Novel magnetic separation mechanism

一种磁分离、新型的技术,应用在分析材料、测试用样品的制备、仪器等方向,能够解决无法实现多工位分离洗涤等问题,达到占用空间小、重复性好、避免交叉污染的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

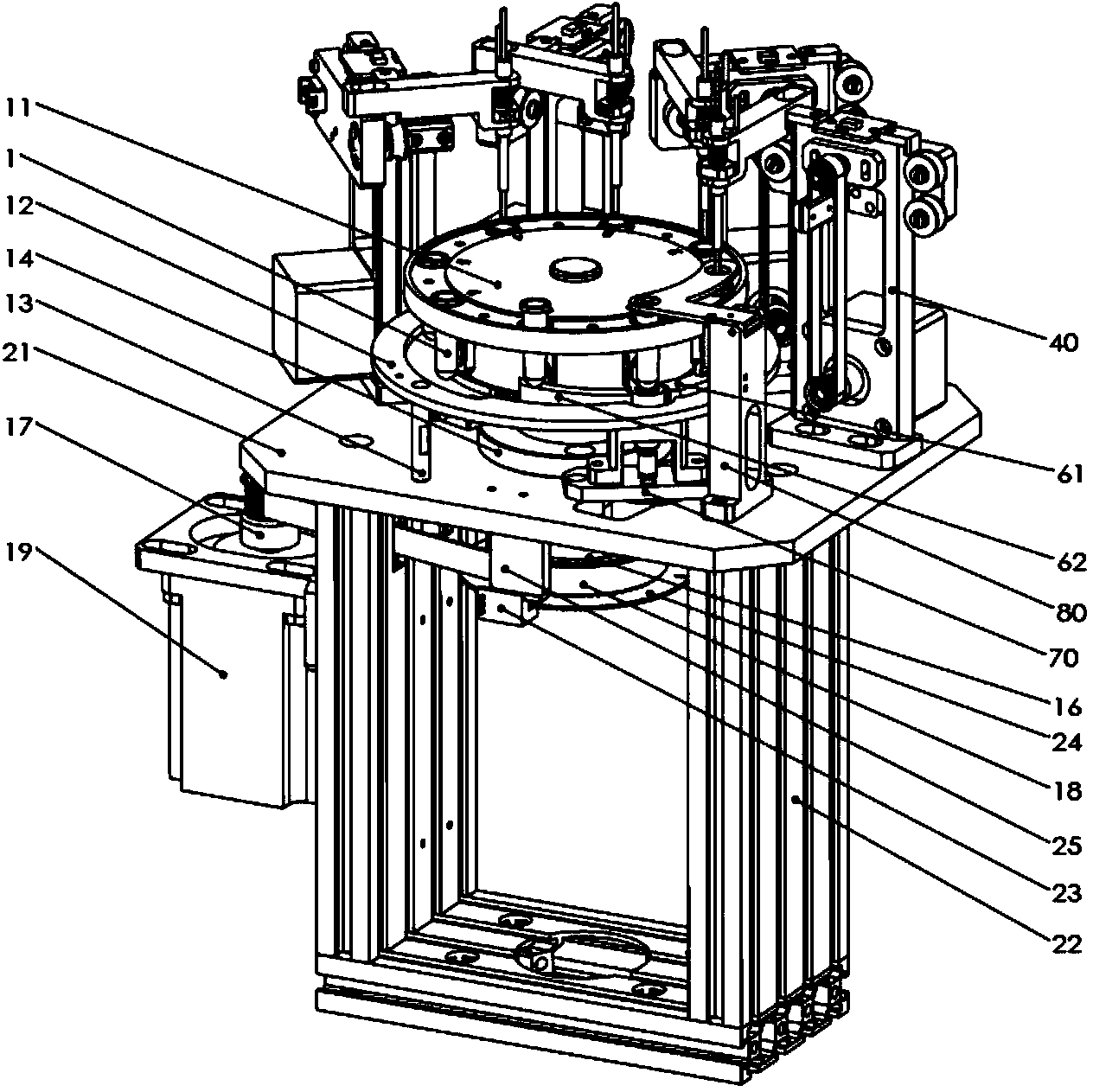

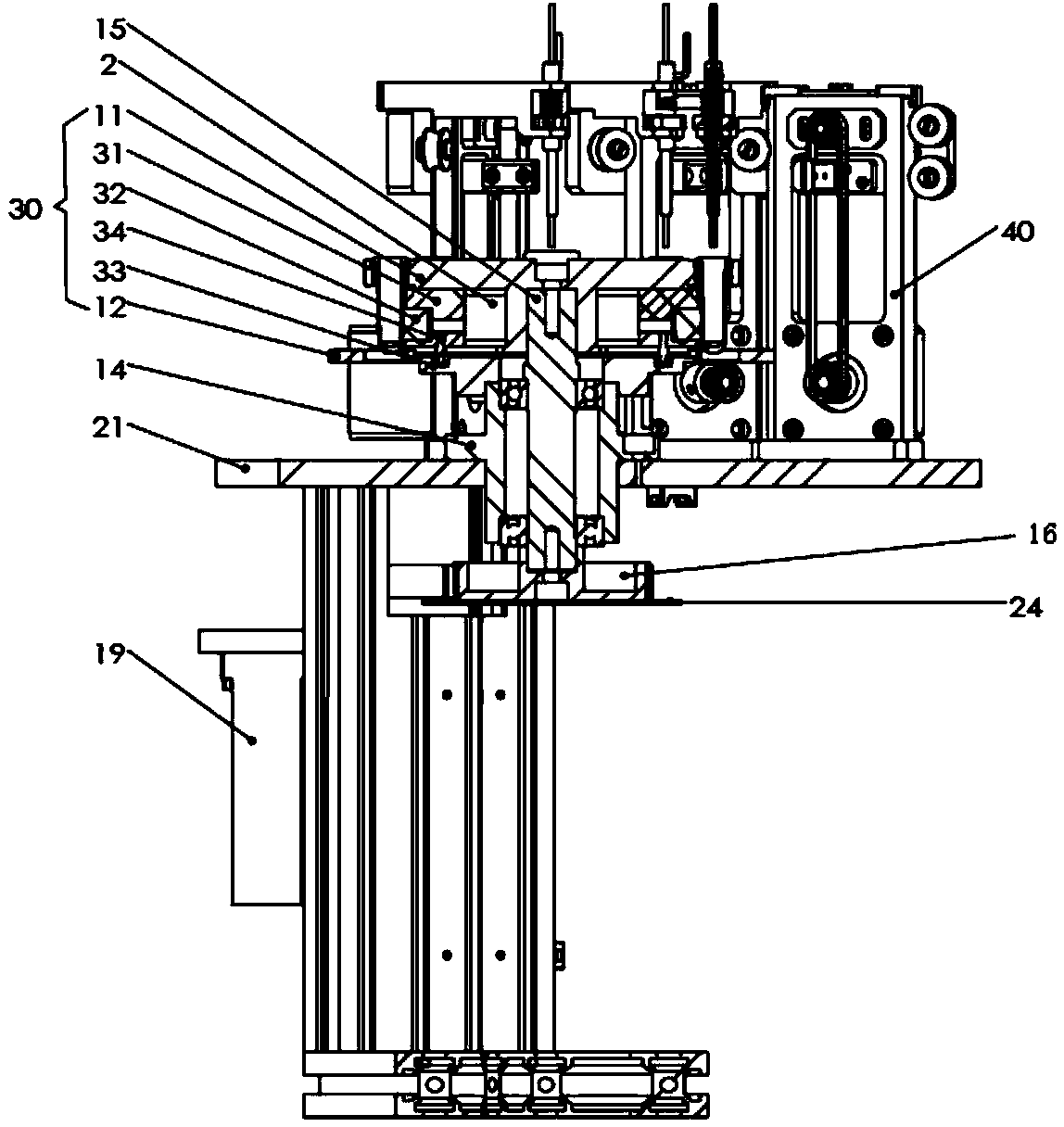

[0060] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

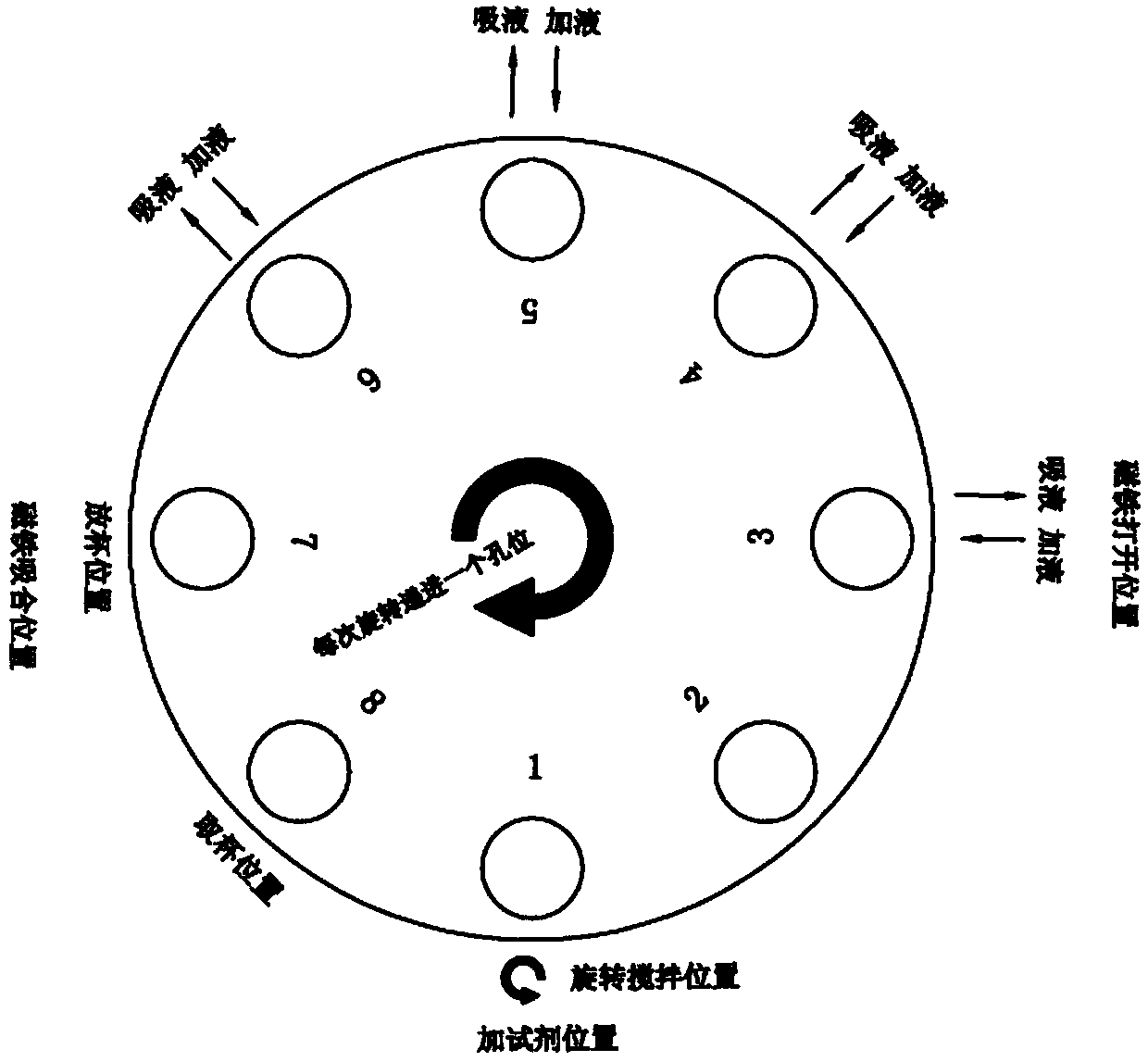

[0061] Such as figure 1 with figure 2 As shown, a new type of magnetic separation mechanism includes an encoding turntable mechanism, a magnet opening and closing mechanism and a cleaning mechanism; the magnet opening and closing mechanism is installed on the encoding turntable mechanism, and the cleaning mechanism is distributed around the encoding turntable mechanism; The opening and closing mechanism controls the magnet to absorb the nano-magnetic beads in the liquid in the cuvette placed on the encoding turntable mechanism, and the liquid in the cuvette is sequentially cleaned by the cleaning mechanism to complete the separation of the nano-magnetic beads;

[0062] The coded turntable mechanism includes a turntable 11, a fixed disk 12, a support nail 13, a bearing seat 14 with bearings, a turntable rotating shaft 15, a first synchronous belt drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com