Experimental method for preparing rubber particle concrete

A technology of rubber granules and experimental methods, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., to achieve the effect of improving integrity and stability, and improving physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

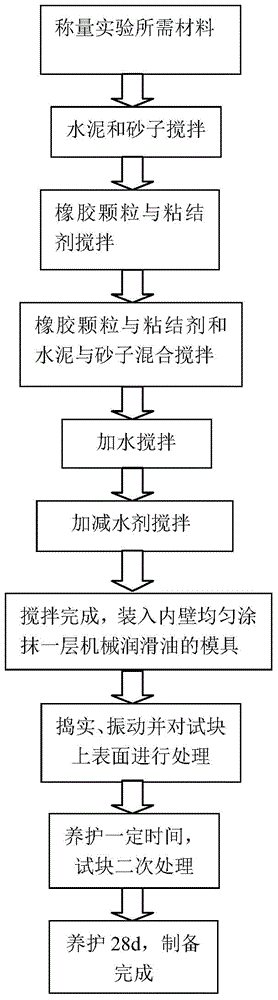

Method used

Image

Examples

Embodiment 1

[0041] Taking the preparation of 20 rubber particle concrete specimens with a rubber particle content of 0%-10% (mass ratio) as an example, first use the balance, electronic scale, measuring cylinder and other experimental instruments to weigh the materials required for the experiment, and use the following experiment Method for preparing rubber particle concrete:

[0042] (1) Stir the weighed rubber particles and binder for 2 minutes.

[0043] (2) Stir the weighed cement and sand in the mixer for 3 minutes, pour the rubber particles evenly mixed with the binder into the well-stirred cement and sand and stir together for 2 minutes.

[0044] (3) Add water measured with a graduated cylinder into the mixer, and stir for 3 minutes; add water reducing agent into the mixer and stir for 3 minutes.

[0045] (4) Put the mixed rubber particle concrete into a standard mold that has been evenly coated with a layer of mechanical lubricating oil on the inner wall. After the mold is full, p...

Embodiment 2

[0049] Take the preparation of 20 rubber particle concrete specimens with a rubber particle content of 10%-20% (mass ratio) as an example, use the balance, electronic scale, measuring cylinder and other experimental instruments to weigh the materials required for the experiment, and adopt the following experimental method Preparation of rubber particle concrete:

[0050] (1) Stir the weighed rubber particles and binder for 2 minutes.

[0051](2) Stir the weighed cement and sand in the mixer for 3 minutes, pour the rubber particles evenly mixed with the binder into the well-stirred cement and sand and stir together for 2 minutes.

[0052] (3) Add water measured with a graduated cylinder into the mixer and stir for 3 minutes; add water reducing agent into the mixer and stir for 5 minutes.

[0053] (4) Put the mixed rubber particle concrete into a standard mold that has been evenly coated with a layer of mechanical lubricating oil on the inner wall. After the mold is full, place...

Embodiment 3

[0057] Take the preparation of 20 rubber particle concrete specimens with a rubber particle content of 20%-30% (mass ratio) as an example, use the balance, electronic scale, measuring cylinder and other experimental instruments to weigh the materials required for the experiment, and adopt the following experimental method Preparation of rubber particle concrete:

[0058] (1) Stir the weighed rubber particles and binder for 5 minutes.

[0059] (2) Stir the weighed cement and sand in the mixer for 5 minutes, pour the rubber particles evenly mixed with the binder into the well-stirred cement and sand and stir together for 3 minutes.

[0060] (3) Add water measured with a graduated cylinder into the mixer and stir for 3 minutes; add water reducing agent into the mixer and stir for 5 minutes.

[0061] (4) Put the mixed rubber particle concrete into the standard mold that has evenly applied a layer of mechanical lubricating oil on the inner wall. During the loading process, it is d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com