High-volume fraction B4C and Si particle mixing enhancement aluminum-based composite material and preparation process thereof

An aluminum-based composite material with a high volume fraction technology, applied in the field of aerospace materials, can solve the problems of not meeting the high-performance requirements of aerospace light-weight, high-strength structural functional parts, and low comprehensive performance of materials, and achieve high strength, low equipment requirements, and high heat. The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

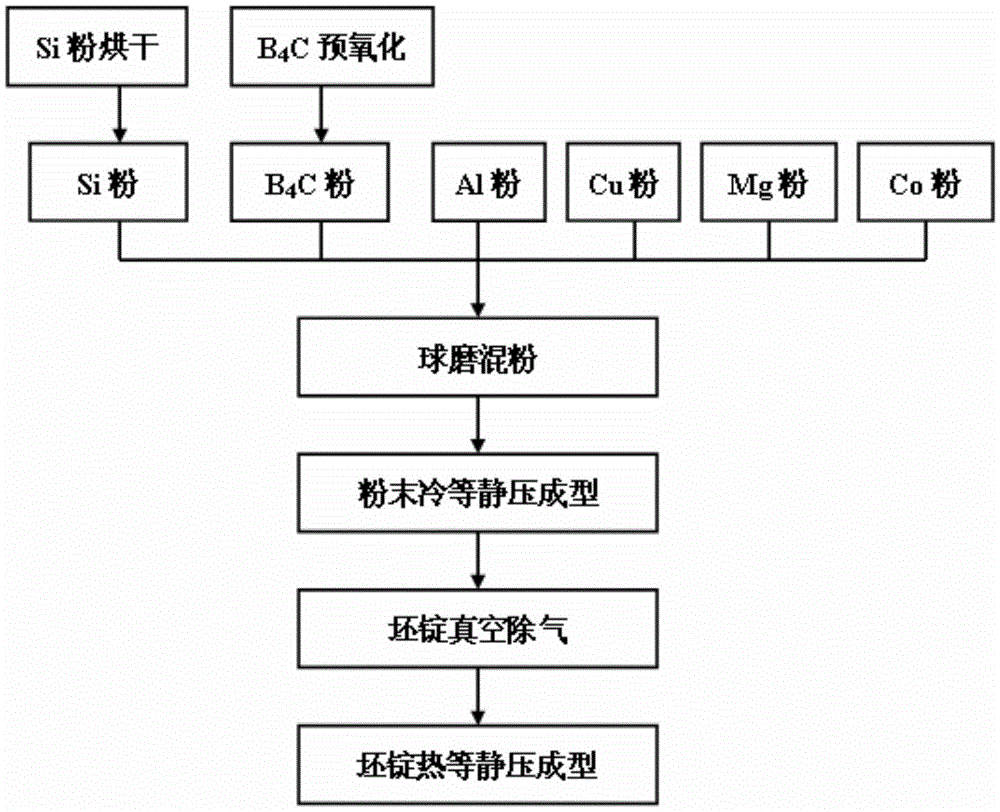

Method used

Image

Examples

Embodiment 1

[0027] The volume fraction of the composite material is: B 4 The C content is 55vol.%, the Si content is 5vol.%, and the Al-Cu-Mg-Co matrix content is 40vol.%. Above B 4 The particle size of C is 11μm, the particle size of Al powder is 20μm, the particle size of Cu powder is 10μm, the particle size of Mg powder is 25μm, and the particle size of Co powder is 3μm. First of all to B 4 The C and Si particles are pre-oxidized and dried separately, and the powder with the nominal composition of Al-3.5Cu-1.0Mg-0.5Co is configured, and then 55vol.% B 4 C. The mixed powder of 5vol.% Si and 40vol.% Al-3.5Cu-1.0Mg-0.5Co is mixed by ball milling, the ball mill speed is 100 rpm, the ball milling time is 20 hours, and the ball-to-material ratio is 2:1; the mixed powder After sieving, the cold isostatic pressing rubber sleeve is installed, and the cold isostatic pressing is formed after sealing. The cold isostatic pressing pressure is 120MPa, and the pressing time is 20 minutes; the cold isost...

Embodiment 2

[0030] The volume fraction of the composite material is: B 4 The C content is 55 vol.%, the Si content is 10 vol.%, and the Al-Cu-Mg-Co matrix content is 35 vol.%. Above B 4 The particle size of C is 11μm, the particle size of Al powder is 20μm, the particle size of Cu powder is 10μm, the particle size of Mg powder is 25μm, and the particle size of Co powder is 3μm. First of all to B 4 The C and Si particles are pre-oxidized and dried separately, and the powder with the nominal composition of Al-3.5Cu-1.0Mg-0.5Co is configured, and then 55vol.% B 4 C. 10vol.%Si and 40vol.%Al-3.5Cu-1.0Mg-0.5Co mixed powders are mixed by ball milling, the ball mill speed is 100 rpm, the ball milling time is 20h, and the ball-to-material ratio is 2:1; the mixed powder After sieving, the cold isostatic pressing rubber sleeve is installed, and the cold isostatic pressing is formed after sealing. The cold isostatic pressing pressure is 120MPa, and the pressing time is 20 minutes; the cold isostatic pr...

Embodiment 3

[0033] The volume fraction of the composite material is: B 4 The C content is 60vol.%, the Si content is 10vol.%, and the Al-Cu-Mg-Co matrix content is 30vol.%. Above B 4 The particle size of C is 11μm, the particle size of Al powder is 20μm, the particle size of Cu powder is 10μm, the particle size of Mg powder is 25μm, and the particle size of Co powder is 3μm. First, pre-oxidize and dry the B4C and Si particles respectively, configure the powder with the nominal composition of Al-3.5Cu-1.0Mg-0.5Co, and then add 55vol.% B 4 C, 10vol.% Si and 40vol.% Al-3.5Cu-1.0Mg-1.0 mixed powder mixed powder, ball mill speed 100 rpm, ball milling time 20h, ball to material ratio 2:1; pass the mixed powder After the sieve is put into the cold isostatic pressing rubber sheath, after sealing, the cold isostatic pressing is carried out, the cold isostatic pressing pressure is 120MPa, and the pressing time is 20 minutes; the cold isostatic pressing billet is vacuum degassed in the well-type resis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com