In-situ SiC-TiC particle mixing enhanced aluminum-based composite material and preparation process thereof

A composite material and a technology for reinforced aluminum matrix, which is applied in the field of in-situ SiC-TiC particle mixed reinforced aluminum matrix composite material and its preparation to achieve the effect of strong interface bonding and good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

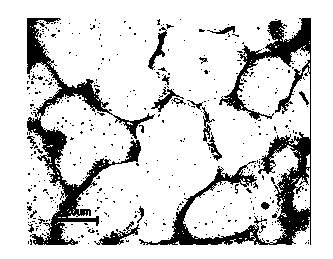

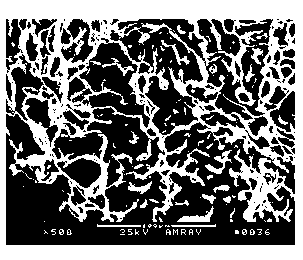

Examples

Embodiment 1

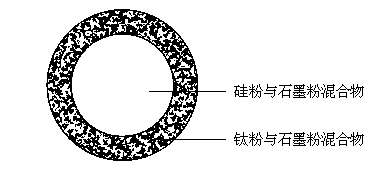

[0028] Grind and mix silicon powder (99% purity, 200 mesh) and graphite powder (99% purity, 200 mesh) with a molar ratio of 1 in a mortar; titanium powder (99% pure, 200 mesh) with a molar ratio of 1 ) and graphite powder (99% purity, 200 mesh) were ground and mixed evenly in a mortar. see figure 1 , put the two mixed powders into a mold with a diameter of 35 mm. The mixture of titanium powder and graphite powder is used as the outer layer of the briquette, and the mixture of silicon powder and graphite powder is used as the inner layer of the briquette. The mass ratio of the outer layer to the inner layer is 3:10 (make the mixture of silicon powder and graphite powder in the middle, surrounded by a mixture of titanium powder and graphite powder). The briquettes are pressed on a press. The pressure is 20MPa, and the holding time is 5 minutes. After pressing, the briquette is taken out from the mold and put into a drying oven to dry.

[0029] Select pure Al ingots and Al-5...

Embodiment 2

[0032] Grind and mix silicon powder (99% purity, 200 mesh) and graphite powder (99% purity, 200 mesh) with a molar ratio of 1 in a mortar; titanium powder (99% pure, 200 mesh) with a molar ratio of 1 ) and graphite powder (99% purity, 200 mesh) were ground and mixed evenly in a mortar. Put the two mixed powders into a mold with a diameter of 35 mm. The mixture of titanium powder and graphite powder is used as the outer layer of the compact, and the mixture of silicon powder and graphite powder is used as the inner layer of the compact. The mass ratio of the outer layer to the inner layer is 3 : 10 (make the mixture of silicon powder and graphite powder in the middle, surrounded by a mixture of titanium powder and graphite powder). The briquettes are pressed on a press. The pressure is 20MPa, and the holding time is 5 minutes. After pressing, the briquette is taken out from the mold and put into a drying oven to dry. Select pure Al ingots and Al-50%Cu intermediate alloy ingo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com