Single-phase reversible and oxidation-resistant hydrogen-storage high-entropy alloy and preparation method thereof

A high-entropy alloy and anti-oxidation technology, which is applied in the field of single-phase reversible and anti-oxidative hydrogen storage high-entropy alloys and their preparation, can solve the problem that high-entropy alloys cannot be widely used, the reversibility of the phase structure is poor, and the high-entropy alloy phase There are many kinds of problems, so as to alleviate the problem of hydrogen absorption poisoning, improve the antioxidant performance, and increase the availability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment prepares Ti 0.2 Zr 0.2 f 0.2 Mo 0.3 Nb 0.1 Alloy, the specific steps are as follows:

[0042] a. Use Ti, Zr, Hf, Mo and Nb metal particle raw materials with a purity greater than or equal to 99.95%, according to Ti 0.2 Zr 0.2 f 0.2 Mo a Nb b The molar ratio of the alloy components is weighed, where, a = 0.3, b = 0.1, electronic balance (accuracy up to 0.1 mg) is used for weighing, the shape of the five metal particle raw materials is irregular, the maximum diameter is less than 10 mm, the surface of the metal particle raw materials presents a metallic luster, and there is no visible oxide layer;

[0043] b. Open the sample chamber; divide the five raw materials into two groups, Ti and Nb are one group, and the Nb element is placed on the upper layer and put into a small crucible in the sample chamber of the vacuum non-consumable arc melting furnace; Zr, Mo , Hf are a group, Hf, Mo elements are placed on the upper layer, and put into another ...

Embodiment 2

[0055] This embodiment prepares Ti 0.2 Zr 0.2 f 0.2 Mo 0.2 Nb 0.2 alloy, the specific implementation is basically the same as in Example 1, the main difference is that Ti 0.2 Zr 0.2 f 0.2 Mo a Nb b middle a = 0.2, b = 0.2.

[0056] The test results are as follows:

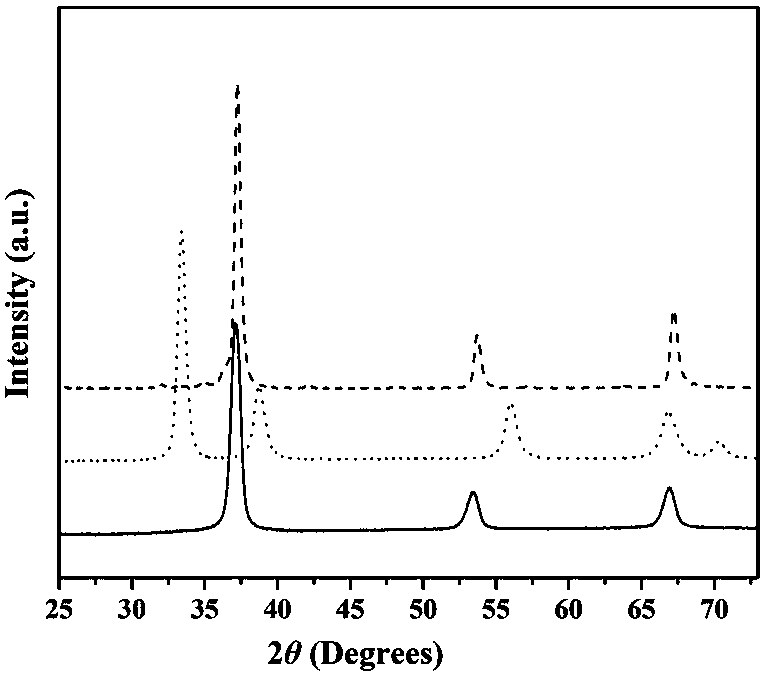

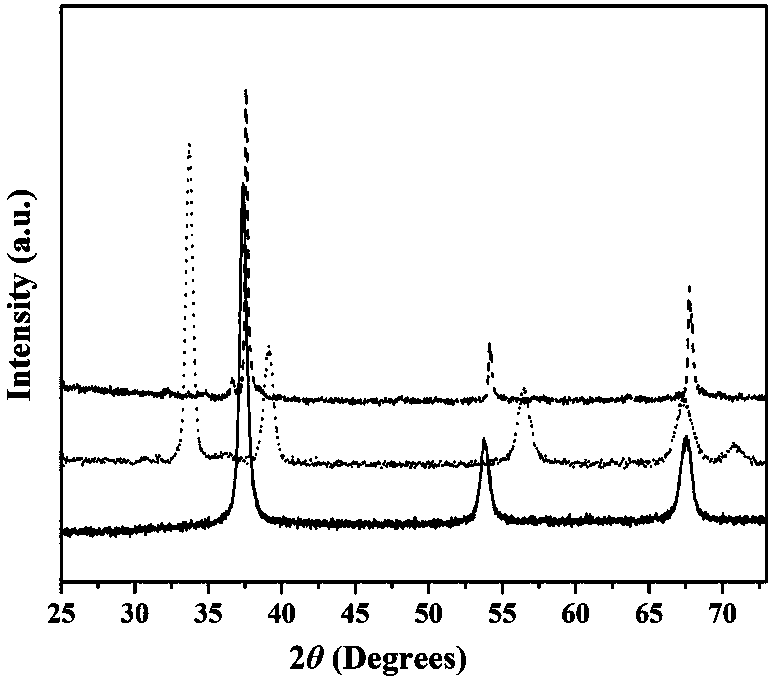

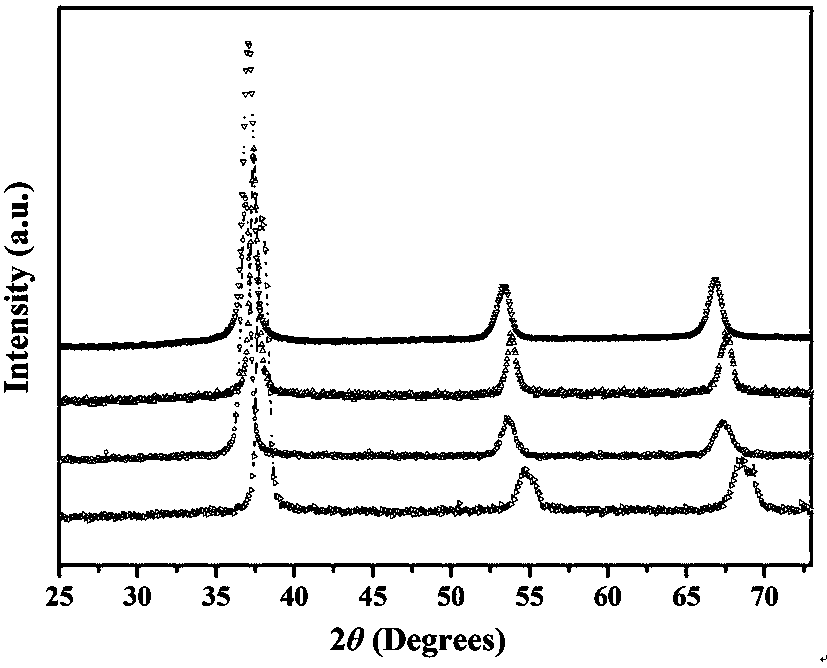

[0057] Depend on figure 1 The XRD spectrum can draw, the prepared Ti 0.2 Zr 0.2 f 0.2 Mo 0.2 Nb 0.2 The alloy is a single-phase BCC structure high-entropy alloy;

[0058] Depend on figure 2 The DSC curve can be drawn, the hydrogenated Ti 0.2 Zr 0.2 f 0.2 Mo 0.2 Nb 0.2 There is only one endothermic peak in the decomposition process of the high-entropy alloy, and the temperature at the peak is 302 o C;

[0059] Depend on image 3 The mass spectrum curve of hydrogen can be drawn, the hydrogenated Ti 0.2 Zr 0.2 f 0.2 Mo 0.2 Nb 0.2 There is only one hydrogen release peak in the decomposition process of high-entropy alloys, and the temperature at the peak is 312 o C, basically consisten...

Embodiment 3

[0063] This embodiment prepares Ti 0.2 Zr 0.2 f 0.2 Mo 0.1 Nb 0.3 alloy, the specific implementation is basically the same as in Example 1, the main difference is that Ti 0.2 Zr 0.2 f 0.2 Mo a Nb b middle a = 0.1, b = 0.3.

[0064] The test results are as follows:

[0065] Depend on figure 1 The XRD spectrum can draw, the prepared Ti 0.2 Zr 0.2 f 0.2 Mo 0.1 Nb 0.3 The alloy is a single-phase BCC structure high-entropy alloy;

[0066] Depend on figure 2 The DSC curve can be drawn, the hydrogenated Ti 0.2 Zr 0.2f 0.2 Mo 0.1 Nb 0.3 There is only one endothermic peak in the decomposition process of the high-entropy alloy, and the temperature at the peak is 332 o C;

[0067] Depend on image 3 The mass spectrum curve of hydrogen can be drawn, the hydrogenated Ti 0.2 Zr 0.2 f 0.2 Mo 0.1 Nb 0.3 There is only one hydrogen release peak in the decomposition process of high-entropy alloys, and the temperature at the peak is 350 o C, basically consistent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com