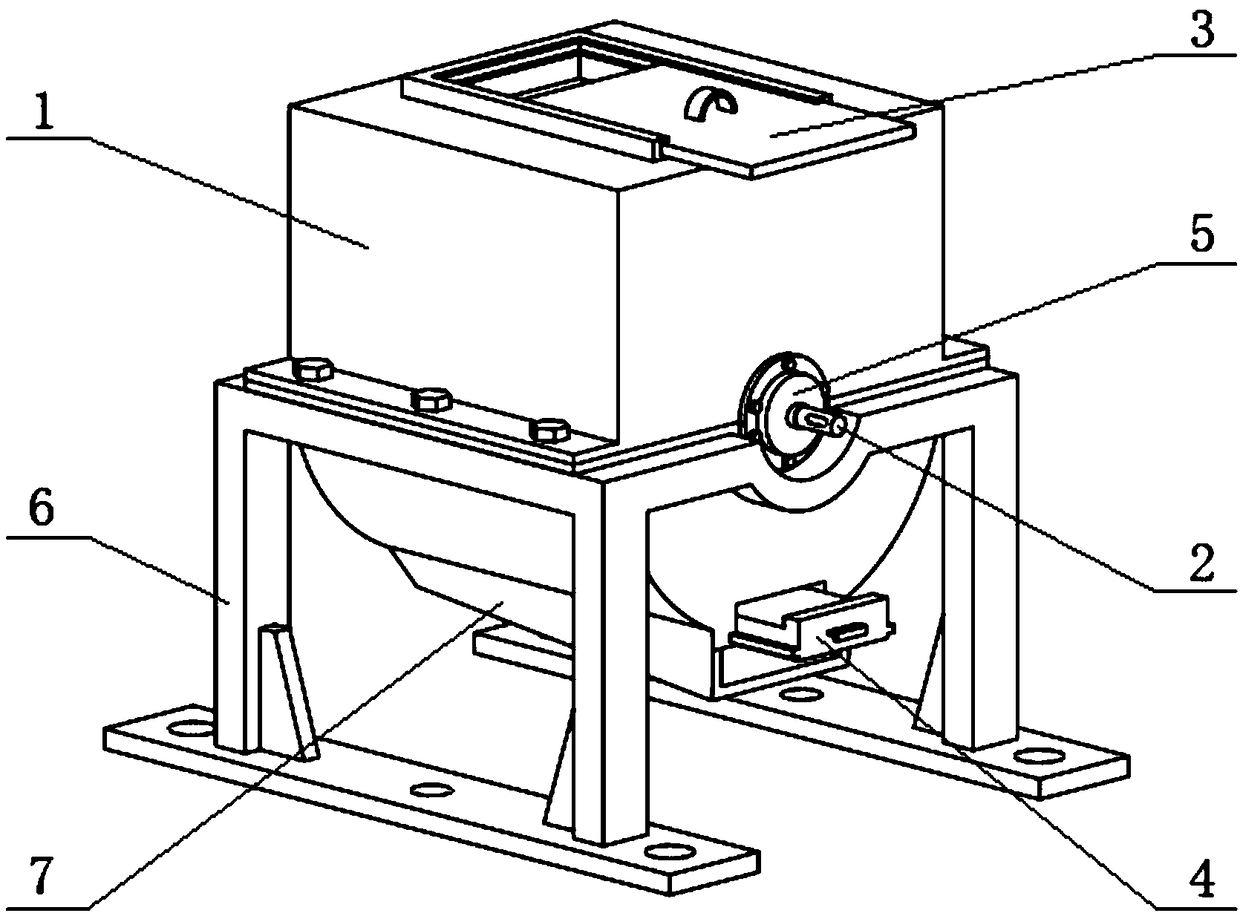

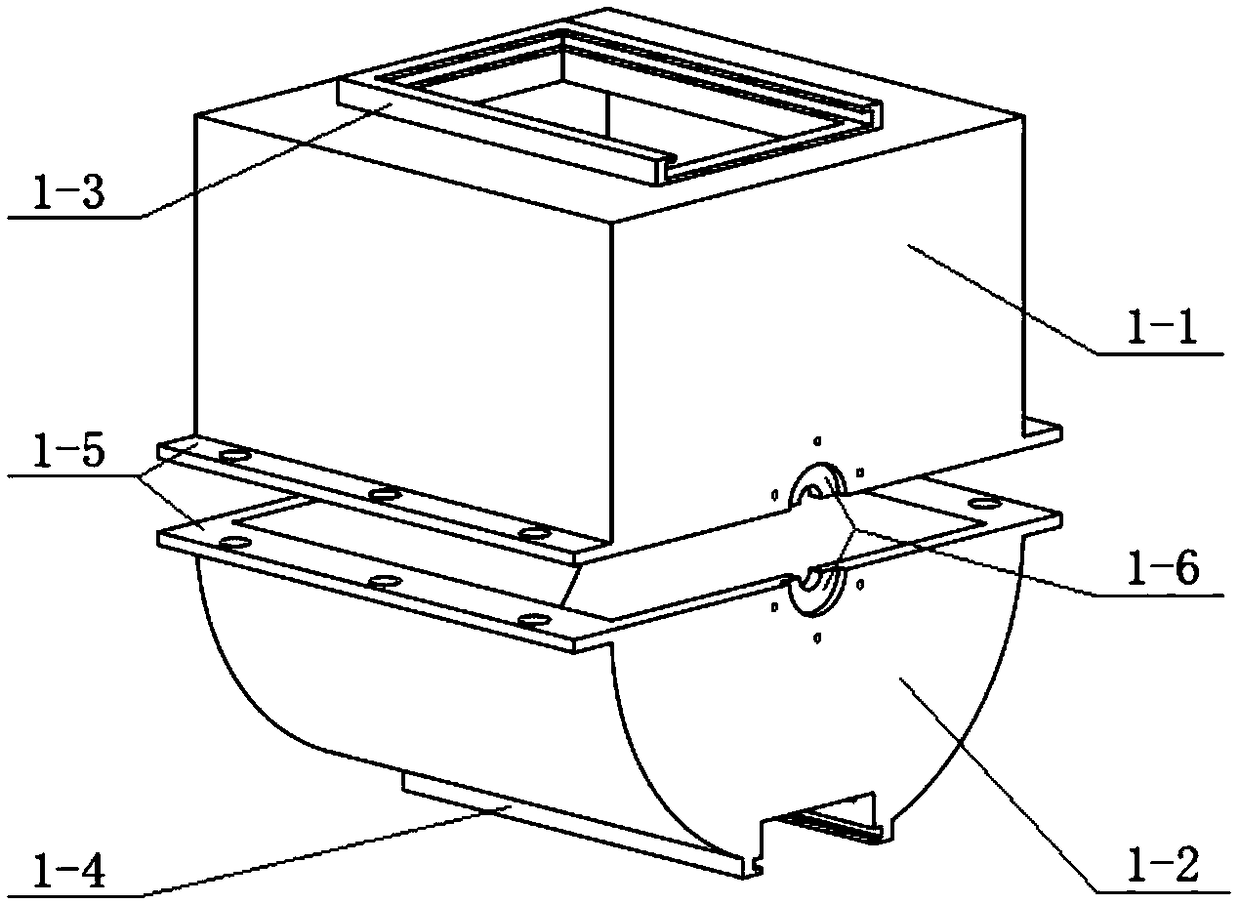

[0026] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

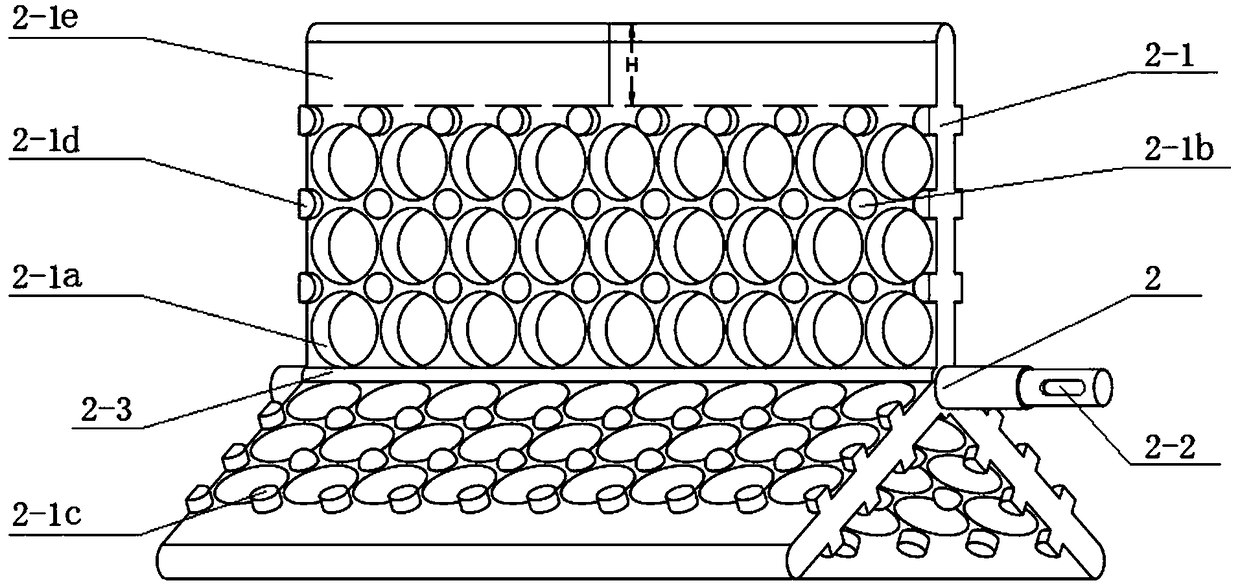

[0027] like figure 1 , figure 2 As shown, a dry particle mixing device of the present invention includes a mixing chamber 1 and an agitator located in the mixing chamber 1; the agitator is composed of an agitating shaft 2 and at least three agitating blades 2-1; the agitating blade 2-1 is provided with a fan-shaped rib 2-3 at the junction of the stirring shaft 2, and the area near the outer edge of each stirring blade 2-1 is the bare plate area 2-1e, and the stirring blade 2-1 outside the light plate area 2-1e There are a plurality of mixing holes along the horizontal and vertical directions, and a plurality of mixing protrusions are distributed on the stirring blade outside the bare plate area 2-1e at the same time, and the mixing holes and mixing protrusions are regular on the stirring blade 2-1 distributed.

[0028] The mixing hole is one o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com