High-performance stirrer used for molten iron mechanical-stirring desulfuration

A mechanical stirring and agitator technology, applied in the field of molten iron pretreatment, can solve the problems of poor kinetic conditions, uneven mixing and dispersion of desulfurizers, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

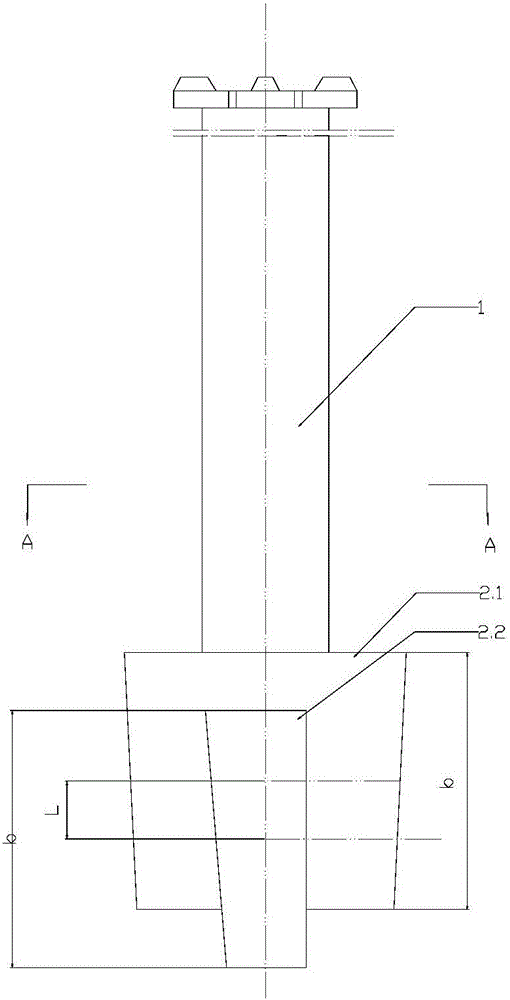

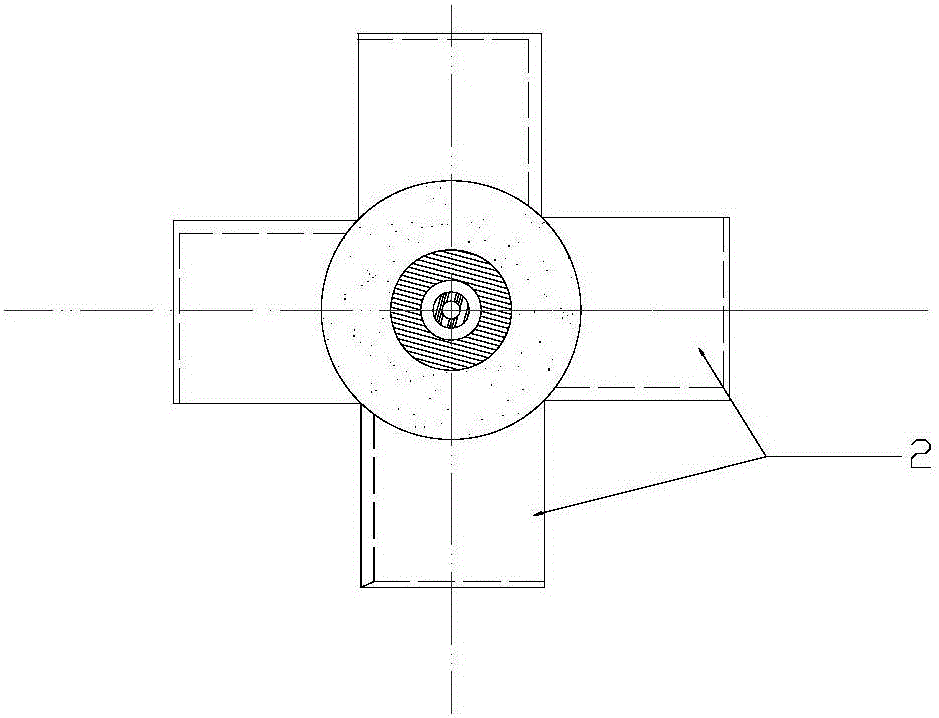

[0021] likefigure 1 , 3 As shown, a high-performance stirrer for mechanical stirring and desulfurization of molten iron is mainly composed of a stirring shaft 1 and a stirring blade 2 . The stirring blade 2 is composed of an upper stirring blade 2.1 and a lower stirring blade 2.2, the number of the upper stirring blade 2.1 and the lower stirring blade 2.2 is 2, and they are evenly distributed around the stirring shaft 1 circumferential direction; the upper stirring blade 2.1 and the lower stirring blade The mixing blades 2.2 intersect in a cross, and the ratio of the layer distance L between the upper stirring blade 2.1 and the lower stirring blade 2.2 to the width b of the stirring blade is 0.10-0.75. The width b of the stirring blade and other structural parameters of the agitator are the same as those of the conventional KR agitator, and the preparation material and process of the agitator are also the same as those of the conventional KR agitator.

[0022] The stirring bl...

Embodiment 2

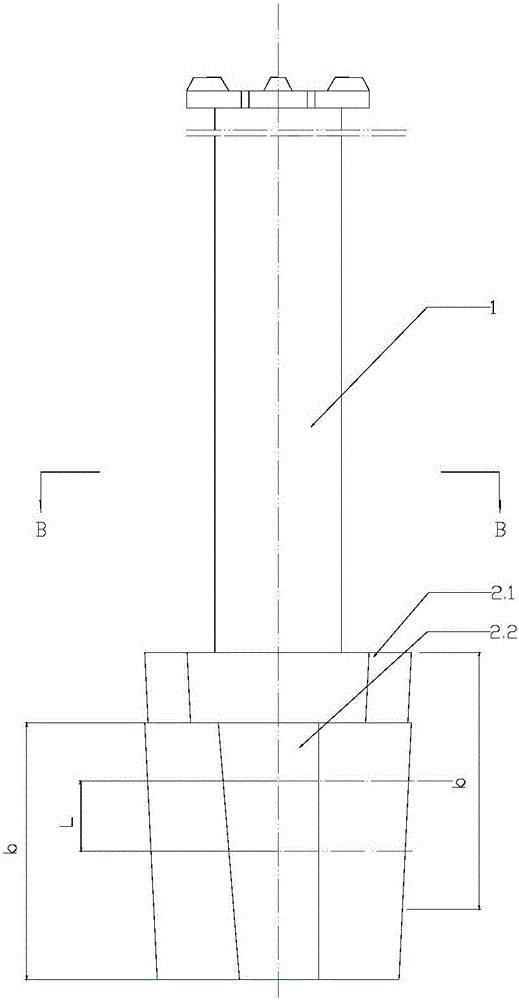

[0024] like figure 2 , 4 As shown, a high-performance stirrer for mechanical stirring and desulfurization of molten iron is mainly composed of a stirring shaft 1 and a stirring blade 2 . The number of the upper stirring blades 2.1 and the lower stirring blades 2.2 is 3, and the upper stirring blades 2.1 and the lower stirring blades 2.2 are arranged alternately. The ratio of the interlayer spacing L between the upper stirring blades and the lower stirring blades to the width b of the stirring blades is 0.3-0.50, and the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com