Supercritical assisted green regeneration process combining double-rotator continuous mixer with screw extruder

A screw extruder and double rotor technology, which is applied in the field of supercritical auxiliary double rotor continuous mixer and screw extruder green regeneration process, can solve the problem of secondary pollution product performance, unsatisfactory, waste tire human living environment damage and other problems, to achieve the effect of promoting uniform heat-cut sulfur regeneration and shortening the regeneration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A green regeneration process for a supercritical auxiliary dual-rotor continuous mixer and screw extruder includes the following process steps:

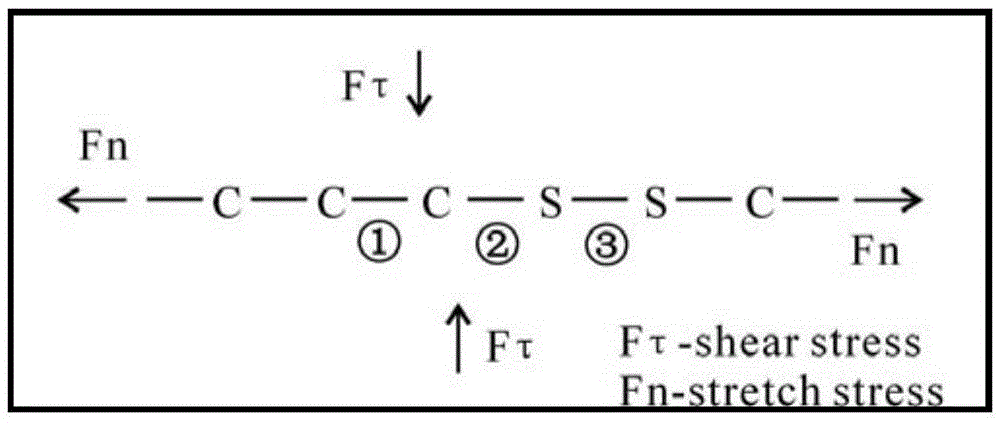

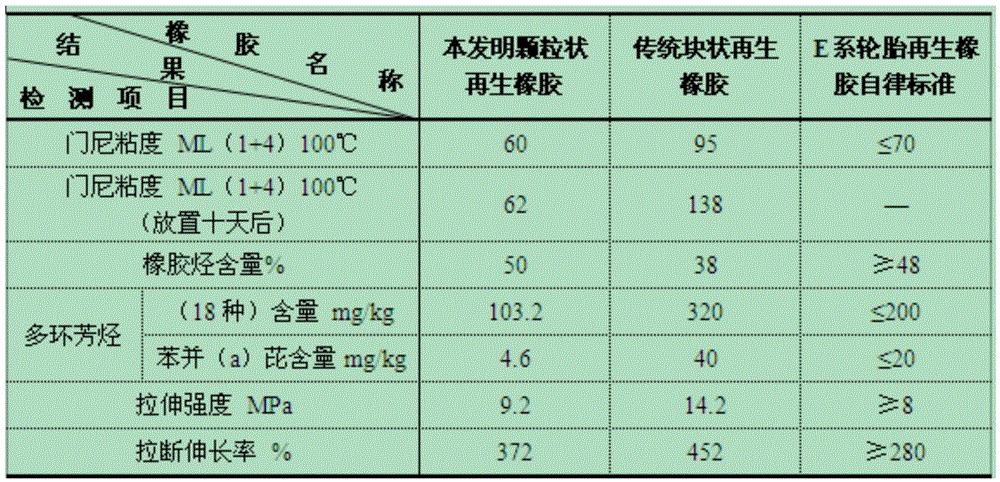

[0019] The 1-10mm rubber particles obtained by crushing and separating the waste rubber are added to the feeding device and conveyed by screw into the double-rotor continuous mixer; in the double-rotor continuous mixer, the supercritical fluid CO 2 In the environment, the rubber particles are subjected to supercritical fluid penetration, swelling and protection of the rubber molecular structure and high shear and strong stretching of the double-rotor mixing flow field, which only promotes the directional and selective rupture of the CS and SS bonds, while the main chain The CC bond is not destroyed, only the three-dimensional grid structure is destroyed, and the sulfur-broken regeneration of rubber particles is realized. The rotor speed of the double-rotor continuous mixer is between 500-800r / min, and the sulfur-broken regeneration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com