Double colour fluorescent chemical sensor used for visually detecting explosive and manufacturing method thereof

A dual-emission fluorescent and chemical sensor technology, applied in the fields of fluorescence/phosphorescence, material excitation analysis, etc., to achieve simple operation, avoid interference, and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

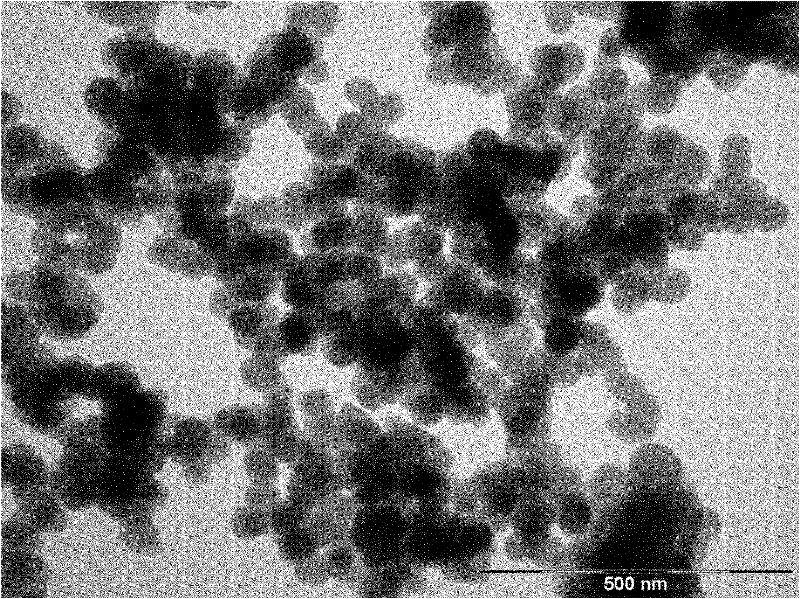

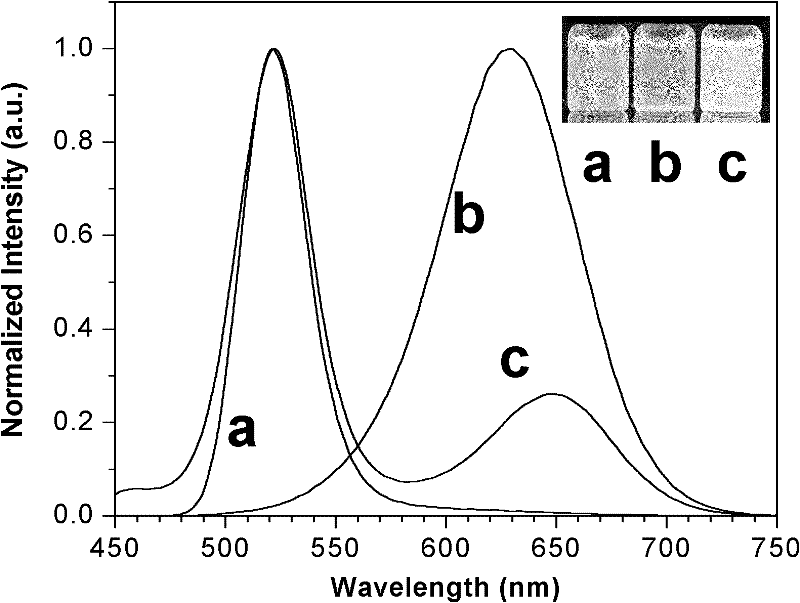

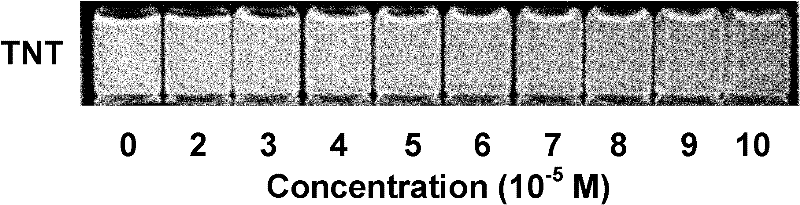

[0030] 1. Preparation of luminescent and stable quantum dot-embedded silica nanoparticles

[0031] 0.2284g cadmium chloride (CdCl 2 ·2.5H 2 O) was added to 250 mL of deoxygenated ultrapure water, followed by 0.21 mL of mercaptopropionic acid, and its pH was adjusted to 11.2 with 1 M NaOH solution to form a solution containing sulfhydryl compounds and cadmium ions. On the other hand, take 0.0319 g of tellurium powder and 0.05 g of sodium borohydride in 2 mL of ultrapure water, and react in an ice bath for more than 8 hours under nitrogen protection. 5mL of 0.5M dilute sulfuric acid solution was poured into the resulting sodium tellurium hydride solution. will generate H 2 All Te was passed into the above-mentioned cadmium ion solution, stirred for 20 minutes, and then heated to reflux. By controlling the reflux time, an aqueous solution of cadmium telluride quantum dots with stable mercaptopropionic acid and a fluorescence emission peak of 490-680 nm can be obtained. The p...

Embodiment 2

[0038] 1. Preparation of luminescent and stable quantum dot-embedded silica nanoparticles

[0039] 0.2284g cadmium chloride (CdCl 2 ·2.5H 2 O) was added to 250 mL of deoxygenated ultrapure water, followed by 0.21 mL of mercaptopropionic acid, and its pH was adjusted to 11.2 with 1 M NaOH solution to form a solution containing sulfhydryl compounds and cadmium ions. On the other hand, take 0.0319 g of tellurium powder and 0.05 g of sodium borohydride in 2 mL of ultrapure water, and react in an ice bath for more than 8 hours under nitrogen protection. 5 mL of 0.5M dilute sulfuric acid solution was poured into the resulting sodium tellurium hydride solution. will generate H 2 All Te was passed into the above-mentioned cadmium ion solution, stirred for 20 minutes, and then heated to reflux. By controlling the reflux time, an aqueous solution of cadmium telluride quantum dots with stable mercaptopropionic acid and a fluorescence emission peak of 490-680 nm can be obtained. The ...

Embodiment 3

[0046] 1. Preparation of luminescent and stable quantum dot-embedded silica nanoparticles

[0047] 0.2284g cadmium chloride (CdCl 2 ·2.5H 2 O) was added to 250 mL of deoxygenated ultrapure water, followed by 0.21 mL of mercaptopropionic acid, and its pH was adjusted to 11.2 with 1 M NaOH solution to form a solution containing sulfhydryl compounds and cadmium ions. On the other hand, take 0.0319 g of tellurium powder and 0.05 g of sodium borohydride in 2 mL of ultrapure water, and react in an ice bath for more than 8 hours under nitrogen protection. 5mL of 0.5M dilute sulfuric acid solution was poured into the resulting sodium tellurium hydride solution. will generate H 2 All Te was passed into the above-mentioned cadmium ion solution, stirred for 20 minutes, and then heated to reflux. By controlling the reflux time, an aqueous solution of cadmium telluride quantum dots with stable mercaptopropionic acid and a fluorescence emission peak of 490-680 nm can be obtained. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com