Device and method for preparing foam aluminum by bottom blowing powder spraying method

A technology of foamed aluminum and powder spraying method is applied in the field of equipment for preparing foamed aluminum, which can solve the problems of temperature drop of molten aluminum, poor particle dispersion effect, poor wettability, etc., so as to reduce the influence of mechanical properties, improve particle dispersion and uniformity. The effect of dispersing bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

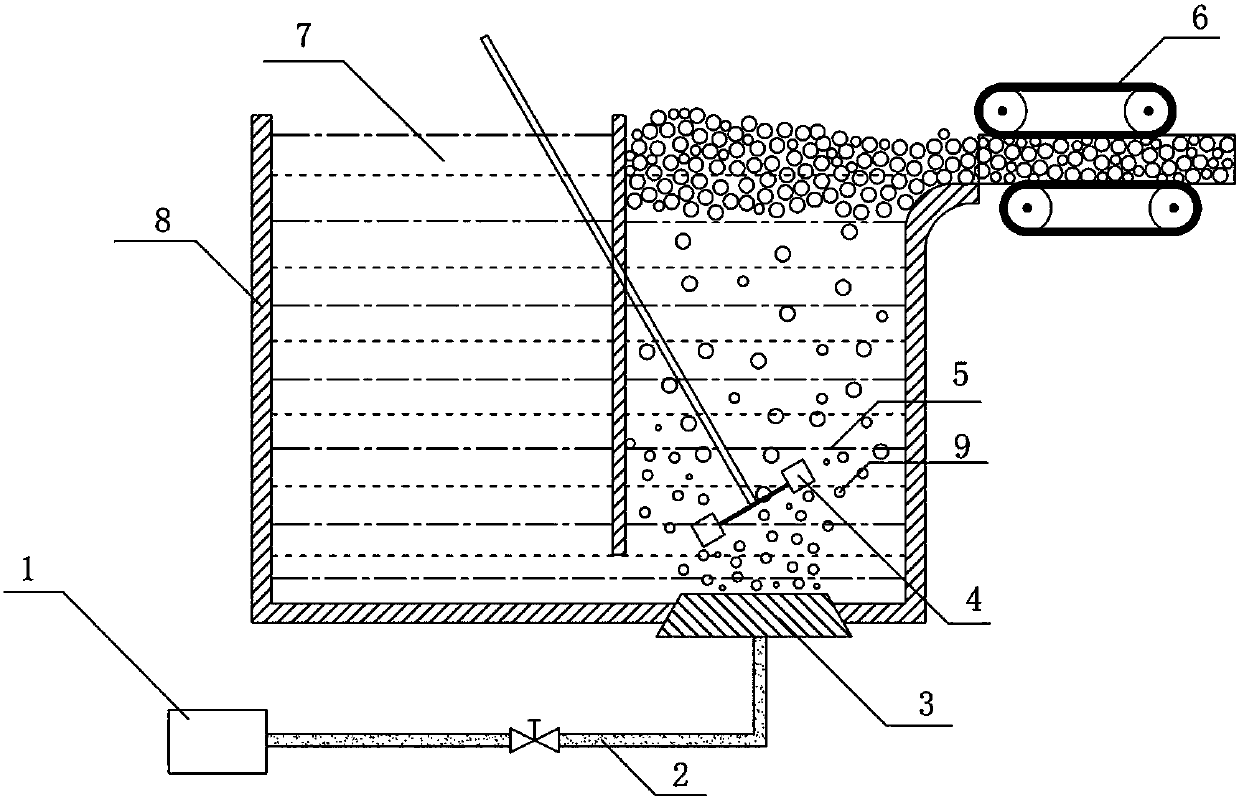

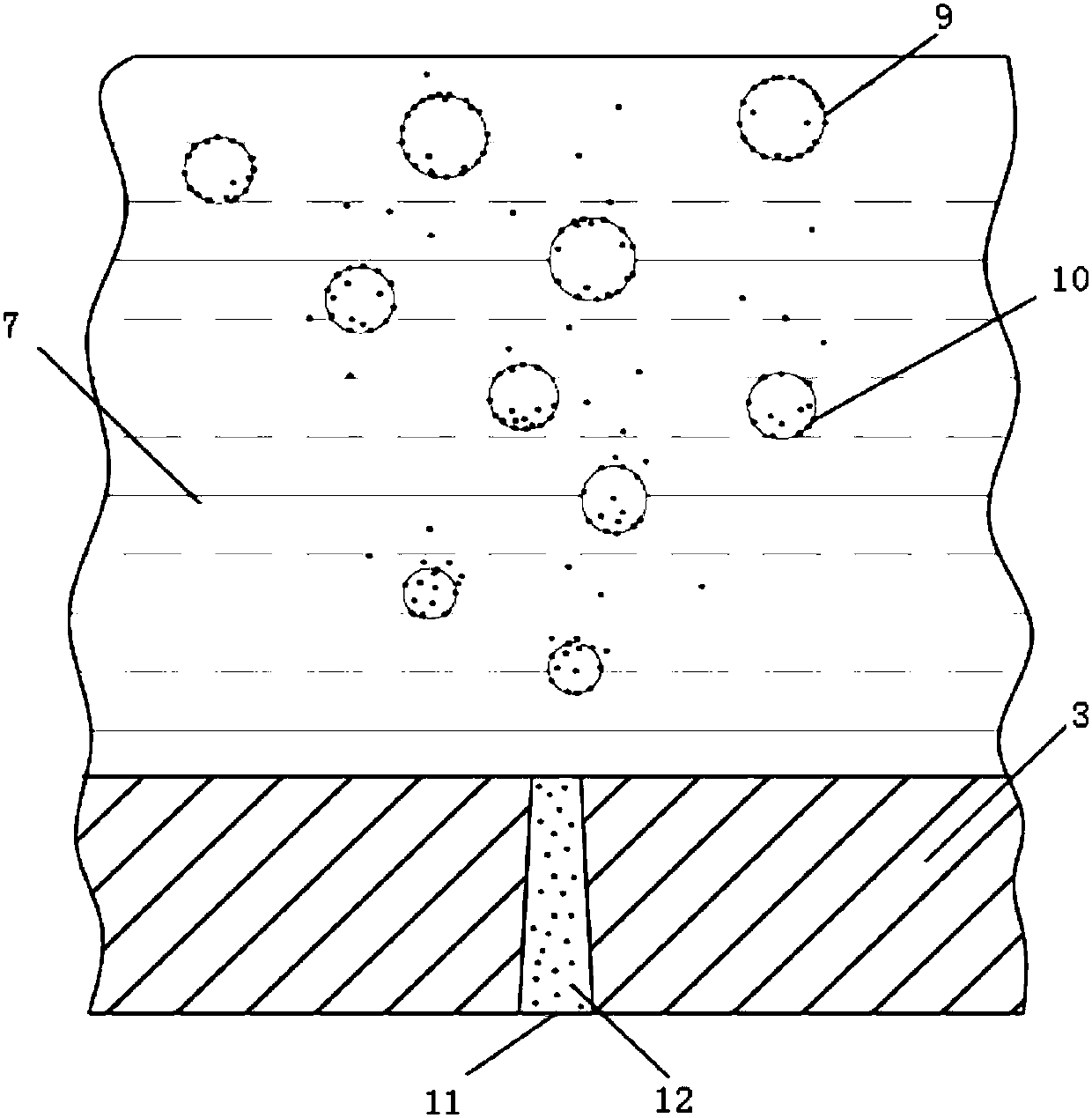

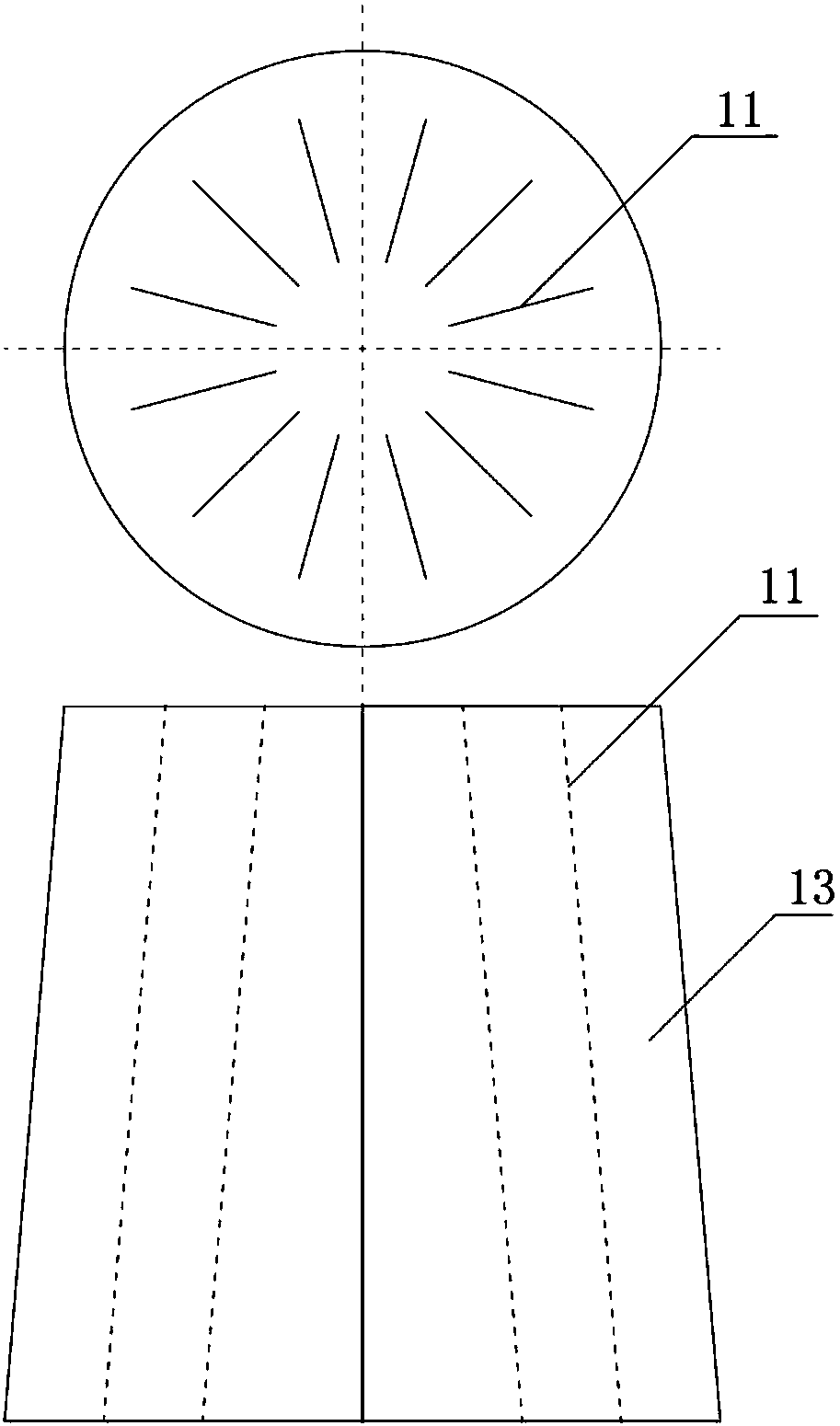

[0054] figure 1 It is the schematic diagram of the device for preparing aluminum foam by the bottom blowing powder method of the present invention, figure 2 It is a schematic diagram of the process of generating air bubbles in the slit brick in the foaming chamber of the present invention, image 3 It is a structural schematic diagram of the slit-type air-permeable brick in the present invention. as the picture shows:

[0055] A device for preparing aluminum foam by bottom blowing powder spraying method, including powder spraying system 1, air blowing pipeline 2, slit-type air-permeable brick 3, agitator 4, foaming chamber 5, rolling system 6, aluminum liquid 7 and crucible8.

[0056] The implementation method of preparing foam aluminum by bottom blowing powder spraying method:

[0057] Implementation conditions:

[0058] Additive particles are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com