High-temperature high-pressure solid-containing multi-phase particle erosive wear testing device

A wear test, high temperature and high pressure technology, applied in the field of erosion wear devices, can solve the problems of unknown erosion speed, uneven mixing of erosion particles and gas, and inaccuracy, so as to meet emission requirements, save experimental time, and improve uniformity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

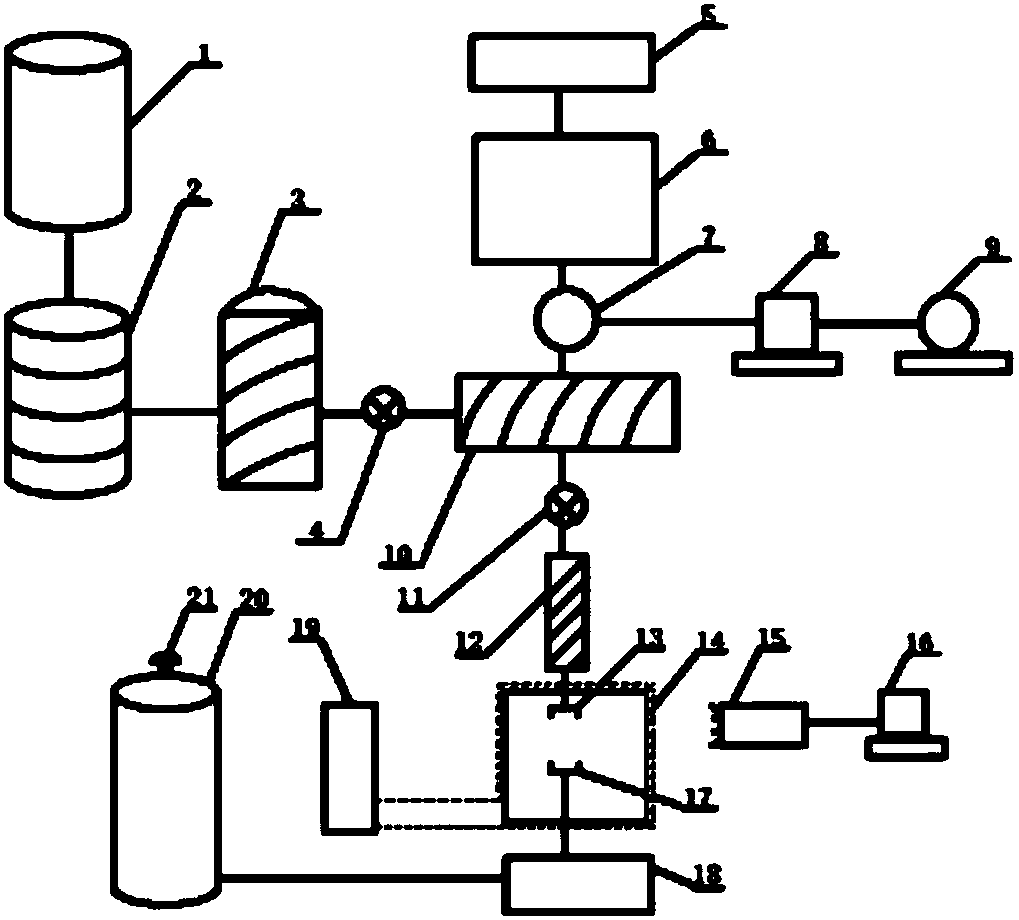

[0025] The present invention will be further described below in conjunction with accompanying drawing.

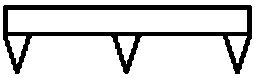

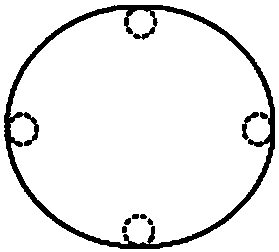

[0026] Such as figure 1 , figure 2 , image 3 Shown, the structure of the present invention is: air compressor 1 links to each other with air drier 2 and high-temperature air heater 3 through pipeline, the outlet of high-temperature air heater connects gas flowmeter and pressure tester 4, particle size screening machine 5 and The solid particle heating chamber 6 is connected to the particle mixing auxiliary heating chamber 10. The falling of the solid particles is controlled by the impeller feeder 7. The impeller feeder is controlled by the reducer 8 and the governor 9. The particle mixing auxiliary heating chamber passes through the solid flow The meter 11 and the acceleration pipeline 12 are connected with the box body 14. The air heated in the high-temperature air heater passes through the gas flow meter and mixes with the solid particles in the particle mixing auxili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com